Patents

Literature

38results about How to "Timely removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

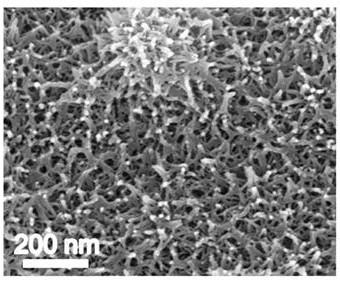

Method for preparing metallic complex film

ActiveCN101135052AReduced separation selectivityReduced stabilityLiquid/solution decomposition chemical coatingSuperimposed coating processReduction ActivityHydrogen

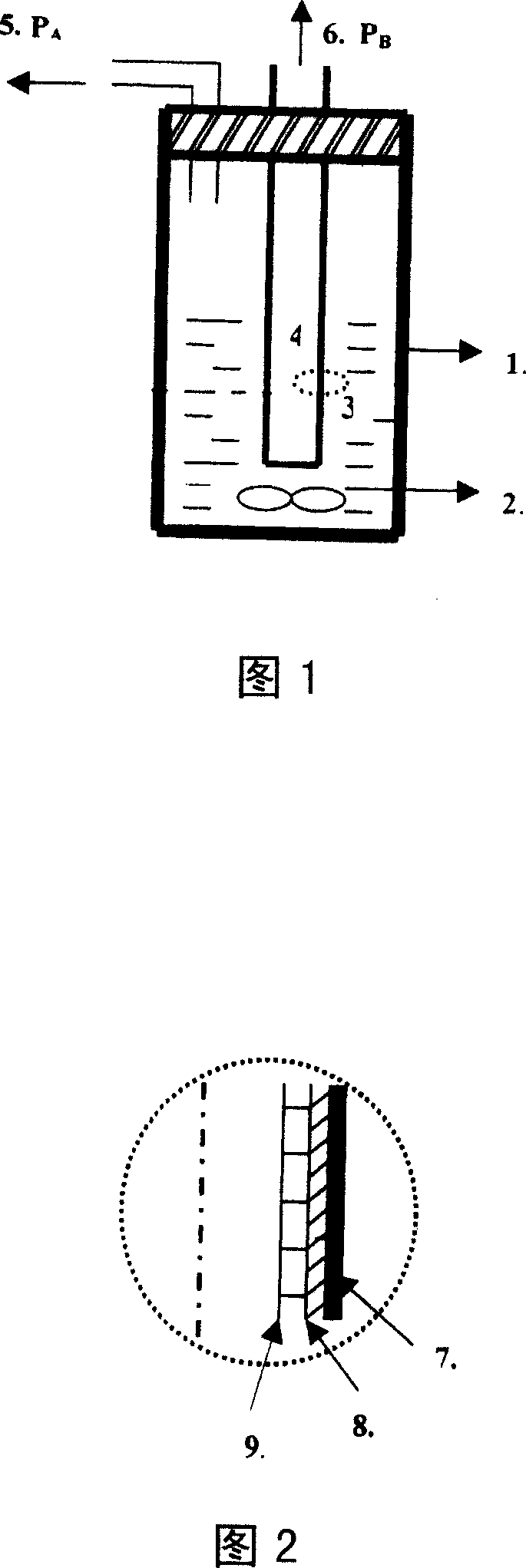

The vacuum chemical plating process for preparing composite metal film includes the first pre-modification of porous film by means of sol-gel technology to introduce one transition layer containing metal crystal seed with self-catalytic reduction activity to the chemical plating, and the subsequent vacuum chemical plating by means of forming different vacuum degrees on two sides of the modified porous composite film. The process can raise the hydrogen permeating performance of the composite metal film and raise the stability of the composite metal film.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for green planting of greenhouse tomatoes

InactiveCN103782770AGood taste and textureUniform fruitSeed and root treatmentAnimal repellantsSite managementUltrasound attenuation

The invention discloses a method for green planting of greenhouse tomatoes. The method comprises the steps of seed selection, greenhouse construction, seedling cultivation, seedling stage gradient temperature control, greenhouse temperature variation management, biological nitrogen fixation bacterial manure attenuation for root dipping of seedlings, planting, greenhouse field management, pest control, harvesting and the like. The tomatoes produced through the method are good in flavor and taste. A physical method is mainly adopted in the method for prevention and control of the pest and disease damage, so that the method has the advantages that remaining medicine is avoided, fruits are even, the yield is high, and the growth period is short.

