Patents

Literature

144 results about "High pressure cell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-Pressure Cell System. The ISS High Pressure Cell System (HP Cell) has been designed for Absorption, Fluorescence, Raman spectroscopy and polarimetry studies of solid and liquid samples. The cell, built in a stainless-steel alloy, reaches pressures up to 400 MPa (4,000 bar) using a hydrostatic pump.

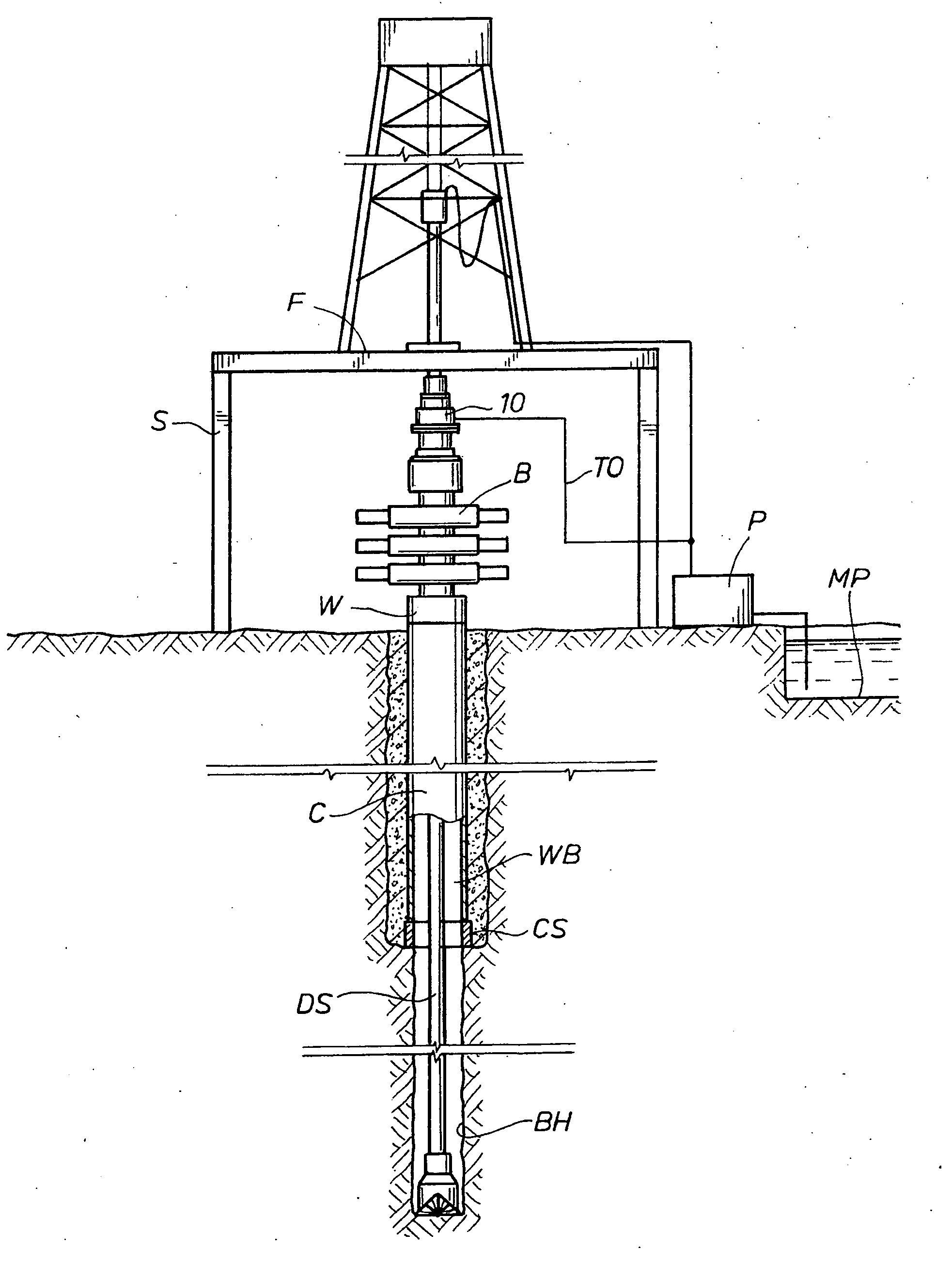

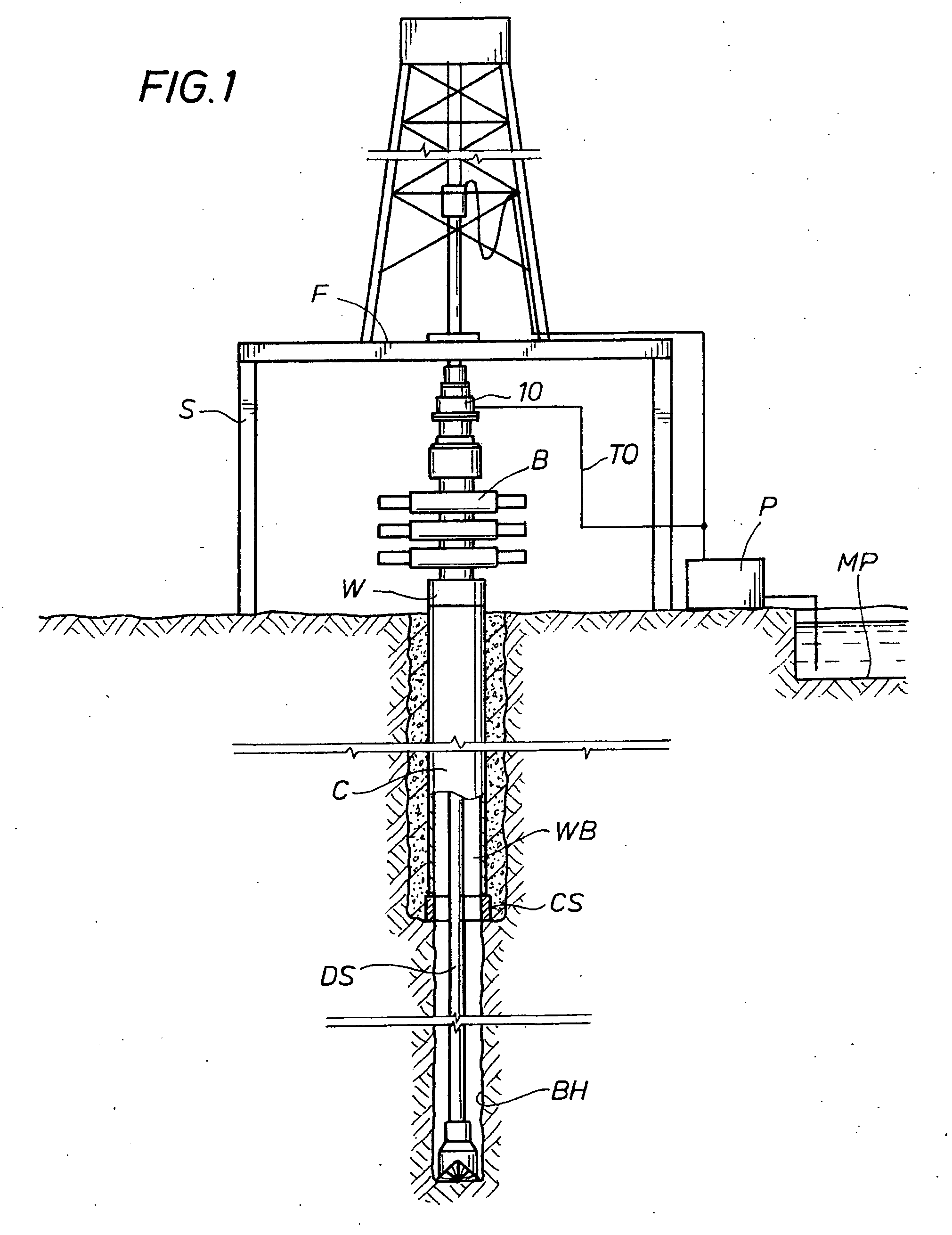

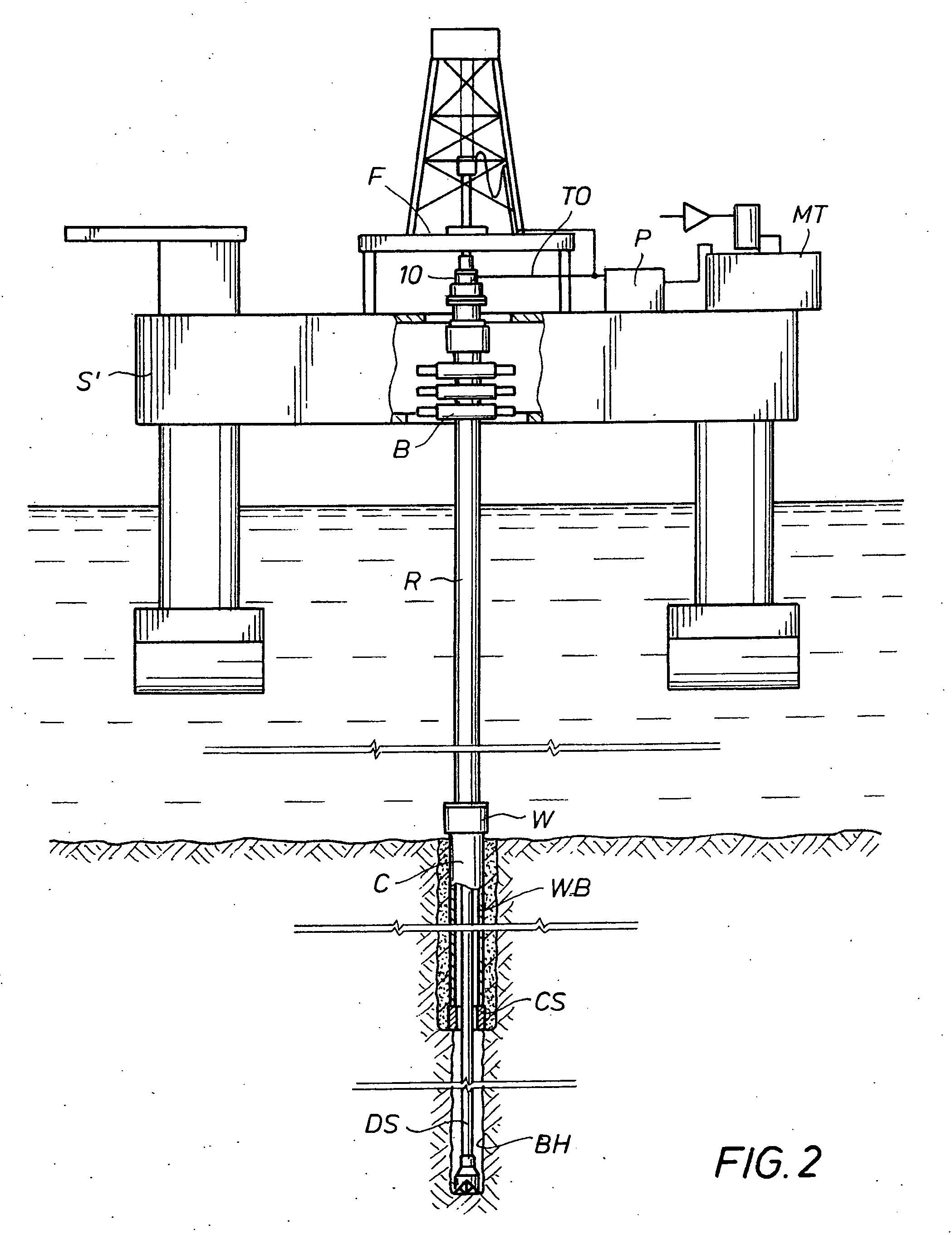

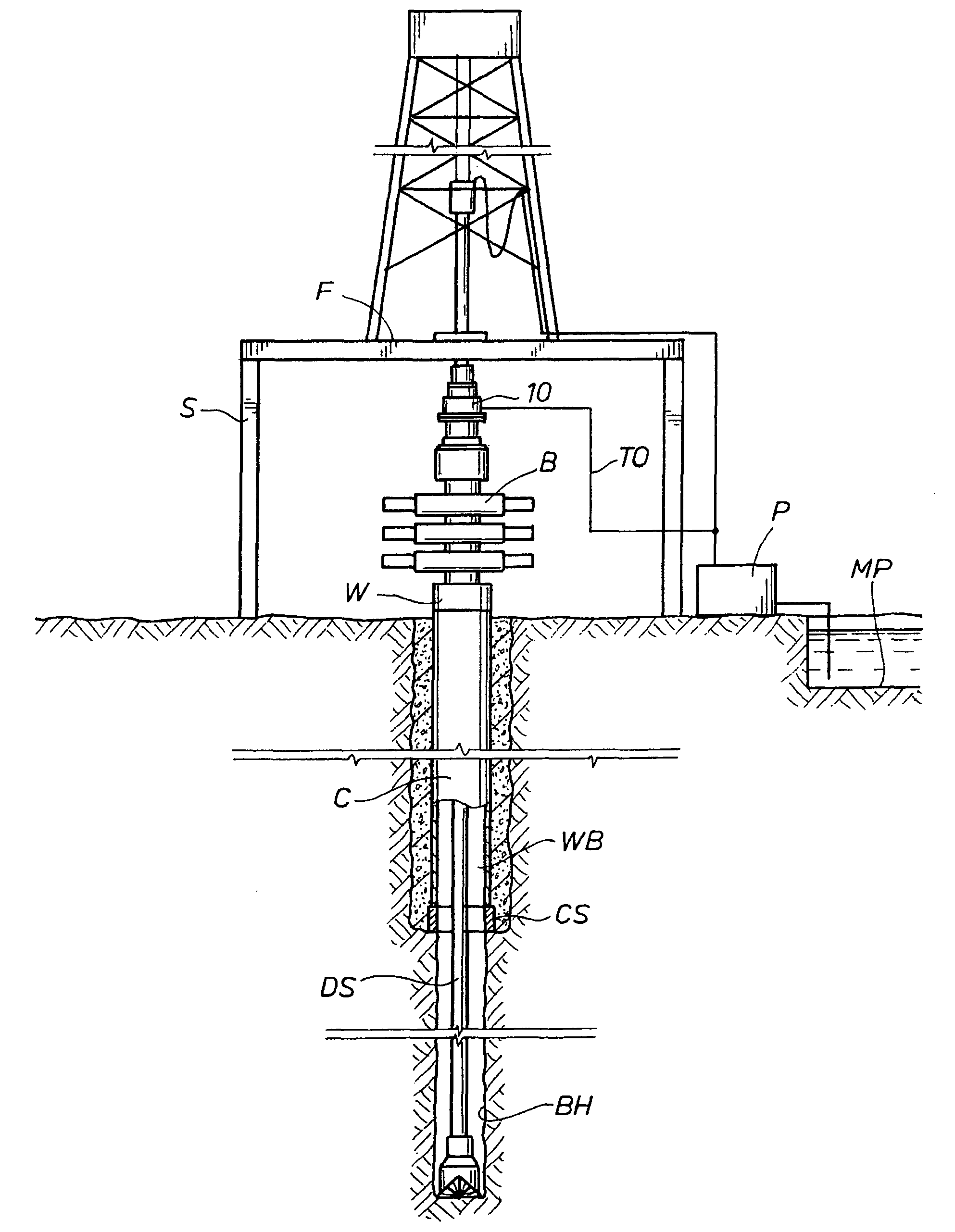

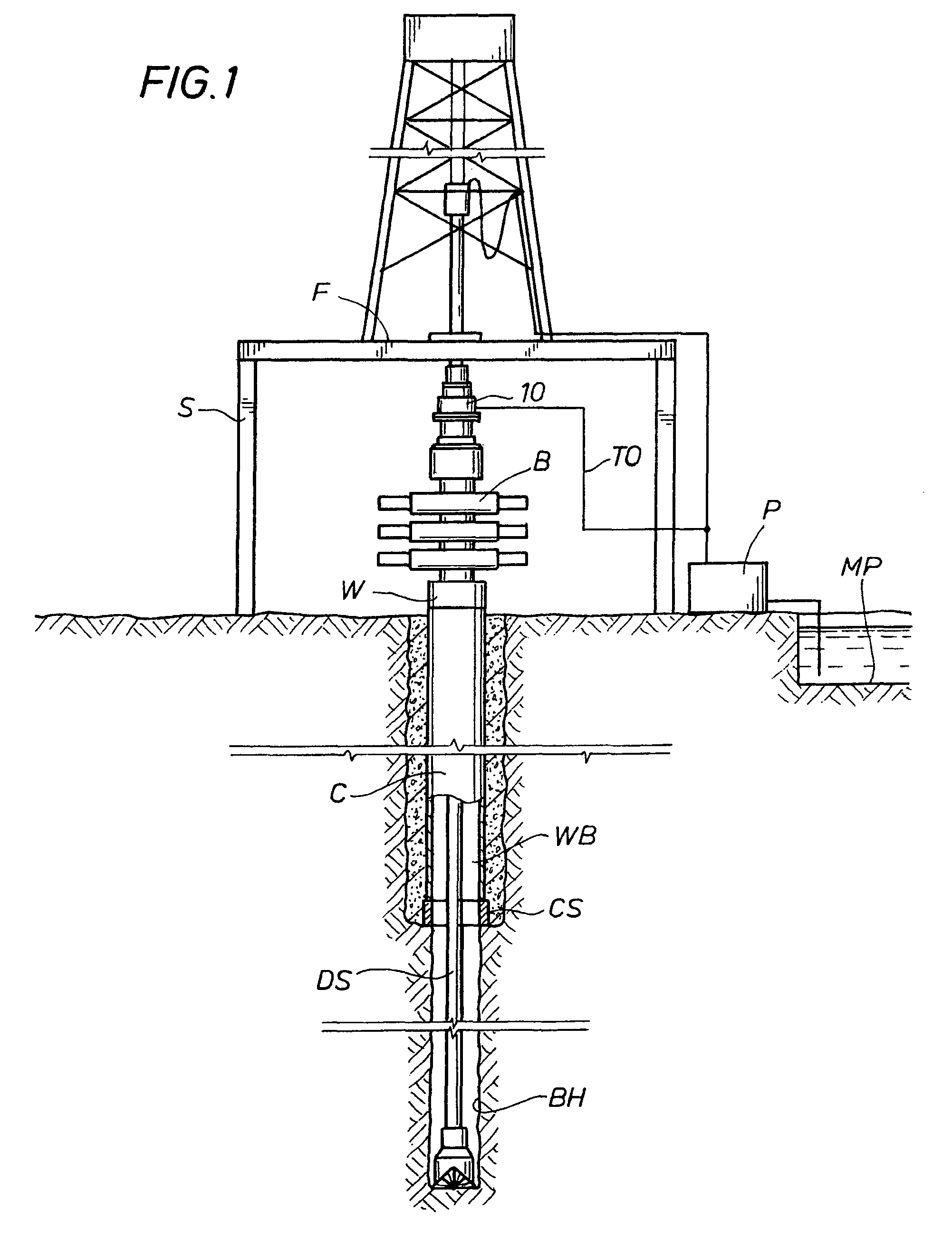

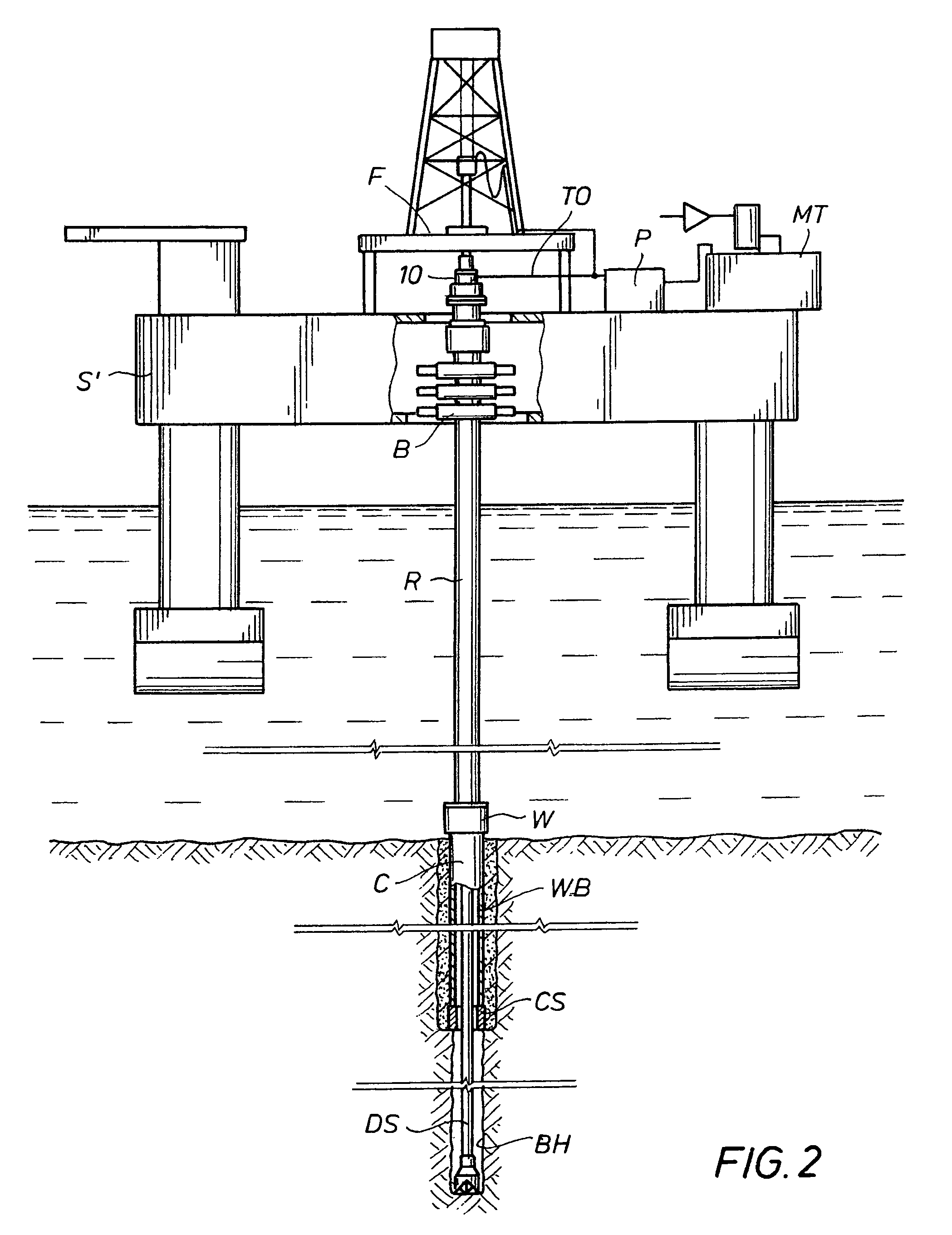

Drilling with a high pressure rotating control device

ActiveUS20110024195A1Operational securityHigh safety factorSurveyDrilling rodsWell drillingControl system

A Drill-To-The-Limit (DTTL) drilling method variant to Managed Pressure Drilling (MPD) applies constant surface backpressure, whether the mud is circulating (choke valve open) or not (choke valve closed). Because of the constant application of surface backpressure, the DTTL method can use lighter mud weight that still has the cutting carrying ability to keep the borehole clean. The DTTL method identifies the weakest component of the pressure containment system, such as the fracture pressure of the formation or the casing shoe leak off test (LOT). With a higher pressure rated RCD, such as 5,000 psi (34,474 kPa) dynamic or working pressure and 10,000 psi (68,948 kPa) static pressure, the limitation will generally be the fracture pressure of the formation or the LOT. In the DTTL method, since surface backpressure is constantly applied, the pore pressure limitation of the conventional drilling window can be disregarded in developing the fluid and drilling programs. Using the DTTL method a deeper wellbore can be drilled with larger resulting end tubulars, such as casings and production liners, than had been capable with conventional MPD applications.

Owner:WEATHERFORD TECH HLDG LLC

Method for reducing defect concentrations in crystals

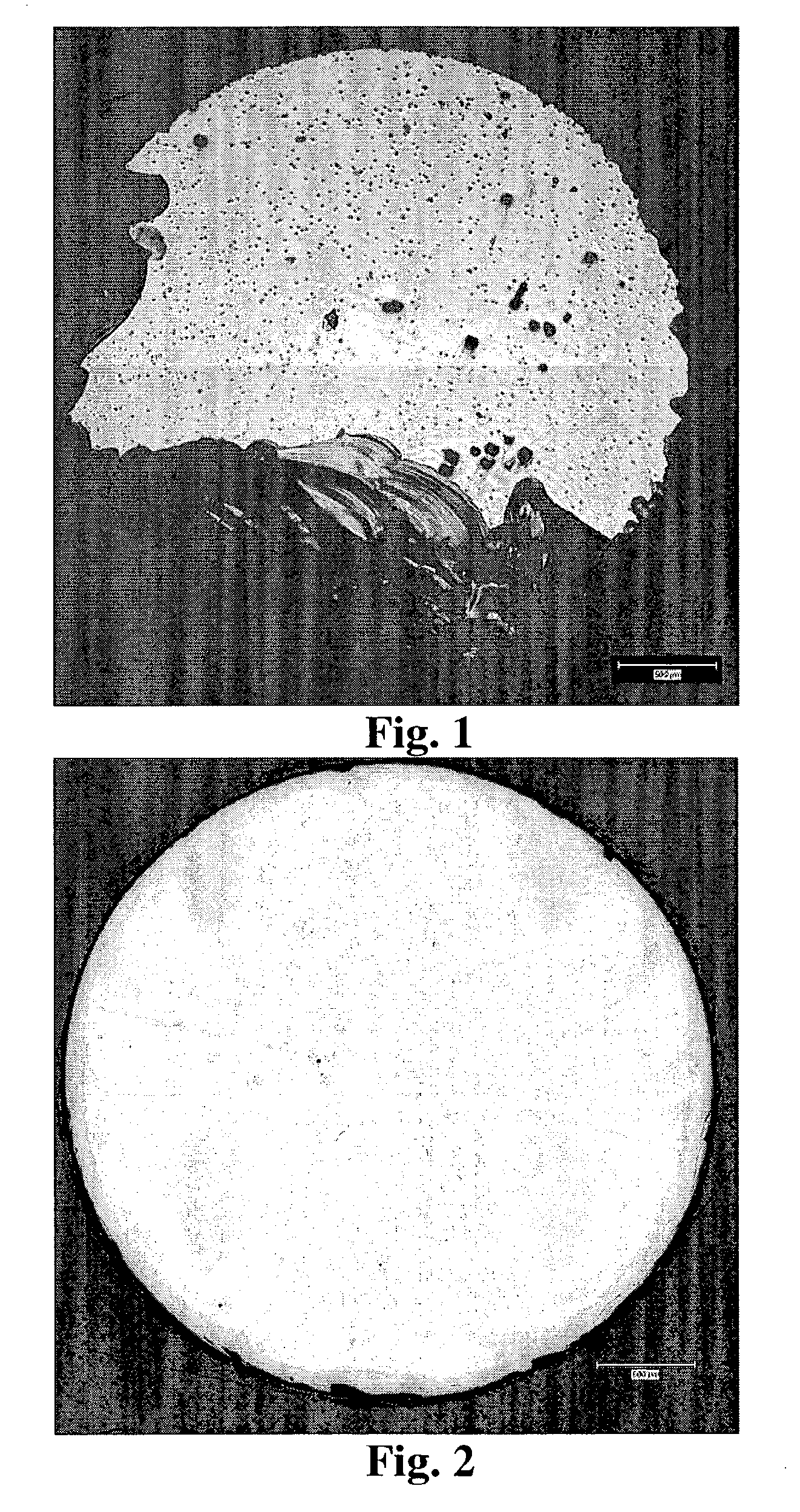

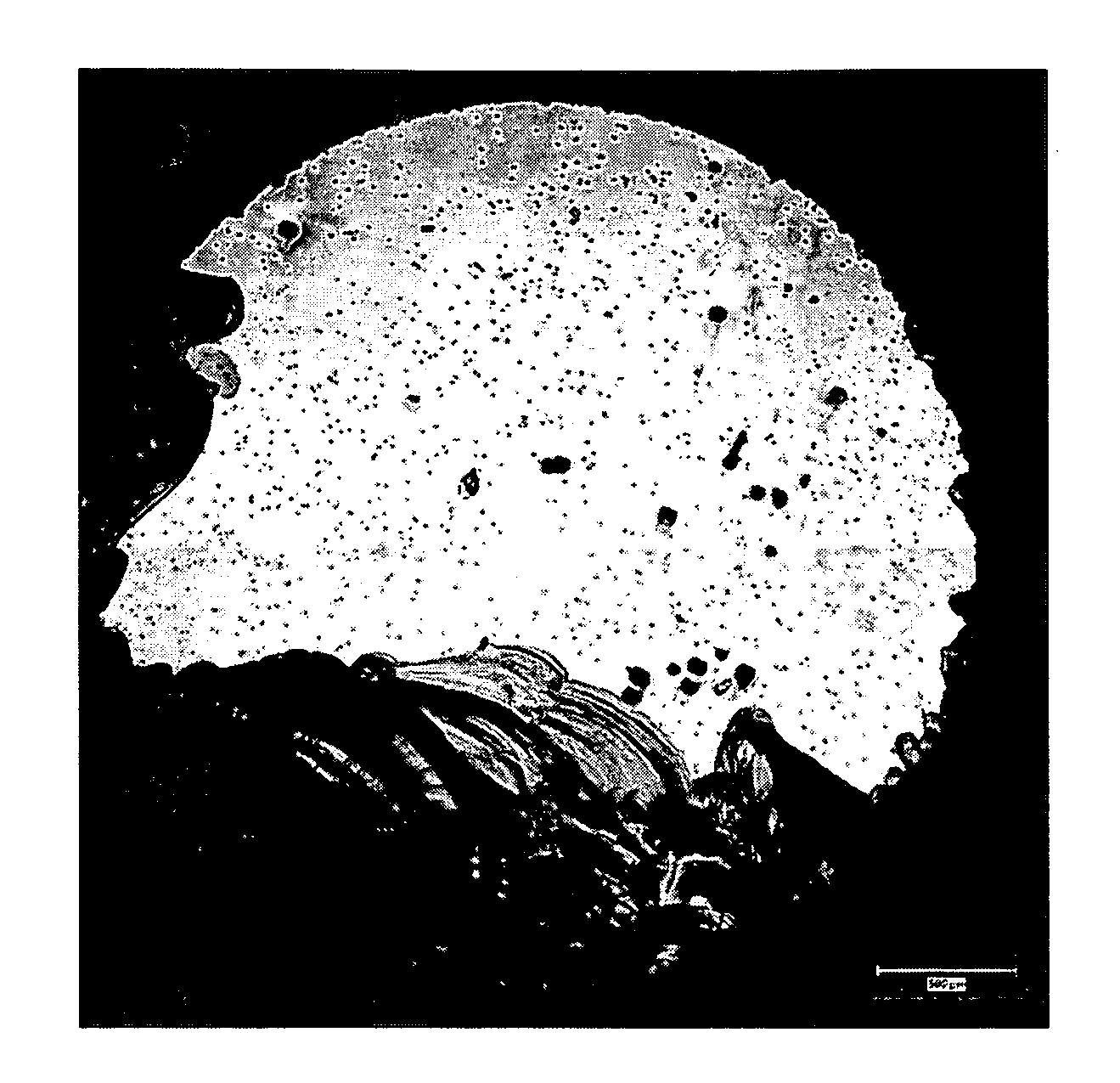

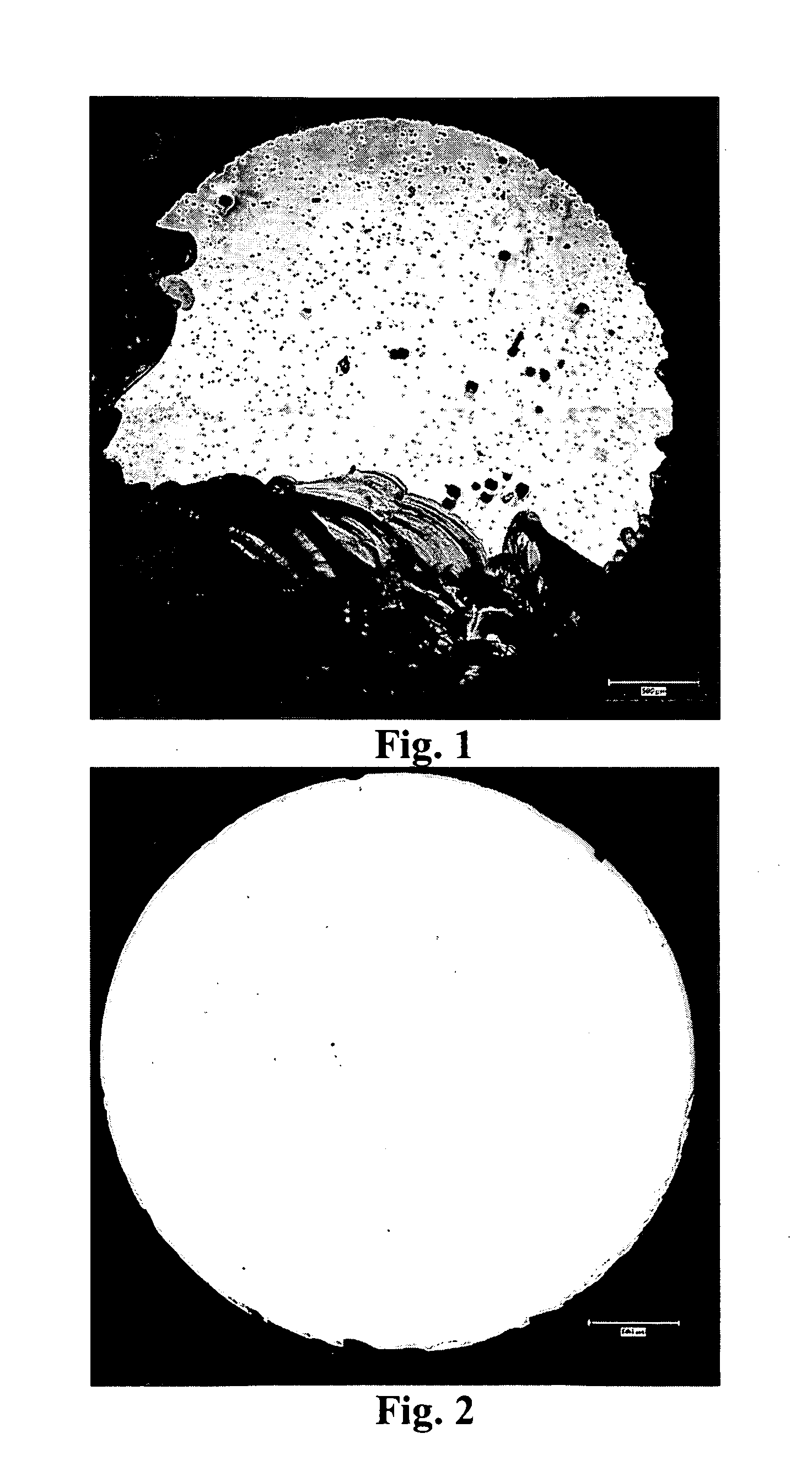

InactiveUS7175704B2Polycrystalline material growthFrom normal temperature solutionsSufficient timeDiamond crystal

