Hydrogenation method for producing aviation biofuel

A biofuel and aviation technology, applied in the direction of fuel, fatty acid hydrogenation, liquid carbon-containing fuel, etc., can solve the problems of reaction product and final product pollution, possibility of final product pollution, large hydrogen consumption for stripping, etc., to achieve It is beneficial to the reaction effect, avoids energy loss, and saves energy consumption of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

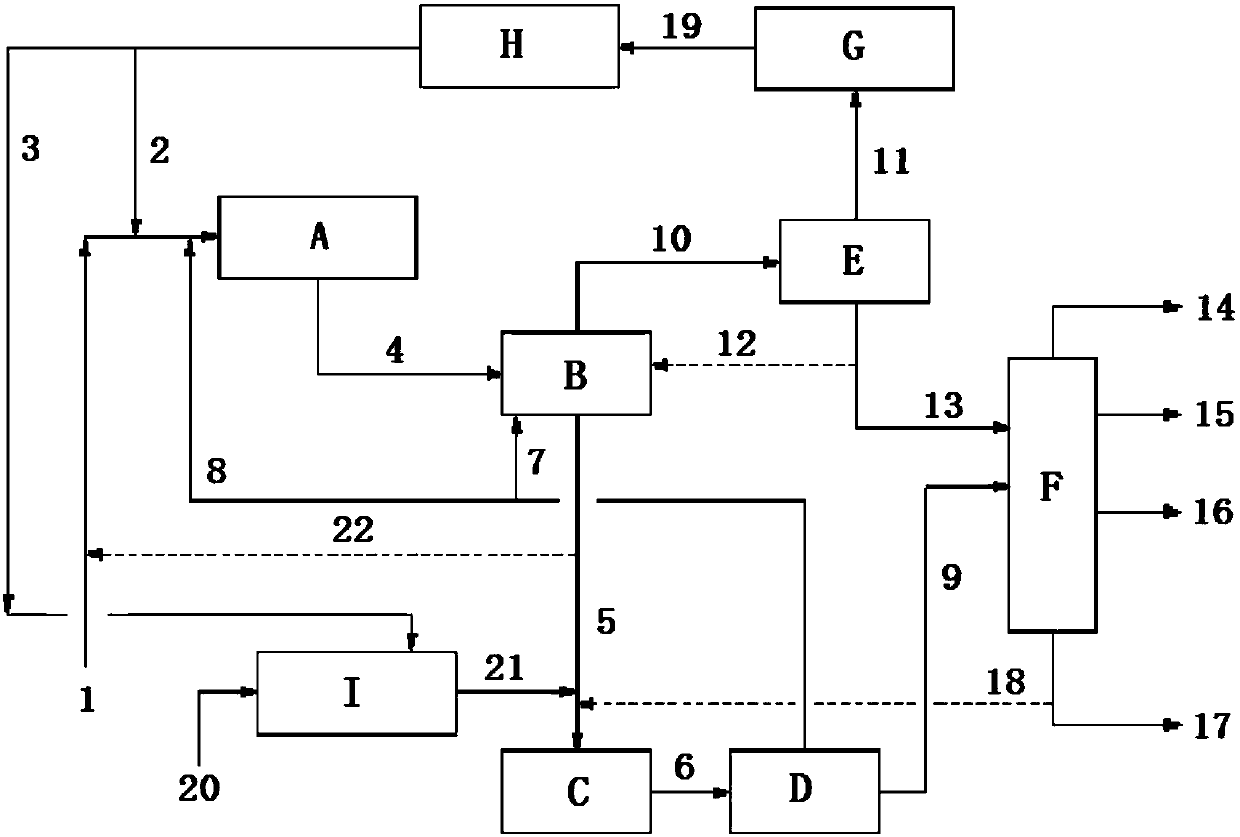

[0048] The raw material oil 1 is mixed with the first circulating hydrogen 2 and the first hydrogen-rich gas phase 8 successively, and enters the hydroprocessing unit A; after heating and reacting in the hydroprocessing unit A, a hydroprocessing product 4 is generated, and enters the high-pressure stripping tower B The upper part is stripped by the second hydrogen-rich gas phase 7 to remove the H generated by the reaction. 2 S and H 2 O, the bottom oil 5 of the high-pressure stripper is mixed with the mixed hydrogen 21 from the new hydrogen compressor I, and enters the hydroconversion unit C. After heating and reacting, the hydroconversion product 6 is generated, and then enters the hot high-pressure separator D.

[0049] The hydrogen-rich gas phase at the top of the hot high-pressure separator D is divided into two streams: the first hydrogen-rich gas phase 8 is mixed with the raw material oil 1 as supplementary hydrogen; the second hydrogen-rich gas phase 7 is sent to the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com