Owner:内蒙古田野餐桌现代农业有限责任公司

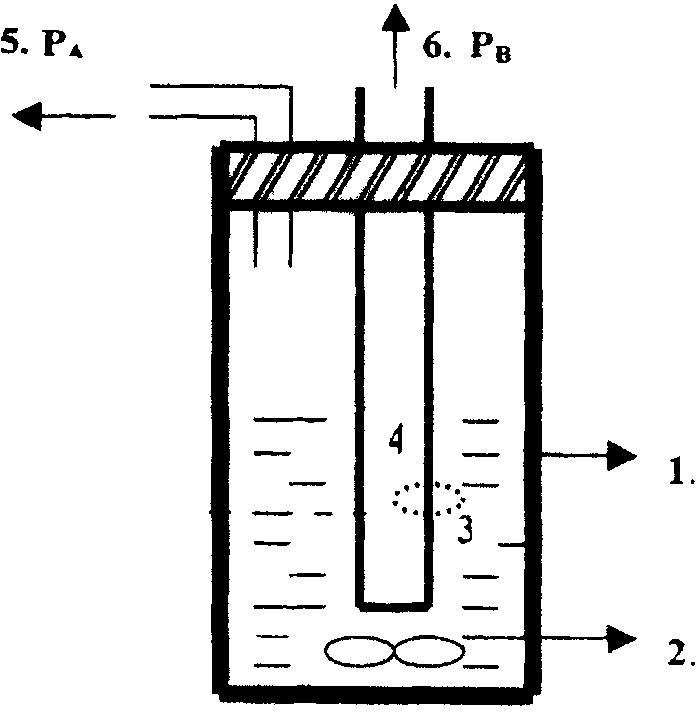

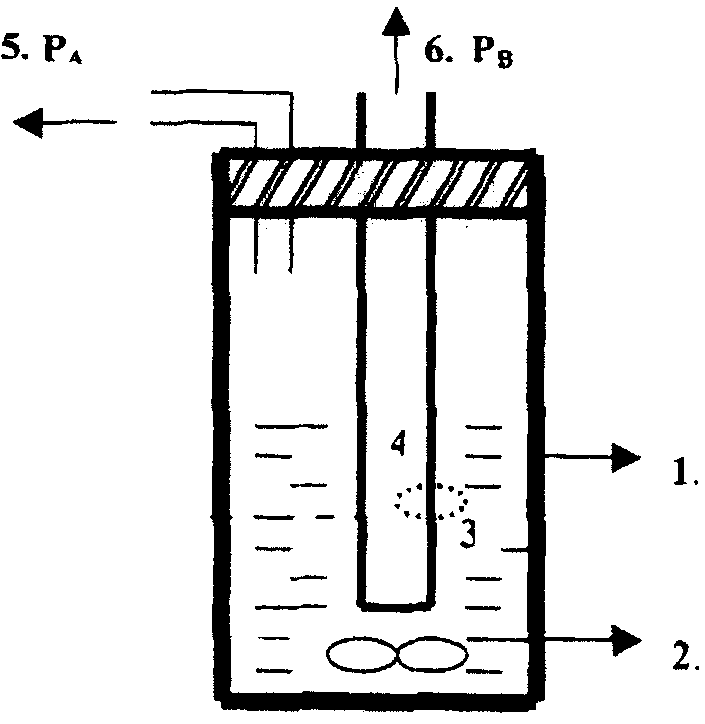

Grating magnetic separation type sewage treatment apparatus

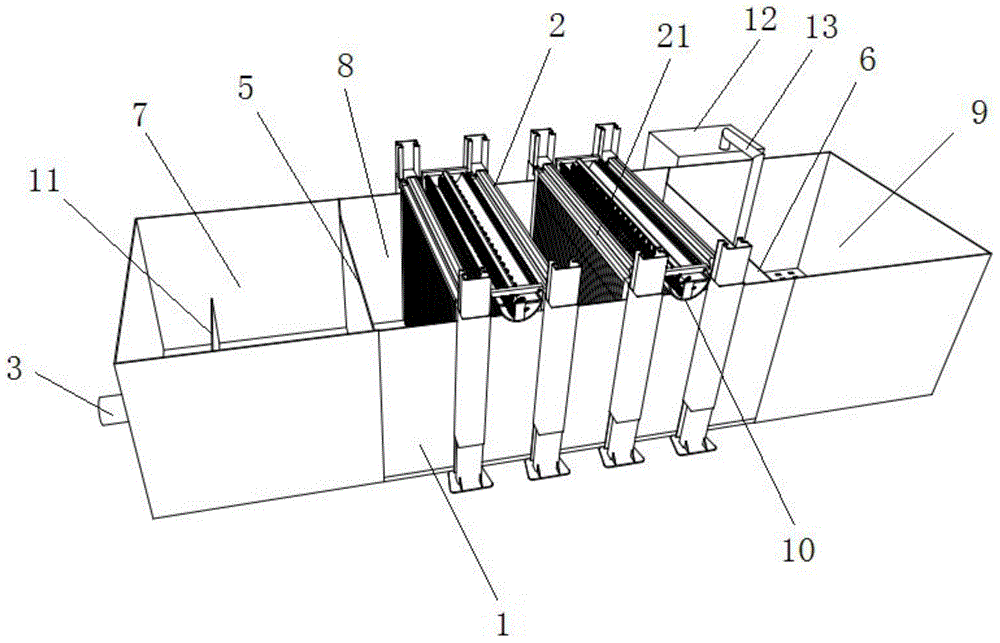

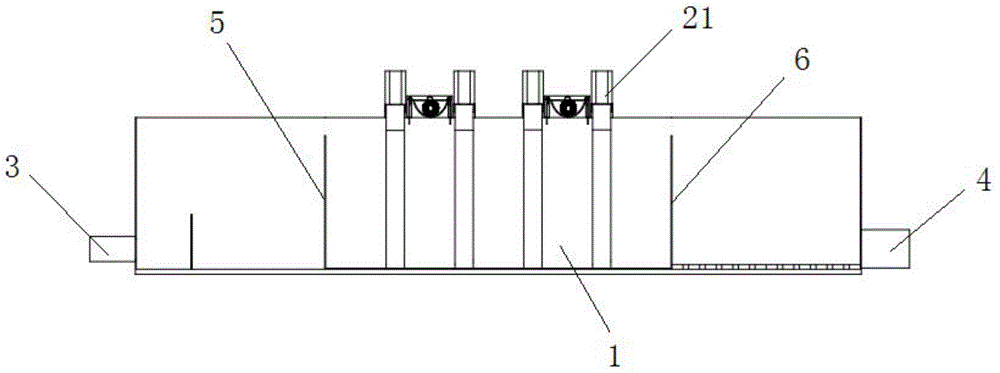

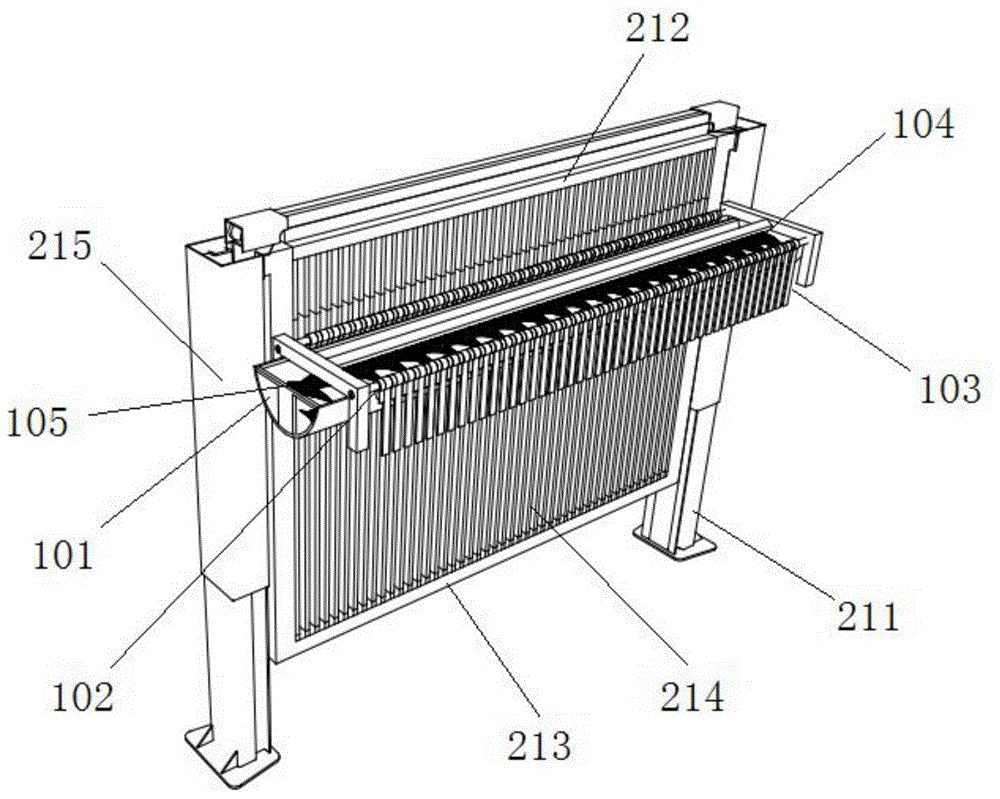

ActiveCN105060423AComprehensive clean water qualityStable speed controlWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentWater qualityWater flow

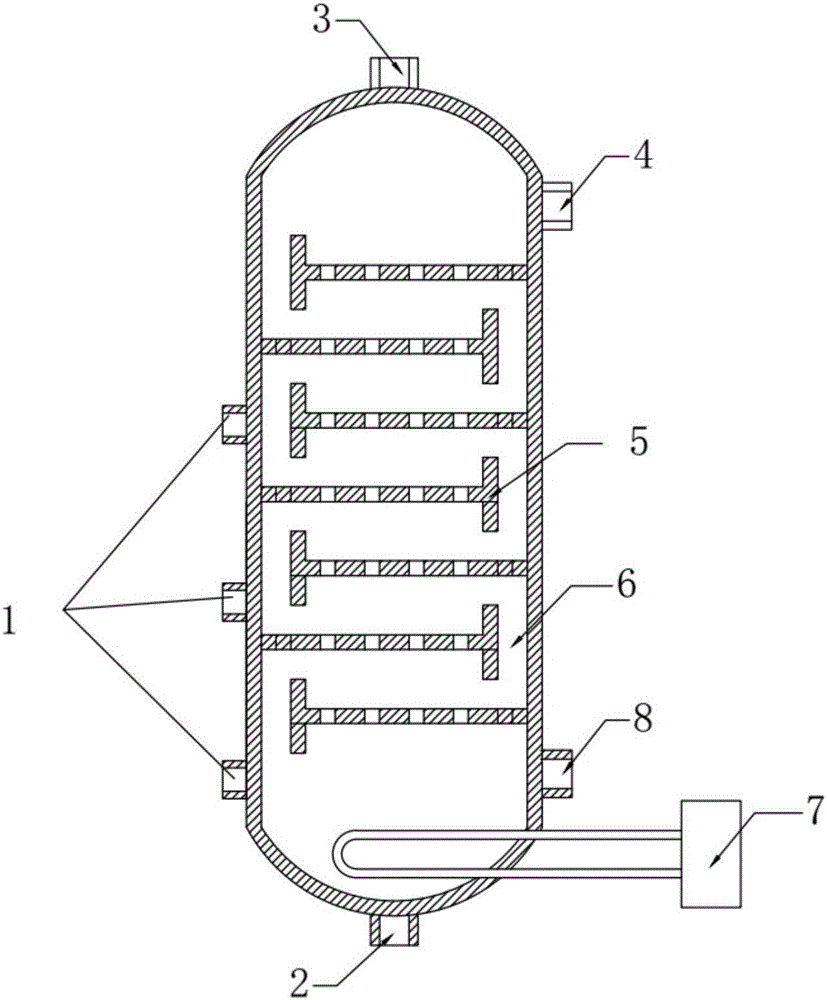

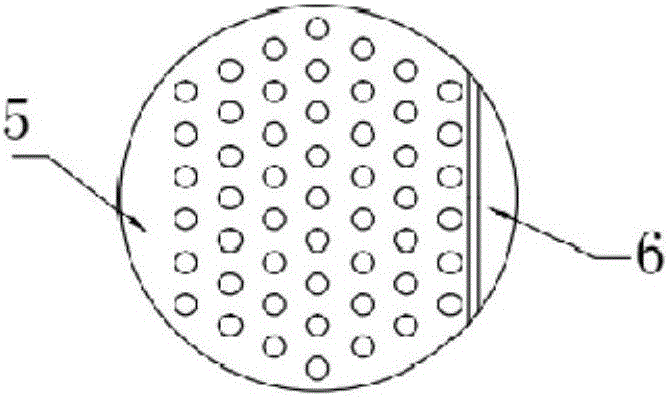

The invention discloses a grating magnetic separation type sewage treatment apparatus. The apparatus comprises a magnetic separation cabinet, the middle portion of the magnetic separation cabinet is provided with a grating magnetic separation purifier, two sides of the magnetic separation cabinet are respectively provided with a water inlet and a water outlet, two sides of the grating magnetic separation purifier in the magnetic separation cabinet are respectively provided with a first perforated wall and a second perforated wall, an inlet water pool is formed between the first perforated wall and the water inlet of the magnetic separation cabinet, a purifying pool is formed between the first perforated wall and the second perforated wall, an outlet water pool is formed between the second perforated wall and the water outlet of the magnetic separation cabinet, and the inlet water pool, the purifying pool and the outlet water pool are sequentially communicated. The apparatus has the advantages of simple structure and convenient manufacturing, allows the speed of water flow in the grating magnetic separation purifier to be stably controlled through using the first perforated wall and the second perforated wall and cooperating with the purifying pool formed by the grating magnetic separation purifier, allows water to be effectively and comprehensively cleaned through the grating magnetic separation purifier, and ensures adaption to large sewage throughout.

Owner:ANHUI PUSHI ECOLOGICAL ENVIRONMENT ENG

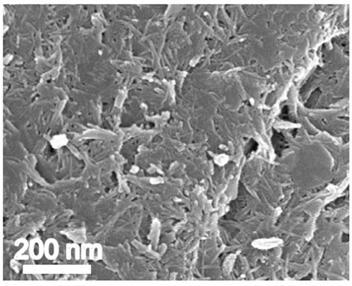

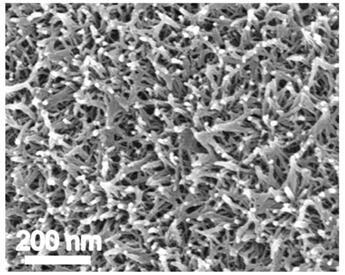

Porous dual-metal hydroxide catalyst for electric catalysis of alcohol selective oxidation and preparation method and application thereof

InactiveCN109772336ALow costIncrease the areaCatalyst activation/preparationElectrolytic organic productionNickel saltSynthesis methods

The invention discloses a porous dual-metal hydroxide catalyst for electric catalysis of alcohol selective oxidation and a preparation method and application thereof. The preparation method of the porous dual-metal hydroxide catalyst comprises the steps that nickel salt, metal M salt (metal M is iron or cobalt or copper) and urea are adopted as raw materials, water is adopted as a solvent, a carbon fabric is adopted as a substate, a nickel-metal M composite hydroxide is loaded on the surface of the carbon fabric substrate through a microwave synthesis method, drying is performed, and finally,the catalyst is placed into a plasma reaction furnace to be activated, and finally the porous dual-metal hydroxide catalyst is obtained. The catalyst has the porous structure, the large specific surface area and the good conductivity, and has the excellent performance in the alcohol selective electro-catalysis oxidation reaction. Meanwhile, the technology for preparing aldehyde or acid through thealcohol selectivity electro-catalysis oxidation reaction is easy to implement, the selectivity of the product aldehyde or acid is high, and the catalyst is low in preparation cost and high in stability and has the good industrial application prospect.