A method for removing defects at high pressure and high temperature (HP / HT) or for relieving strain in a non-diamond crystal commences by providing a crystal, which contains defects, and a pressure medium. The crystal and the pressure medium are disposed in a high pressure cell and placed in a high pressure apparatus, for processing under reaction conditions of sufficiently high pressure and high temperature for a time adequate for one or more of removing defects or relieving strain in the single crystal.

Owner:DIAMOND INNOVATIONS INC

Method for reducing defect concentration in crystals

ActiveUS20060096521A1Reduce defect concentrationRelieve pressureAfter-treatment detailsUltra-high pressure processesDiamond crystalHigh pressure cell

A method for removing defects at high pressure and high temperature (HP / HT) or for relieving strain in a non-diamond crystal commences by providing a crystal, which contains defects, and a pressure medium. The crystal and the pressure medium are disposed in a high pressure cell and placed in a high pressure apparatus, for processing under reaction conditions of sufficiently high pressure and high temperature for a time adequate for one or more of removing defects or relieving strain in the single crystal.

Owner:SLT TECH

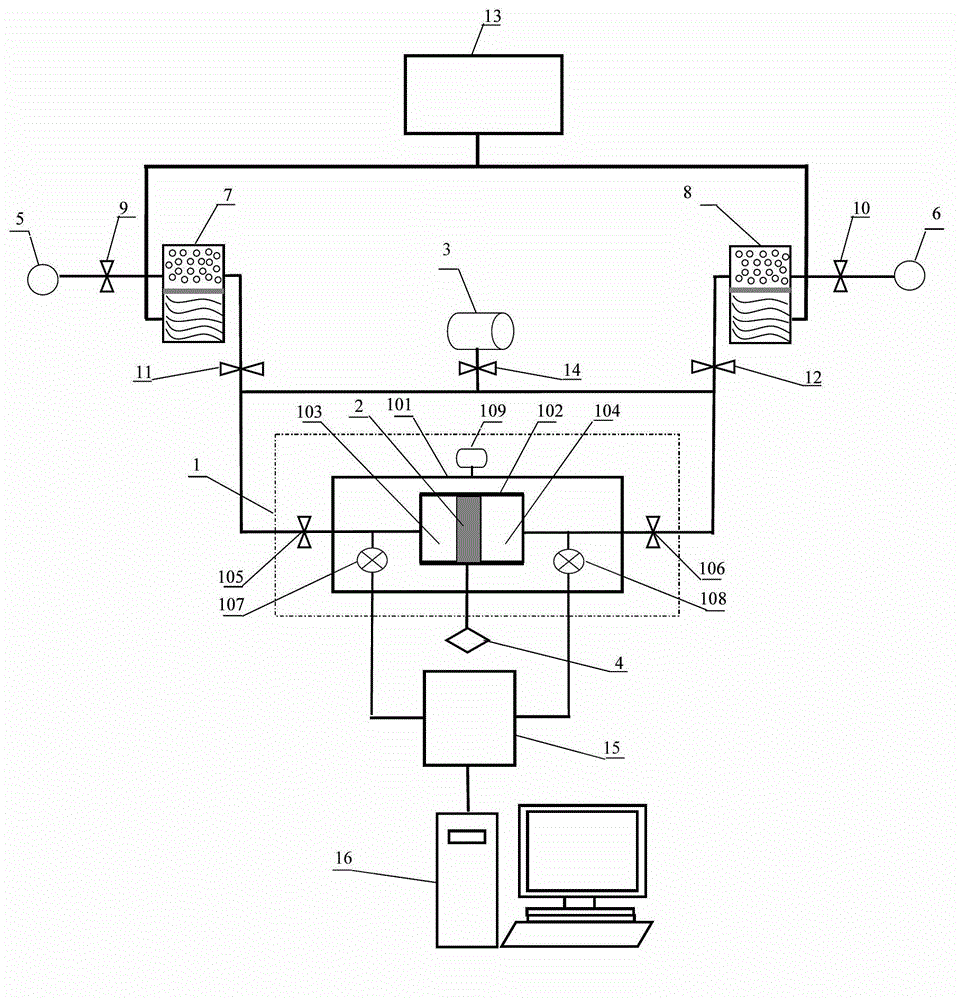

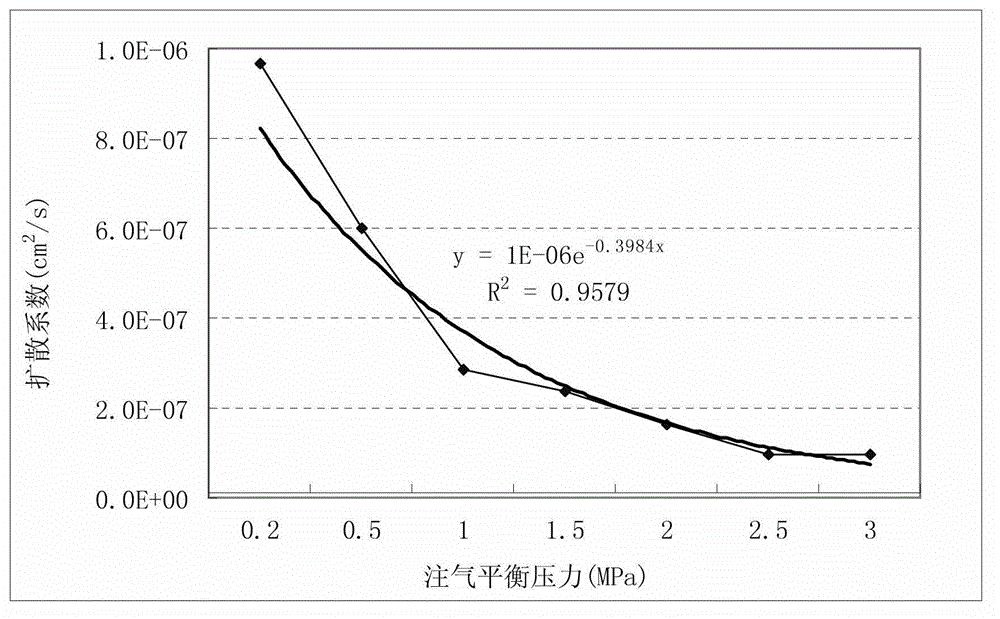

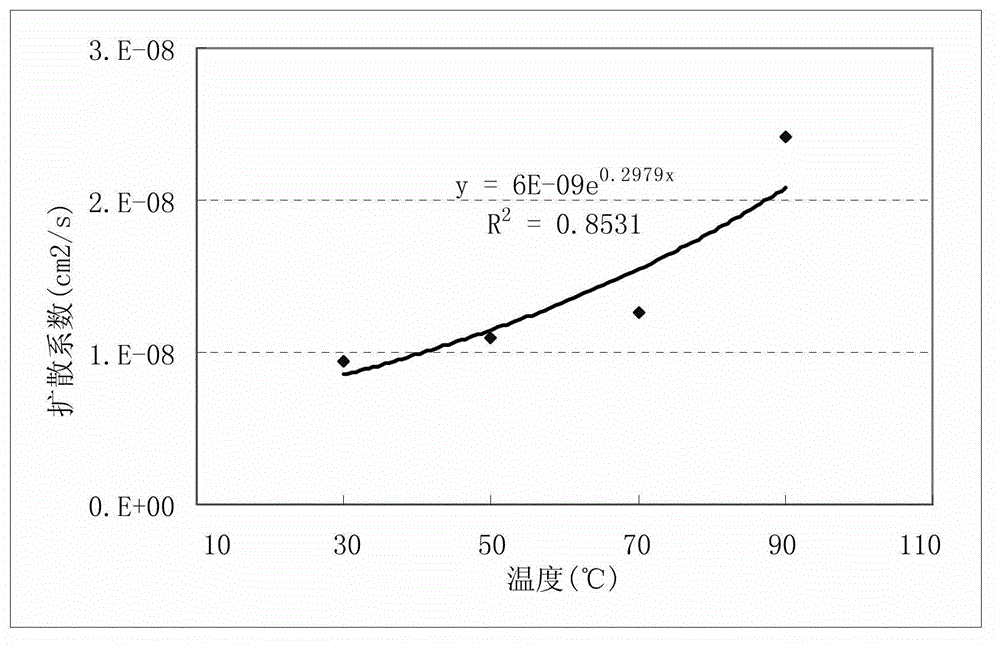

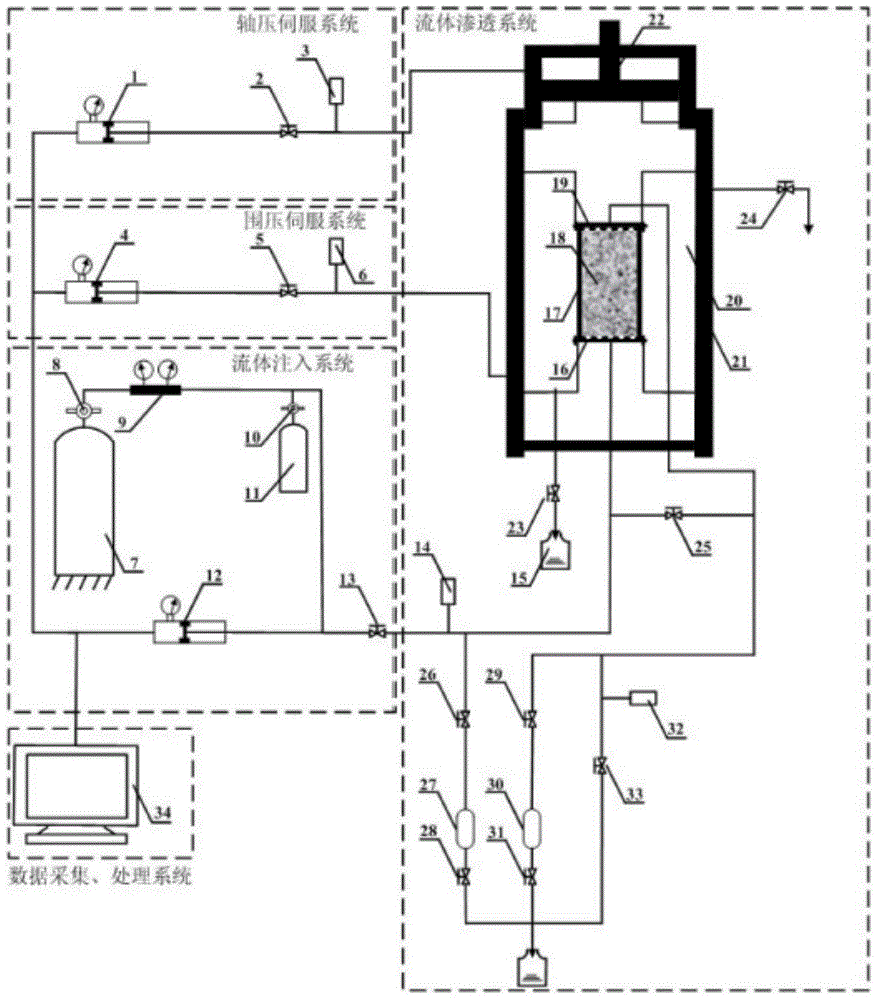

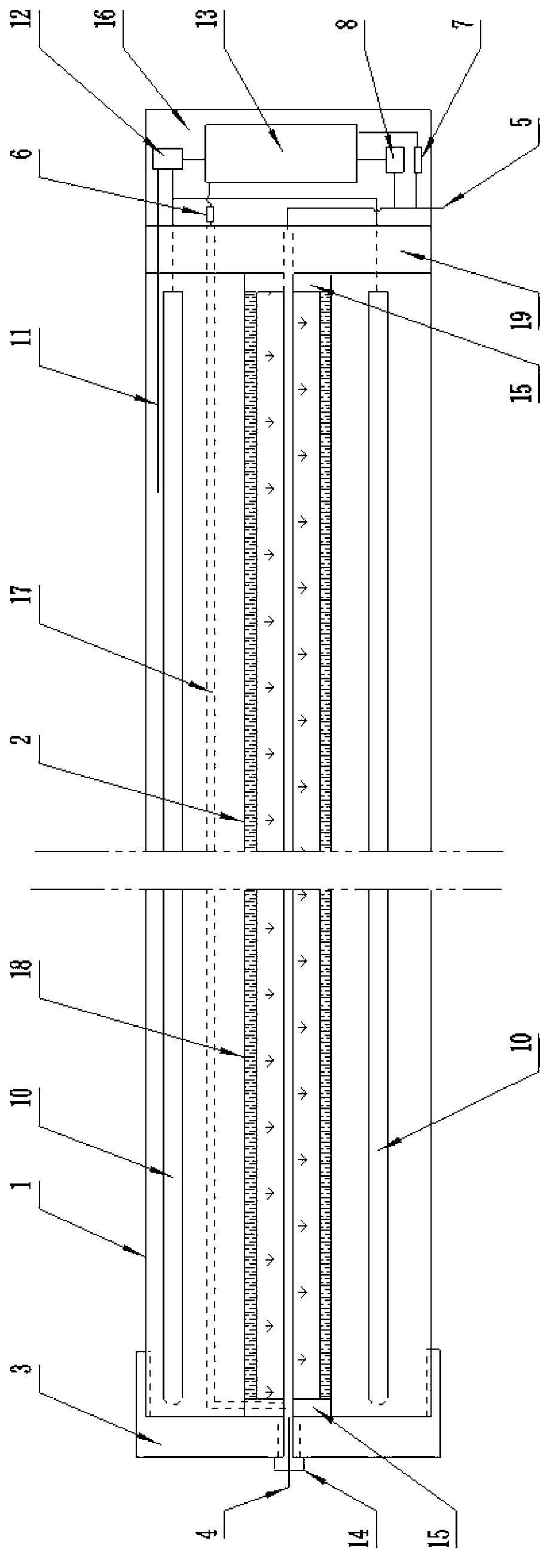

Device and measuring method for hydrocarbon diffusion coefficient in rocks under high temperature and high pressure

ActiveCN102980837AGas injection balance pressure is accurate and consistentSolve stressSurface/boundary effectConcentration gradientNormal diffusion

The invention provides a device and measuring method for the hydrocarbon diffusion coefficient in rocks under high temperature and high pressure. The device mainly comprises a rock diffusion coefficient tester, a vacuum pump, a confining pressure pump, hydrocarbon gas source, nitrogen (N2) gas source, a left piston container, a right piston container, an automatic pressure pump, a chromatographic detector, a computer, a drying device and a rock saturated water device and the like. According to the device and method, the consistent accurate accordance of the gas injection balance pressure in the diffusion chambers respectively arranged at two ends of a core holder can be achieved and the existence of the hydrocarbon diffusion driven by the concentration gradient not by the pressure gradient in the whole process of experiment is ensured. Meanwhile, according to the device and method, the problem of low gas injection balance pressure, relatively low experimental temperature and having difference with the actual formation condition of the gas source balance pressure control device in the measuring of normal diffusion coefficient is resolved.

Owner:PETROCHINA CO LTD

Drilling with a high pressure rotating control device

A Drill-To-The-Limit (DTTL) drilling method variant to Managed Pressured Drilling (MPD) applies constant surface backpressure, whether the mud is circulating (choke valve open) or not (choke valve closed). Because of the constant application of surface backpressure, the DTTL method can use lighter mud weight that still has the cutting carrying ability to keep the borehole clean. The DTTL method identifies the weakest component of the pressure containment system, such as the fracture pressure of the formation or the casing shoe leak off test (LOT). With a higher pressure rated RCD, such as 5,000 psi (34,474 kPa) dynamic or working pressure and 10,000 psi (68,948 kPa) static pressure, the limitation will generally be the facture pressure of the formation or the LOT. In the DTTL method, since surface backpressure is constantly applied, the pore pressure limitation of the conventional drilling window can be disregarded in developing the fluid and drilling programs.

Owner:WEATHERFORD TECH HLDG LLC

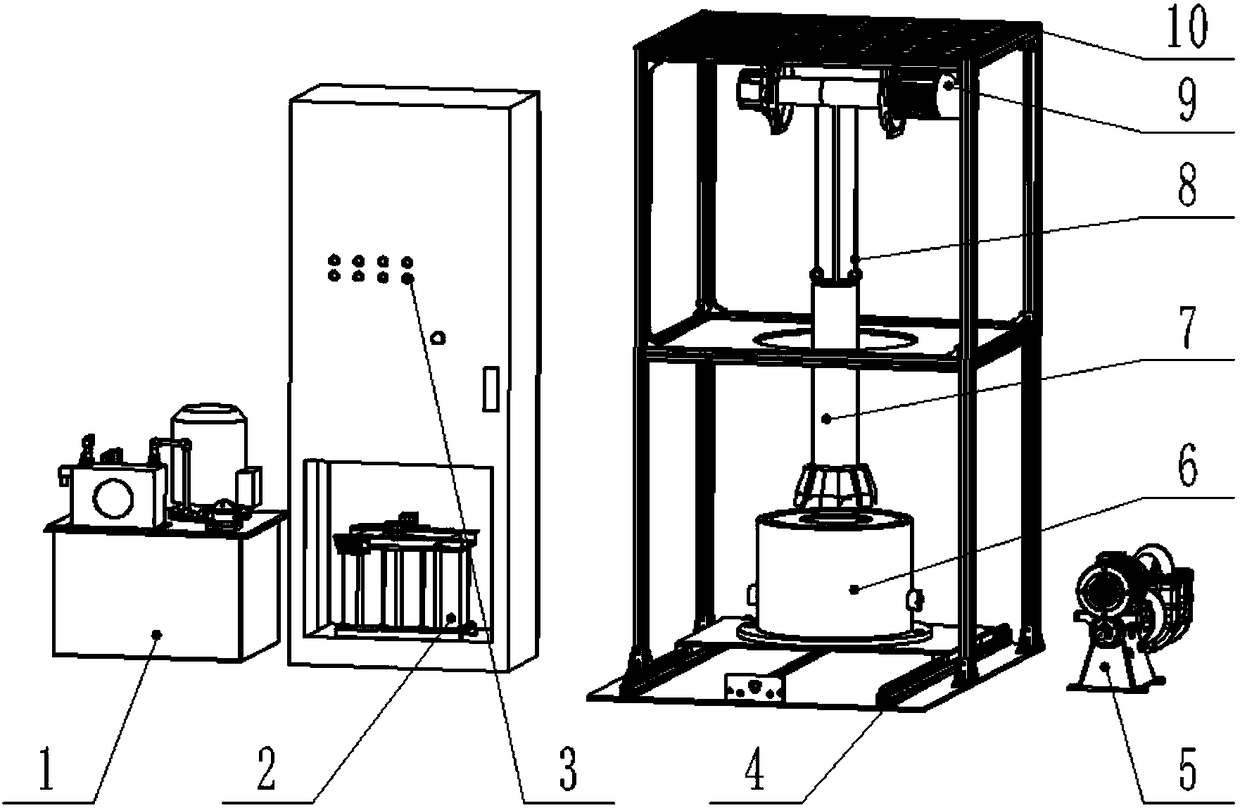

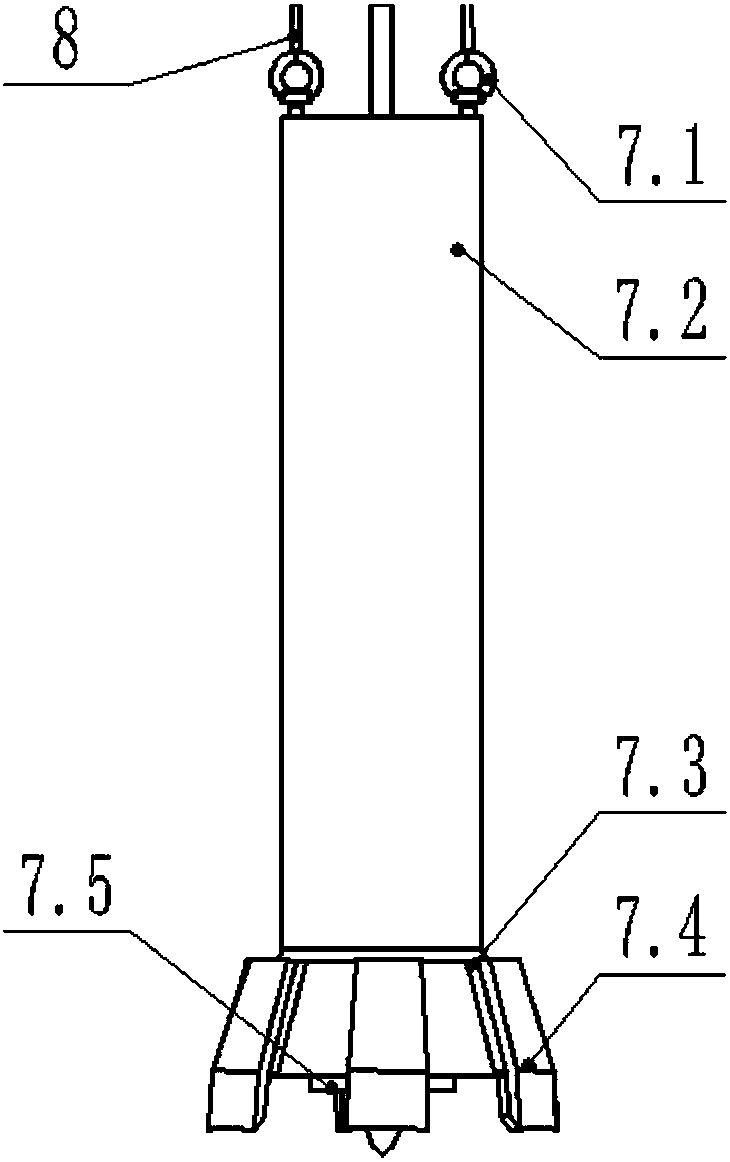

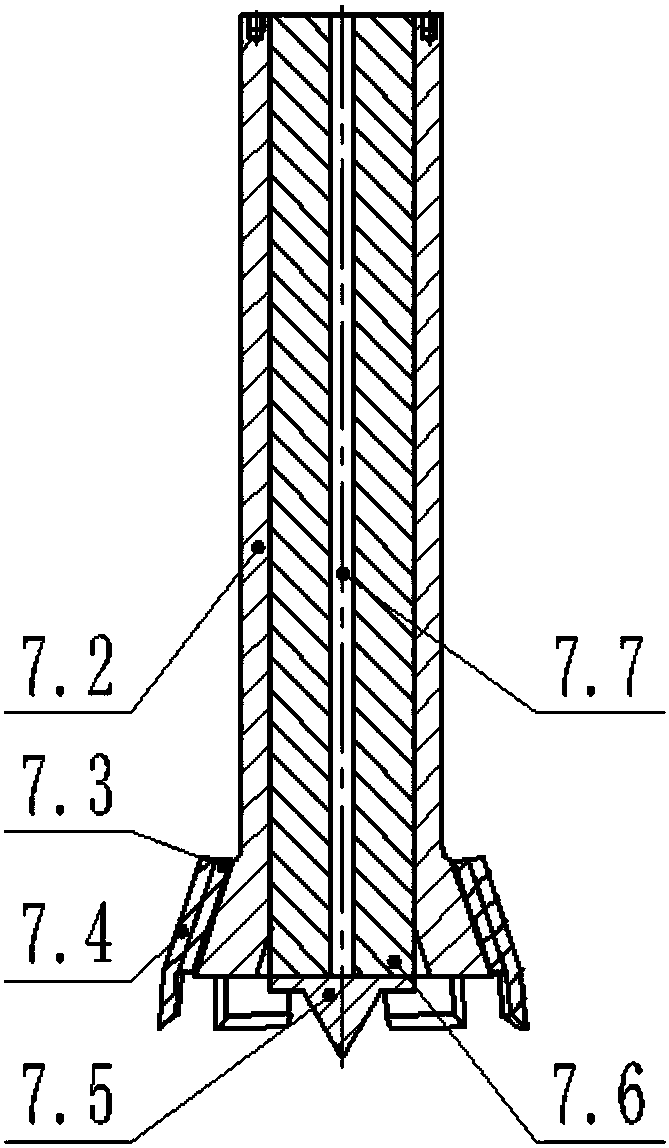

Electric pulse rock-breaking dill bit and experimental facility thereof

ActiveCN108222838AImprove energy efficiencyImprove drilling qualityMachine part testingDrill bitsLow voltageElectrical impulse

The invention discloses an electric pulse rock-breaking dill bit and an experimental facility thereof. The electric pulse rock-breaking experimental facility comprises a confining pressure pumping station, a pulsed power supply, a PLC control device, a confining pressure cylinder horizontal-moving device, a water inlet and outlet pump, a confining pressure cylinder assembly, a high-pressure electric pulse rock-breaking drill bit body, and the like. The high-voltage pulsed power supply is used for transmitting high-voltage pulse electricity from a high voltage electrode to a low voltage electrode through a cable, the high-voltage pulse electricity meeting certain conditions breaks through rocks firstly to generate a discharge channel, a plasma channel expands when heated, when the pressureexceeds the stress intensity of the rocks, and the rocks are broken and the high-voltage pulse discharge drilling is realized. The high-pressure electric pulse rock-breaking experimental facility cansimulate the high voltage environment of deep drilling in the earth, electric pulse drilling experiments carried out on high temperature and high pressure deep wells and ultra-deep wells are more close to actual drilling environments, experimental studies on the geometrical shape, distribution, spacing and electrode materials of electrodes of high-voltage electric pulse rock-breaking drill bit inthe deep wells and the ultra-deep wells can be realized, and the high-voltage pulse discharge drilling has broad development prospects.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

