Polysaccharide degradation method and low-molecular-weight polysaccharide

A low molecular weight, polysaccharide technology, applied in the field of degradation of polysaccharide compounds, can solve the problems of increased production cost, high cost, poor applicability, etc., and achieves the effects of low time consumption and energy consumption, easy operation and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

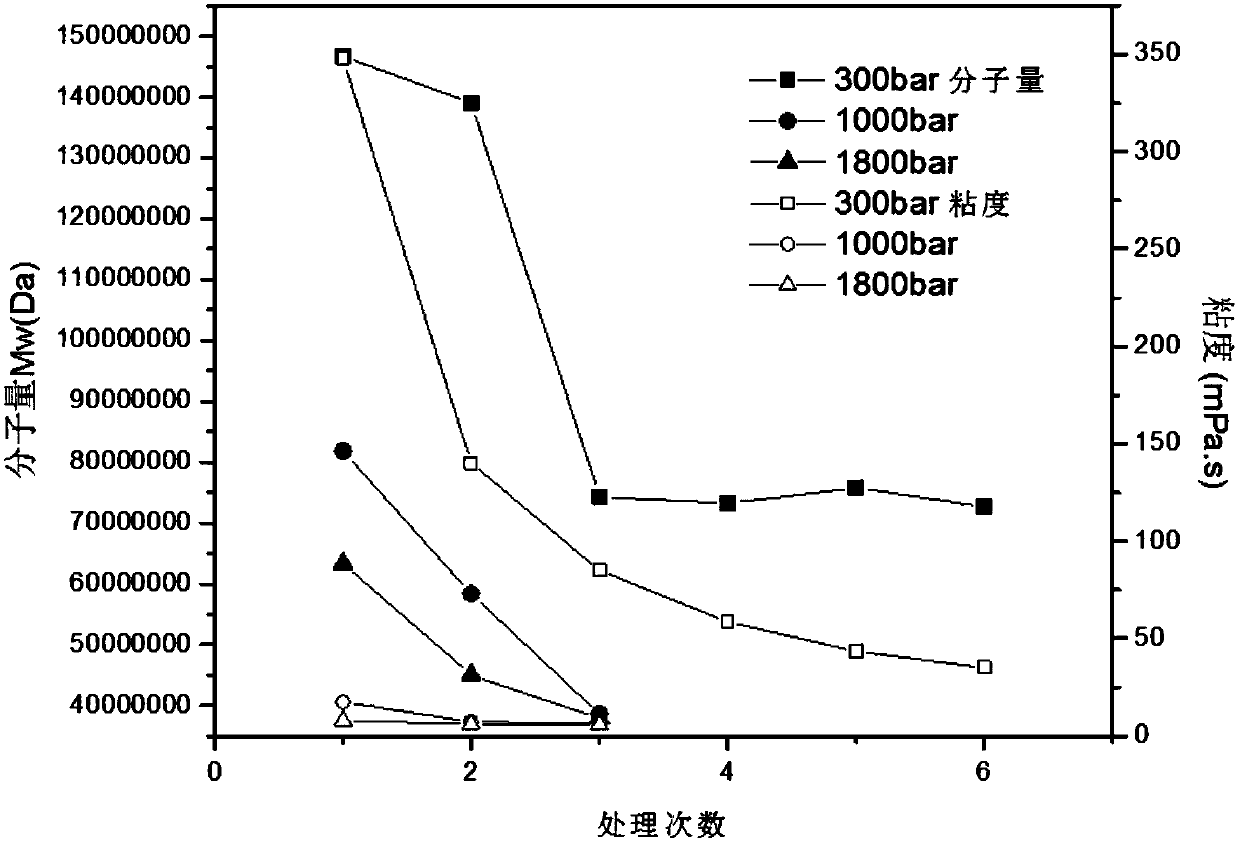

Image

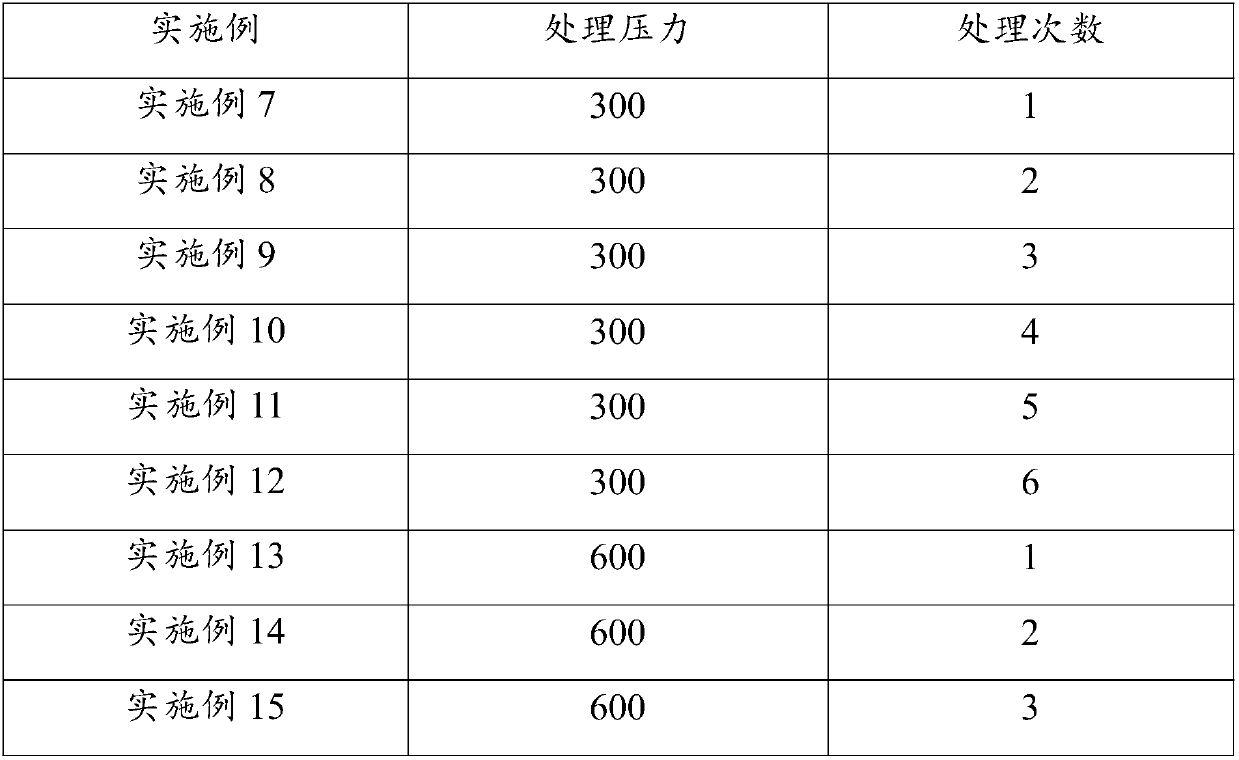

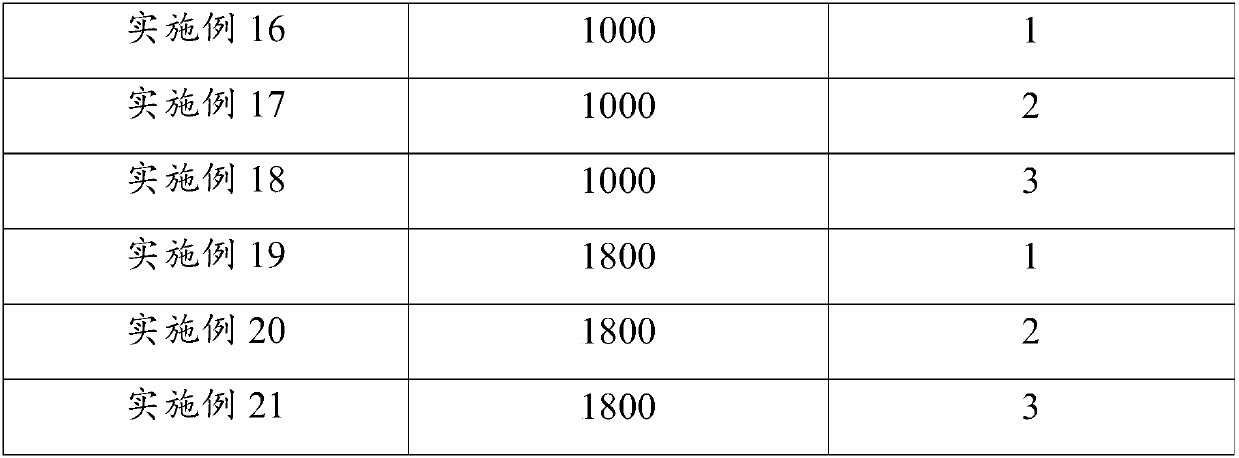

Examples

Embodiment 1

[0114] A polysaccharide degradation method, comprising the following steps:

[0115] (a) Take the weight average molecular weight at 5×10 5 An appropriate amount of Lycium barbarum polysaccharides of about Da is made into a 20g / L polysaccharide solution. The polysaccharide solution was microfiltered through a ceramic membrane with a pore size of 0.1 μm, the microfiltration speed was 35 L / h, the microfiltration pressure was 0.1 MPa, and the microfiltration temperature was 40 ° C to remove impurities in the fermentation broth;