Owner:ZHEJIANG UNIV OF TECH

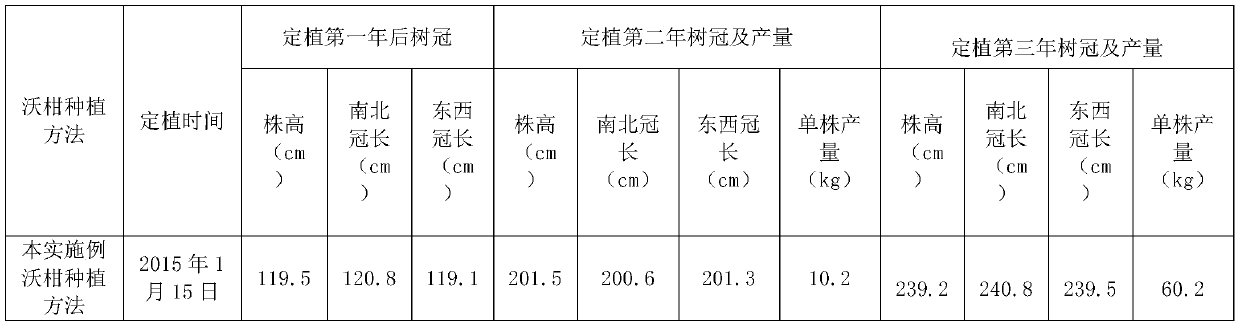

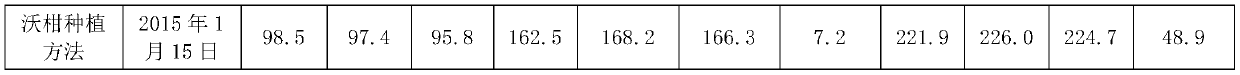

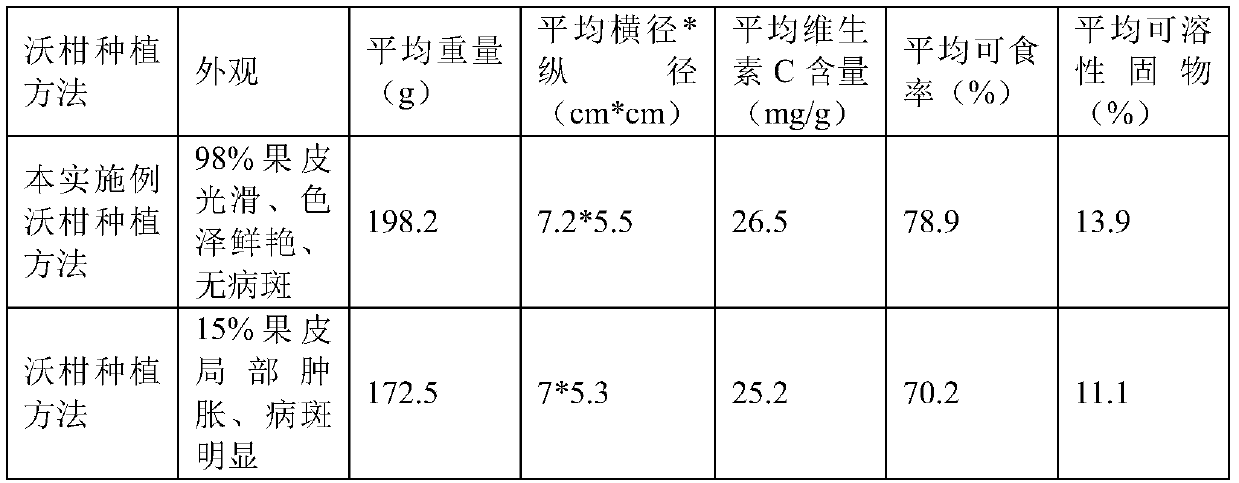

Method of cultivating Citrus Or by green manure intercropping

InactiveCN110199756AReduce mortalityPrevent teeth grindingFertilising methodsCultivating equipmentsShootYoung tree

The invention relates to the technical field of planting of Citrus Or and discloses a method of cultivating Citrus Or by green manure intercropping. The method comprises (1) selecting a plantation site, and building a plantation, to be specific, selecting a level land or low-lying land as the plantation having the soil, air and irrigation water quality meeting the 'three-product one-indication' standard of producing area environment; (2) selecting plantlets; (3) carrying out field planting; (4) applying fertilizers three years after field planting; (5) shaping and pruning young trees; (6) carrying out bud control and flower-fruit thinning techniques for the young trees; (7) intercropping grass, to be specific, intercropping a leguminous dwarf herb green manure among rows of fruit trees; (8) culturing robust autumn shoots; (9) pruning fruiting trees; (10) picking; and (11) cleaning the plantation. The problems of the prior art can be solved that unreasonable selection for a plantation site causes high mortality of seedlings, fertilizer application means are improper, planting management is unscientific, shoot tips and buds are not managed, Citrus Or grows slow, and fruit quality andyield are low.

Owner:广西鸣鸣果业有限公司

Method for removing crystalline salt as well as design method and application thereof

ActiveCN105273759AAchieve removalComplete dissolution achievedHollow article cleaningCorrosion preventionHydrogenation processNitrogen

Owner:CATECH TECH

Method for preparing long-chain dicarboxylic dialkyl ester

InactiveCN1508117AEasy to separateLess side effectsOrganic compound preparationCarboxylic acid esters preparationAlcoholDistillation

The method for preparing long-chain dicarboxylic acid dialkyl ester uses dicarboxylic acid of C8-C18 and excess C6-C18 monobasic alcohol as raw material, adopts proper acidic resin as catalyst, and makes them implement esterification reaction at higher temp., at the same time of esterification the formed water content is evaporated out, the conversion rate of reaction can be raised, and the reaction liquid can be undergone the processes of distillation, etc. and can be purified. Said invention has the advantages of short process, high esterification rate, short operation period, and low energy consumption, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