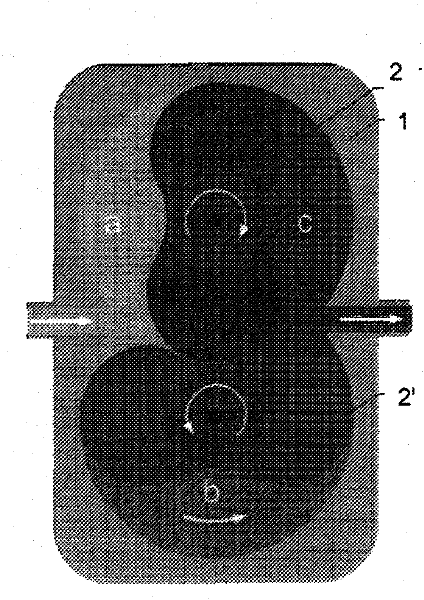

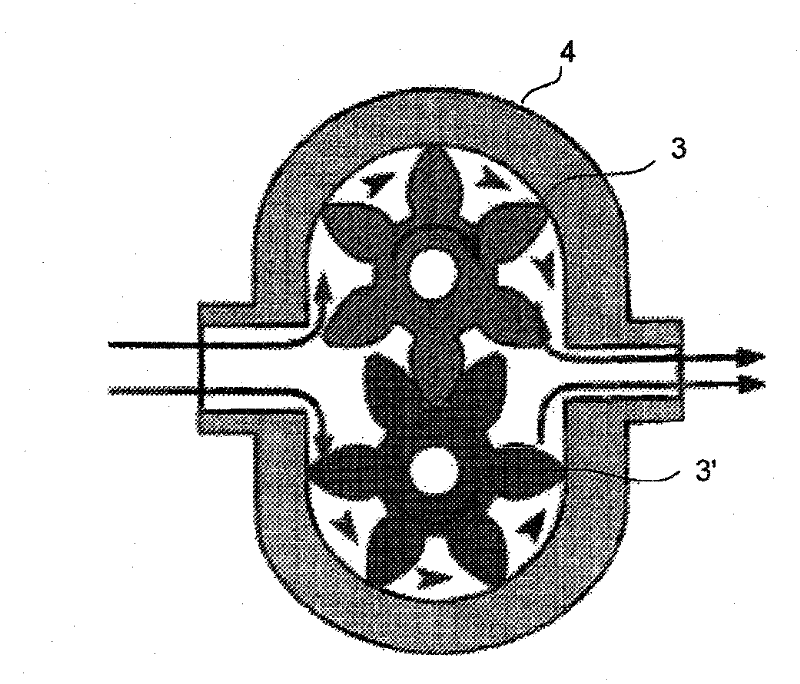

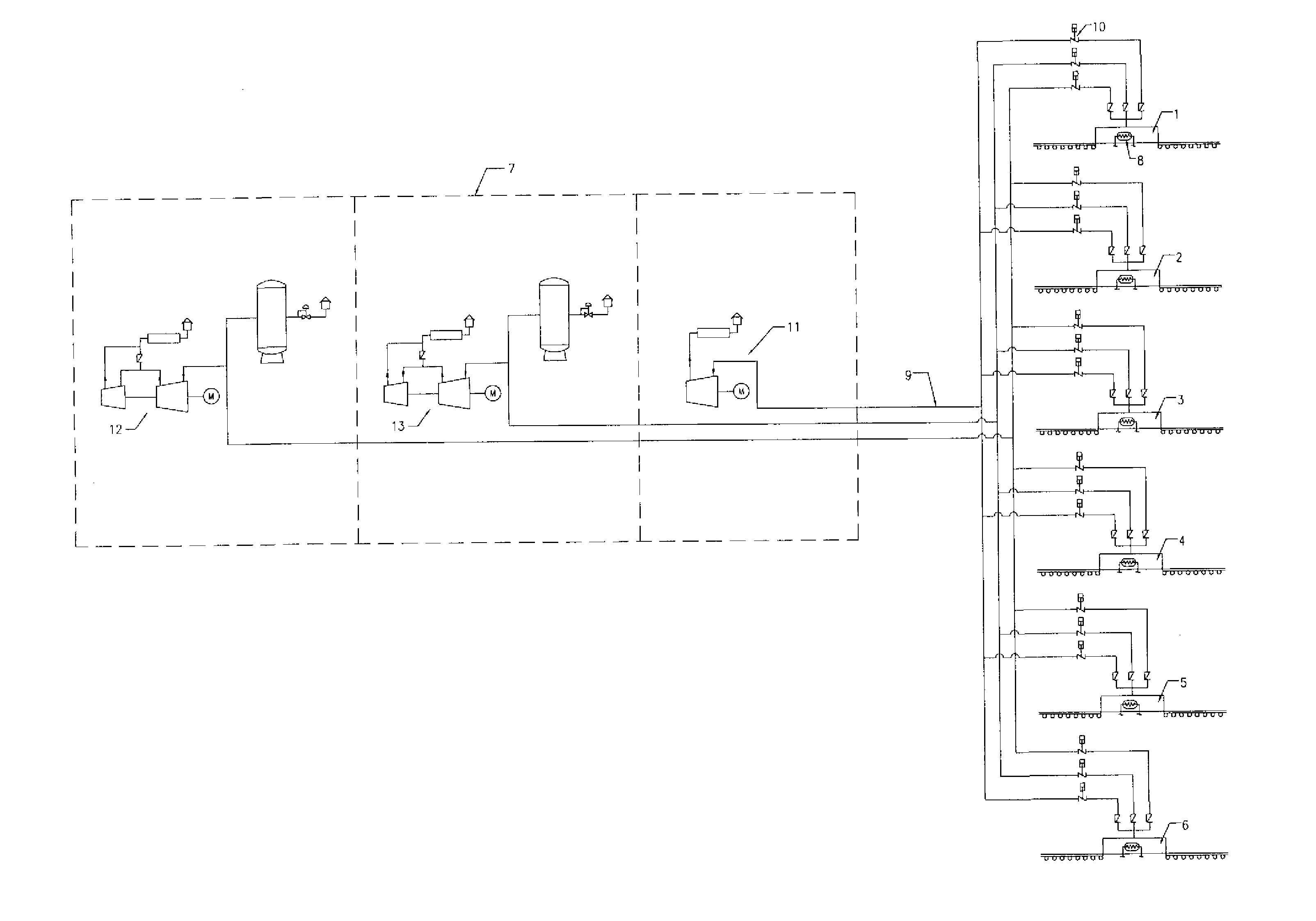

A compressible fluid pumping system

ActiveCN102203421AAchieve mass flow controlComponent separationSolid sorbent liquid separationHigh pressure cellEngineering

An invention is claimed that enables the pumping of compressible fluids at high pressures when an accurate flow is desired. Two pressure sources, for example pumps plumbed in series, separate thermodynamic work, such as pressurization, at the first pressure source from a volumetric or matter metering function in the second pressure source. One example is a flowstream delivery for a chemical instrumentation system that is manufactured from relatively unsophisticated pumps yet delivers precise flows with low pulsation (<1%) over pressures greater than 100 bar. An advantage of one embodiment allows the economical conversion of typical HPLC systems to state of-the-art supercritical fluid chromatography (SFC) systems with minimal modification to system components.

Owner:AGILENT TECH INC

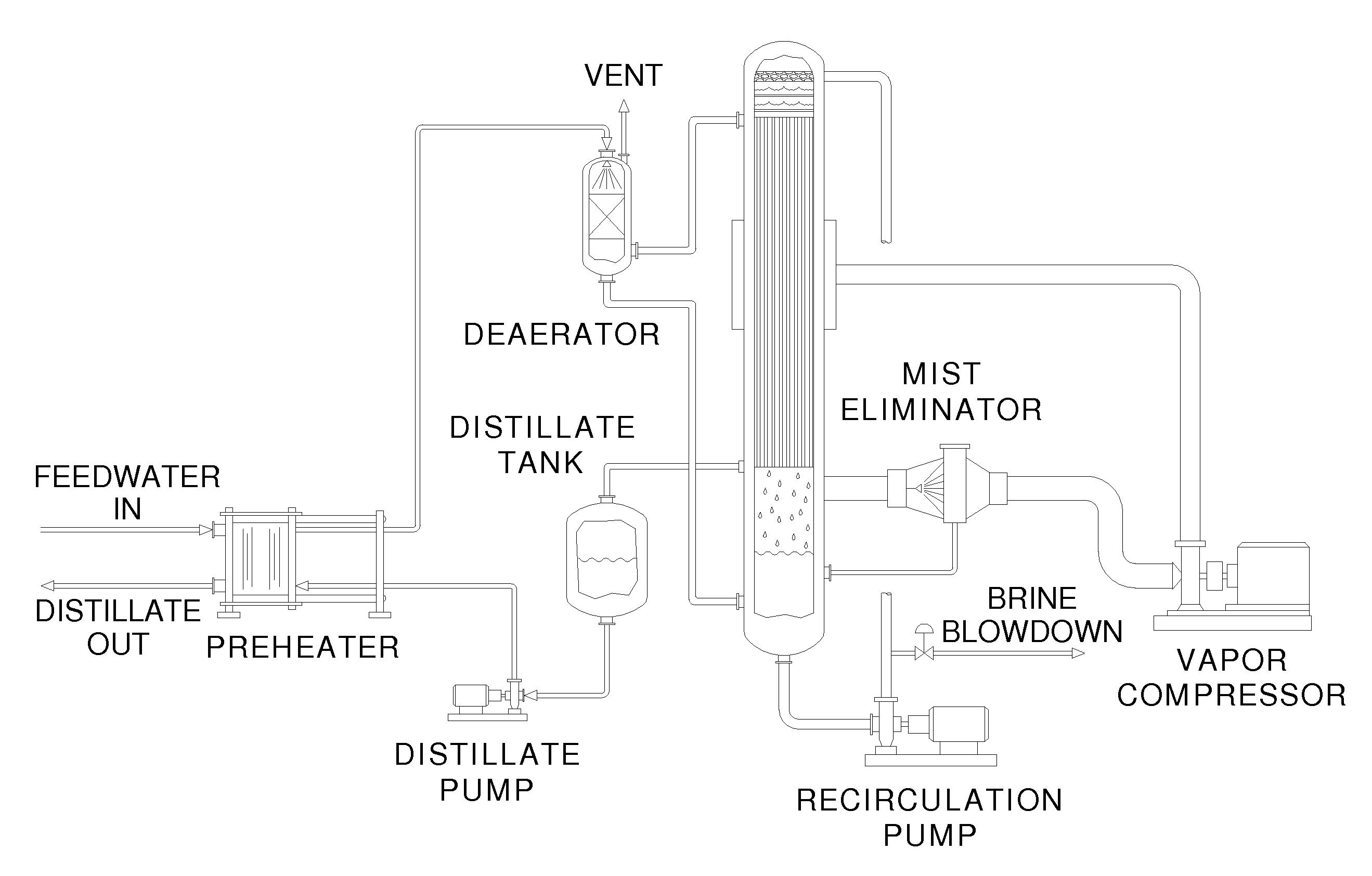

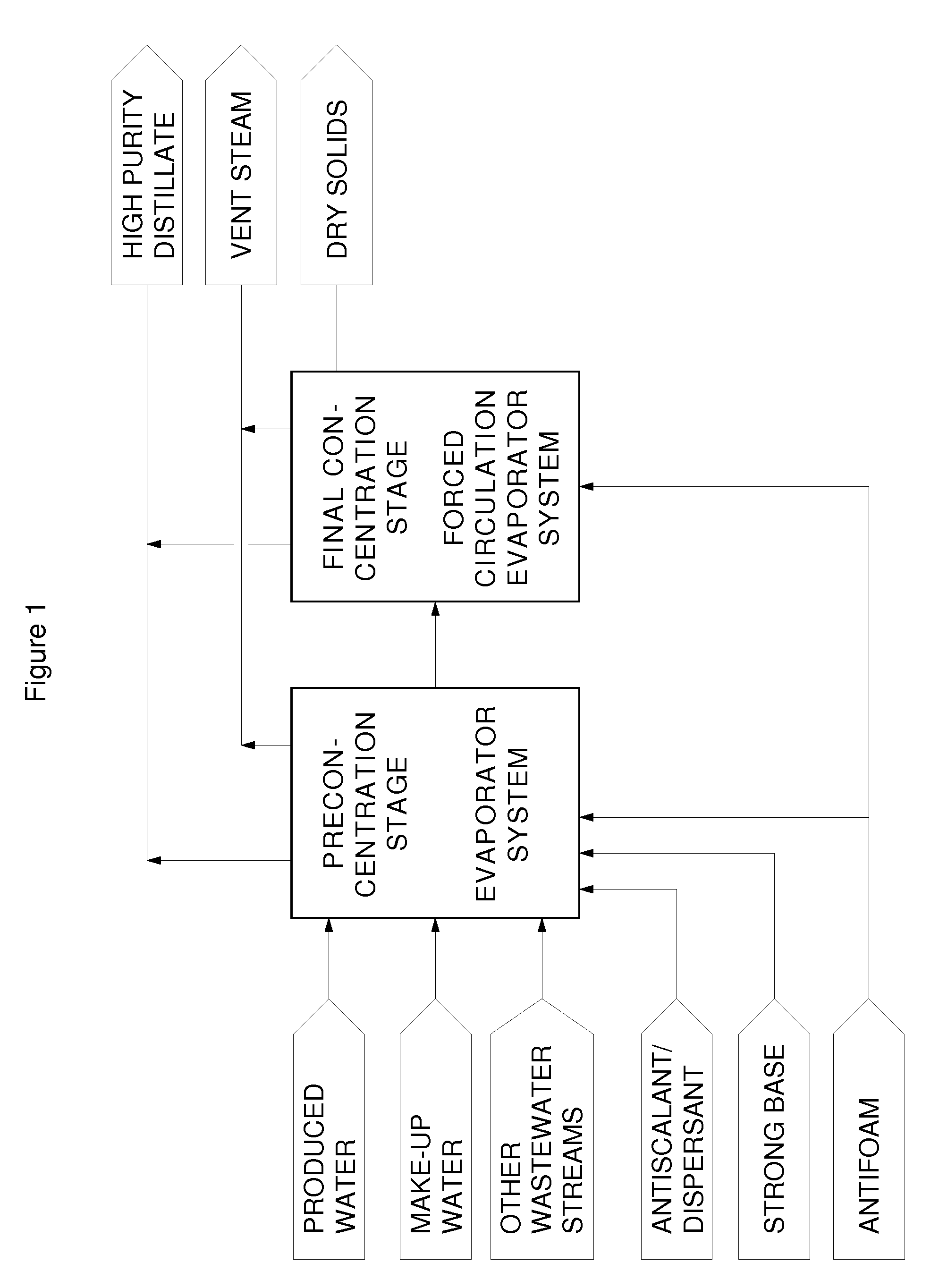

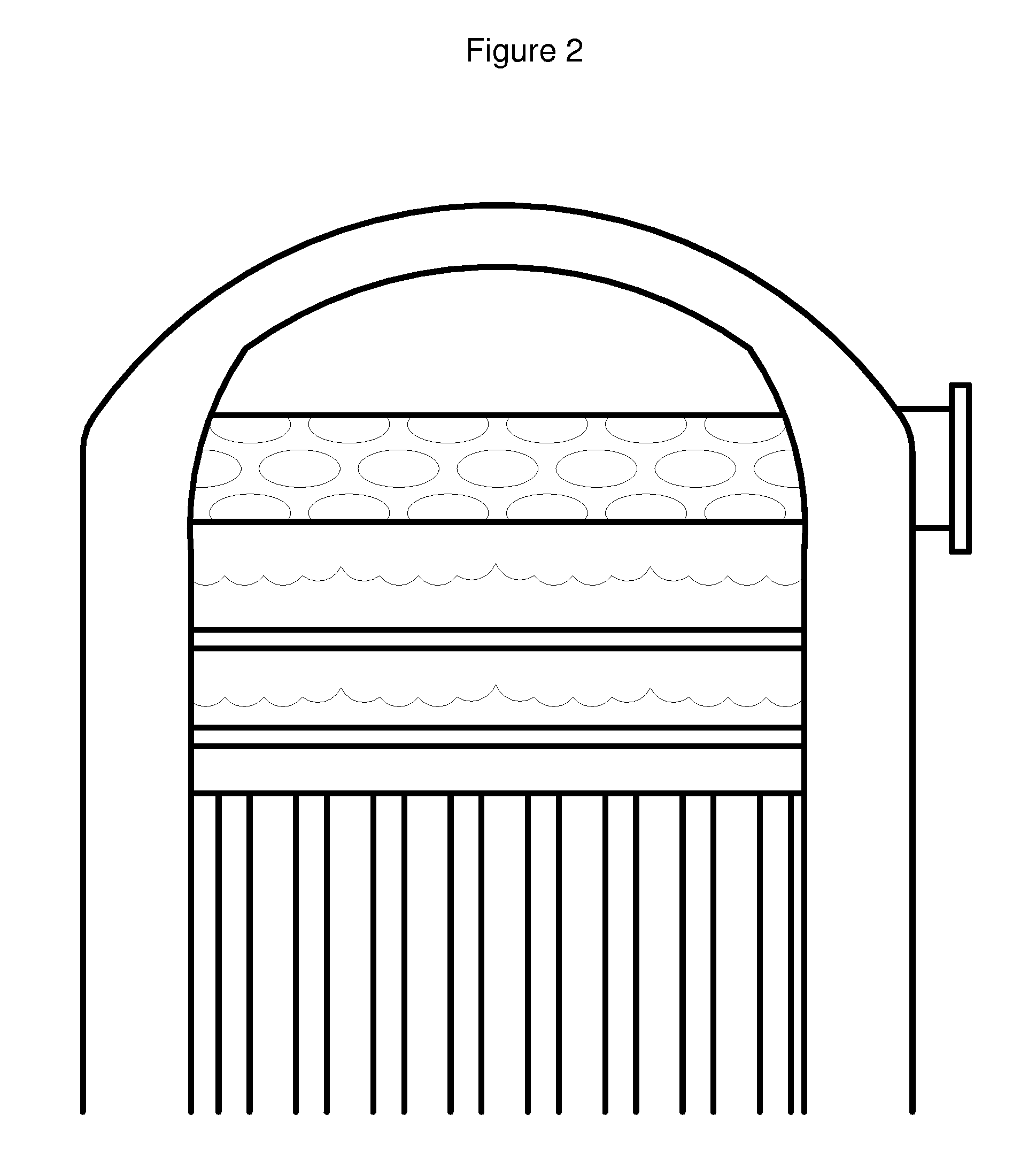

Method for production of high purity distillate from produced water for generation of high pressure steam

ActiveUS20110061867A1High work pressureIncrease vaporization rateUsing liquid separation agentInsulationEvaporationEngineering

Embodiments presented herein provide an evaporation based zero liquid discharge method for generation of up to 100% quality high pressure steam from produced water in the heavy oil production industry. De-oiled water is processed in an evaporation system producing a distillate that allows steam to be generated with either drum-type boilers operating at higher pressures or once-through steam generators (OTSGs) operating at higher vaporization rates. Evaporator blowdown is treated in a forced-circulation evaporator to provide a zero liquid discharge system that could recycle>98% of the deoiled water for industrial use. Exemplary embodiments of the invention provide at least one “straight sump” evaporator and at least one hybrid external mist eliminator. Embodiments of the evaporation method operate at a higher overall efficiency than those of the prior art by producing distillate at a higher enthalpy which minimizes the high pressure boiler preheating requirement.

Owner:AQUATECH INT LLC

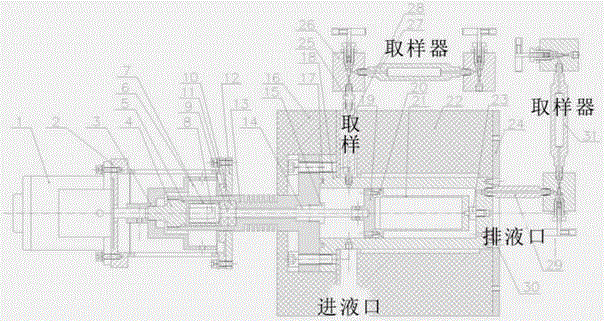

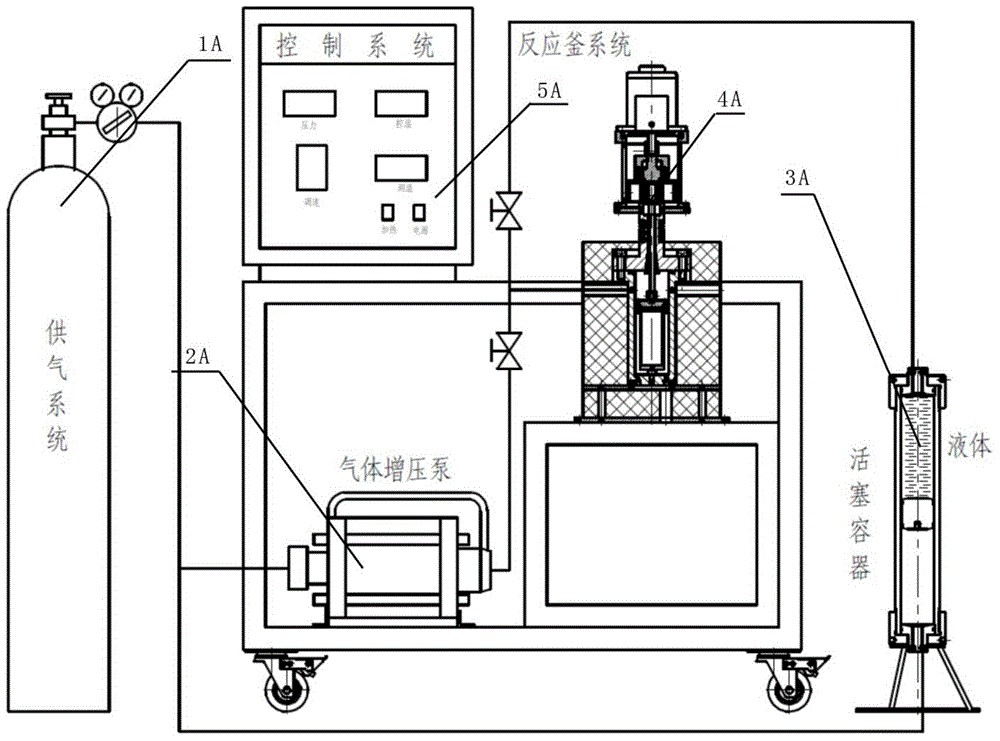

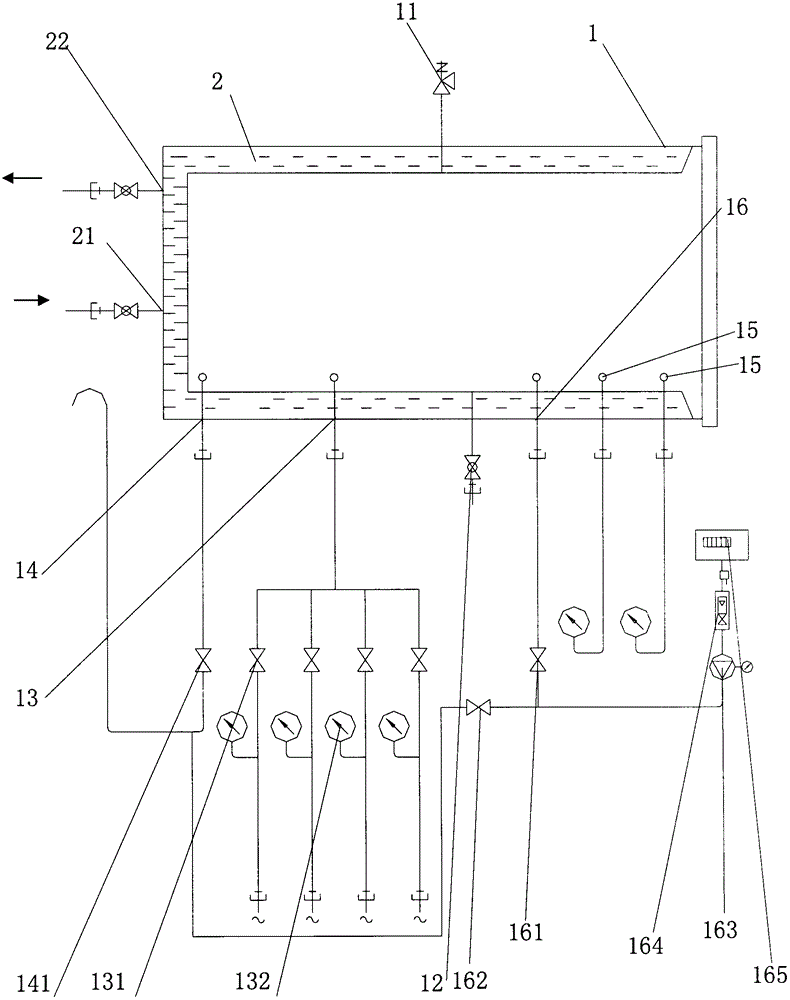

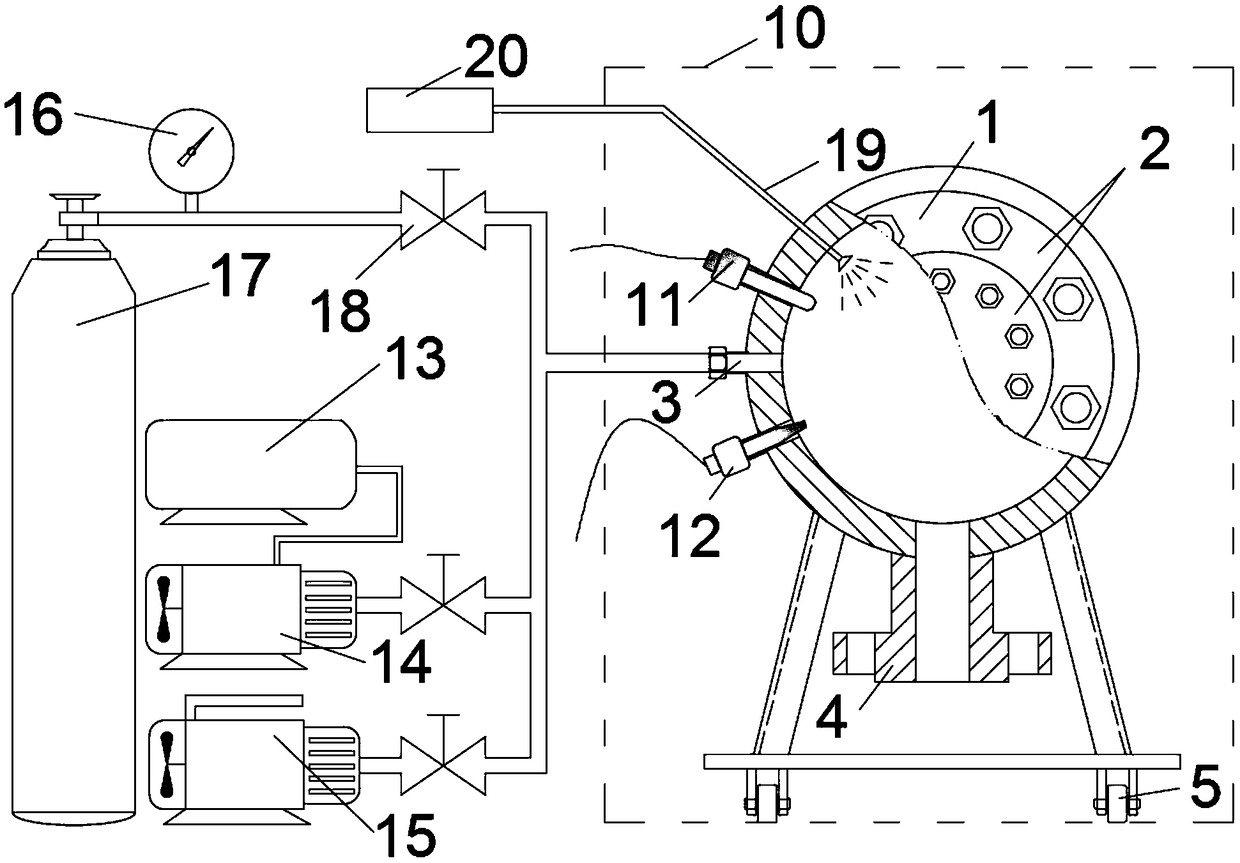

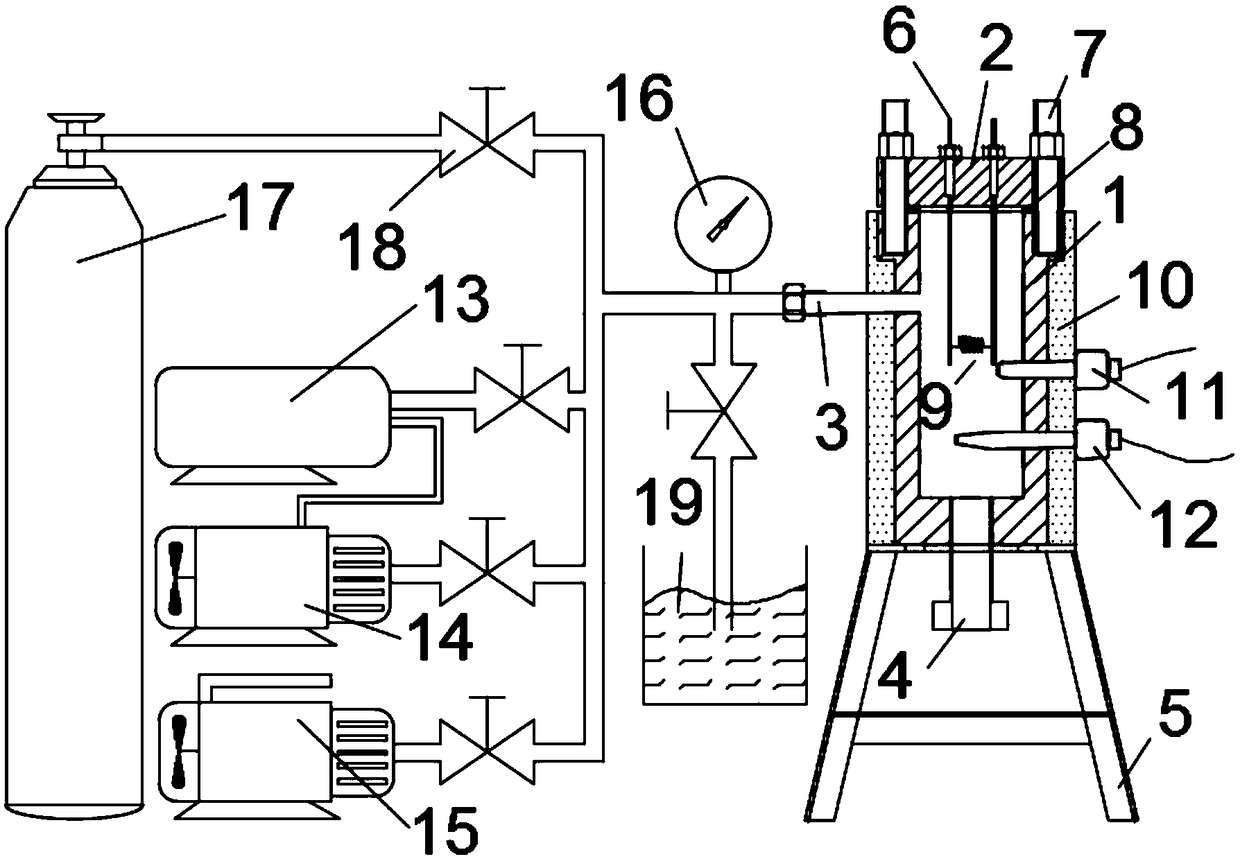

Experimental device for high temperature and high pressure anti-corrosion reaction

InactiveCN104459055ARealize online samplingImprove corrosion resistanceWithdrawing sample devicesTemperature stressChemical reaction

