Silane natural-crosslinked polyethylene cable insulating material and its production process

A natural cross-linking and cable insulation technology, applied in the direction of insulated cables, insulated conductors, cables, etc., can solve the problems of difficult implementation and poor effect in cable material factories, and achieve the effects of less equipment investment, lower production costs, and convenient organization of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

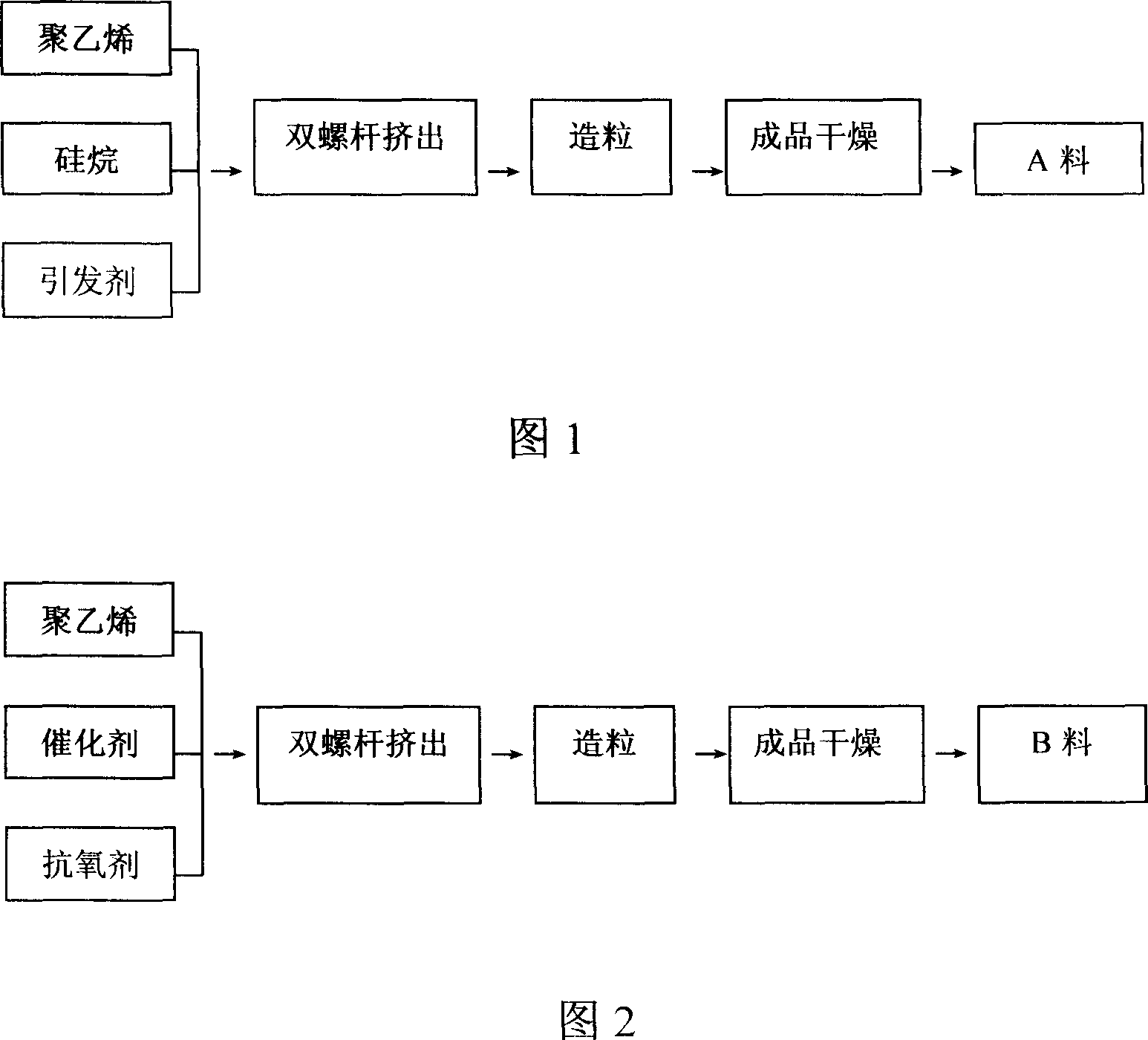

[0059] A material production:

[0060] The weight ratio of A component and each component is: high density polyethylene resin 100Kg; vinyl trimethoxysilane 0.5Kg; DCP 0.02 Kg;

[0061]Load the high-density polyethylene resin, vinyl trimethoxysilane and DCP into the storage compartment of the automatic weighing scale, set the feeding ratio according to the above ratio, and feed all the raw materials into the twin-screw extruder in proportion The extruder has a length-to-diameter ratio of 40:1, a diameter of 75cm, and a temperature setting of 120°C in zone 1, 150°C in zone 2, 180°C in zone 3, 200°C in zone 4, 210°C in zone 6, 210°C in zone 6, 7 zone 215℃, 8 zone 220℃, 9 zone 225℃, flange 225℃, machine head 225℃, extrude, stretch and pelletize, dry the finished product at 70℃ for 2 hours, and finally pack the dried finished product. Get A material.

[0062] Production of material B: the component name and weight ratio of material B are: high-density polyethylene resin 100Kg; antioxid...

Embodiment 2

[0066] The weight ratio of A component and each component is: high-density polyethylene resin 100Kg; vinyl triethoxysilane 3.5Kg; DCP 0.2Kg;

[0067] The component name of B material and the weight ratio of each component are: high-density polyethylene resin 100Kg; antioxidant 1010 20.0Kg; tert-butyl peroxide 3,5,5-trimethylhexyl ester 5Kg.

[0068] The ratio of material A and material B is 85:15 by weight, and the production process is the same as in Example 1.

Embodiment 3

[0070] The weight ratio of A component and each component is: high-density polyethylene resin 100Kg; vinyl trimethoxysilane 1.0Kg; BPO 0.04Kg;

[0071] The component name of B material and the weight ratio of each component are: low density polyethylene resin 100Kg; antioxidant 1686.0Kg; t-butyl peroxyacetate 0.8Kg.

[0072] The ratio of material A and material B is 88:12 by weight, and the production process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com