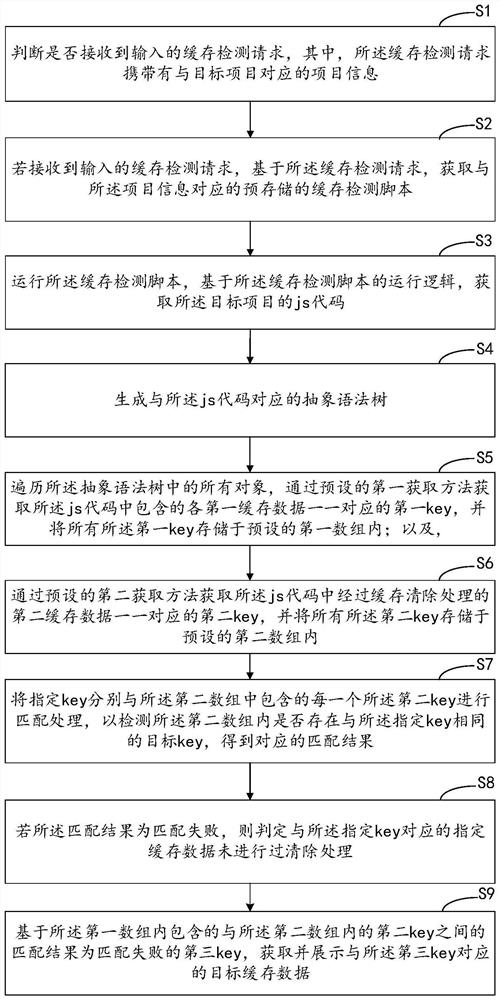

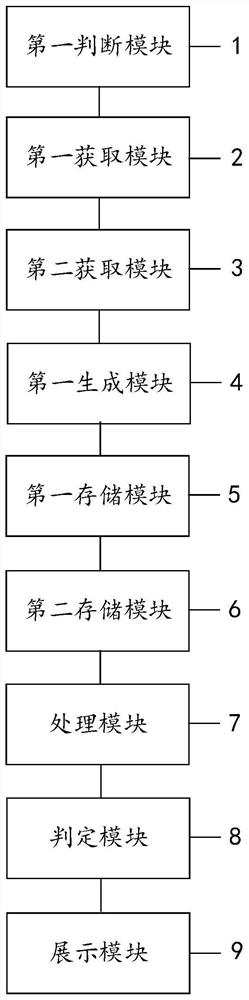

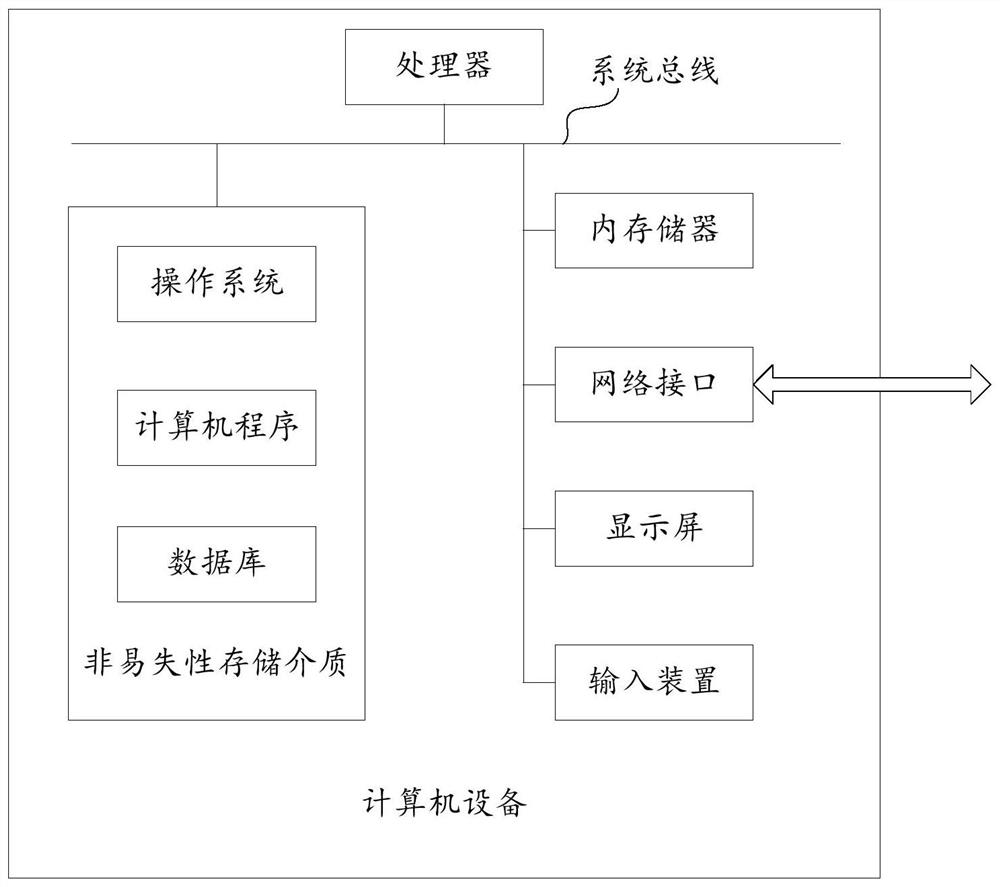

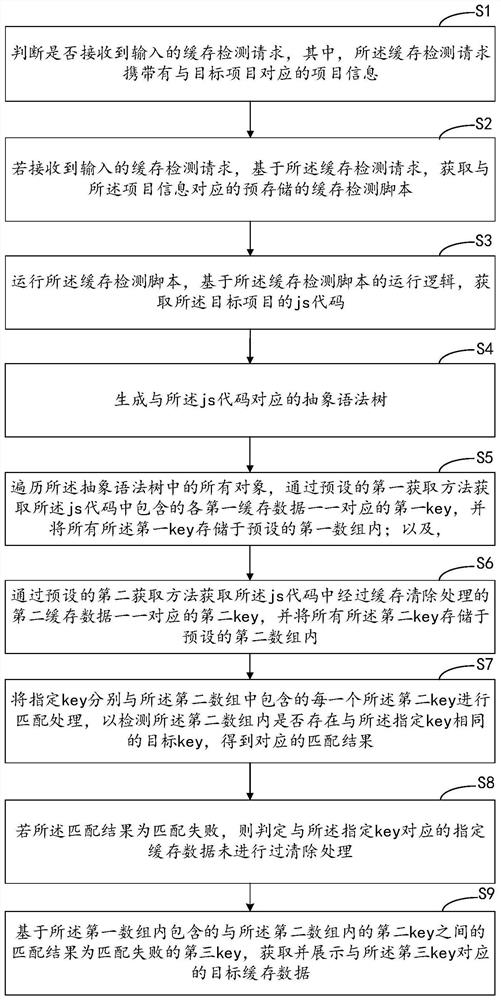

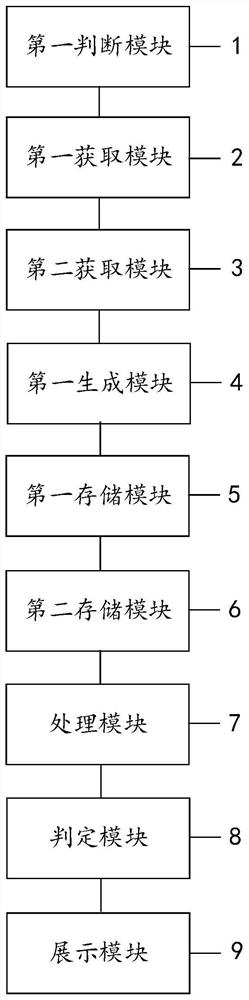

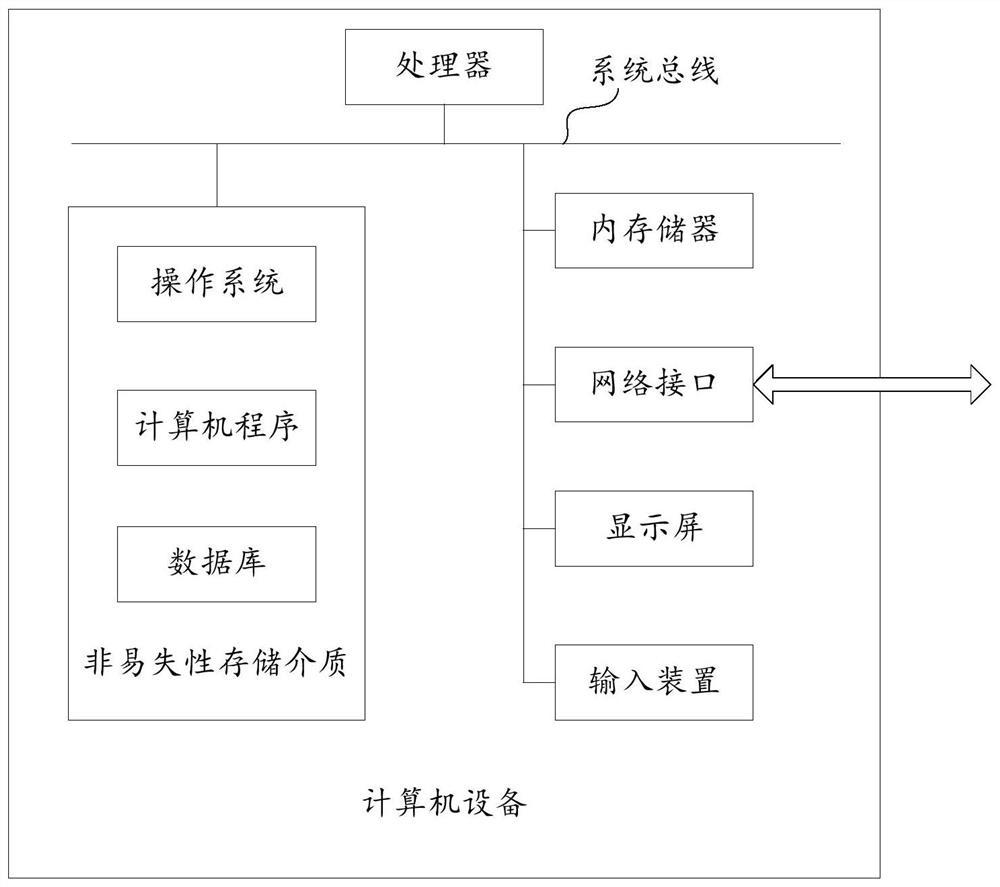

Cache data detection method and device, computer equipment and storage medium

ActiveCN112540811AImprove detection efficiencyKeep abreast ofExecution paradigmsCode generationParallel computing

The invention relates to the technical field of data processing, and provides a cache data detection method and device, computer equipment and a storage medium, and the method comprises the steps: obtaining a cache detection script corresponding to project information when an input cache detection request is received; running the cache detection script, and obtaining a js code of the target project; generating an abstract syntax tree corresponding to the js code; traversing all objects in the abstract syntax tree, and obtaining a first key of each piece of first cache data contained in the jscode; obtaining a second key of the second cache data subjected to cache clearing processing; and obtaining and displaying target cache data corresponding to a third key based on the third key which is contained in the first key and has a matching result with the second key as matching failure. According to the method and the device, the target cache data which are not subjected to clearing processing in the local cache can be quickly detected. The method can also be applied to the field of block chains, and the target cache data and other data can be stored on the blockchains.