The invention discloses an experimental device for high temperature and high pressure anti-corrosion reaction, and belongs to the technical field of high temperature and high pressure anti-corrosion reaction. An existing high temperature and high pressure reaction kettle has the defects that a kettle body is heavy, is difficult to detach and is insufficiently sealed, the temperature and the pressure are unlikely to control, and the on-line sampling cannot be realized. The experimental device for the high temperature and high pressure anti-corrosion reaction comprises an air supply system, a piston container, a reaction kettle system and a control system. Various materials can generate chemical reaction in the experiment device in a high temperature and high pressure range of 50MPa pressure and 350 DEG C temperature; components, such as a piston, a cylinder body, an end cap, the reaction kettle body and a sampler, directly in contact with a reaction solution are made from a hastelloy material so as to have the strong corrosion resistance. The experimental device has functions of temperature and pressure presetting, and temperature and pressure overload protection; meanwhile, the experimental device is provided with electromagnetic propelled stirring blades which can be used for stirring reactors during reaction, so that the reaction speed is increased; furthermore, the experimental device is provided with the sampler so as to realize the on-line sampling on the reaction solution.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

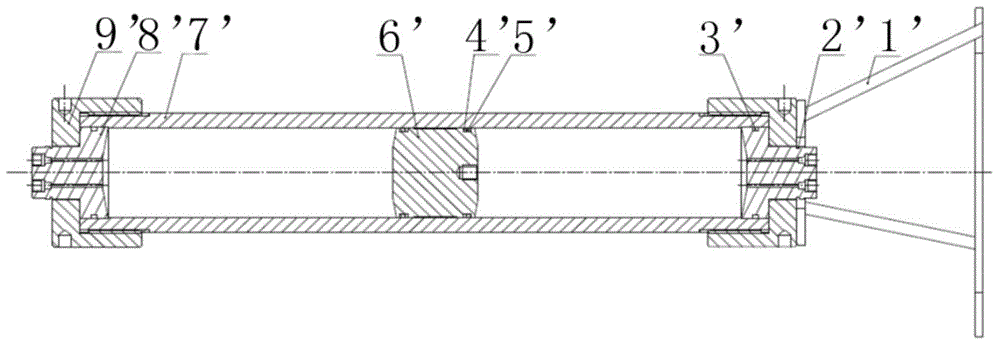

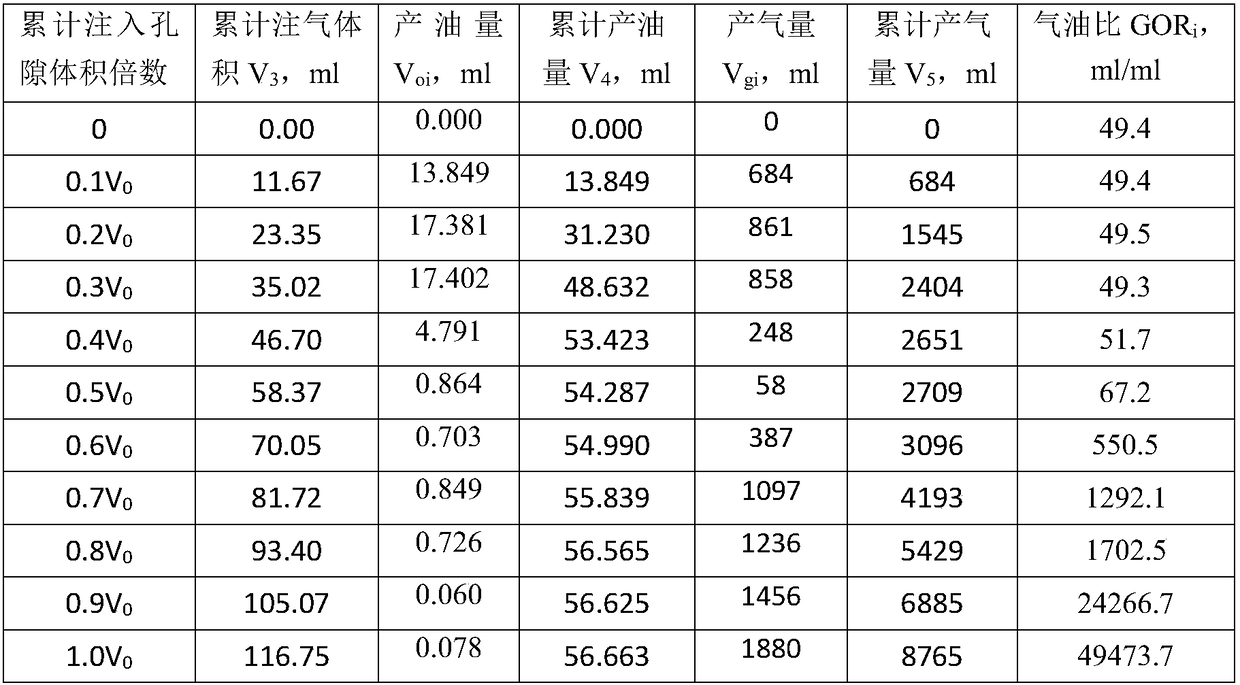

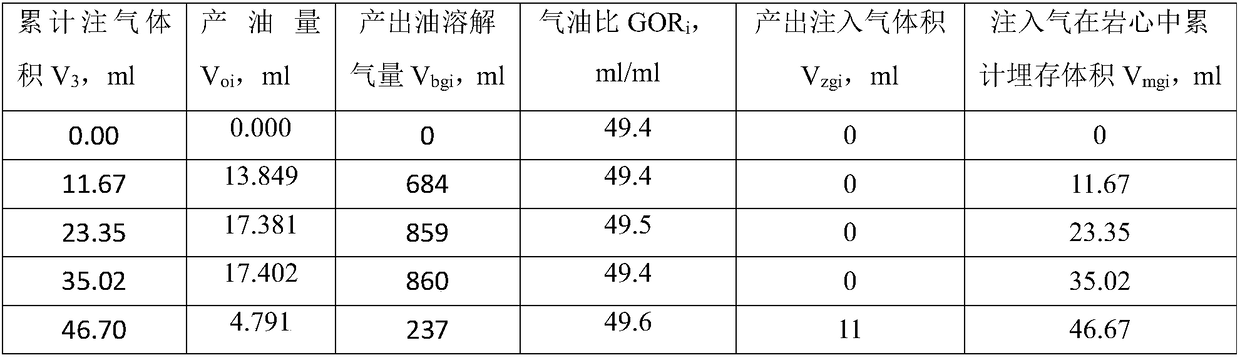

Experimental test method of buried displacing oil storage quantity of mixed gas flooding under high temperature and high pressure

ActiveCN108490156AReliable principleSimple and fast operationEarth material testingRock coreGas composition

The invention discloses an experimental test method of mixed gas flooding storage capacity under high temperature and high pressure. The experimental test method comprises the following steps: (1) preparing a crude oil fluid sample; (2) testing the single degassing oil ratio GORO; (3) testing injected gas composition and volume coefficients; (4) obtaining a reservoir plunger rock core sample in anactual gas reservoir; (5) putting a combined long rock core in a rock core clamper; (6) testing through connecting an experimental device, injecting a water sample in a formation water intermediate container into the rock core till formation water visiblely flows out of a separator; (7) injecting an oil sample in a formation oil sample intermediate container into the rock core till the water sample in the separator is not increased; (8) injecting a gas ample in an injected gas intermediate container into the rock core till no oil is produced at the outlet end of the rock core; (9) calculatingthe storage capacity of injected gas according to the GORi at different moments in the gas flooding process and the GOR0 of the prepared crude oil sample. The experimental test method disclosed by the invention is reliable in principle, simple and convenient to operate, strong in applicability and capable of determining the storage capacity and the distribution characteristics of each of injectedgas components in the rock core.

Owner:SOUTHWEST PETROLEUM UNIV

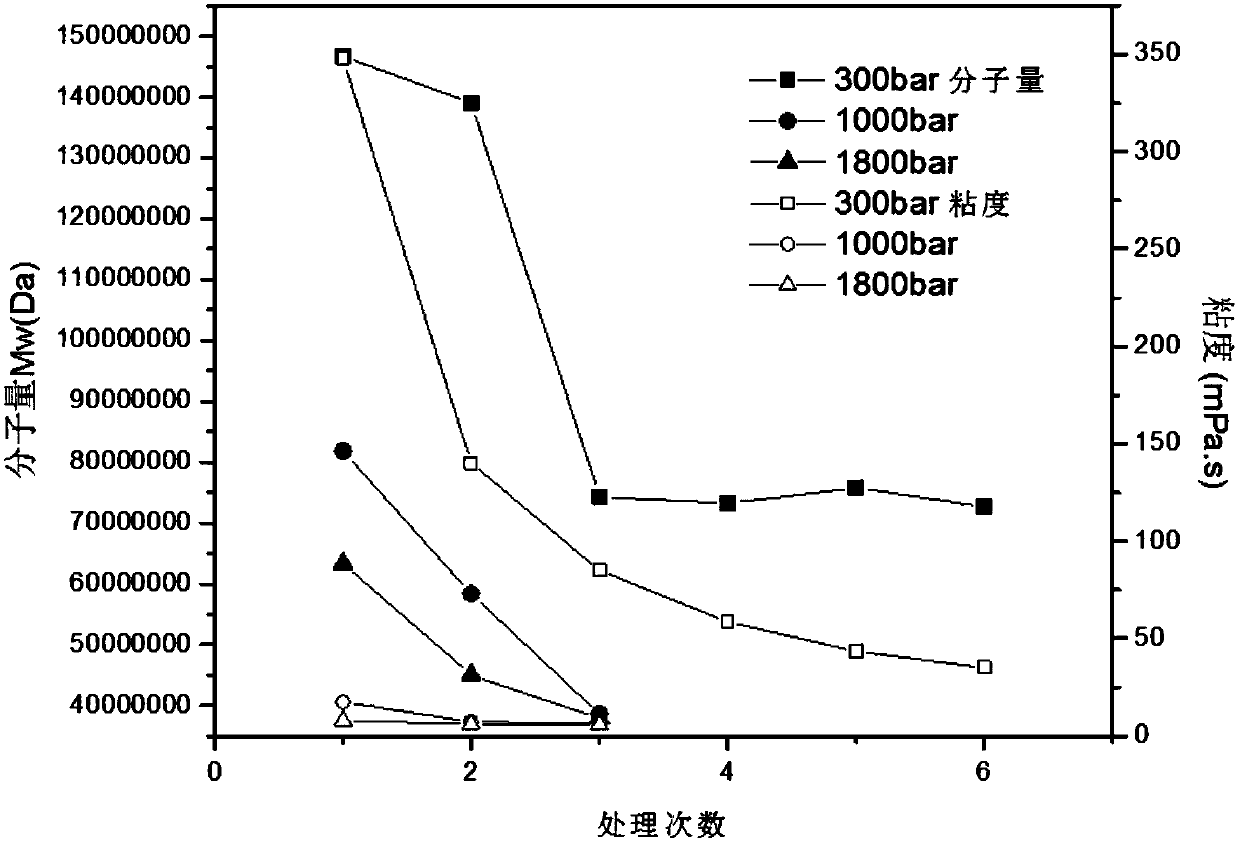

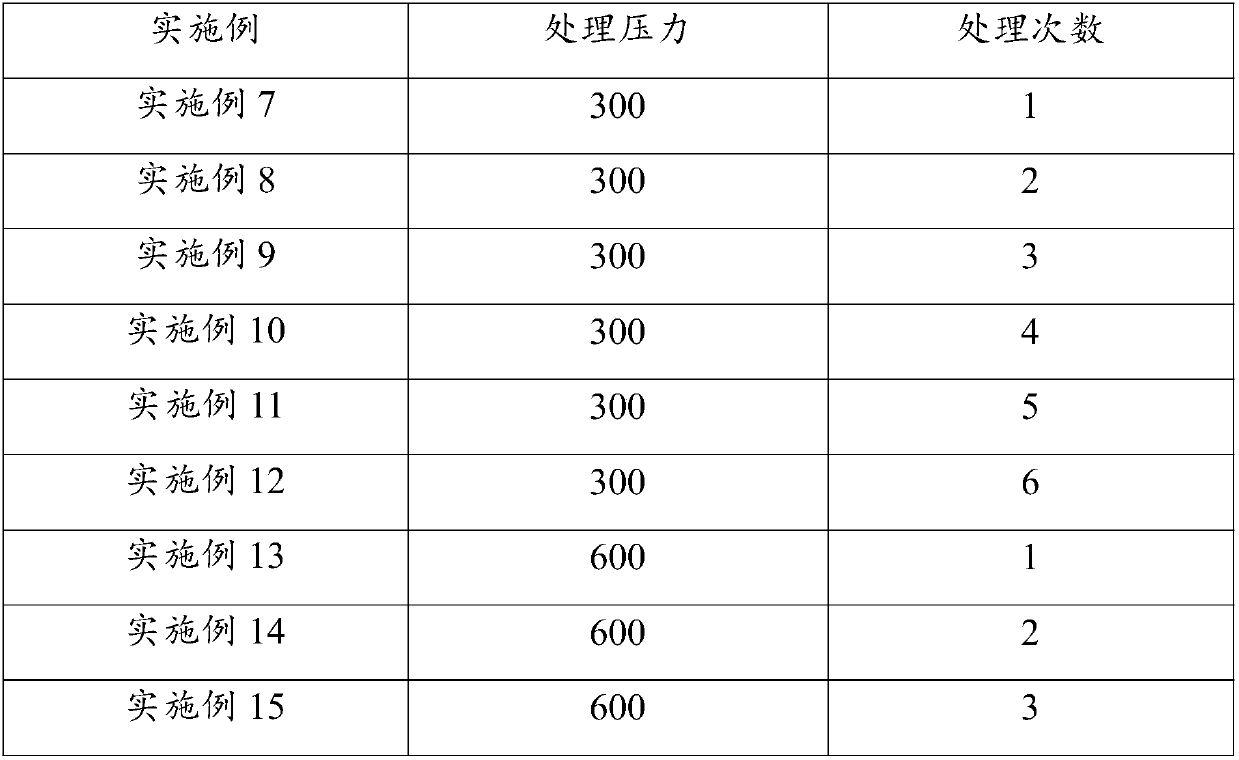

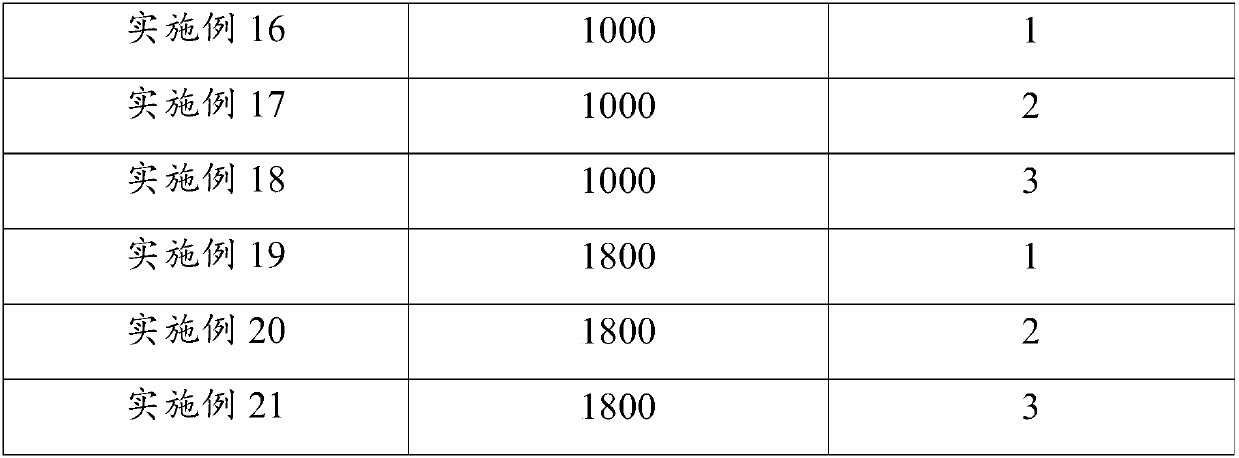

Polysaccharide degradation method and low-molecular-weight polysaccharide

The invention discloses a polysaccharide degradation method and low-molecular-weight polysaccharide, and relates to the field of degradation of a polysaccharides compound. The polysaccharide degradation method comprises the following step: treating a polysaccharide solution by adopting a high-pressure cell crushing device to obtain the low-molecular-weight polysaccharide. The polysaccharide degradation method disclosed by the invention overcomes the shortcomings that a conventional ultrasonic method is long in time and low in efficiency, a chemical method is low in reaction regularity and hasa hardly controlled process, and an enzyme hydrolysis method is low in applicability and high in cost and can hardly realize large-scale production. According to the method, the high-pressure cell crushing device is adopted to degrade polysaccharide, so that the polysaccharide which has a relatively low molecular weight is obtained by shearing and collision at high pressure; the molecular weight of the polysaccharide can be precisely controlled by adjusting the treatment pressure and the number of times; the polysaccharide degradation method has the advantages of small noise, zero pollution and high speed, and the physiological activity of the polysaccharide cannot be destroyed.

Owner:GUANGDONG MARUBI BIOLOGICAL TECH CO LTD

Rock naked triasial compression test apparatus and test method

ActiveCN105181469AAvoid mixingSimulation is accurateMaterial strength using tensile/compressive forcesWhole bodyPressure balance

The invention discloses a rock naked triasial compression test apparatus and a test method, and relates to the field of a technology for testing the intensity characteristic of solid materials by using mechanical stress. During application, a whole body is placed in a triaxial cell, the whole body comprises a container, an airbag, a communicating pipe and a piston, a naked rock core sample is accommodated in a container, and the container is communicated with an airbag by a communicating pipe. An engineering fluid is injected into the container, so that the sample directly contacts the engineering fluid; high pressure hydraulic oil of the triaxial cell is used for transmitting the high pressure to the engineering fluid by an airbag, so that the high pressure engineering fluid directly contacts the sample, thereby the naked triaxial test is developed, the near field surrounding rock mechanical property is simulated, and a more accurate service is provided for the engineering stability evaluation. In addition, a chamber and the airbag separate the engineering fluid and the hydraulic oil, the pressure between the chamber and the triaxial cell is balanced, a seal is provided, so that in the test process, a mixing of the engineering fluid and the hydraulic oil is prevented, and entrance of the collapsed and scattered sample into the hydraulic oil is avoided.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Seaweed organic fertilizer and preparation method thereof

ActiveCN102584440APromote the formation of aggregate structureImproves pore spaceFertilizer mixturesHigh pressure cellPreservative

The invention discloses a seaweed organic fertilizer, which comprises following materials by mass percent: 40% to 70% of seaweed concentration stock solution formed by concentrating fresh seaweed, 1% to 6% of vitamin K1 derivatives, 28% to 50% of biological fulvic acid and 1% to 4% of aseptic. Simultaneously, the invention further discloses a preparation method for the seaweed fertilizer, which comprises the following steps of (1) utilizing a rotary harvest method to harvest fresh seaweed; (2) cleaning the harvested fresh seaweed, removing residues, smashing, pulping, obtaining coarse liquid through low temperature high pressure cell rupture technology, then filtering, and concentrating the seaweed concentration stock solution; and (3) preparing the vitamin K1 derivatives and the biological fulvic acid, and adding the aseptic and the seaweed concentration stock solution to obtain the seaweed organic fertilizer. The seaweed organic fertilizer can improve soil, promotes crop root systems to be developed, greatly reduces pesticide using amount and is environmental-prevention and safe.

Owner:江门市杰士植物营养有限公司

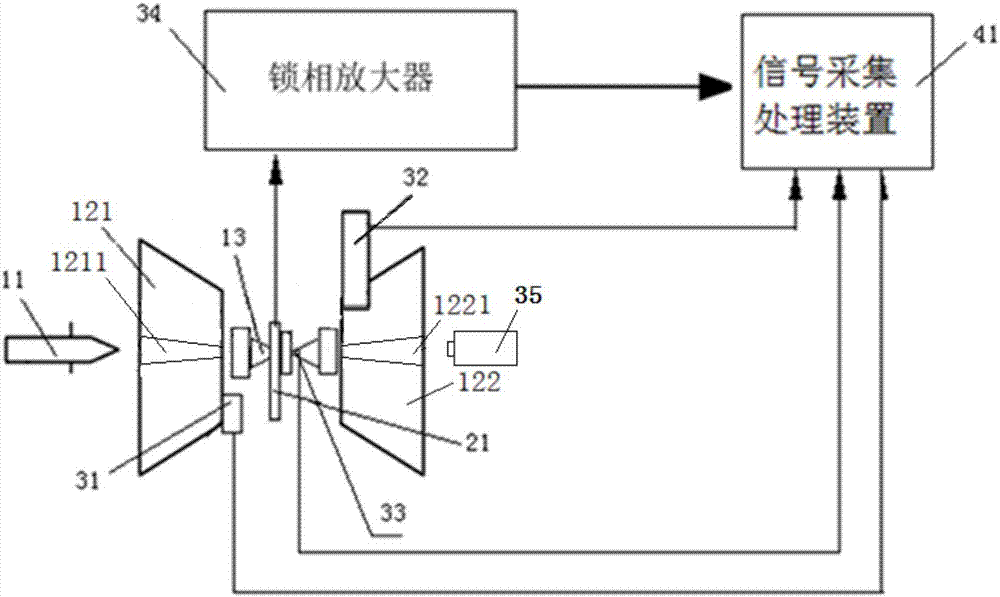

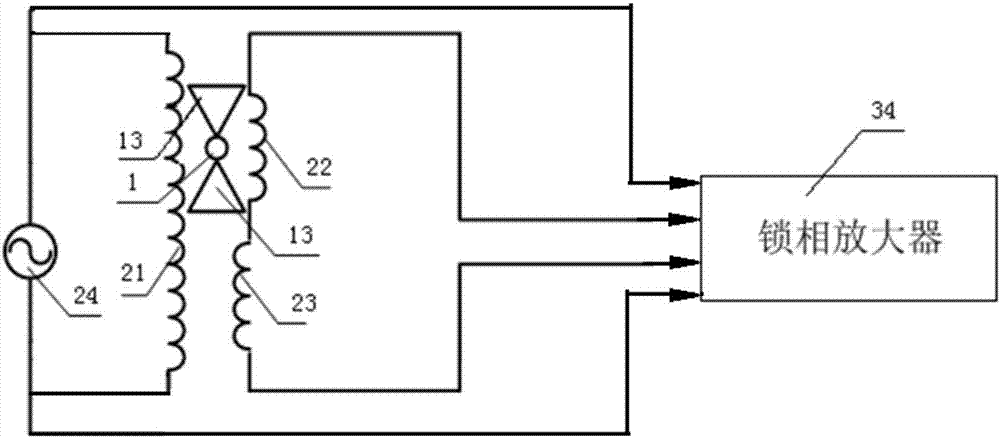

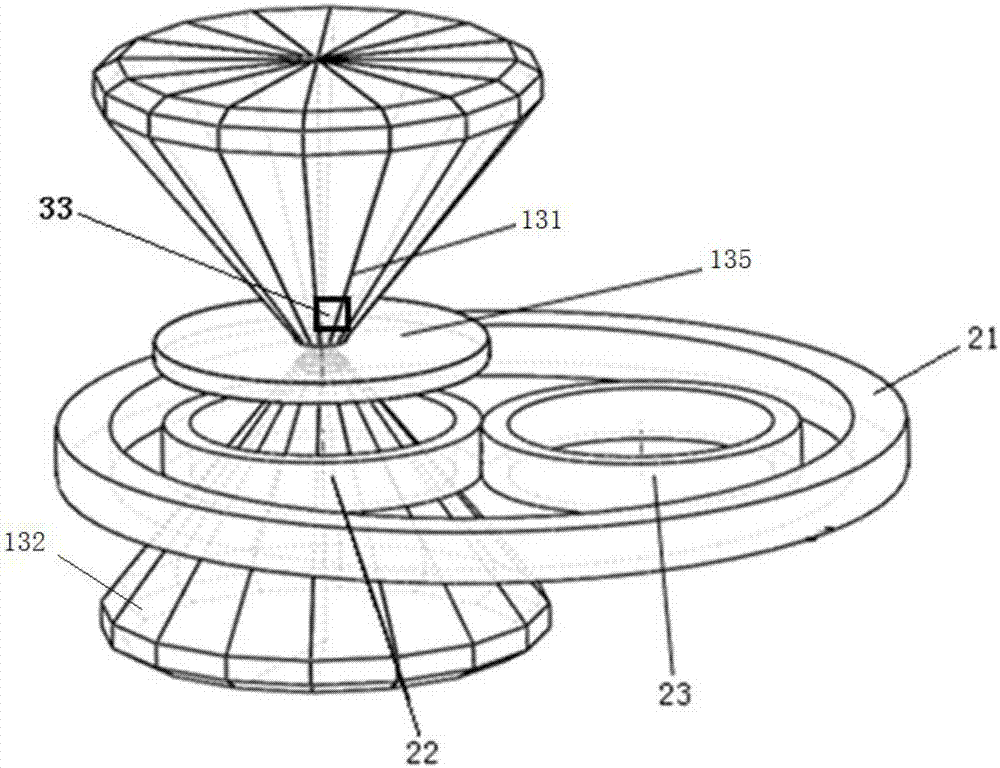

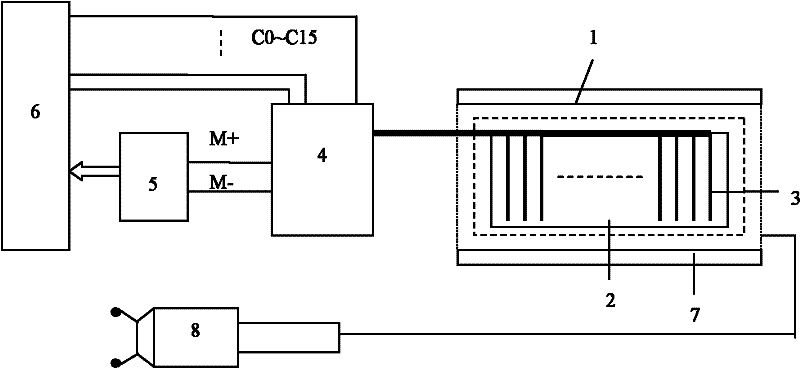

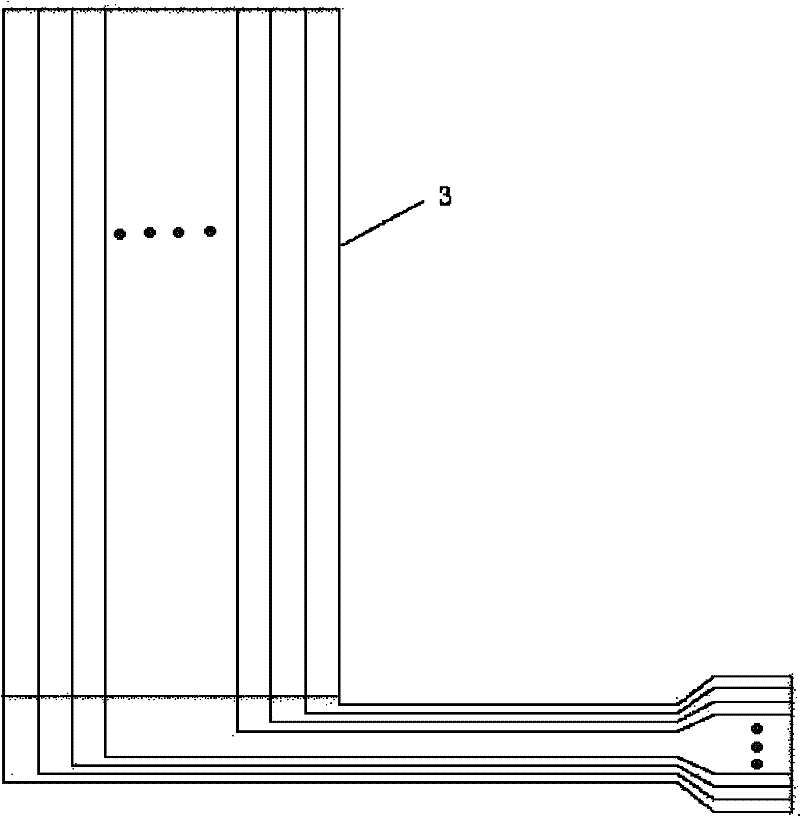

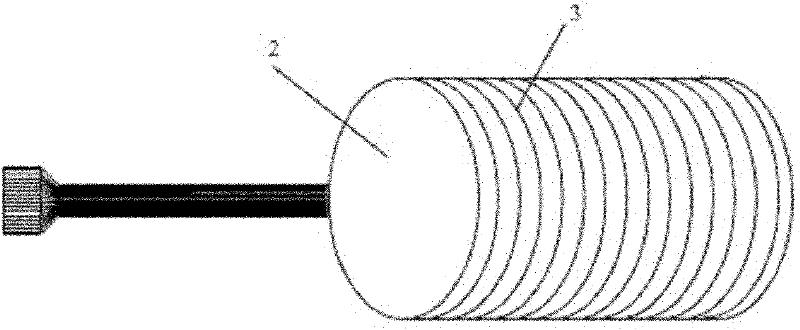

Measuring system and measuring method of Curie temperature of substance under high pressure

InactiveCN107044995ABroaden the range of measurable parametersRealize measurementInvestigating phase/state changeCurie temperatureAlternating current

The invention relates to a measuring system and measuring method of the Curie temperature of a substance under high pressure. In the system, a sample is placed in a sample cavity in the center of a metal gasket of a diamond anvil cell, and the sample is compacted by two diamonds of the diamond anvil cell; the light beam of a laser device is focused to the sample through the diamond anvil cell; an excitation coil is connected with two electrodes of an alternating current source, and an induction coil is arranged on one diamond of the diamond anvil cell in a sleeved mode and is close to the sample; a compensating coil and the induction coil are arranged in parallel in the excitation coil and are reversely connected in series; a lock-in amplifier is provided with reference signals by the alternating current source, and simultaneously receives, amplifies and detects the magnetic induction signals of the induction coil and the compensating coil; a sample temperature measuring device is arranged in a position close to the sample; and the outputs of the lock-in amplifier and the sample temperature measuring device are connected to a signal acquisition and processing device. The measuring system and measuring method realize measurement of the Curie temperature point of the substance under high pressure, and widen the range of measurable parameters by magnetic measurement under high pressure.

