Steel plate and method thereof used for producing water heater linear enamel by flexible thin slab rolling line

A water heater liner and thin slab continuous casting technology, applied in the field of steel for enamel, can solve the problems of large amount of added alloy elements, many production processes, unstable quality, etc., achieve stable recovery rate, control hydrogen content, improve resistance The explosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below by embodiment, the present invention will be further described.

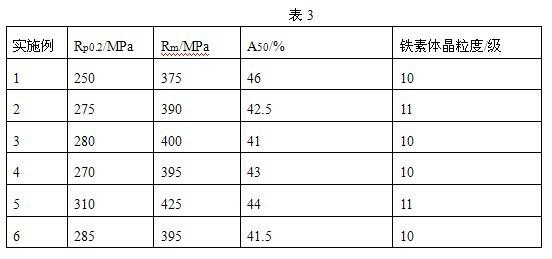

[0025] A thin slab continuous casting and rolling line to produce a steel plate for water heater liner enamel, the composition mass percentage is: carbon 0.03-0.10, manganese 0.15-0.40, silicon ≤ 0.06, sulfur 0.004-0.040, phosphorus ≤ 0.15, aluminum 0.03-0.05 , Nitrogen 0.002-0.008, Titanium 0.02-0.10, and the rest are iron and unavoidable impurities; the steel structure for enamelling the water heater liner is fine-grained ferrite + a small amount of pearlite, and the grain size grade is ≥10.

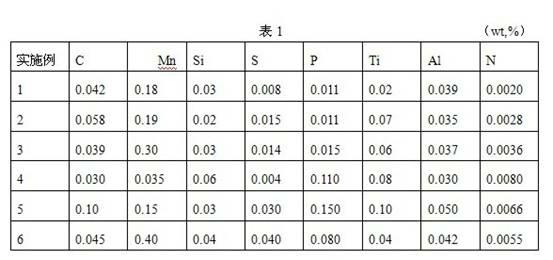

[0026] The chemical composition of 6 embodiments of the present invention is referring to Table 1:

[0027]

[0028] A thin slab continuous casting and rolling line for producing steel plates for water heater inner tank enamel, in which hot-rolled steel plates for water heater inner tank enamel are produced on the FTSR thin slab continuous casting and rolling production line, including pre-desulfurization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com