Owner:PING AN TECH (SHENZHEN) CO LTD

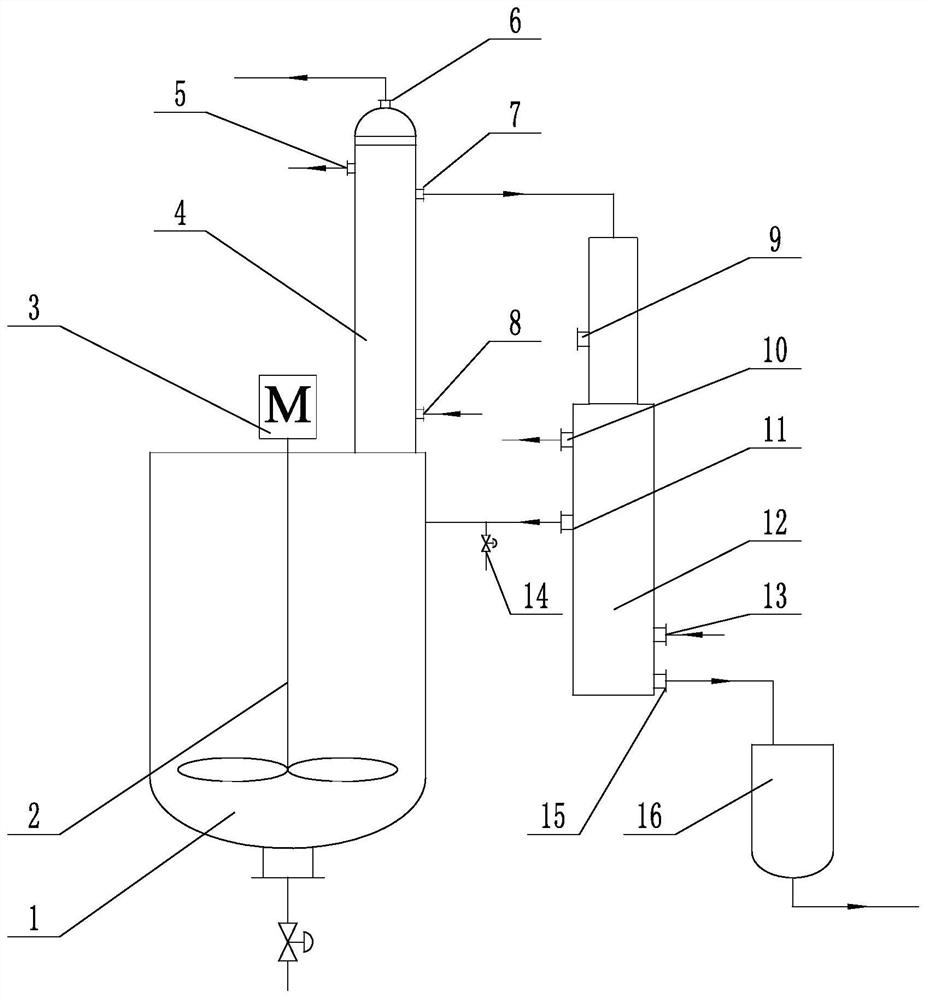

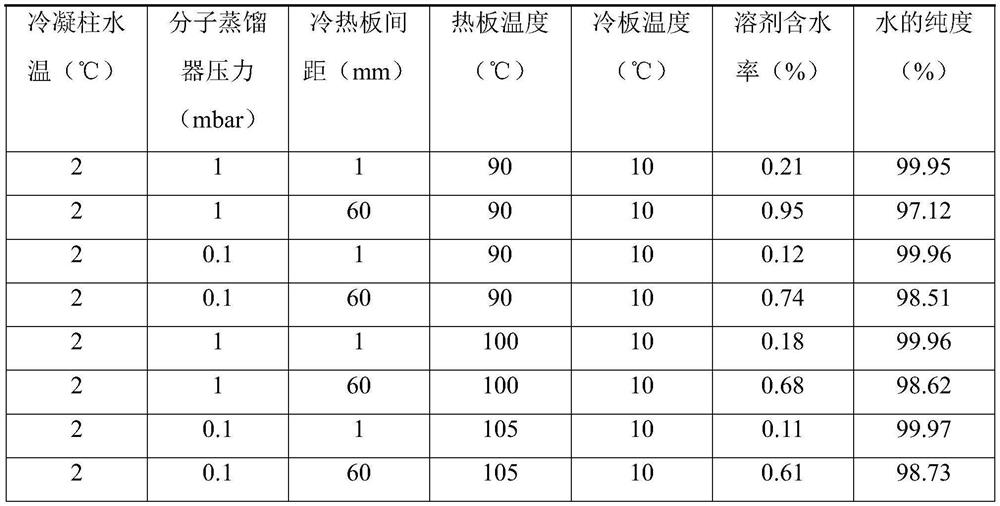

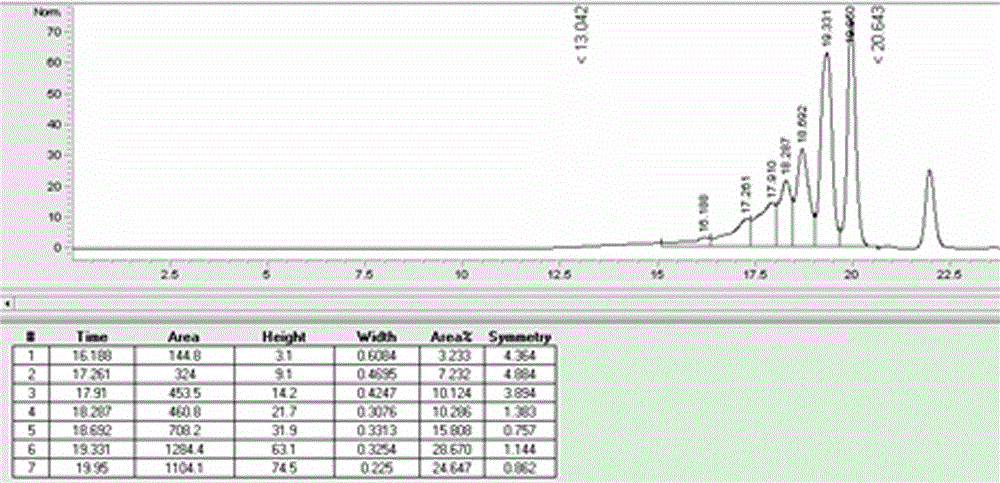

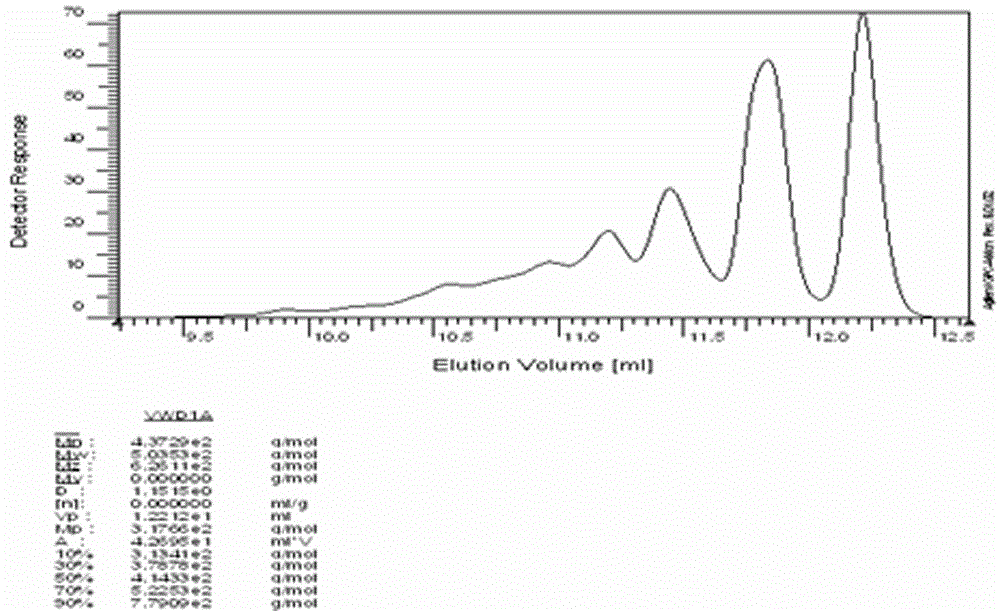

Polysulfone series resin polymerization dehydration process

The invention belongs to the technical field of high polymer materials, and particularly relates to a polysulfone series resin polymerization dehydration process. A rapid dehydration process is adopted in the polymerization process, and the system is heated to the boiling point of a solvent and is dehydrated in an azeotropic manner of the solvent and water. An ultralow-temperature condenser is matched with a novel molecular distiller, the mixed solution is quickly subjected to short-range separation, water and a pure solvent are recovered respectively, the almost anhydrous pure solvent is directly returned to the polymerization kettle, the solvent consumption for dehydration can be reduced by 30-50 wt%, no pollution is caused to the product, no dehydrating agent is left, the process is green and environmentally friendly; meanwhile, the production period can be shortened from 14-16 h to 10-12 h through the rapid and efficient dehydration process and the high dehydration temperature, andthe polymerization period is shortened by 25-28%. The obtained polysulfone polymer material has the advantages of high purity, low ash content, stable performance, low cost, no pollution and the like, and can be applied to the fields of medical instruments, aerospace, automobile parts, electronic components and the like.

Owner:FUHAI (DONGYING) ADVANCED MATERIAL TECH CO LTD

Preparation method of low-hydrolysable chloride itaconic acid epoxy resin

ActiveCN104311511AAchieving a closed-loop reactionLess side effectsOrganic chemistryEpoxyItaconic acid

The invention discloses a preparation method of low-hydrolysable chloride itaconic acid epoxy resin. The method comprises the following steps: carrying out addition ring opening on raw materials comprising itaconic acid and epoxy chloropropane under the action of a catalyst under the protection of nitrogen to obtain a chlorohydrin ester structure intermediate, carrying out an alkali addition ring closing reaction to form an epoxy structure, and post-processing to obtain the low-hydrolysable chloride itaconic acid epoxy resin; and the alkali addition ring closing reaction is realized through carrying out reduced pressure refluxing under a vacuum degree of 100-150Torr, cooling to 40-60DEG C, adding an aqueous solution of an alkaline compound in a dropwise manner for 2-6h, carrying out reduced pressure refluxing in the dropwise addition process in order to remove water in a system, heating after the dropwise addition, and continuously carrying out a reduced pressure refluxing reaction for 1-3 to remove parts of excess epoxy chloropropane. The itaconic acid epoxy resin prepared through the method has the advantages of low hydrolysable chloride, narrow molecular weight distribution, low viscosity, high purity and the like, can be used as an epoxy resin diluent.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

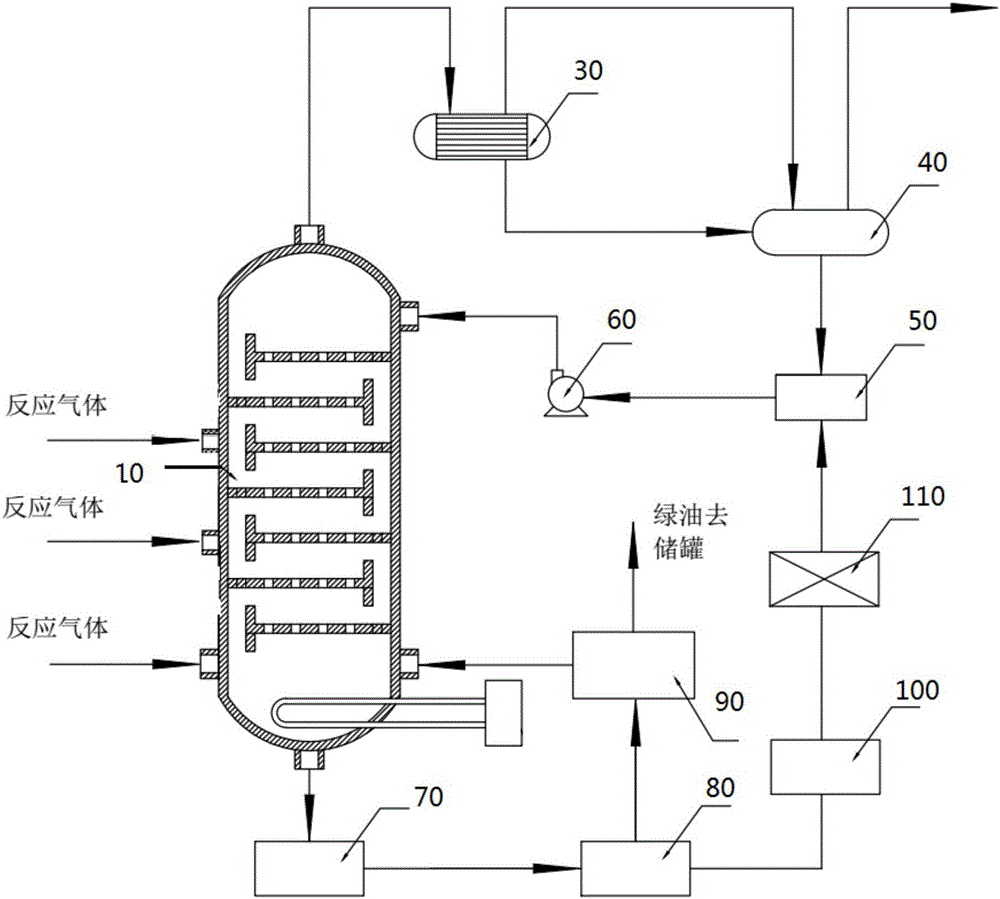

Built-in instant dehydration micro-interface reinforced DMC preparation system and method

InactiveCN113499738APlay a supporting roleGood application effectPreparation from carbon monoxide and oxygenChemical/physical processesMicrobubblesMechanical engineering

The invention provides a built-in instant dehydration micro-interface reinforced DMC preparation system and method, wherein the system comprises a reaction tower; the middle part of the reaction tower is provided with a sealing plate; a first reaction section is arranged above the sealing plate, and a second reaction section is arranged below the sealing plate; the side wall of the first reaction section is connected with a methanol pipeline and a mixed gas pipeline from top to bottom; a first micro-interface generator is arranged in the first reaction section, a second micro-interface generator is arranged above the first micro-interface generator, and the first micro-interface generator and the second micro-interface generator are both connected with the mixed gas pipeline so as to disperse and crush mixed gas into micron-level microbubbles; a microbubble outlet is formed above the first micro-interface generator and clings to the first micro-interface generator; and a bottom outlet of the second micro-interface generator is connected with a micro-bubble pipeline. The preparation system disclosed by the invention is low in required reaction temperature and pressure, few in side reaction, high in methanol conversion rate and worthy of wide popularization and application.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