Owner:JILIN UNIV

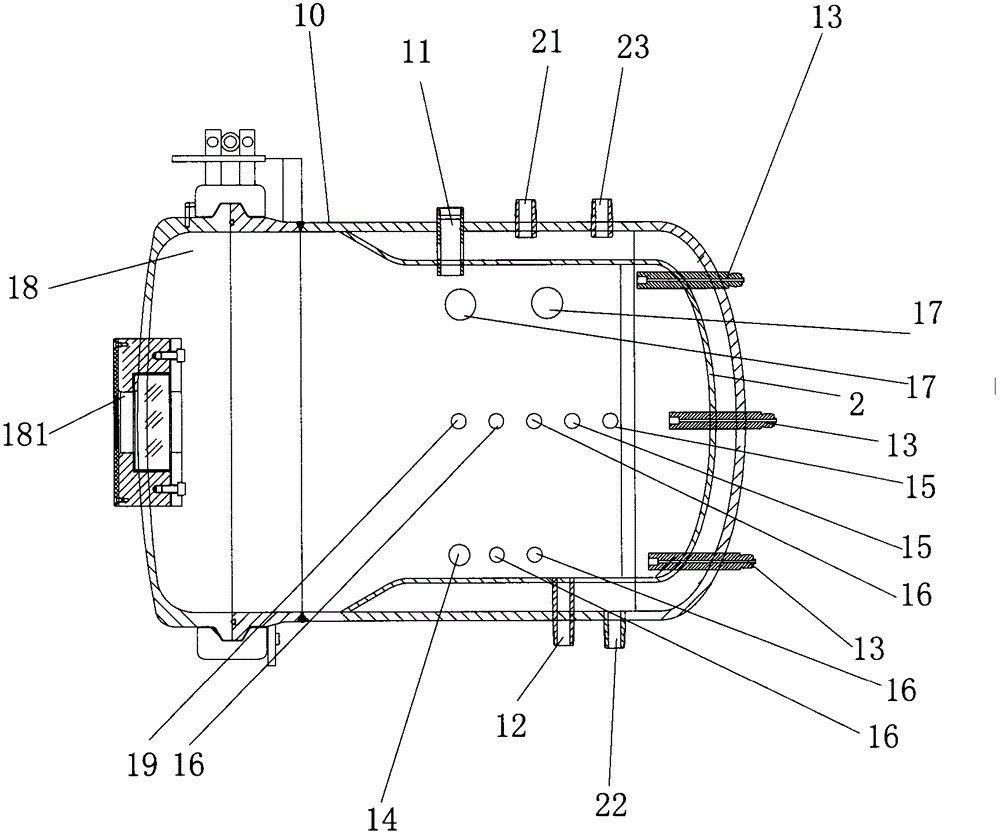

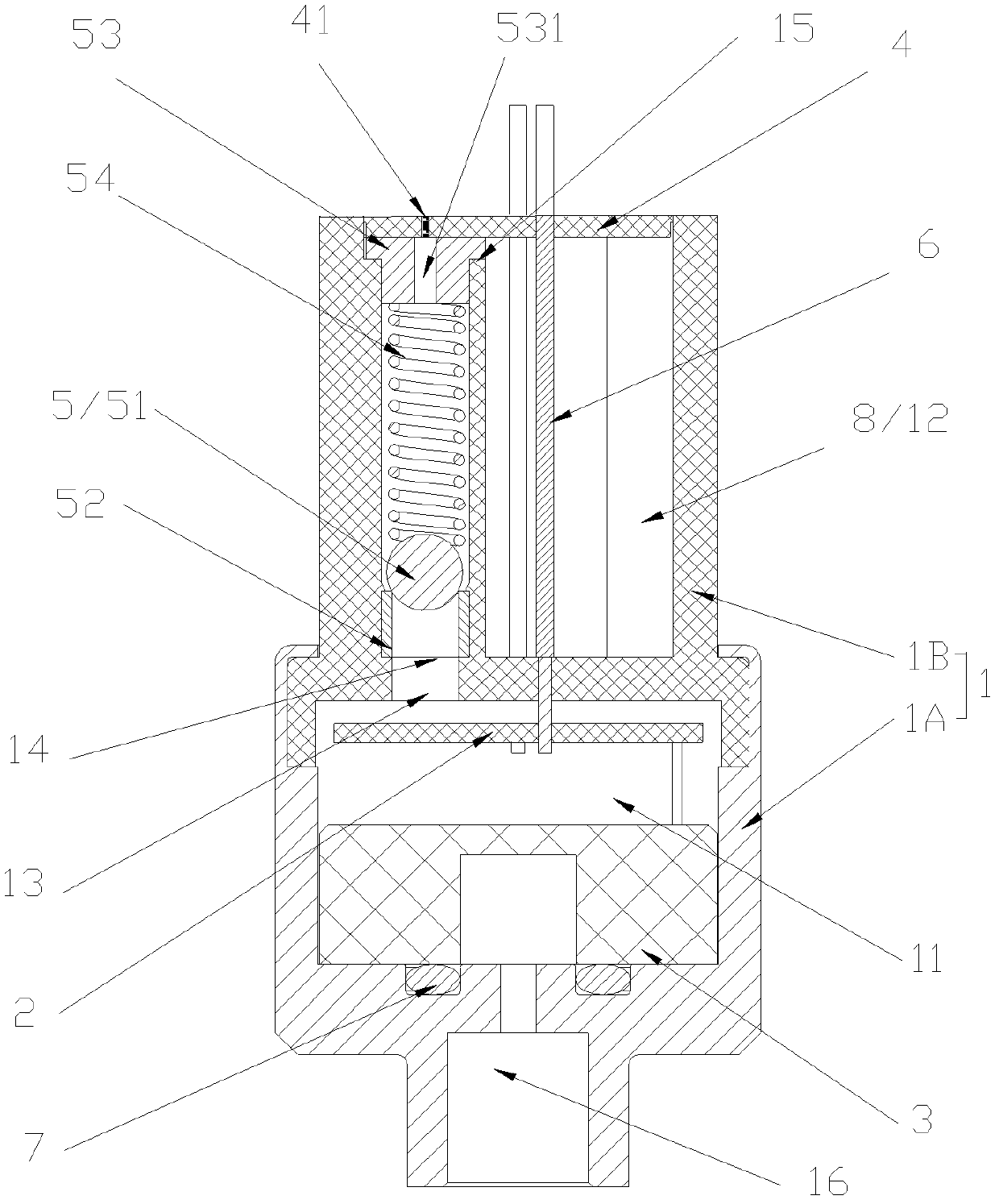

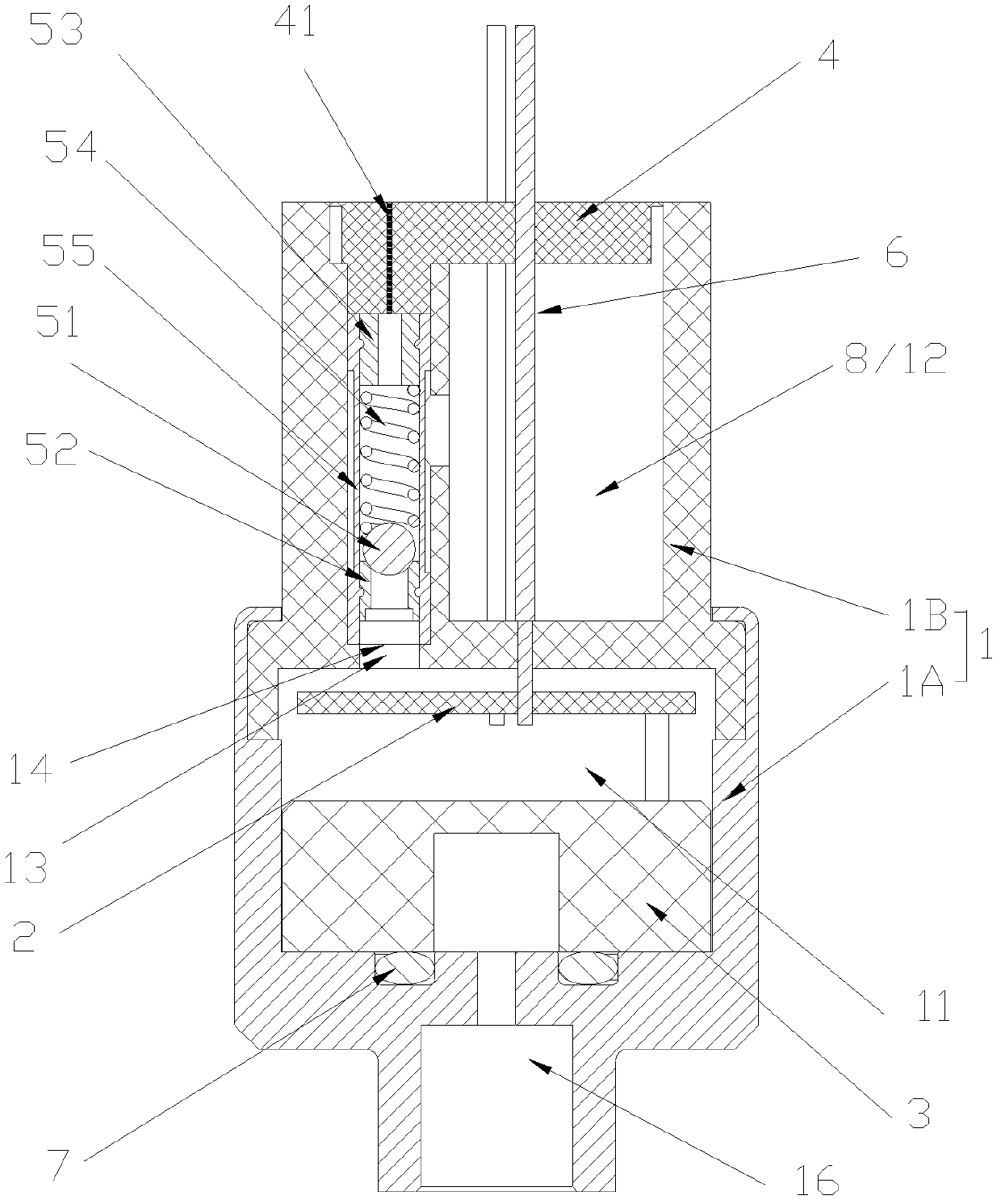

High-pressure cell incubator, temperature control method and pressure control method thereof

InactiveCN102978112ATemperature effectAvoid explosive situationsBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlHigh pressure cell

The invention relates to a high-pressure cell incubator. The high-pressure cell incubator comprises a box body, and a water jacket for providing a working temperature for the box body, wherein the water jacket covers on the inner surface of the box body. The invention also provides a temperature control method and a pressure control method of the high-pressure cell incubator. By adoption of the technical scheme of the high-pressure cell incubator, a growing environment for cells under high pressure can be provided.

Owner:NAVY MEDICINE RES INST OF PLA

System and method for testing ignition and explosion characteristics of combustible medium under high temperature and high pressure

ActiveCN109374678AGuaranteed sealing performanceEasy to replaceMaterial exposibilityData acquisitionIgnition system

The invention provides a system and a method for testing ignition and explosion characteristics of a combustible medium under high temperature and high pressure and belongs to the field of gas explosion science. The experimental system comprises a cylindrical explosion vessel, a heating system, an air distribution system, an ignition system, a water cooling system, a thermocouple, a high-temperature-resistant pressure sensor and a data acquisition and control system. The test volume of 20L is a widely recognized explosion parameter determination volume worldwide at present, and explosion characteristic parameters of the combustible medium can be tested at a temperature from a normal temperature to 500 DEG C and under a pressure from a normal pressure to 5MPa. The special ignition system can realize ignition in a high-temperature and high-pressure environment while ensuring container seal and is convenient to detach, and different types of ignition heads can be replaced. Whether the combustible medium reaches an explosion state is judged by monitoring the pressure and temperature change in the vessel, and explosion characteristic parameters of different components can be measured according to real-time monitoring data. The device can provide reliable data for preventing explosion of the high-temperature high-pressure combustible medium in industrial production.

Owner:DALIAN UNIV OF TECH

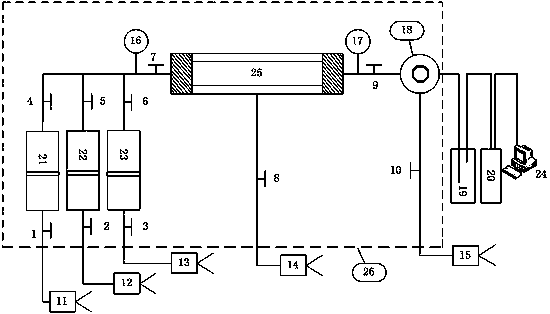

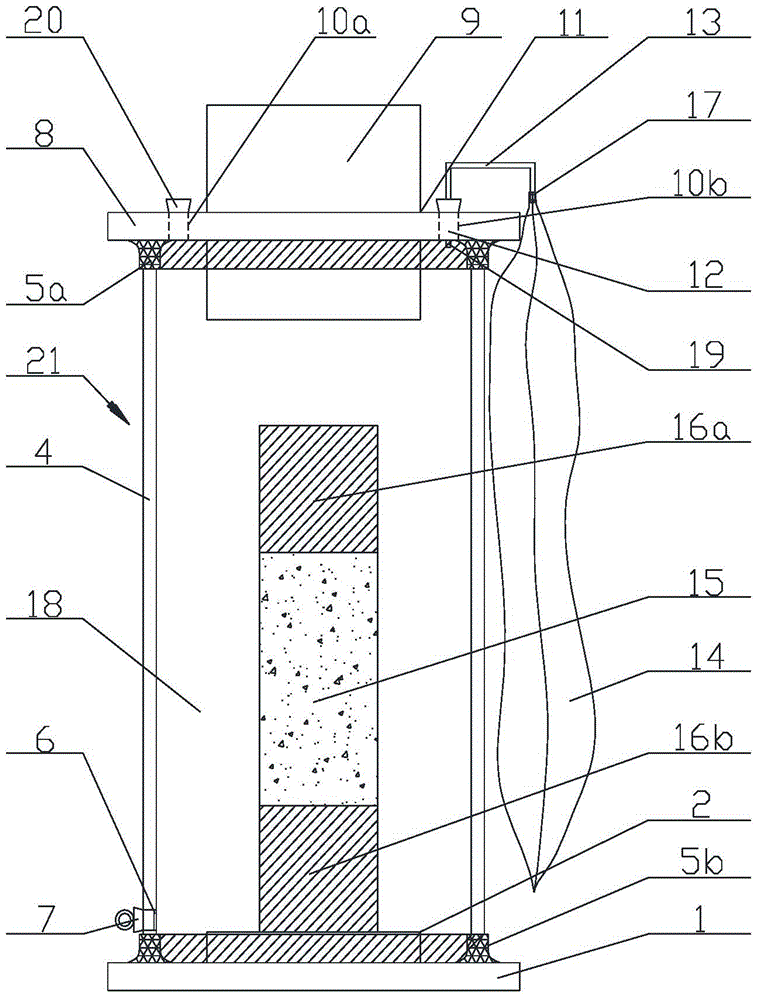

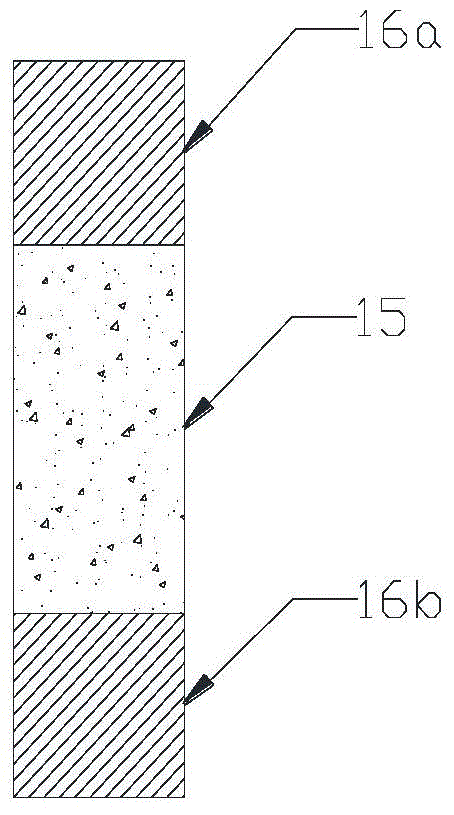

Device and method for monitoring fluid flow in rock sample at high temperature and high pressure

InactiveCN102175726AReliable principleSimple structureMaterial resistanceUltra high pressureHigh pressure cell

The invention relates to device and method for monitoring fluid flow in a rock sample at high temperature and high pressure, wherein the device mainly comprises microelectrodes, a rock sample, an insulation material sheet and a rock sample clamper; at least three microelectrodes are fixed and arranged at equal intervals on the insulation material sheet; the rock sample is wrapped by the insulation material sheet; the surface of the rock sample is contacted with the one side, fully distributed with the electrodes, of the insulation material sheet; each electrode is bended into an end-to-end ring; and each microelectrode leads out a wire to form an external test circuit together with an electrode control module, a resistivity collecting module and a computer. The device can test the resistivity between different sections of the rock sample so as to obtain the saturation level and distribution of conducting flow in the rock sample. In the invention, a microelectrode technology is used in the field of petroleum engineering; the corresponding software and hardware are configured for monitoring the important parameters of fluid flow in the rock sample during a dialysis / absorption / displacement test procedure; and the principle is reliable, the operation is convenient, and real and reliable flow rules of underground fluid can be obtained under simulated actual formation conditions and a high-temperature and high-pressure closed environment.

Owner:SOUTHWEST PETROLEUM UNIV

Rapid testing system and method for explosion limit of combustible medium under high temperature and high pressure

ActiveCN109374677ASuppression of explosion effectsRapid coolingMaterial exposibilityNuclear engineeringData acquisition

The invention provides a rapid testing system and method for an explosion limit of a combustible medium under high temperature and high pressure and belongs to the field of gas explosion science. Theexperimental system comprises a cylindrical explosion vessel, a heating system, an air distribution system, an ignition system, a water cooling system, a thermocouple, a pressure sensor and a controland data acquisition system. The test volume is 1-5L, and the explosion limit of the combustible medium can be tested at a temperature from a normal temperature to 500 DEG C and under a pressure froma normal pressure to 5MPa. The device is equipped with the water cooling system, so that rapid cooling can be realized, and the experimental efficiency is greatly improved. Whether the combustible medium reaches an explosion state is judged by monitoring the pressure and temperature change in the vessel, and the explosion limits of different gas components can be measured according to real-time monitoring data. The device can provide reliable data for preventing explosion of the high-temperature high-pressure combustible medium in industrial production.

Owner:DALIAN UNIV OF TECH

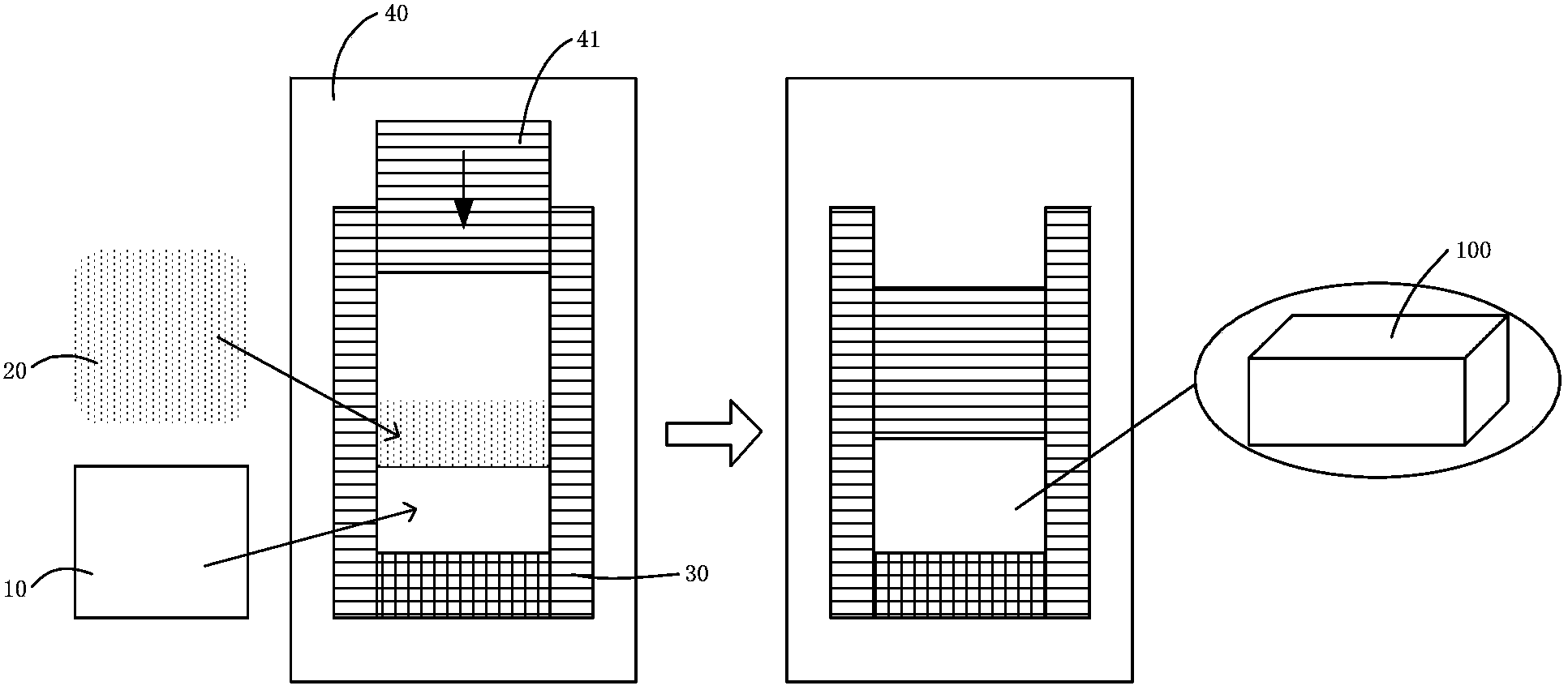

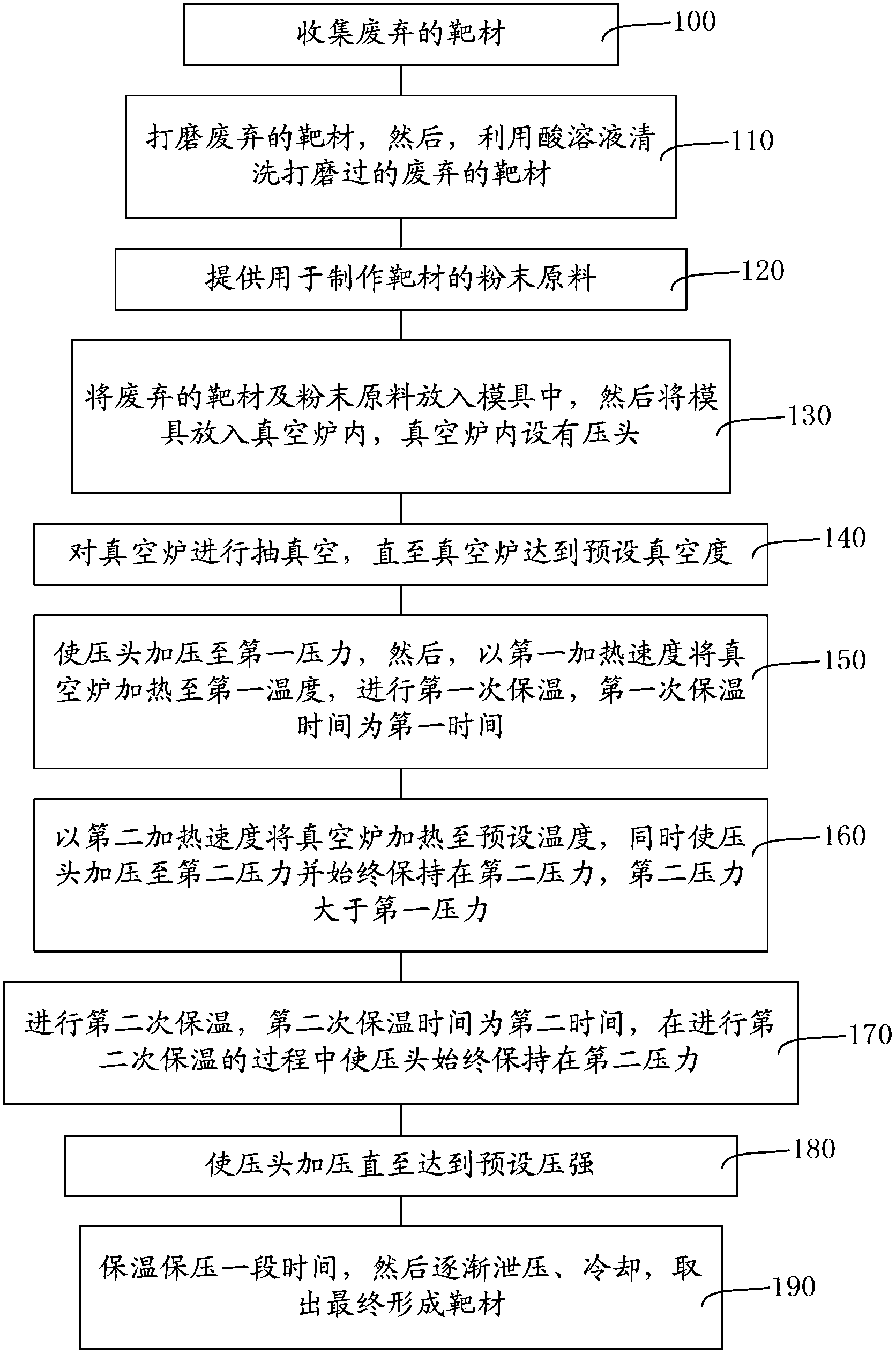

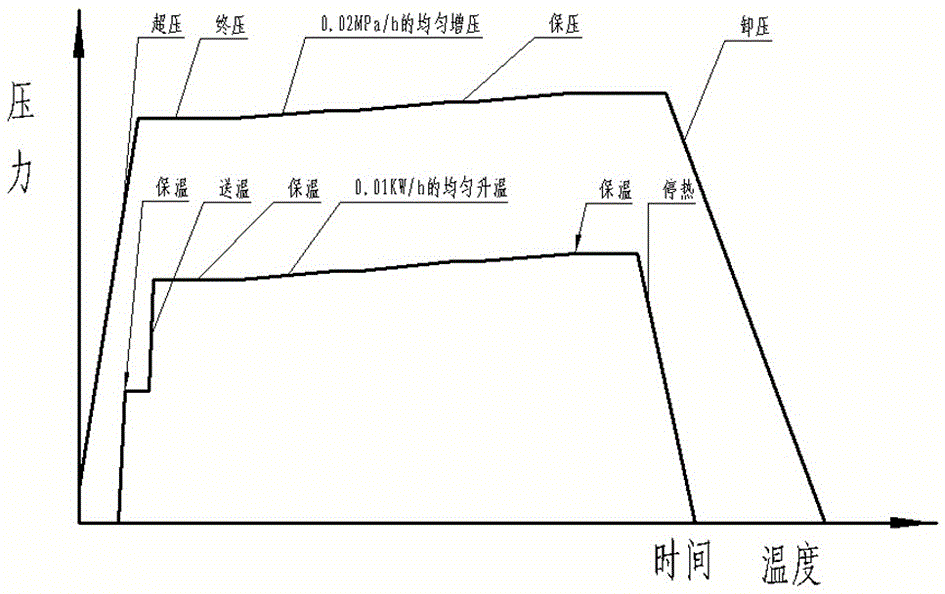

Target manufacturing method

ActiveCN103447535AClosely connectedTightly connected and combinedVacuum evaporation coatingSputtering coatingHigh pressure cellVacuum furnace

The invention discloses a target manufacturing method which includes the steps: collecting waste targets; providing powder stock for manufacturing targets; placing the waste targets and the powder stock into a mould and then placing the mould into a vacuum furnace with a pressure head inside; vacuumizing the vacuum furnace until the vacuum furnace reaches a preset vacuum degree; heating the vacuum furnace to reach a preset temperature after the vacuum furnace reaches the preset vacuum degree, and tightly pressing the waste targets and the powder stock to reach a preset pressure intensity by the aid of the pressure head; performing heat preservation and pressure maintenance for a period of time, then gradually releasing pressure, cooling the vacuum furnace and taking out the targets. Under the action of high temperature and high pressure, the powder stock and the waste targets can be closely connected and combined into a whole, so that the targets with needed sizes are obtained. The vacuum furnace can be adjusted to reach the preset temperature and the preset pressure intensity step by step in a few stages, the heating and pressurizing process of the vacuum furnace is more gentle, and the finally formed targets are better in compactness.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

