Ternary electrolyte molten salt magnesium electrolysis

An electrolyte and magnesium electrolysis technology, which is applied in the field of molten salt magnesium electrolysis, can solve problems such as heat tanks, and achieve the effects of improving production economic indicators, improving electric energy efficiency, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

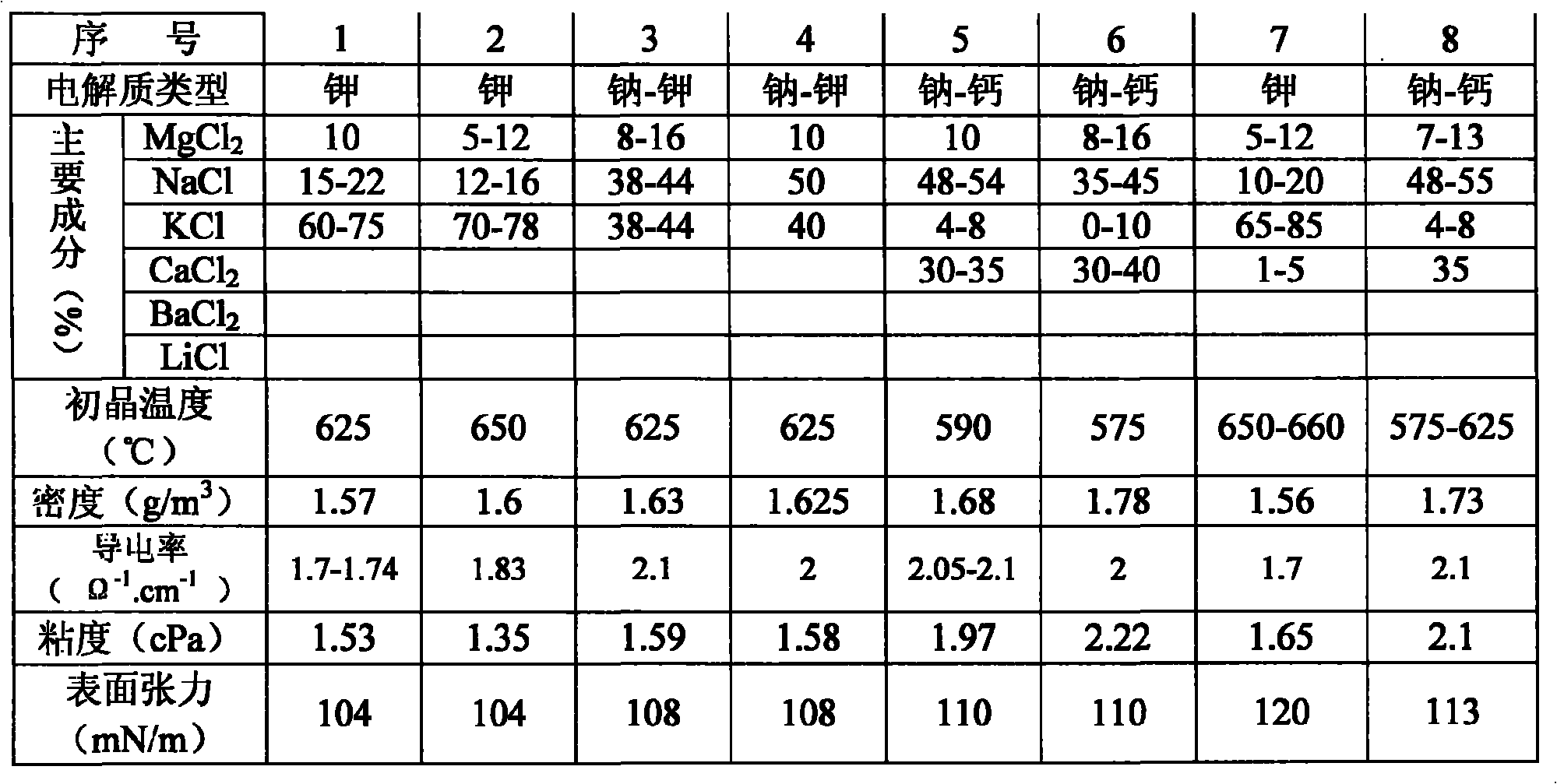

Embodiment 1

[0027] Molten salt magnesium electrolytic electrolyte, the mass component is MgCl 2 16.25%, NaCl57%, CaCl 2 23.5%. Its main properties are primary crystal temperature of 575°C and density of 1.65g / m 3 , Conductivity 1.85Ω -1 .cm -1 , viscosity 1.83cPa, surface tension 118mN / m. The protective effect of liquid magnesium during electrolysis is ideal, basically no longer burns, and the flow characteristics of electrolyte have been significantly improved.

Embodiment 2

[0029] Molten salt magnesium electrolytic electrolyte, the mass component is MgCl 2 18.7%, NaCl54.2%, CaCl 2 25%. Its main properties are primary crystal temperature of 578°C and density of 1.67g / m 3 , Conductivity 1.83Ω -1 .cm -1 , viscosity 1.83cPa, surface tension 118mN / m. The protective effect of liquid magnesium during electrolysis is ideal, basically no longer burns, and the flow characteristics of electrolyte have been significantly improved.

Embodiment 3

[0031] Molten salt magnesium electrolytic electrolyte, the mass component is MgCl 2 19.4%, NaCl54%, CaCl 2 26.8%. Its main properties are primary crystal temperature of 590°C and density of 1.685g / m 3 , Conductivity 1.824Ω -1 .cm -1 , viscosity 1.83cPa, surface tension 118mN / m. During the electrolysis process of this component electrolyte, the calorific value is slightly greater than that of Example 1 and Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com