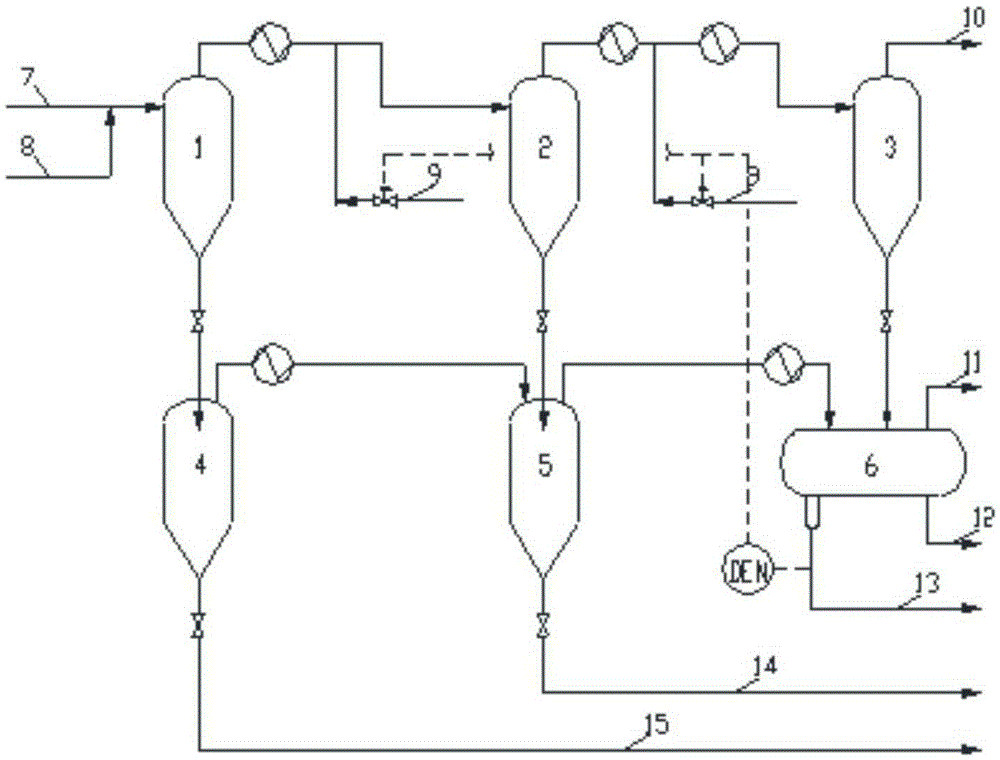

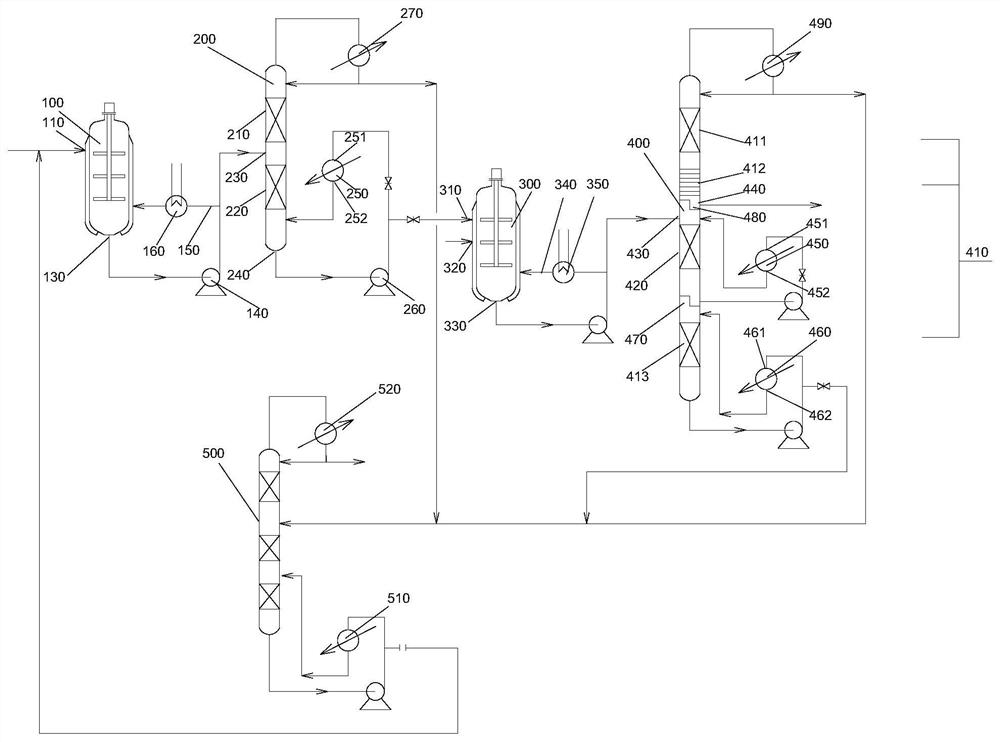

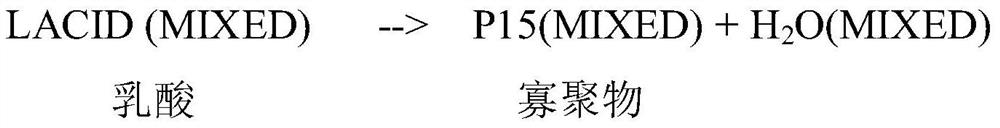

Reaction system and method for preparing lactide from lactic acid

PendingCN112851628AOptimize the reaction routeImprove reaction separation efficiencyOrganic chemistryChemical industryReactive separationChemistry

The invention provides a reaction system and method for preparing lactide from lactic acid. The reaction system comprises a lactic acid oligomerization reaction kettle, a first reactive distillation tower, a lactide synthesis kettle and a second reactive distillation tower which are connected in sequence; the first reactive distillation tower comprises a first tower kettle reboiler, a purification section and a deep oligomerization dehydration reaction section, the purification section and the deep oligomerization dehydration reaction section are arranged from top to bottom, and a first feed port is formed in the tower section between the purification section and the deep oligomerization dehydration reaction section and used for introducing a product of the lactic acid oligomerization reaction kettle into the first reactive distillation tower. According to the reaction system provided by the invention, by uniformly integrating rectification and deep synthesis reaction, the reaction route is optimized, the reaction separation efficiency is improved, the product quality and yield are further improved, and in addition, the effects of saving the equipment cost and saving the occupied area of the equipment are also achieved.