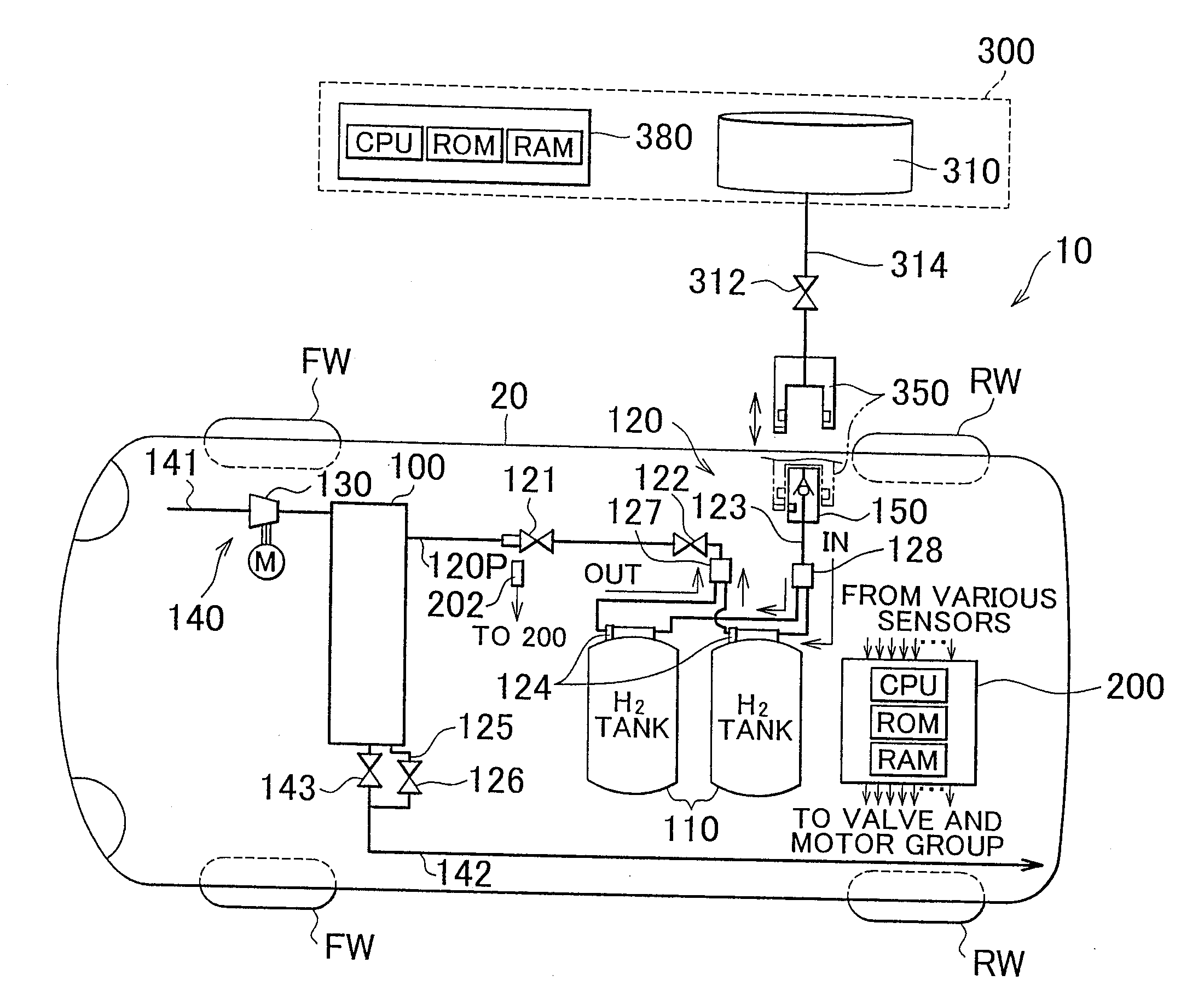

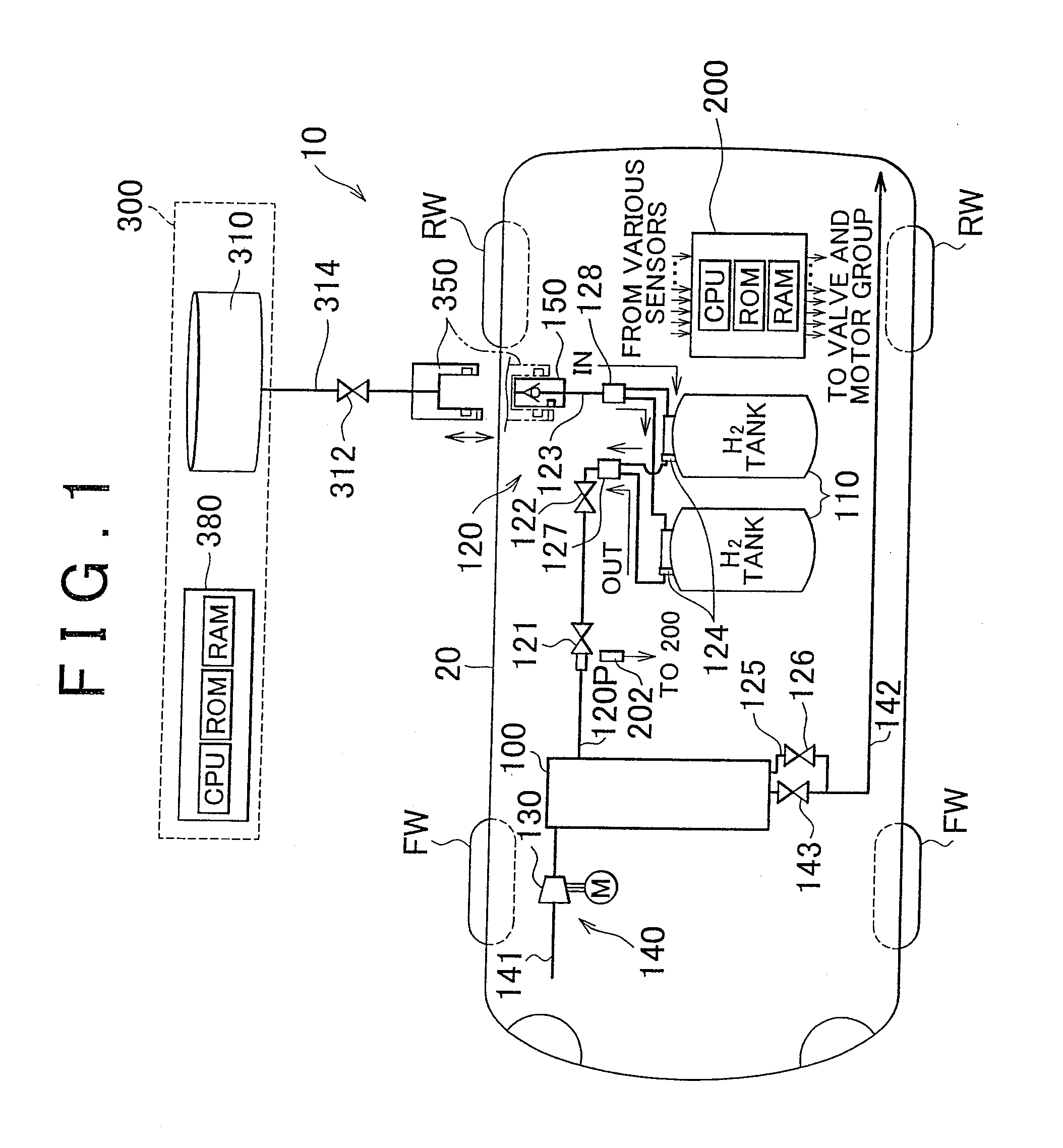

High pressure gas supply system and fuel cell system

ActiveUS20130052553A1Guaranteed uptimeReduce functionFuel cell heat exchangeReactant parameters controlPressure decreaseHigh pressure cell

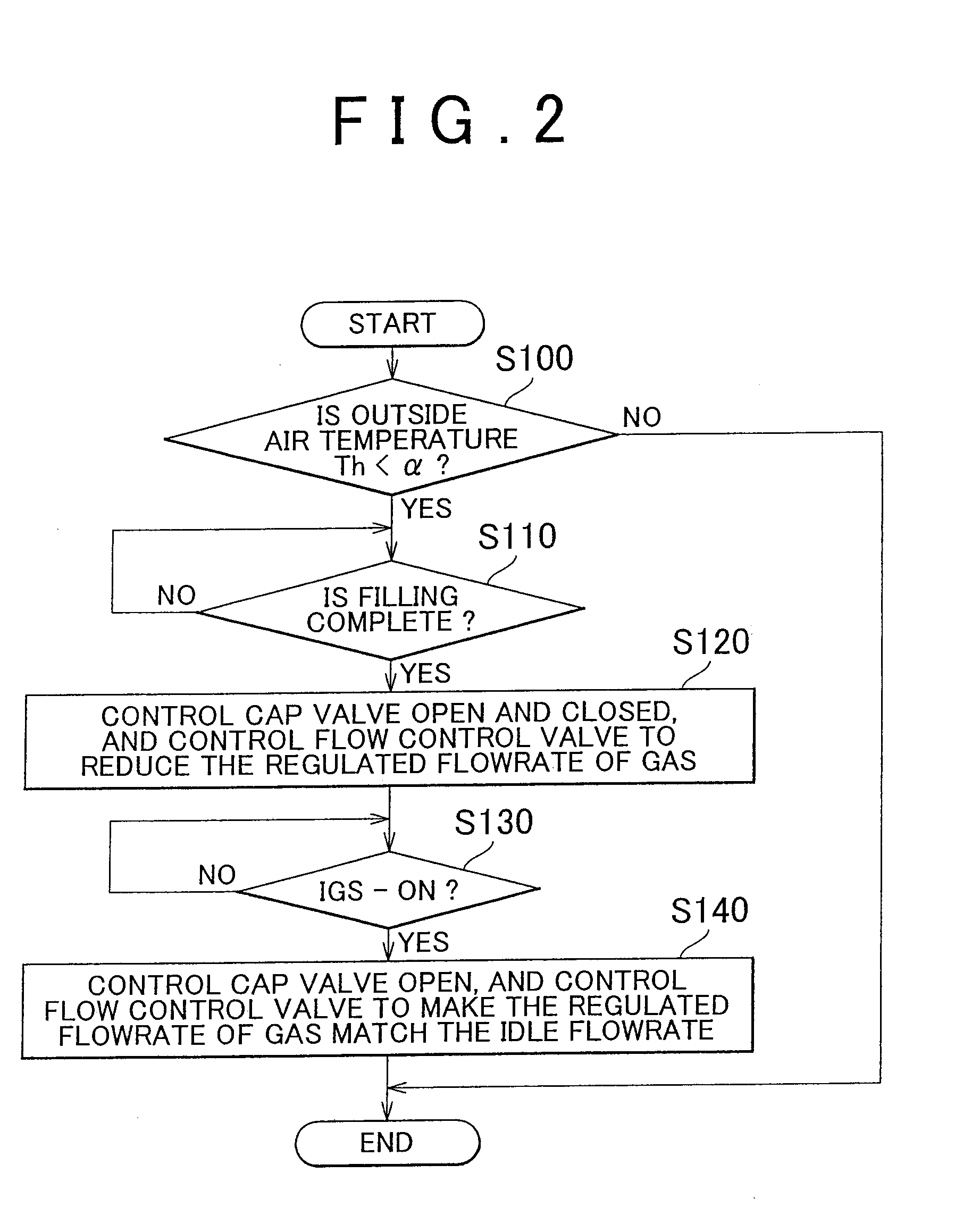

A fuel cell system (10) includes a pressure decrease valve (121) and a flow control valve (122) provided in a hydrogen supply line (120P) that extends from a high pressure gas tank (110) to a fuel cell (100). A low temperature environment may cause the function of these devices to decrease. Therefore, if the gas temperature inside the high pressure gas tank (110) is higher than the temperature of this low temperature environment and is a temperature at which the decreased function can be recovered, high pressure gas inside the tank is made to flow through the hydrogen supply line (120P) to expose the pressure decrease valve (121) and the like to the relatively high temperature gas before a start signal that starts the system is received.

Owner:TOYOTA JIDOSHA KK

Leak detection method and system for a high pressure automotive fuel tank

InactiveUS8689613B2Detection of fluid at leakage pointMeasurement of fluid loss/gain rateHigh pressure cellEngineering

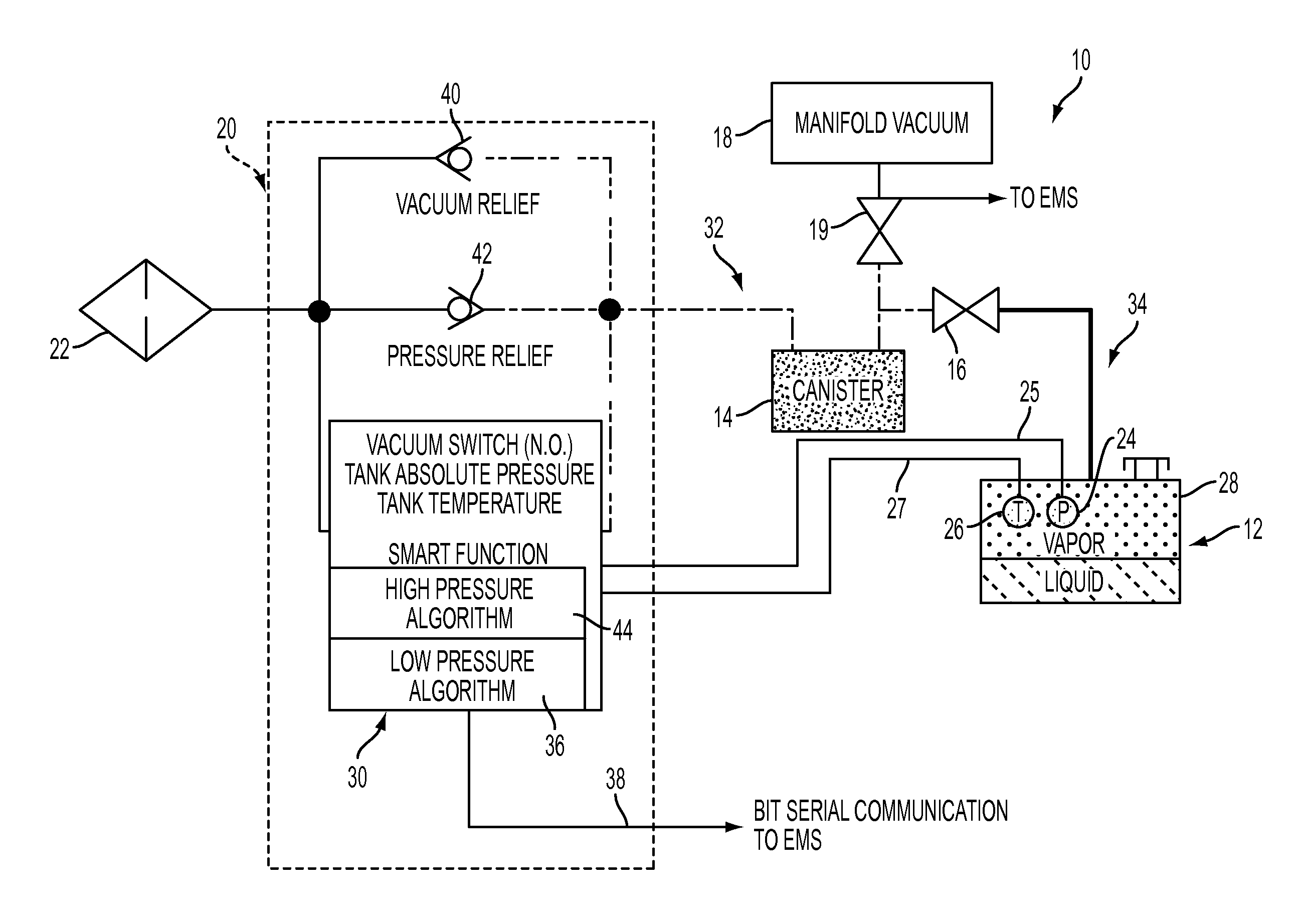

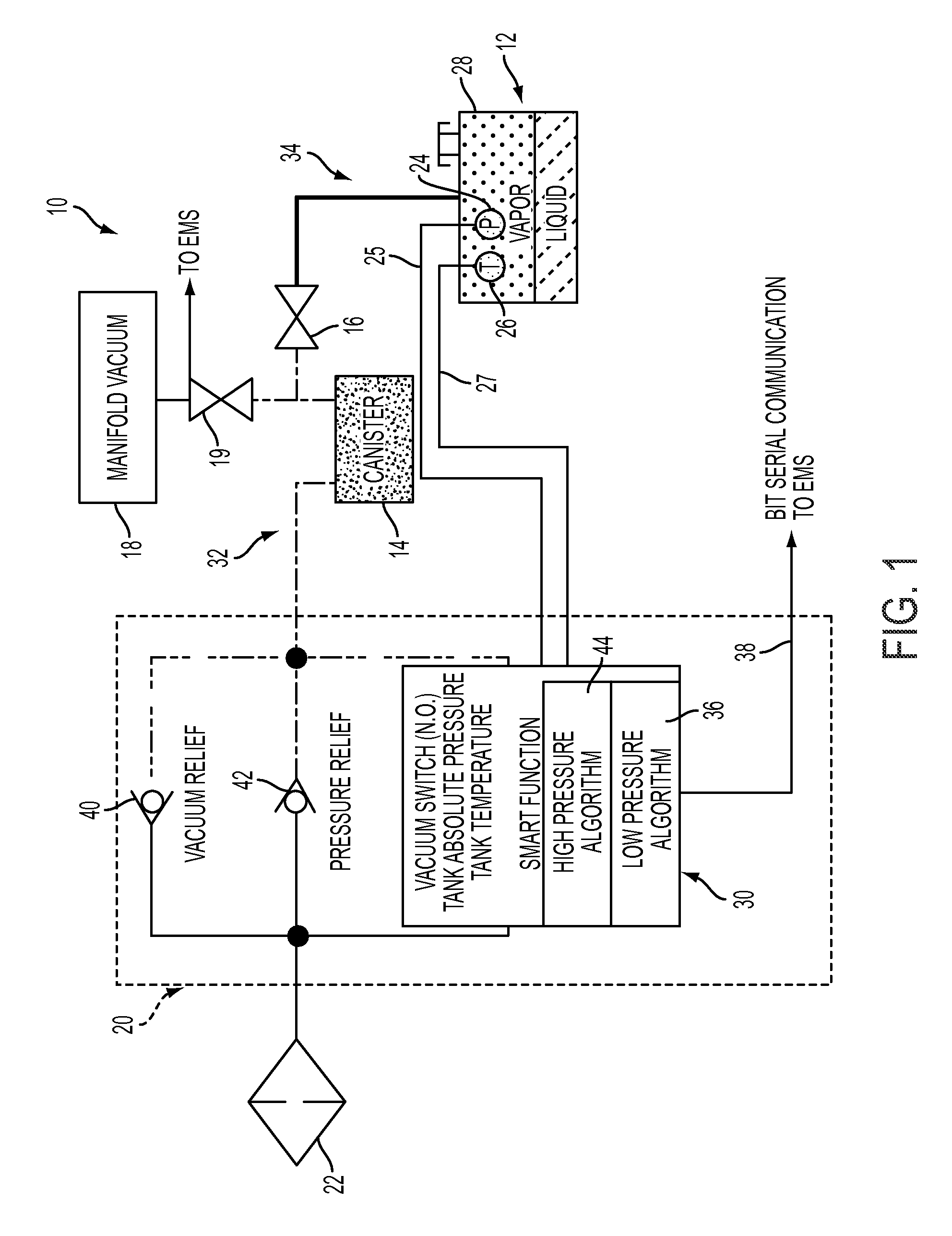

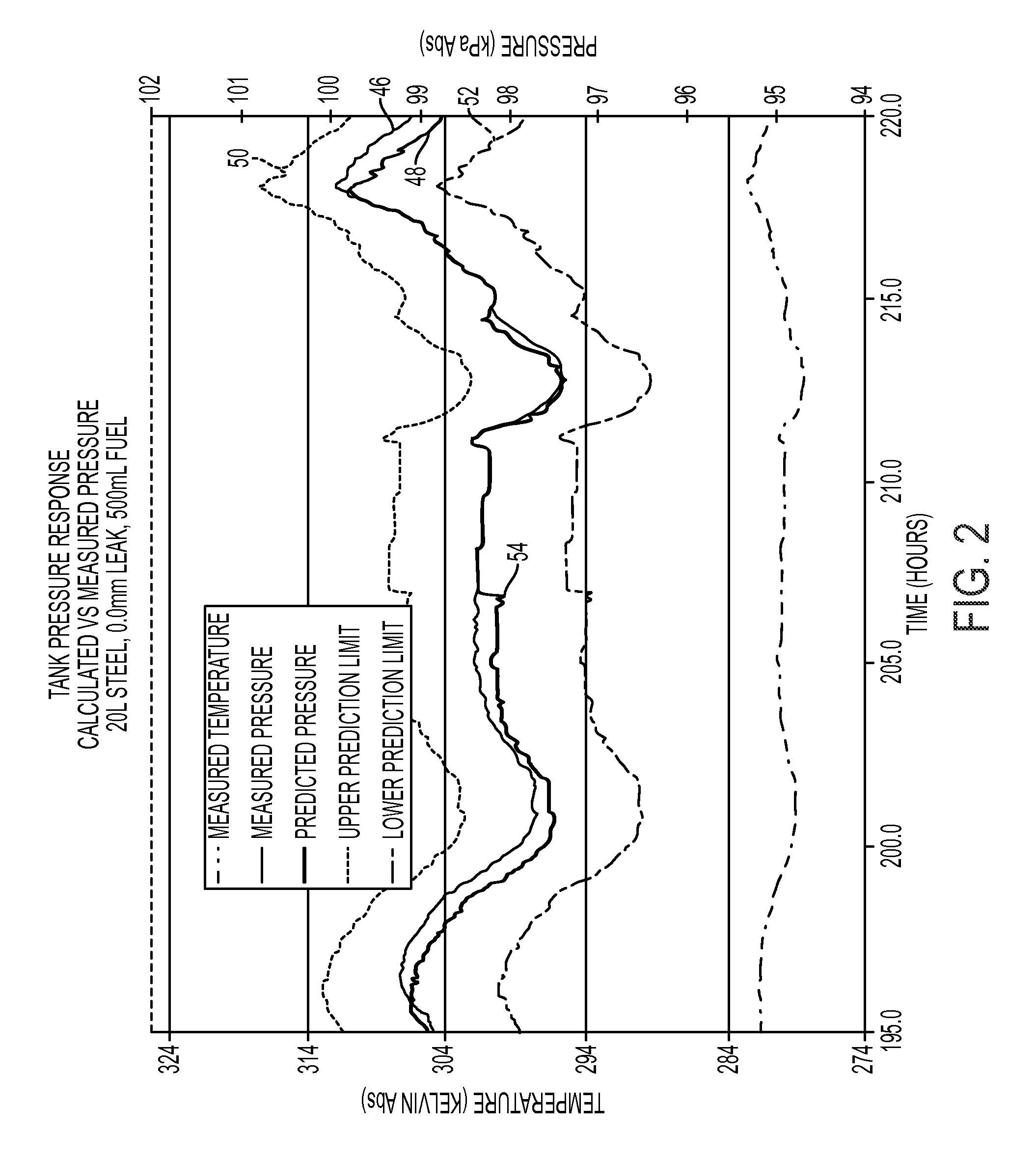

A vapor management system (10) includes a fuel tank (12), a canister (14), a pressure control valve (16) between the tank and canister and defining a high pressure side (34) and a low pressure side (32), a vacuum source (18), a purge valve (19) between the canister and vacuum source, a leak detection valve (20) connected with the canister and including a processor (30). A pressure sensor (24) and a temperature sensor (26) are disposed in a fuel vapor cavity of the fuel tank, with signals from the sensors being received by the processor. Based on an absolute temperature measured by the temperature sensor, the processor compares a predicted pressure in the fuel tank to the measured absolute pressure, and identifies a leak on the high pressure side if the predicted pressure is outside a tolerance range, while maintaining pressure in the fuel tank.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

Method for extracting white fungus polysaccharides at high temperature under high pressure

The invention provides a method for extracting white fungus polysaccharides at high temperature under high pressure, which comprises the following steps: (1) selecting insect-free white fungus, pulverizing in a pulverizer, passing through a 40-mesh screen, and drying in a drying machine; (2) adding a distilled water extractant into the container containing white fungus dry powder in a material / liquid ratio of 1:60-1:80, sealing with parchment paper, and extracting in a 100-120-DEG C water bath and a high-pressure sterilizer under the pressure of 0.2-0.6 MPa respectively for 2 hours; and (3) after finishing extraction, extruding the extracting solution through filter cloth to filter out impurities, and centrifuging in a centrifuge at the speed of 4000 r / min. The extraction method has the characteristics of high extraction yield, high purity, short time consumption and the like, is simple and easy to operate, and is suitable for industrial production.

