Method for simultaneously and efficiently extracting soluble sugar and organic acid from peach pulp

A soluble, organic acid technology, applied in the field of chemical analysis and instrumental analysis in the chemical industry, can solve problems such as sample damage, harsh conditions, and slow down research progress, and achieve the effect of slowing down degradation and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] a. Accurately weigh 4g of metaphosphoric acid, dissolve and constant volume with 1L ultrapure water to obtain a 0.4% metaphosphoric acid aqueous solution; pipette 800ml absolute ethanol and 200ml 0.4% metaphosphoric acid aqueous solution respectively, and mix to obtain extractant ethanol: 0.4 % metaphosphoric acid aqueous solution=80:20V / V;

[0042] b. Accurately weigh 0.5g of ripe fruit pulp of the 'Xiahui No. 8' variety, add 8mL extractant, ultrasonically extract for 1h, centrifuge at 10,000rpm at 4°C for 10min, take the supernatant and filter it through a 0.22mm water filter head to obtain a sample solution;

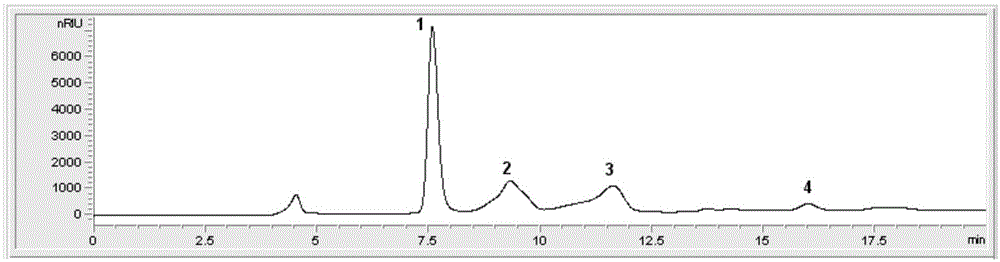

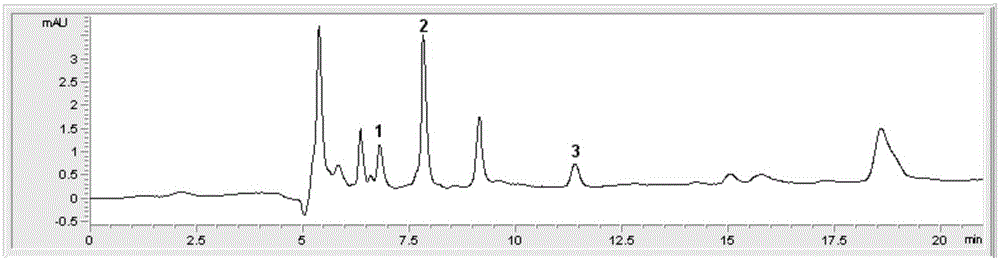

[0043] c, under chromatographic conditions, sample solution is carried out to the high-performance liquid chromatography analysis of soluble sugar and organic acid respectively, obtain as follows figure 1 The HPLC profile of the soluble sugars shown, and as figure 2 HPLC profiles of the indicated organic acids. The calculated contents of various organic acid...

Embodiment 2

[0061] a. Accurately weigh 4g of metaphosphoric acid, dissolve it with 1L of ultrapure water to obtain a 0.4% metaphosphoric acid aqueous solution; respectively pipette 800ml of absolute ethanol and 200ml of 0.4% metaphosphoric acid aqueous solution, and mix to obtain the extractant ethanol: 0.4% metaphosphoric acid aqueous solution = 80:20.

[0062] b. Accurately weigh 0.5g of 4 portions of ripe fruit pulp of the 'Xiahui No. 8' variety, add 8mL extractant ethanol:0.4% metaphosphoric acid aqueous solution=80:20V / V, and let stand at room temperature. After standing for 1 week, 2 weeks, 3 weeks and 4 weeks respectively, centrifuge at 10,000 rpm for 10 min at 4°C, take the supernatant and filter it through a 0.22 mm water filter head to obtain a sample solution.

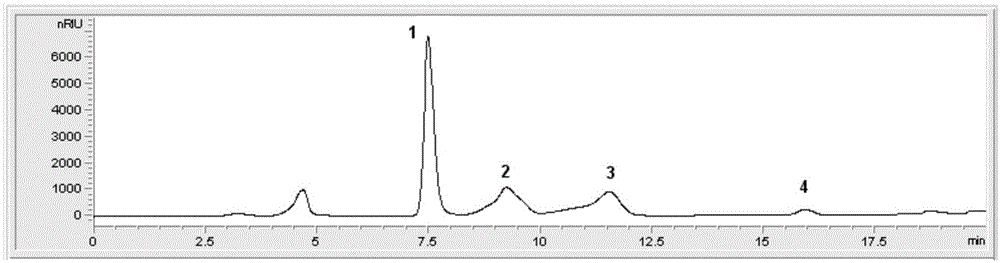

[0063] c. Under the same chromatographic conditions as in Example 1, the high performance liquid chromatography analysis of soluble sugar is carried out to the sample solution respectively, and the following results are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com