Owner:TOWERSMASTER NANJING

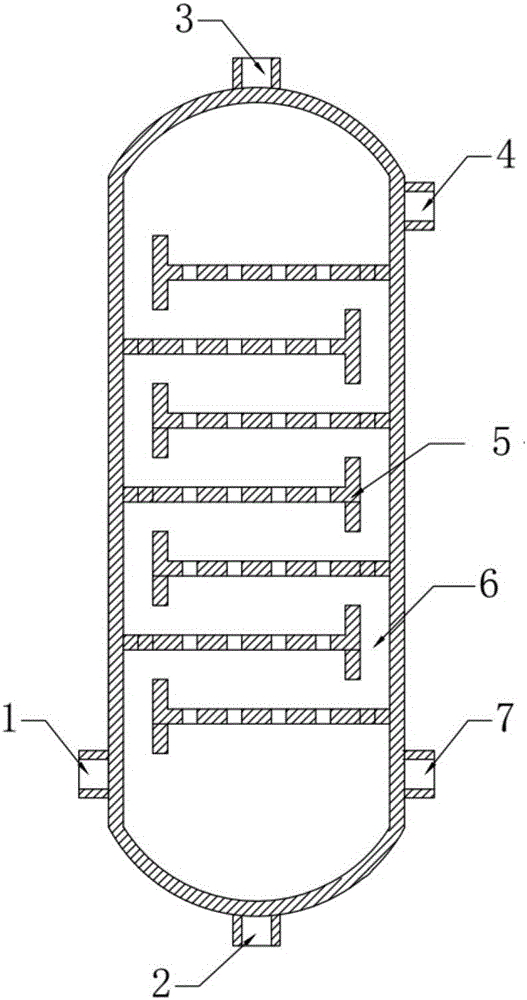

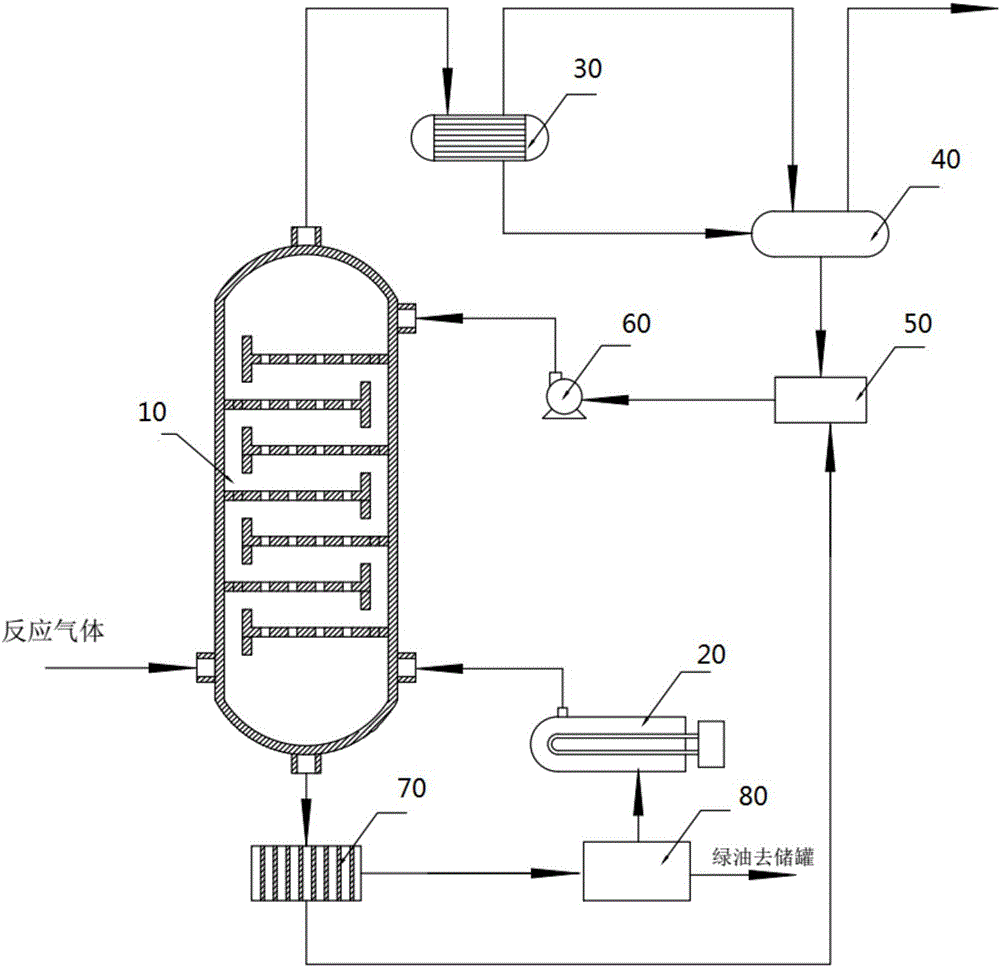

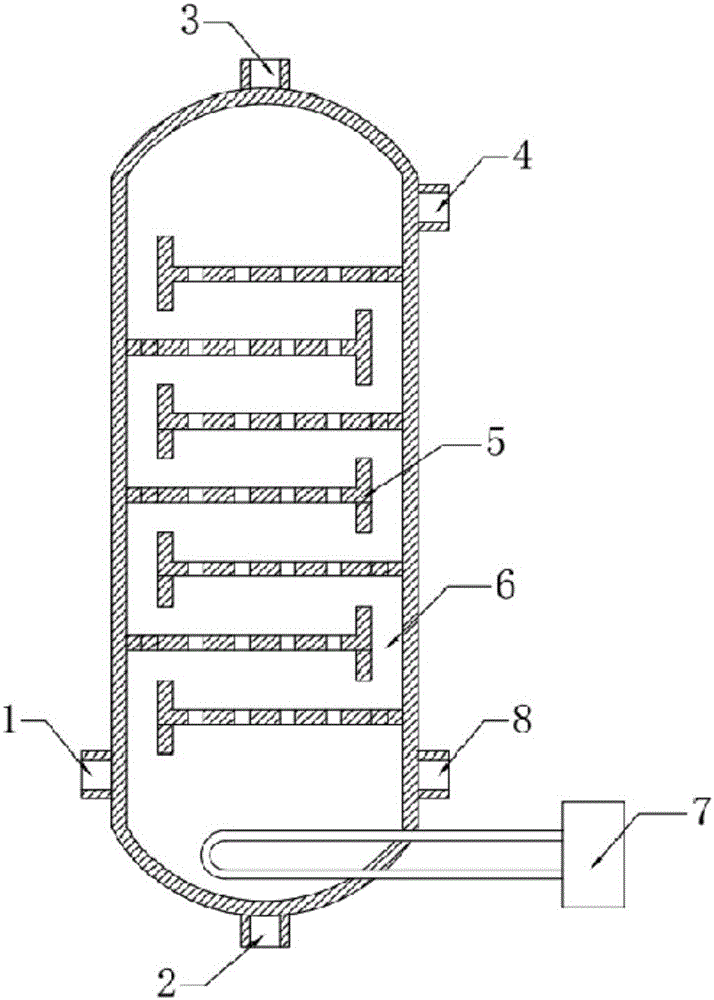

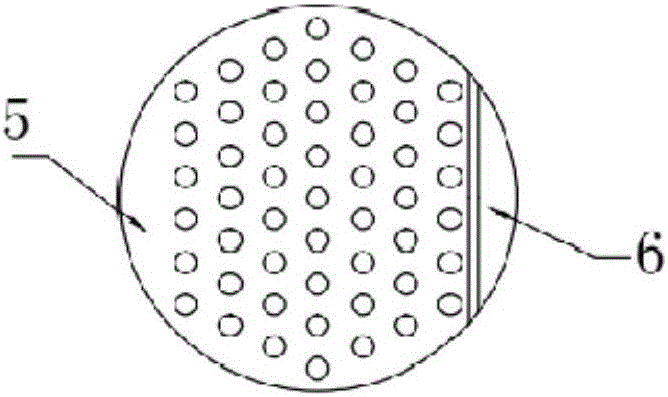

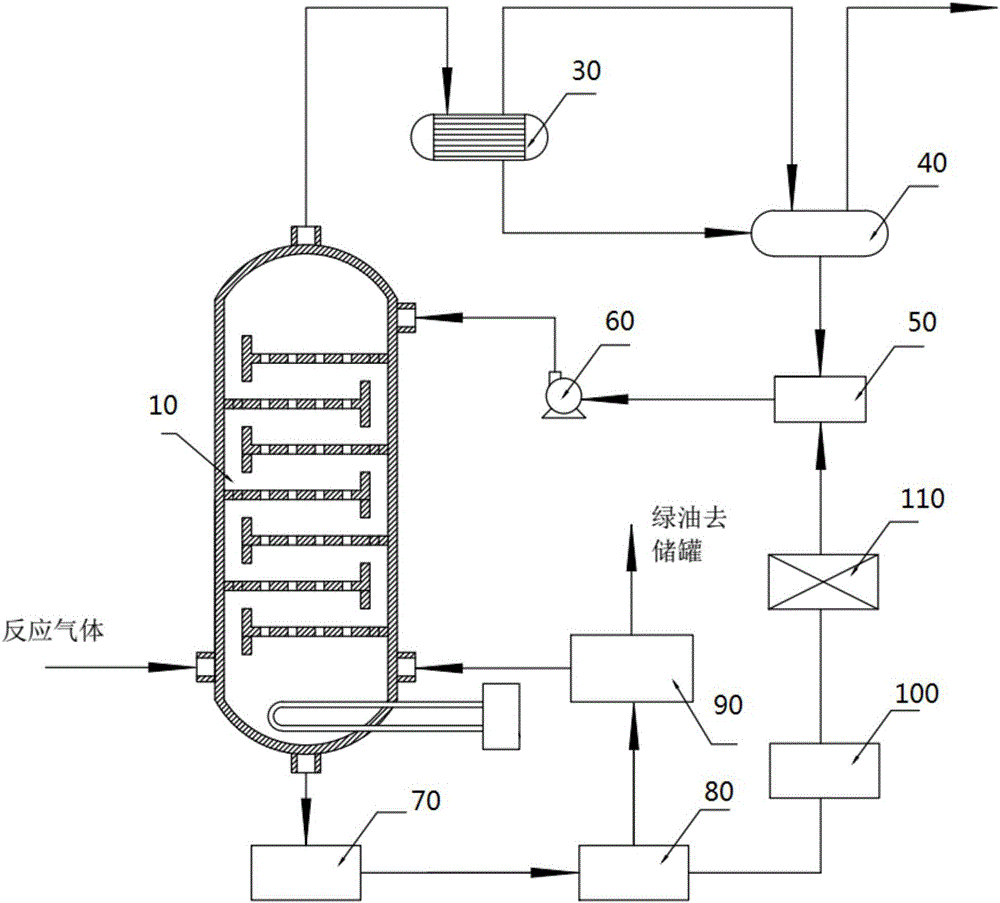

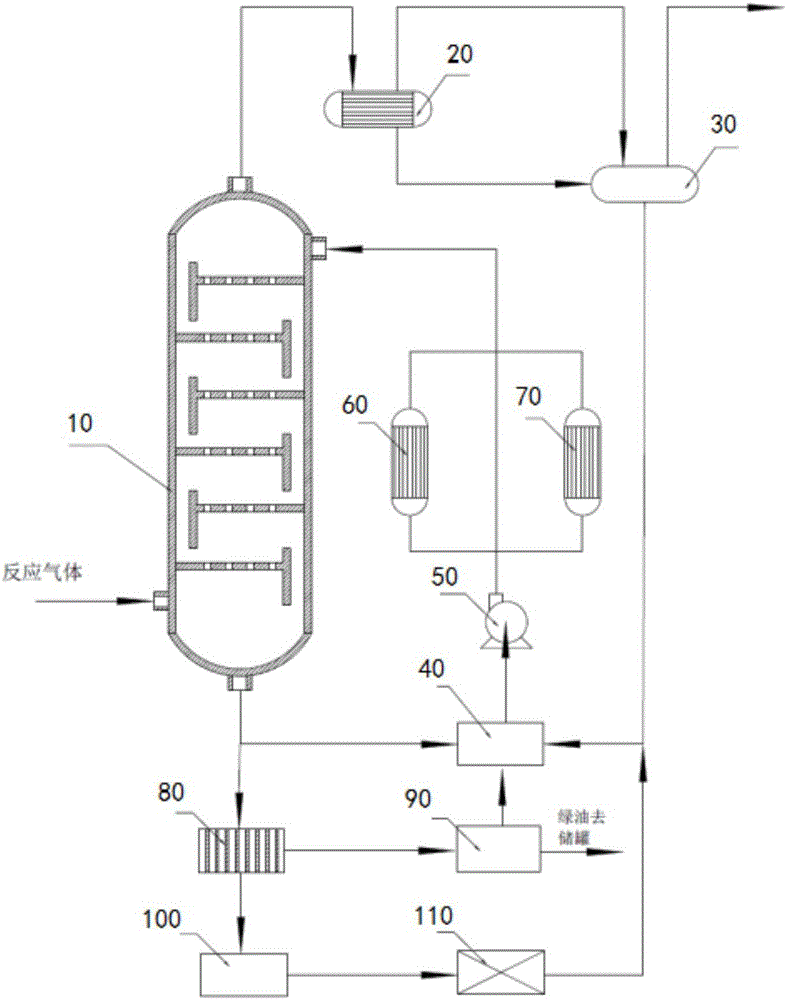

External heating reaction system and method for preparing ethylene

InactiveCN105906469ATimely removalSimple methodHydrocarbon by hydrogenationHydrocarbon purification/separationHydrogenProduct gas

The invention relates to an external heating reaction system and method for preparing ethylene. The system comprises a slurry bed reactor, a condenser, a condensation separator, a condensate storage tank, a solvent pump, a filter device, a green oil removal system and a solvent heater. The slurry bed reactor comprises a shell and a screen plate. A reaction gas inlet, a solvent steam inlet and a liquid outlet are formed in the lower portion of the shell. A gas outlet and a liquid inlet are formed in the upper portion of the shell. The screen plate is located inside the shell, fixed to the inner wall of the shell and located below the liquid inlet and above the reaction gas inlet and the solvent steam inlet. The invention further provides a method utilizing the system for preparing ethylene. The method comprises the steps that acetylene and hydrogen mixed gas is sent into the slurry bed reactor to be subjected to a reaction; ethylene is obtained through condensation and separation of the gas obtained after the reaction; a catalyst obtained through filtering can be recycled. According to the external heating reaction system and method, the problems that according to existing ethylene preparation equipment, internal heat is not likely to be transmitted out, and the catalyst utilization rate is low can be effectively solved.

Owner:SHENWU TECH GRP CO LTD

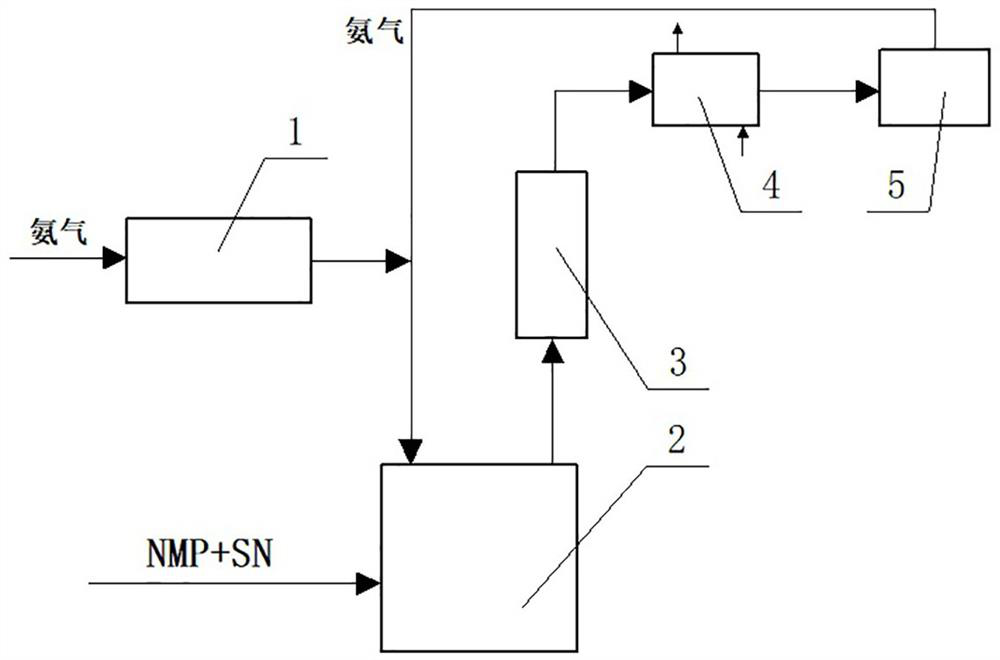

4-aminobutyronitrile preparation method and device adopting pyrrolidone liquid phase method