Owner:高枫

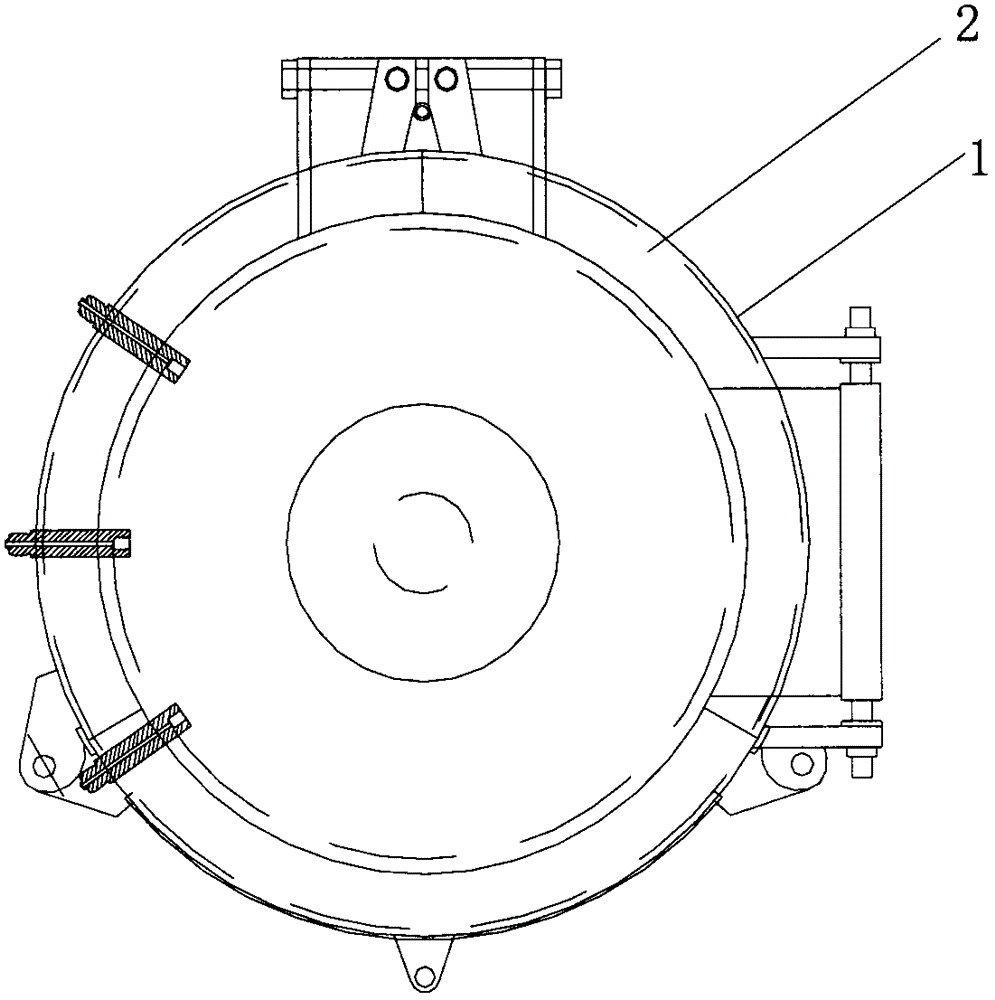

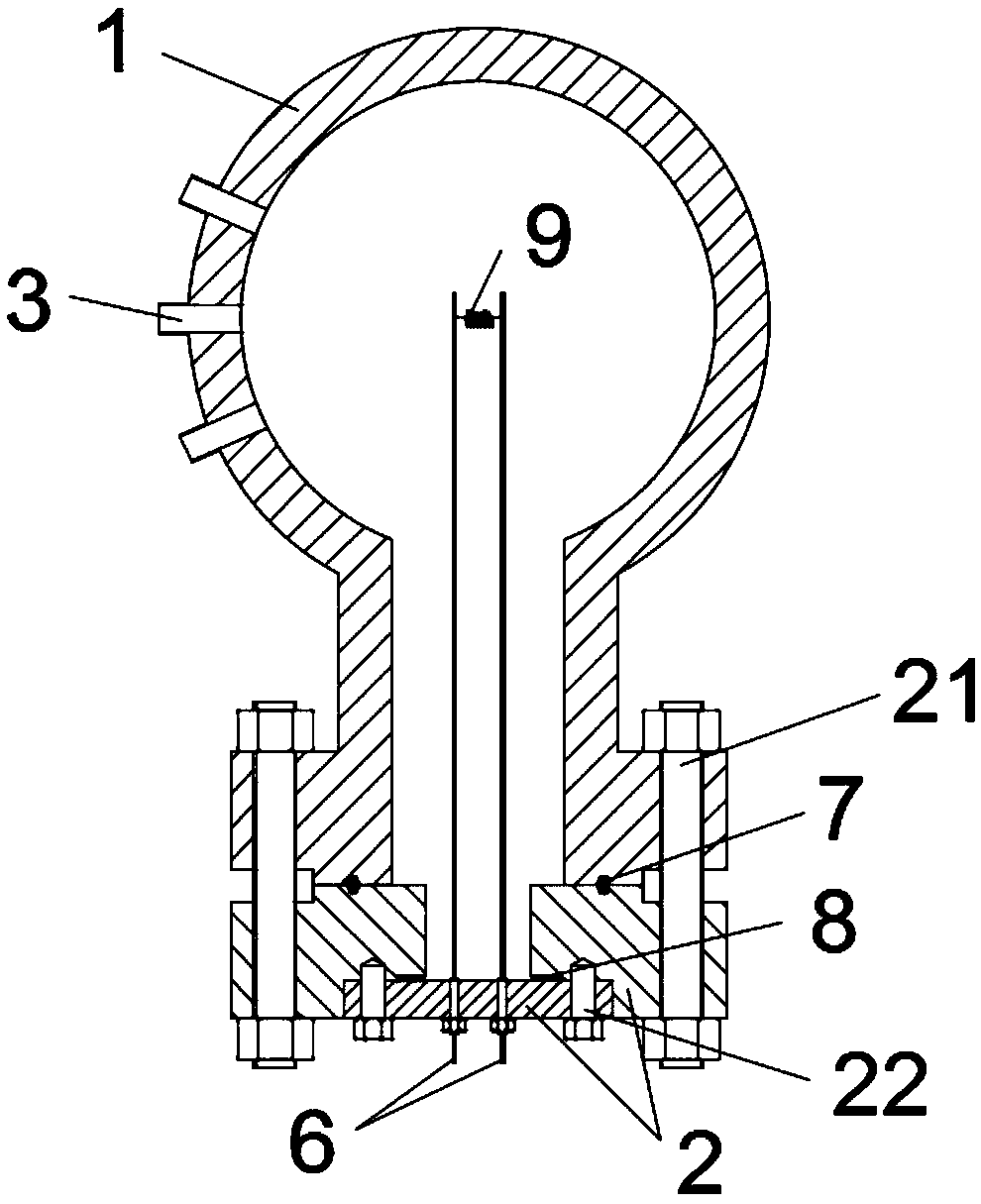

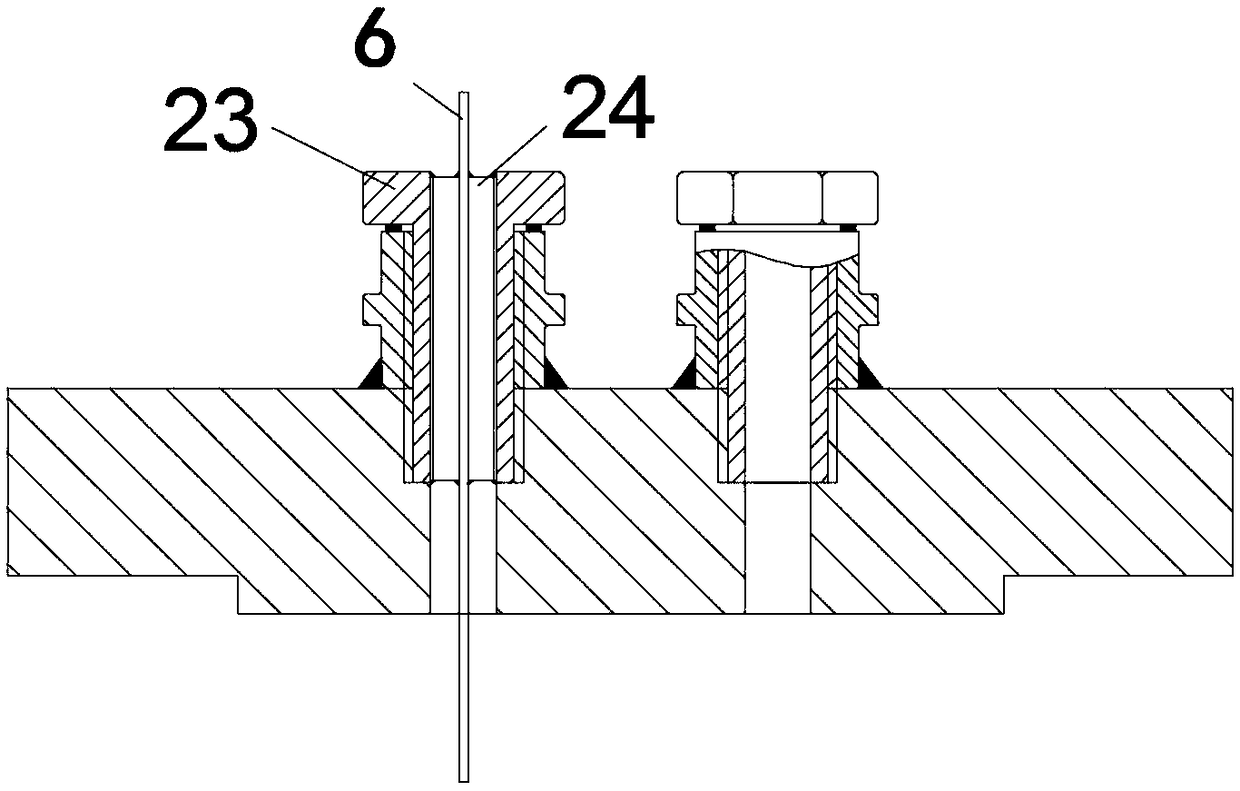

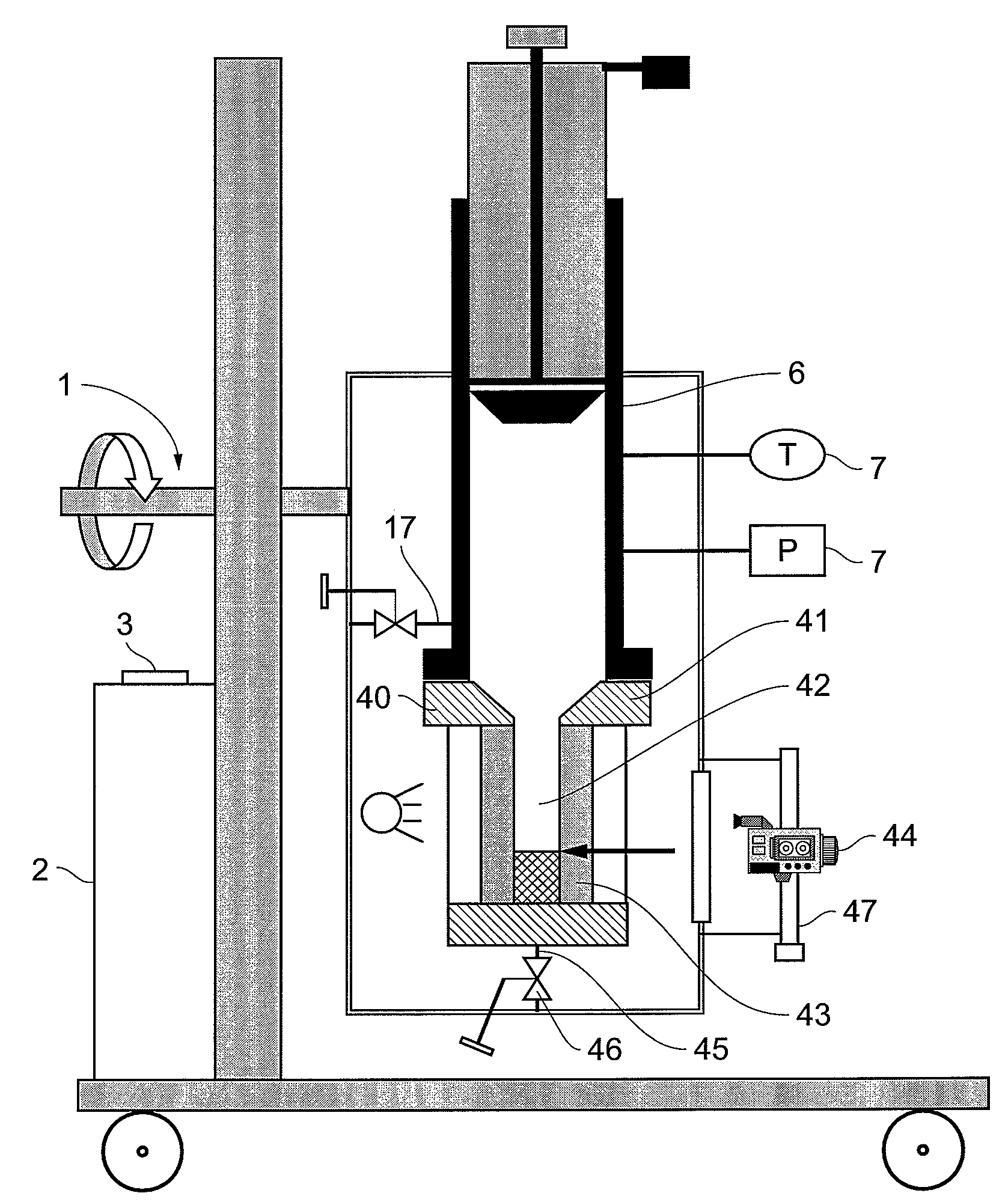

Online rapid viscosity measuring device for rock core displacement experiment under high temperature and high pressure

ActiveCN103226086AReduce distractionsSimple and fast operationDirect flow property measurementFast measurementRock core

The invention discloses an online rapid viscosity measuring device for a rock core displacement experiment under a high temperature and a high pressure. The device comprises a cylindrical housing (1) and a glass capillary (2) arranged in the housing (1), wherein one end of the glass capillary (2) is connected with a first pressure transducer (6), and the other end of the glass capillary (2) is connected with a second pressure transducer (7) and a mass flowmeter (8). The online rapid viscosity measuring device for the rock core displacement experiment under the high temperature and the high pressure uses the glass capillary to sample, and meanwhile measuring results can be rapidly displayed through a data calculating display unit, so that the measuring device need few samples and can rapidly and accurately measure in real time. During a process of a physical model test, monitoring point needed viscosity measuring can be randomly measured, and a seepage field inside the model can be maintained to be relatively stable, thereby providing an effectively technique means for dynamically analyzing viscosity fields of the physics models.

Owner:PETROCHINA CO LTD

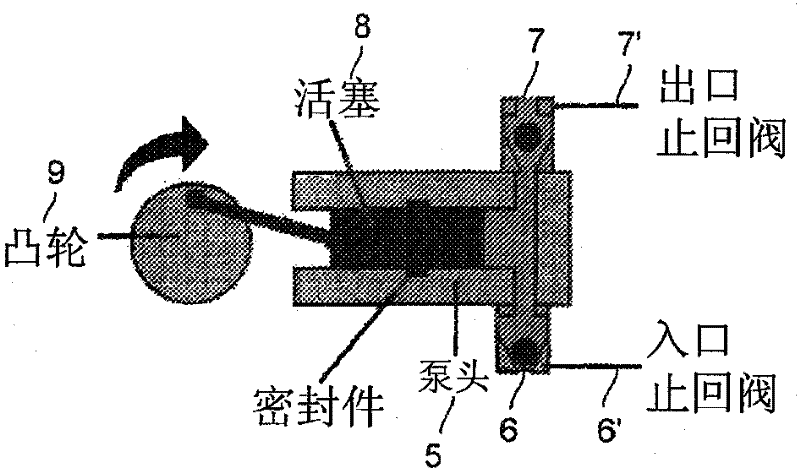

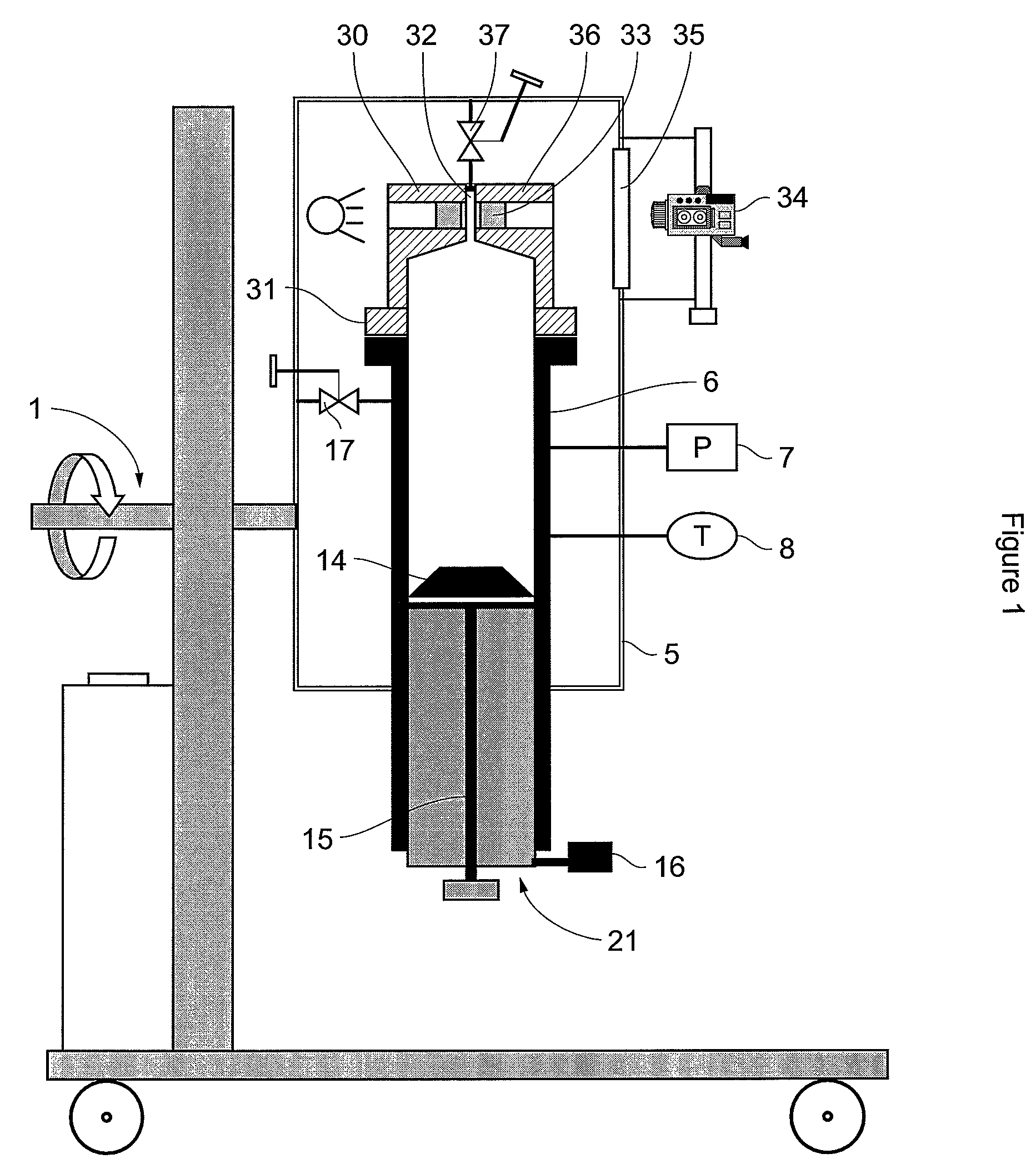

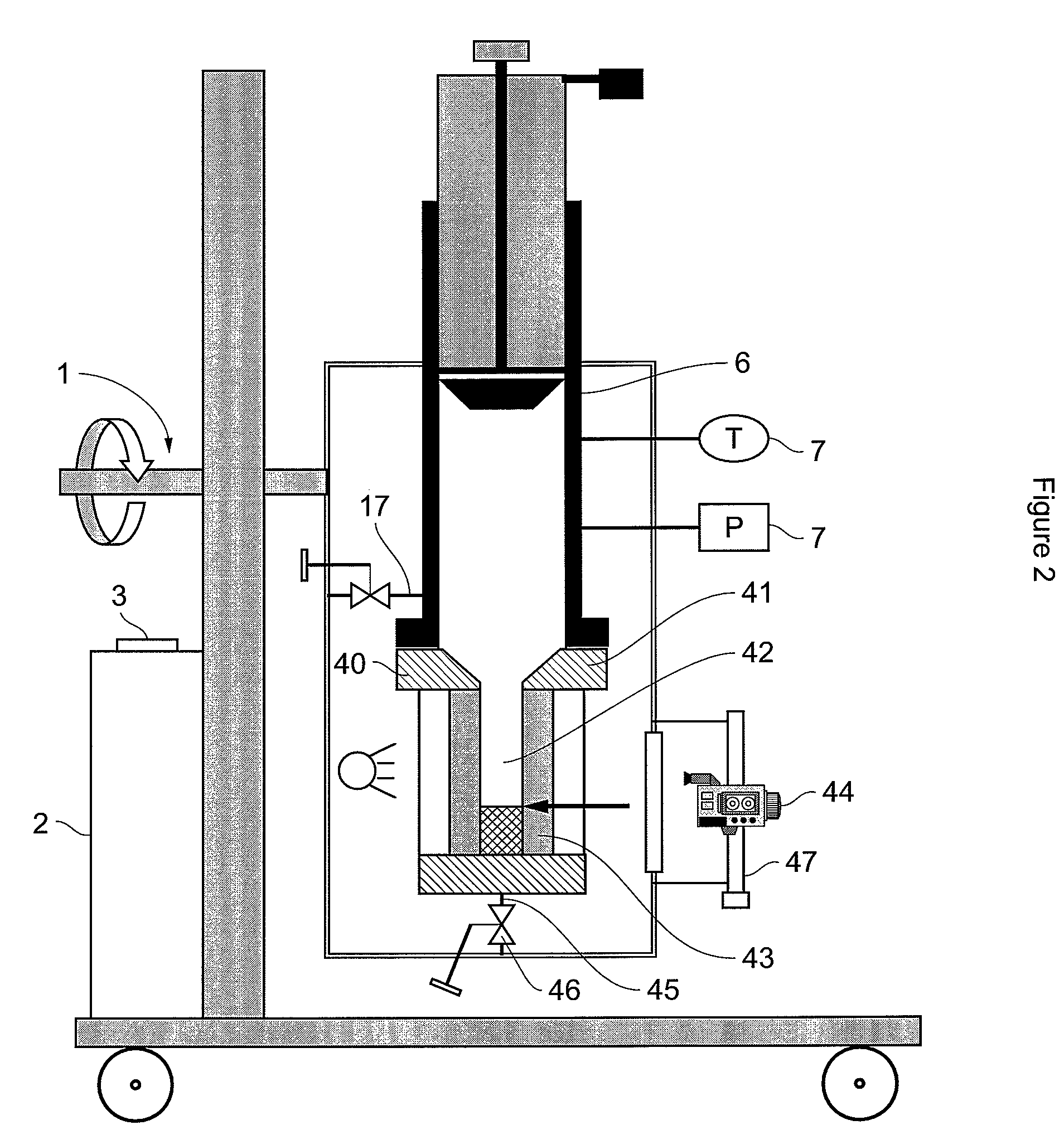

Device and method for thermodynamic measurements on petroleum fluids

ActiveUS7628058B2Surface/boundary effectMaterial thermal analysisHigh pressure cellElectrical battery

Device for measuring thermodynamic characteristics of a fluid sample, comprising in combination: a high-pressure cell (6) equipped with a motorized piston, a drying oven surrounding the cell and intended to vary the cell temperature, motorization means arranged outside the drying oven, means for stirring the fluid placed within the cell, a frame supporting said oven and means (1) for tilting said frame so as to tip the cell up. The cell comprises:—a specific head for measurements on condensate gas wherein a chamber (42) of elongate shape along the axis of the cell is intended to collect the liquids, and—means (44) for visualizing the position of the liquid / gas interface.

Owner:VINCI TECH

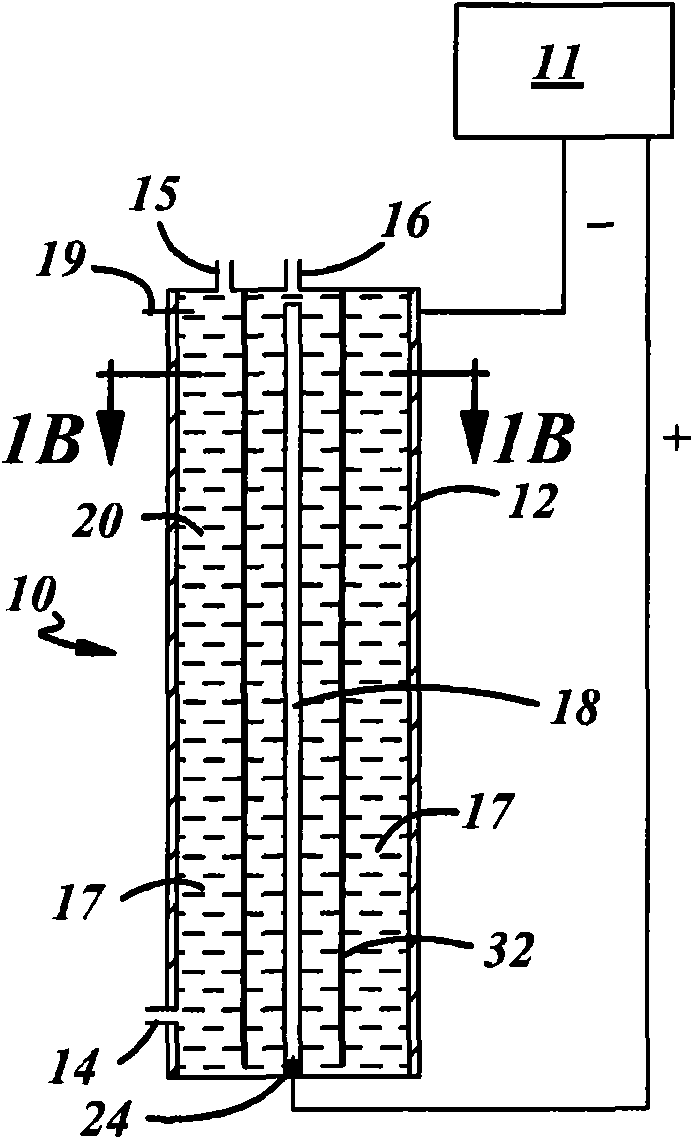

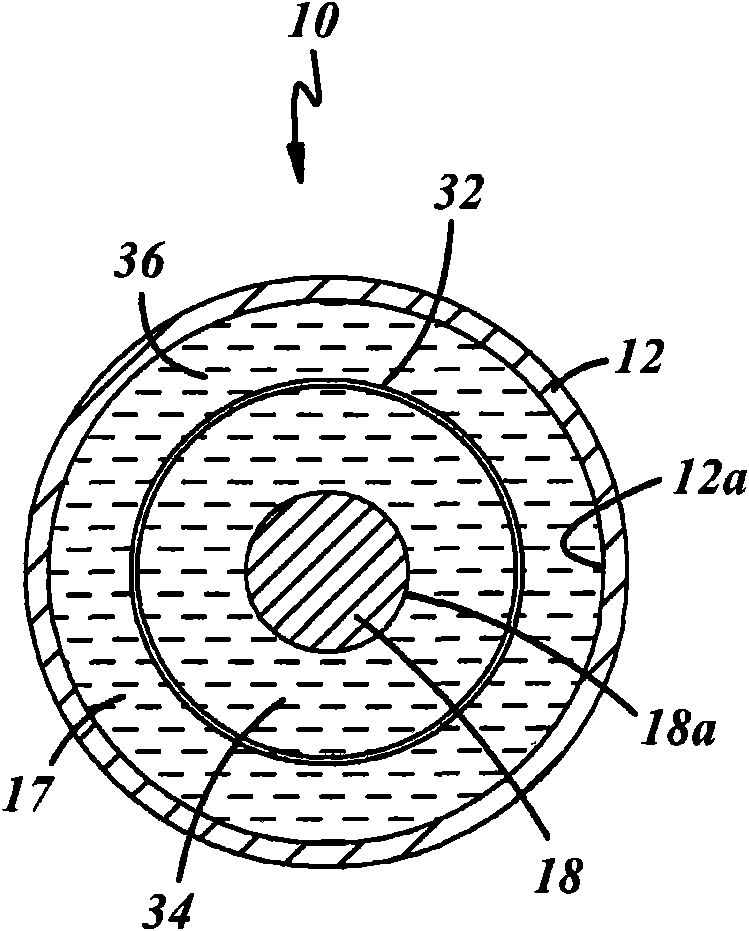

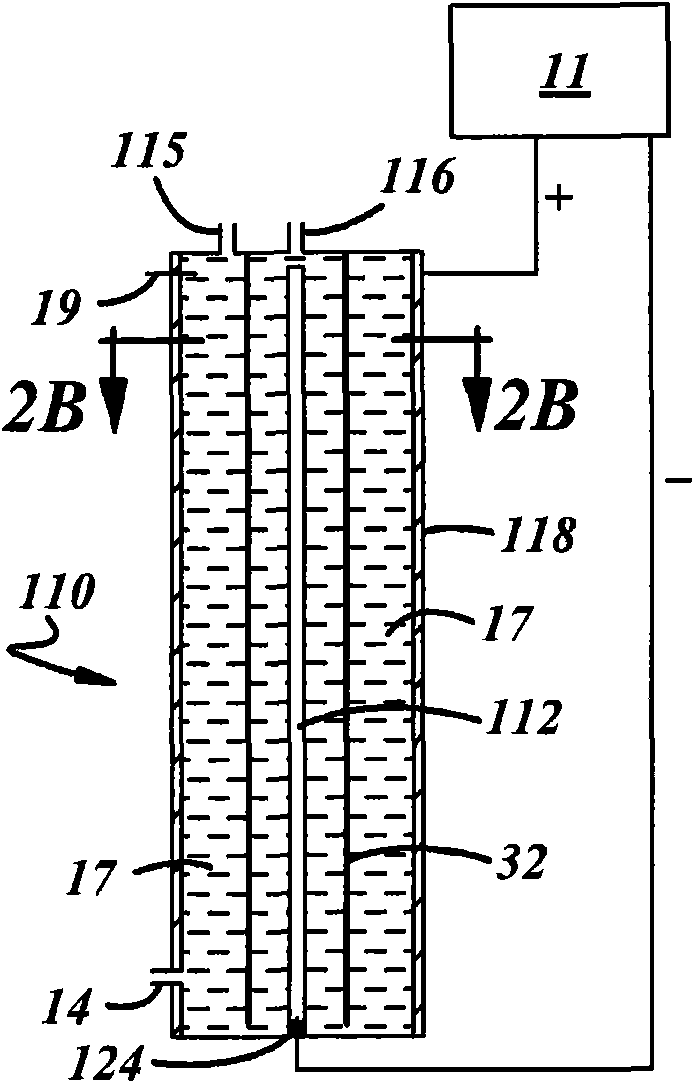

High pressure electrolysis cell for hydrogen production from water

Exemplary embodiments include a method or apparatus for improving the electrolysis efficiency of high-pressure electrolysis cells by decreasing the current density at the anode and reducing an overvoltage at the anode while decreasing the amount of hydrogen permeation through the cell membrane from the cathode chamber to the anode chamber as the high-pressure electrolysis cell is operated.

Owner:GM GLOBAL TECH OPERATIONS LLC

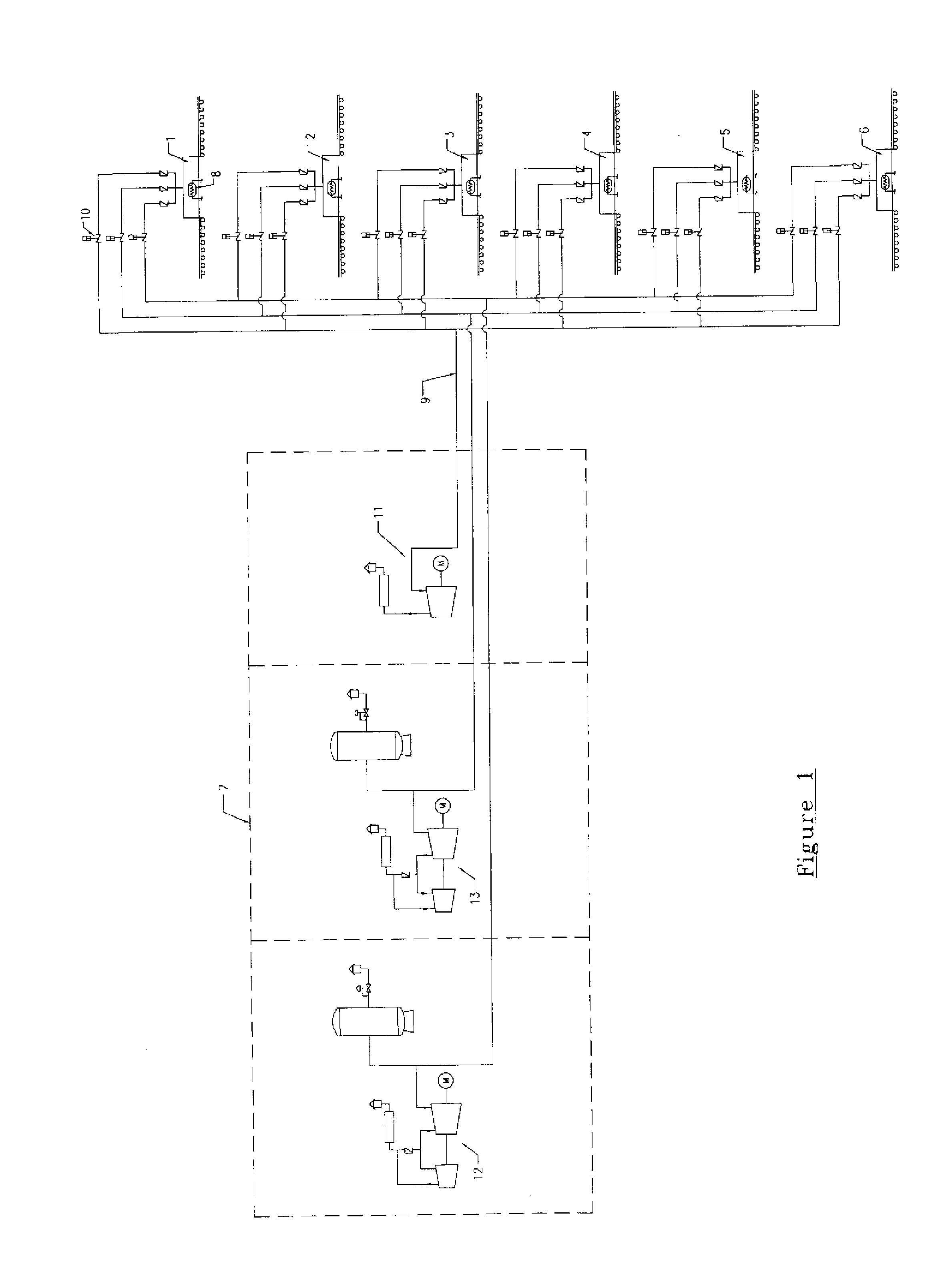

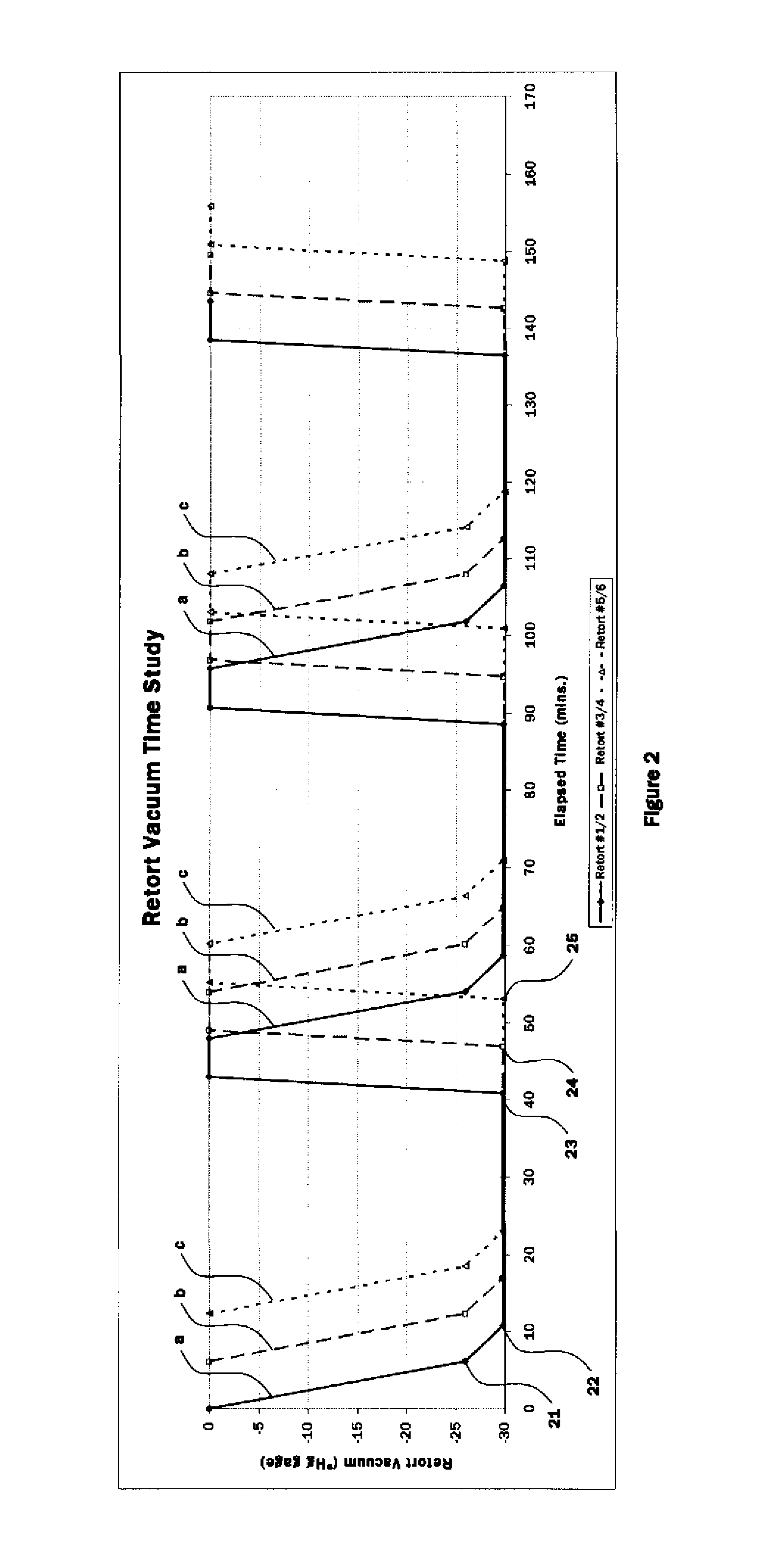

Central Vacuum Cooling Plant

ActiveUS20110300278A1Save energyMinimum power consumptionFood processingPackaging under vacuum/special atmosphereWater vaporEngineering

Described is a method as well as an apparatus for vacuum cooling of food produce through moisture removal, which method comprising the steps of loading the food produce to be cooled into a vacuum chamber, lowering the pressure inside the vacuum chamber to a predetermined pressure level and maintaining the vacuum chamber at this predetermined pressure level both by removing air through a vacuum pump system for a sufficient of time to allow heat transfer out of the food produce to take place, and condensing water vapor inside the vacuum chamber through a refrigeration system. The method and apparatus is unique in that the step of lowering the pressure inside the vacuum chamber to the predetermined pressure level is carried out using a single stage vacuum pump and the step of maintaining the vacuum chamber at this predetermined pressure level is carried out using a two stage vacuum pump.There is obtained a significant energy saving, which mainly is caused by splitting up the pressure lowering and maintaining steps into two distinct phases in which specifically sized vacuum pumps are used to most efficiently draw the required vacuum during the cooling process. Thus, the single stage vacuum pump used for the pressure lowering step has no high pressure stage that is idling during this step, meaning there is a net power saving or alternatively an increase in performance. Further, the two stage vacuum pump maintaining the pressure in the vacuum chamber for the required duration may be very small having very low displacement and thus low power consumption. In addition, splitting up the pressure lowering and maintaining steps into two distinct phases makes it possible to operate more vacuum chambers simultaneously in any combination, i.e. where some vacuum chambers are in the pressure lowering step others may be in the pressure maintaining step.