[0116] (b) Treat the solution obtained in step (a) with an ultra-low temperature and high pressure cell crusher to treat the polysaccharide solution. The treatment process is: treatment pressure 200 bar, treatment times 6 times, treatment temperature 4°C, treatment speed 1.25mL / s;

[0117] (c) Ultrafiltering and drying the solution treated in step (b), and drying into freeze-drying, the freeze-drying process conditions are: freezing temperature -60°C, f...

Embodiment 2

[0119] A polysaccharide degradation method, comprising the following steps:

[0120] (a) Take the weight average molecular weight at 2×10 8 Appropriate amount of chitosan about Da is made into 5g / L polysaccharide solution. The polysaccharide solution was microfiltered through a ceramic membrane with a pore size of 0.1 μm, the microfiltration speed was 45 L / h, the microfiltration pressure was 0.15 MPa, and the microfiltration temperature was 50 ° C to remove impurities in the fermentation broth;

[0121] (b) Treat the solution obtained in step (a) with an ultra-low temperature and high pressure cell crusher to treat the polysaccharide solution. The treatment process is: treatment pressure 1800 bar, treatment times 1 time, treatment temperature 4°C, treatment speed 1.25mL / s;

[0122] (c) Ultrafiltering and drying the solution treated in step (b), and drying into freeze-drying, the freeze-drying process conditions are: freezing temperature -50°C, freezing time 48h and vacuum deg...

Embodiment 3

[0124] A polysaccharide degradation method, comprising the following steps:

[0125] (a) Take the weight average molecular weight at 10 6 An appropriate amount of black fungus acidic heteropolysaccharide of about Da is made into a 10g / L polysaccharide solution. The polysaccharide solution was microfiltered through a ceramic membrane with a pore size of 0.1 μm, the microfiltration speed was 40 L / h, the microfiltration pressure was 0.1 MPa, and the microfiltration temperature was 45° C. to remove impurities in the fermentation broth;

[0126] (b) Treat the solution obtained in step (a) with an ultra-low temperature and high pressure cell crusher to treat the polysaccharide solution. The treatment process is as follows: the treatment pressure is 300 bar, the treatment times are 3 times, the treatment temperature is 4°C, and the treatment speed is 1.25mL / s;

[0127] (c) Ultrafiltering and drying the solution treated in step (b), and drying into freeze-drying, the freeze-drying pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com