Owner:F L SMIDTH & CO AS

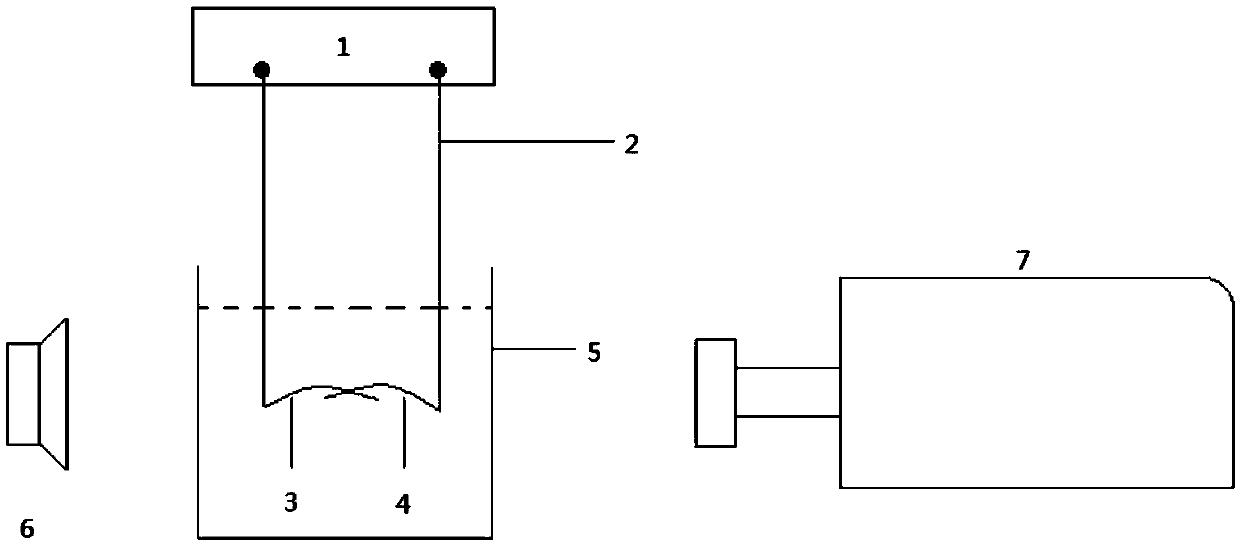

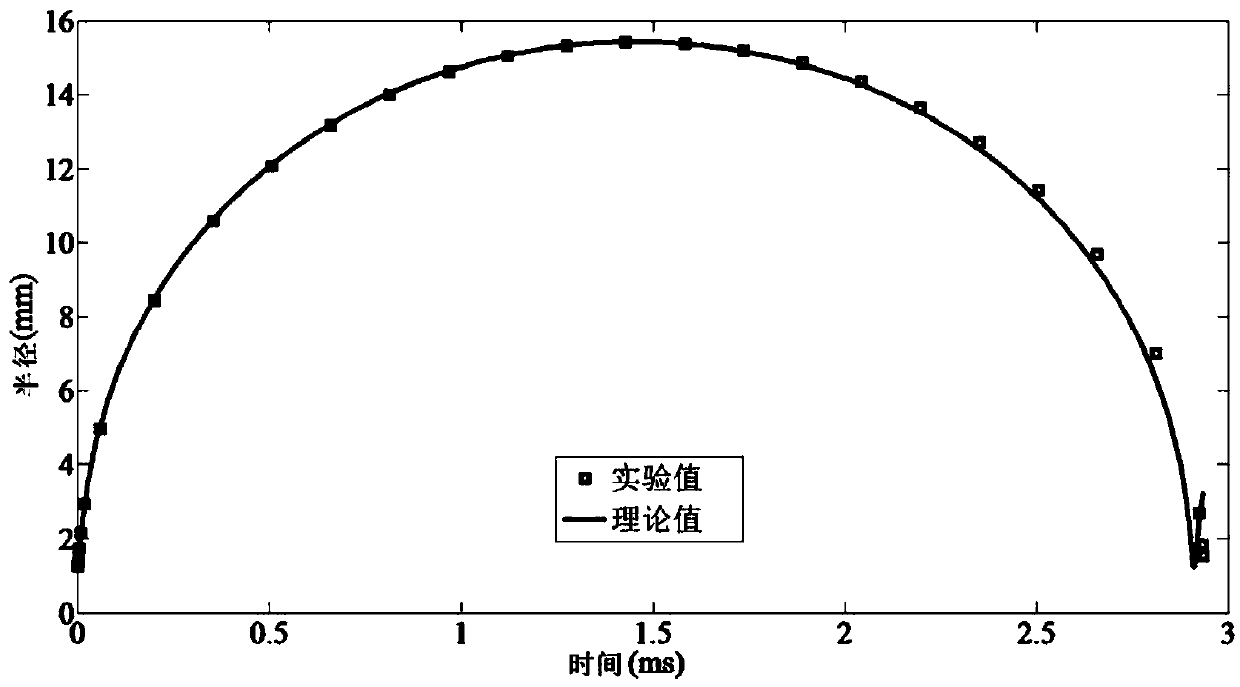

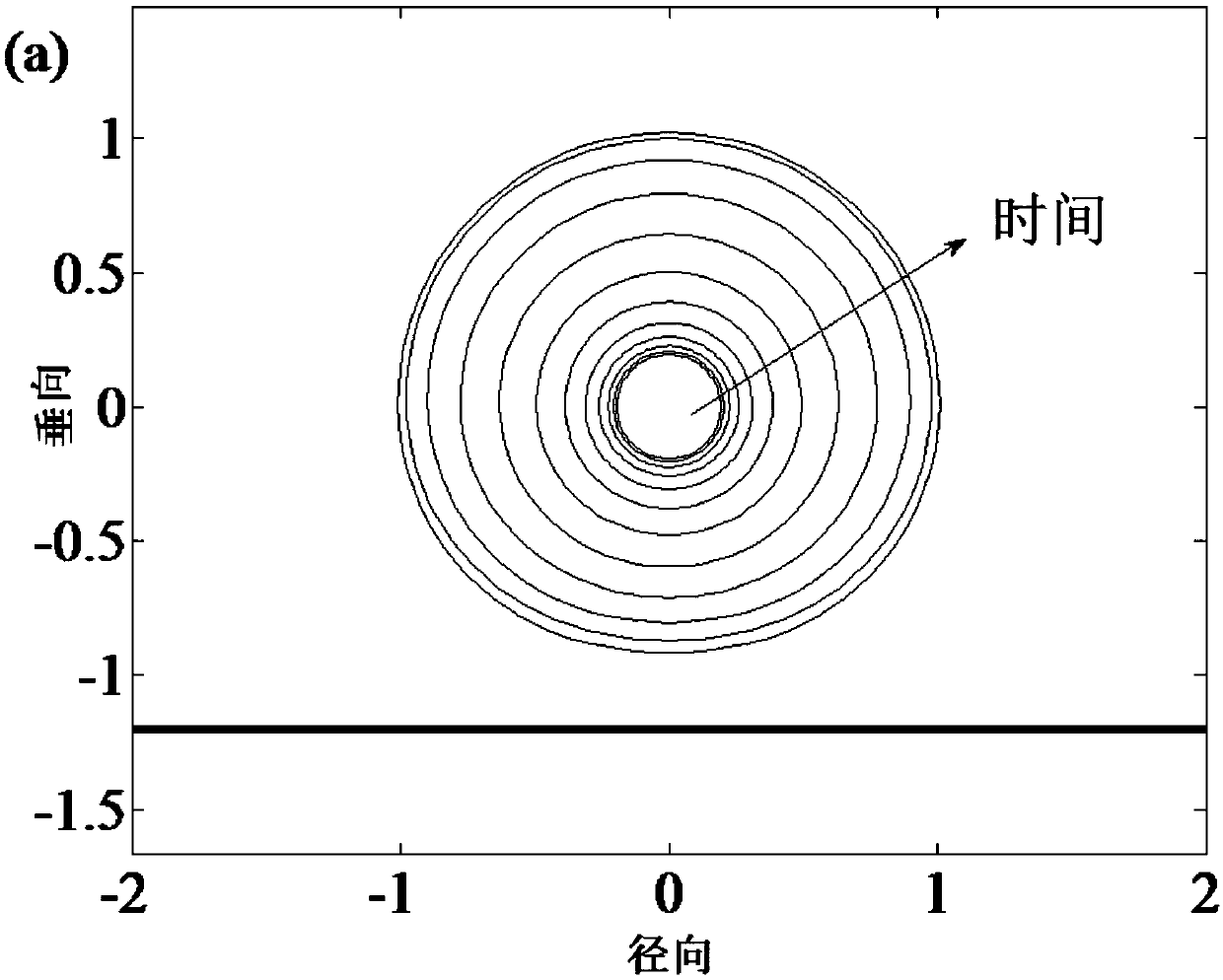

Experimental and numerical combined method for high pressure pulsating bubble motion and load in water

ActiveCN108846185AImprove research technologyImprove research toolsDesign optimisation/simulationComplex mathematical operationsChemical industryUnderwater explosion

The invention discloses an experimental and numerical combined method for high pressure pulsating bubble movement and load in water. The method comprises the following steps of: (1), using the Rayleigh-Plesset spherical bubble theory to calibrate the free-field high-pressure pulsating bubble experiment method, and determining a bubble initial condition; (2), using the calibrated bubble experimentmethod to carry out bubble dynamics experiments under different boundary conditions; (3), using a boundary element method to calculate dynamic characteristics of aspherical bubbles on the basis of theobtained experimental result; (4), adopting an auxiliary function method to calculate the velocity field and the pressure field around the bubbles; and (5), performing post-processing on the calculation result. The invention is suitable for studying the motion and load characteristics of the bubbles near a structure and a free surface in the gravity field, has the calculation accuracy and efficiency meeting the engineering needs, and has wide application prospect in the fields of underwater explosion, cavitation, medicine, cleaning, the chemical industry and the like.

Owner:HARBIN ENG UNIV

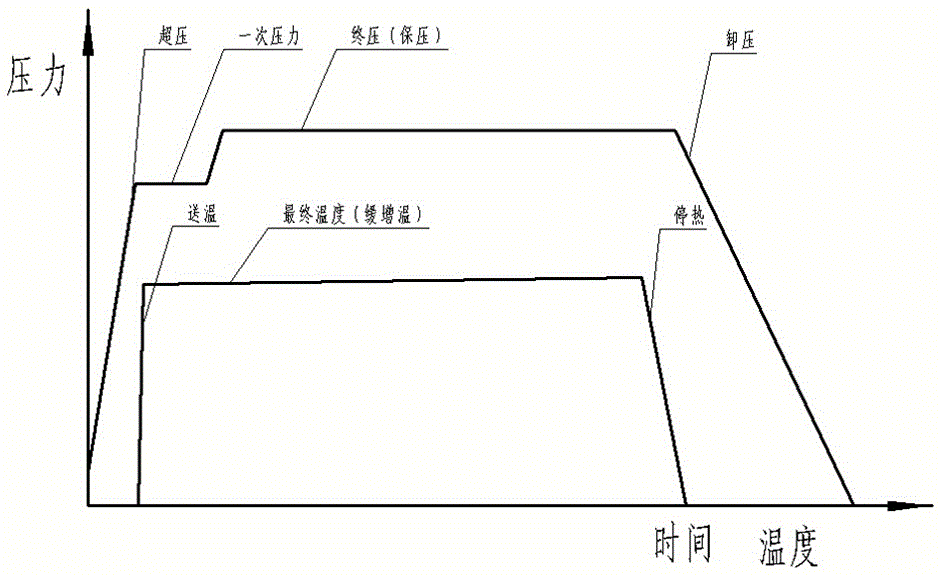

Synthetic process for gem grade diamond

ActiveCN106824002AImprove qualityStable growthUltra-high pressure processesPressure riseSpontaneous nucleation

A synthetic process for gem grade diamond comprises the following steps: (1) placing an assembled synthetic block in a high pressure chamber of a cubic press; after pressurizing the synthetic block to a final pressure of 90-95 MPa at one time, maintaining the pressure; when the pressure rises to 40-50% of the final pressure, starting heating and enabling the heating power to rise to 4-5 kw within 10-15 s; after preserving the heat of the synthetic block for 3-5 min, increasing the heating power to 9-10 kw for heat preservation; (2) after preserving the heat of the synthetic block for 5-10 h, entering a continuous heat preserving and pressure maintaining stage after continuous temperature increasing, heat preserving, pressure increasing and pressure maintaining; (3) after continuous heat preservation, stopping heating and cooling the synthetic block to room temperature; releasing the pressure when the temperature is halved; finishing the process till the pressure is released to normal pressure. The synthetic process for the gem grade diamond is especially suitable for multi-crystal-seed synthetic processes, can reasonably supply enough carbon source according to the growing speeds of crystal seeds in the control process and can enable the crystal seeds to stably grow for a long time without being affected by spontaneous nucleation to synthesize large particle size and inclusion-free high-quality diamond single crystal; the crystal is colorless and transparent and the quality of the crystal is good; the synthetic process for the gem grade diamond can realize mass production and low production cost.

Owner:ZHENGZHOU SINO CRYSTAL DIAMOND

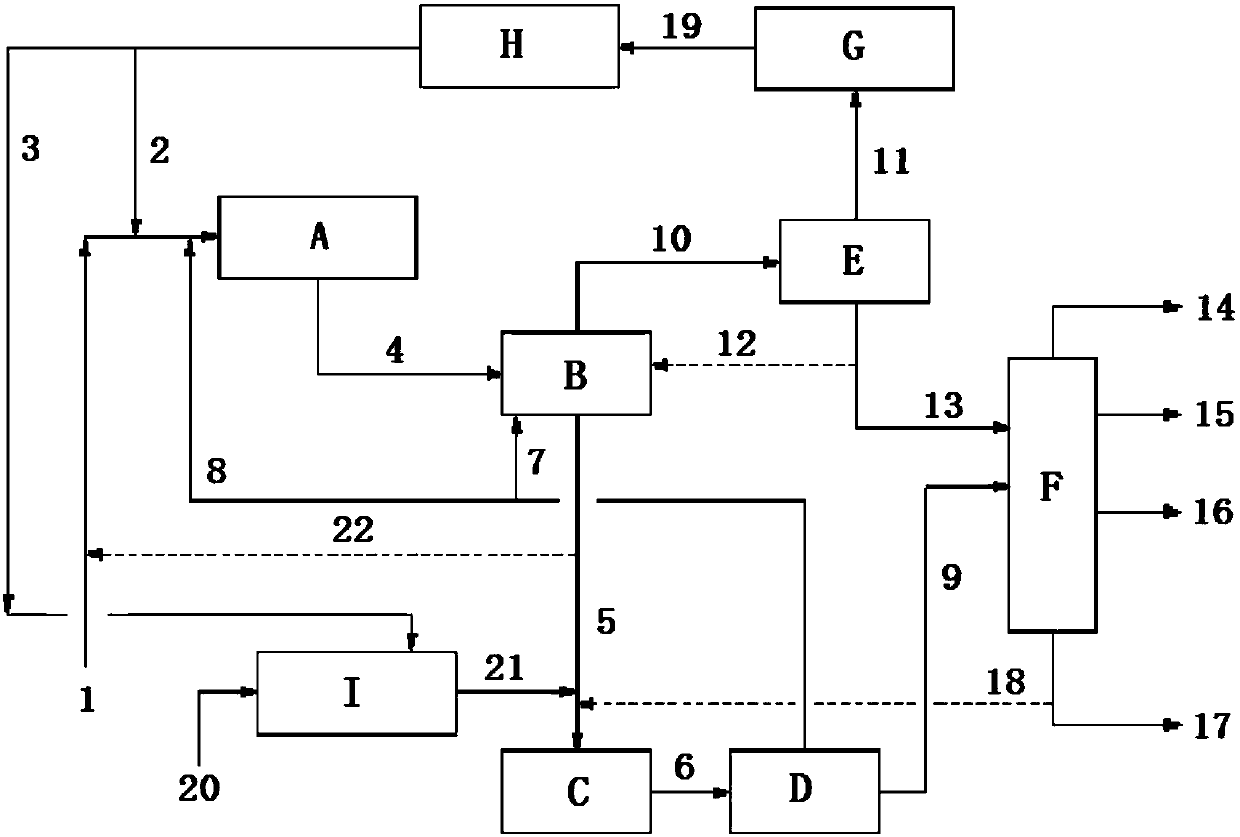

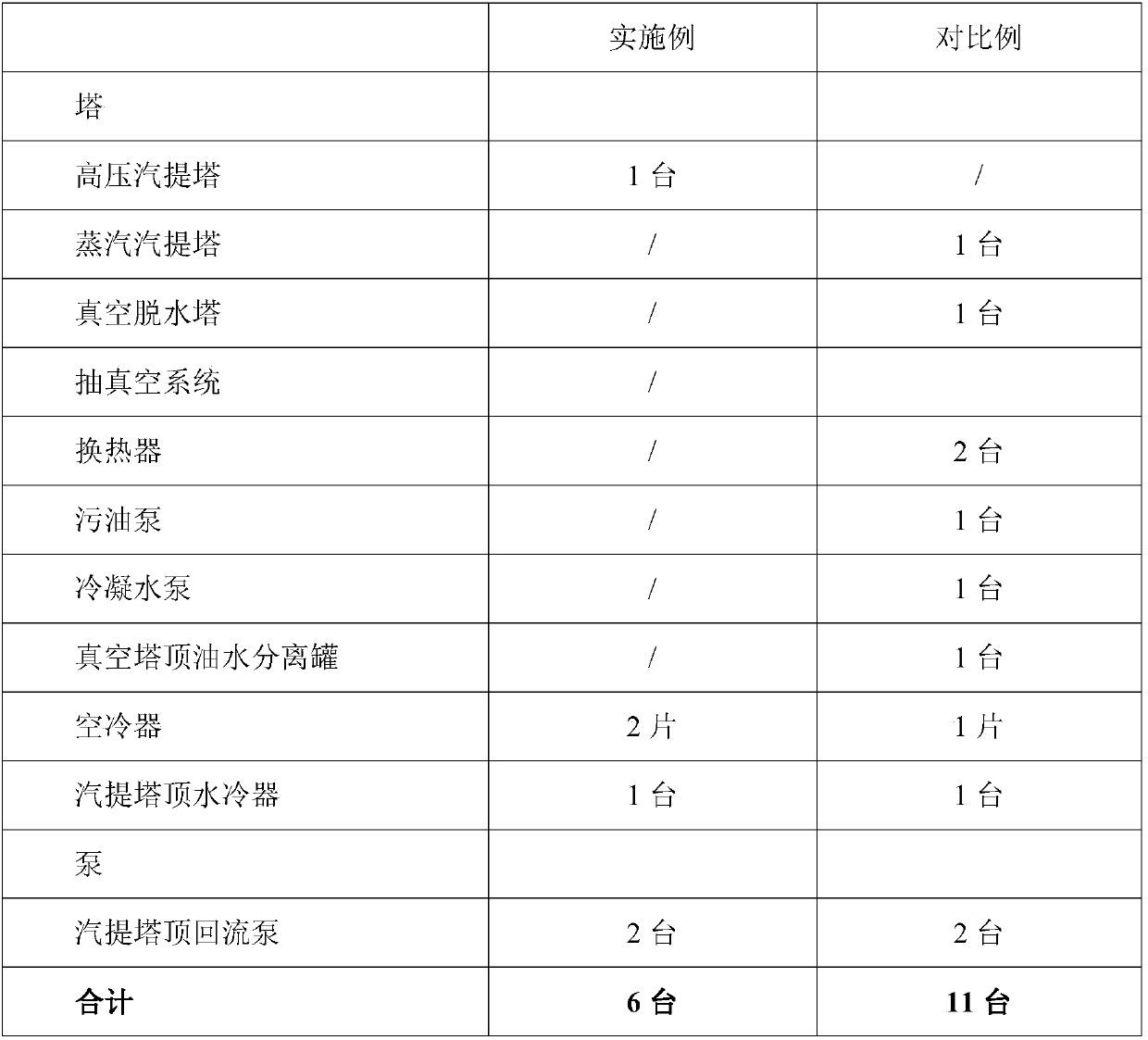

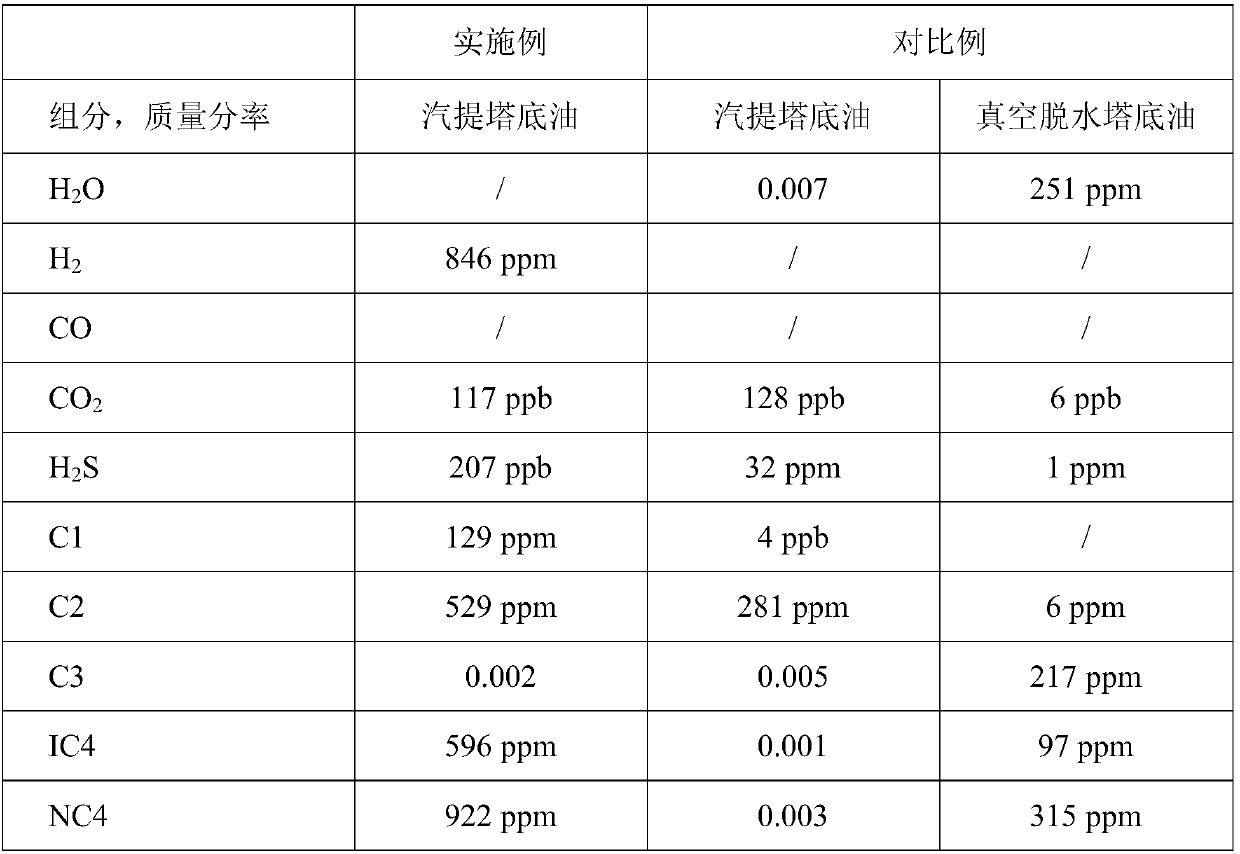

Hydrogenation method for producing aviation biofuel

InactiveCN109666509ASimple processReduce energy consumptionFatty acid hydrogenationLiquid carbonaceous fuelsIsomerizationGas phase

The invention belongs to the field of renewable energy processing, and relates to a hydrogenation method for producing an aviation biofuel. The hydrogenation method comprises that (1) raw material oil, first circulating hydrogen and a first hydrogen-rich gas phase are mixed, and impurities are removed in a hydrotreating unit; (2) the hydrotreated product enters a high pressure steam stripping tower, a second hydrogen-rich gas phase is injected from the tower bottom, steam stripping separation of light components is performed, and the gas phase from the top of the steam stripping tower is purified by a gas purifying unit so as to be recycled; (3) the refined oil from the bottom of the high pressure steam stripping tower, new hydrogen and second circulating hydrogen are mixed, the obtained mixture enters a hydroconversion unit, and a selective cracking and isomerization reaction is performed; and (4) the hydroconverted product is subjected to gas-liquid separation, the obtained hydrogen-rich gas phase is respectively fed to the hydrotreating unit and the high pressure steam stripping tower, and the liquid phase is separated by a fractionation unit to obtain the aviation biofuel product and the by-product. According to the present invention, the hydrogenation method has advantages of compact process, low energy consumption, small occupation area, low equipment investment and the like.

Owner:SINOPEC ENG +1

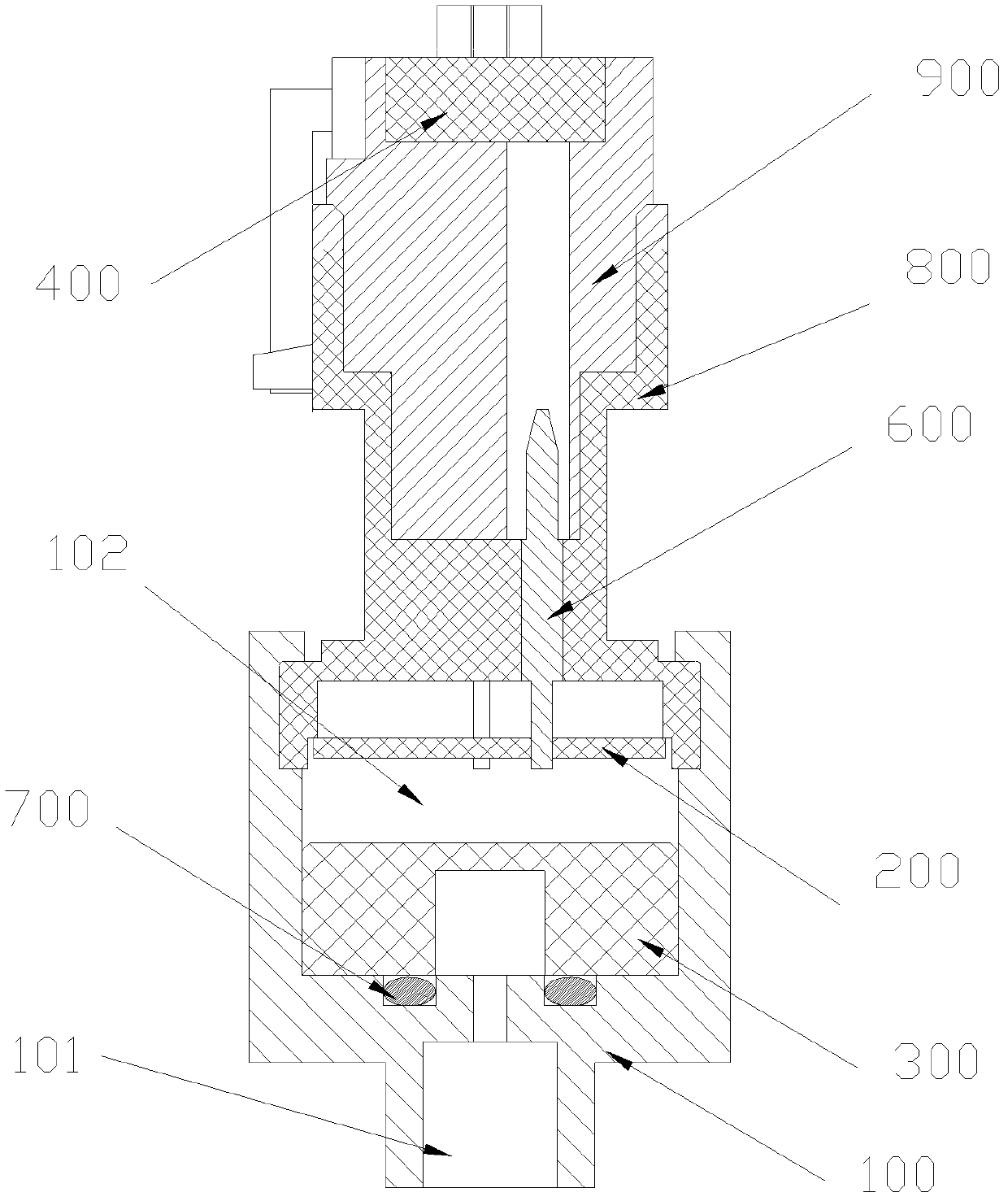

Pressure sensor

InactiveCN103376179AAvoid enteringSimple structureFluid pressure measurement by mechanical elementsHigh pressure cellEngineering

The invention relates to the refrigeration technical field, and specifically relates to a pressure sensor. The pressure sensor comprises: a body (1) which contains a medium introducing port (16) and an inner cavity (11), a signal induction component (3) which is arranged between the medium introducing port (16) and the inner cavity (11) and seals the inner cavity (11), and a circuit board (2) which is arranged inside the inner cavity (11) and is provided with a leading wire (6). The signal induction component (3) converts medium pressure changes of the medium introducing port (16) into electrical signals and the electrical signals are output through the leading wire (6). The pressure sensor is characterized in that: the body (1) is further provided with a one-way valve mechanism (5) which is capable of releasing pressure inside the inner cavity (11). Through arrangement of the one-way valve mechanism on the body, the pressure sensor can discharge high pressure accumulated in the inner cavity, and meanwhile, external water and gases can be prevented from entering the inner cavity; and the pressure sensor is simple in structure and reliable in performance.

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com