PendingCN112979496AImprove product qualityReduce energy consumptionOrganic compound preparationPreparation by carboxylic acid amide dehydrationFluid phaseOrganosolv

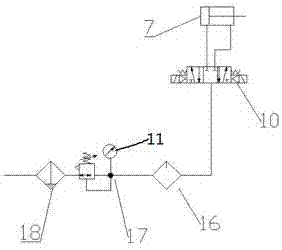

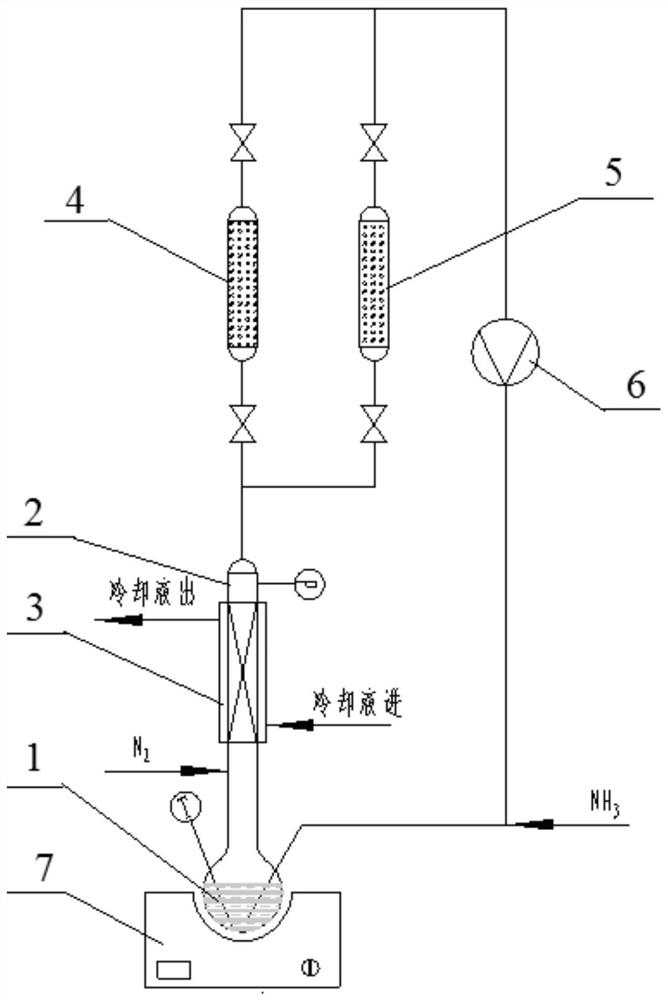

The invention discloses a 4-aminobutyronitrile preparation method and device adopting a pyrrolidone liquid phase method. The preparation method comprises the following steps: mixing pyrrolidone and an organic solvent, and preheating at the preheating temperature of 90-110 DEG C; purifying and preheating ammonia gas, with the preheating temperature being 90-110 DEG C; fully mixing the pyrrolidone, the organic solvent and a catalyst, heating to a certain temperature, and introducing the ammonia gas into a reaction kettle for reaction; and after the reaction is finished, carrying out reduced pressure distillation on the reaction product to obtain the product 4-aminobutyronitrile. The preparation device comprises an ammonia gas pretreatment device, a reaction kettle, an ammonia water separator, a condenser and a gas-liquid separator, wherein a gas outlet of the reaction kettle is communicated with a gas inlet of the ammonia water separator, a gas outlet of the ammonia water separator is communicated with a gas inlet of the condenser, a gas outlet of the condenser is communicated with a gas inlet of the gas-liquid separator, a gas outlet of the gas-liquid separator is communicated with a gas inlet of the reaction kettle, and a water outlet is formed in the gas-liquid separator. The method and the device are low in energy consumption, easy in reaction, high in conversion rate and stable in product quality.

Owner:PINGDINGSHAN PUEN TECH CO LTD

Method for preparing metallic complex film

ActiveCN101135052BReduced stabilityIncrease roughnessLiquid/solution decomposition chemical coatingSuperimposed coating processReduction ActivityHydrogen

The vacuum chemical plating process for preparing composite metal film includes the first pre-modification of porous film by means of sol-gel technology to introduce one transition layer containing metal crystal seed with self-catalytic reduction activity to the chemical plating, and the subsequent vacuum chemical plating by means of forming different vacuum degrees on two sides of the modified porous composite film. The process can raise the hydrogen permeating performance of the composite metal film and raise the stability of the composite metal film.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Prevention and treatment method for botrytis cinerea disease of panax notoginseng

InactiveCN105010005AReduce the incidence of BotrytisReduce the incidence of mildewAnimal corpse fertilisersPlant cultivationDiseasePlant disease

The invention relates to a prevention and treatment method for botrytis cinerea disease of panax notoginseng, comprising following steps: 1. ecological management: 1) applying microorganism fertilizer of Difulai; 2) applying microorganism fertilizer of High Yield Technology; 2. agricultural prevention and treatment; 2. biological prevention and treatment: at early stage of morbidity, spraying 0.3% polyoxin aqua 300 times solution to prevent botrytis cinerea disease; 4. biological control: reinforcing field and surrounding environmental management, reducing host of pathogenic bacteria; 5. physical prevention and treatment: timely removing infected leaves, concentrating and disposing the leaves with high temperature retting, deep burial or destruction; 6. chemical prevention and treatment: spraying 80% mancozeb wettable powder 500 times solution after infection,once every 10 days and for 3 times in a continuous way; By use of the method, botrytis cinerea disease of panax notoginseng can be effectively prevented, average morbidity of botrytis cinerea disease is reduced, production and grade of panax notoginseng are increased, and economic benefit is achieved.

Owner:云南天质弘耕科技有限公司

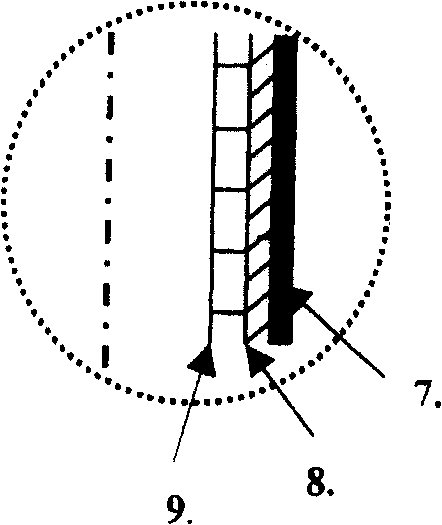

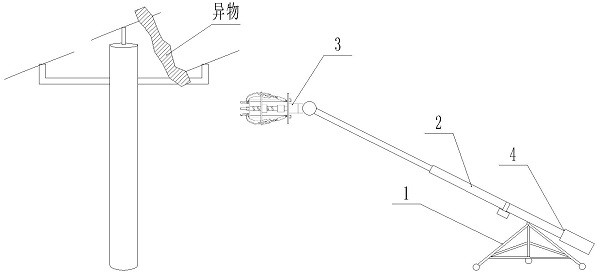

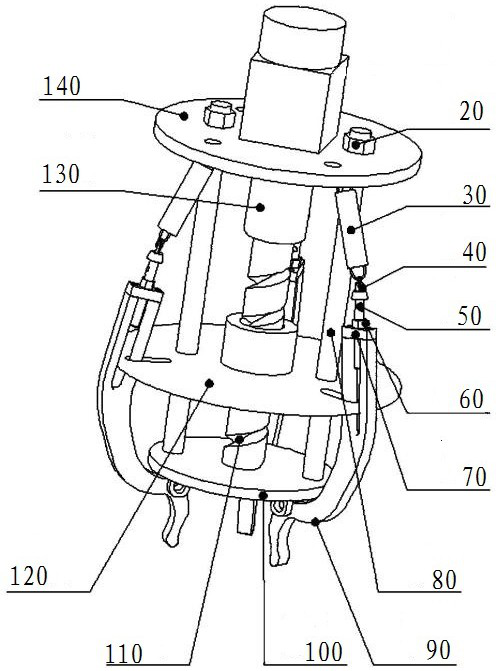

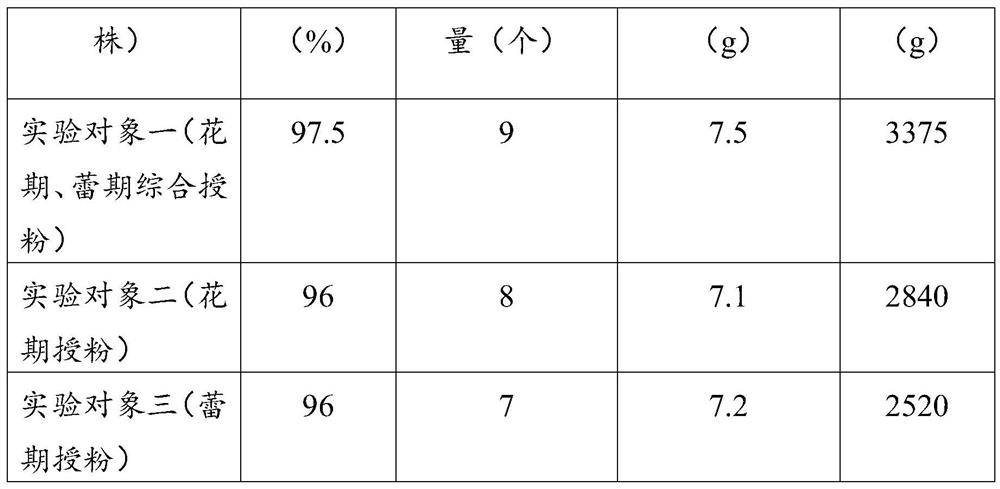

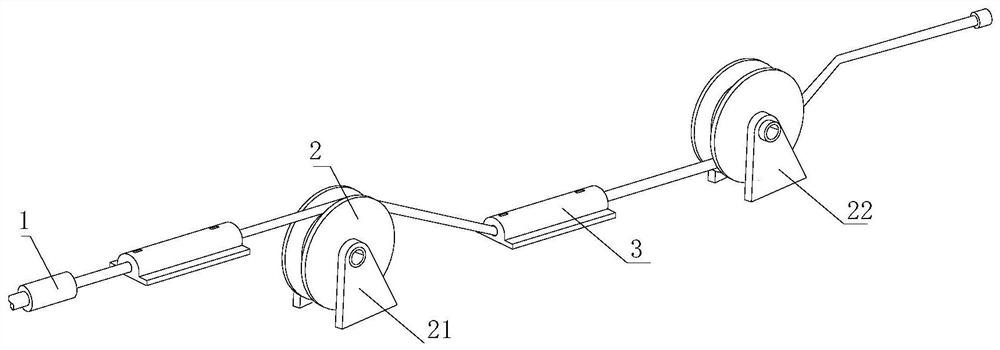

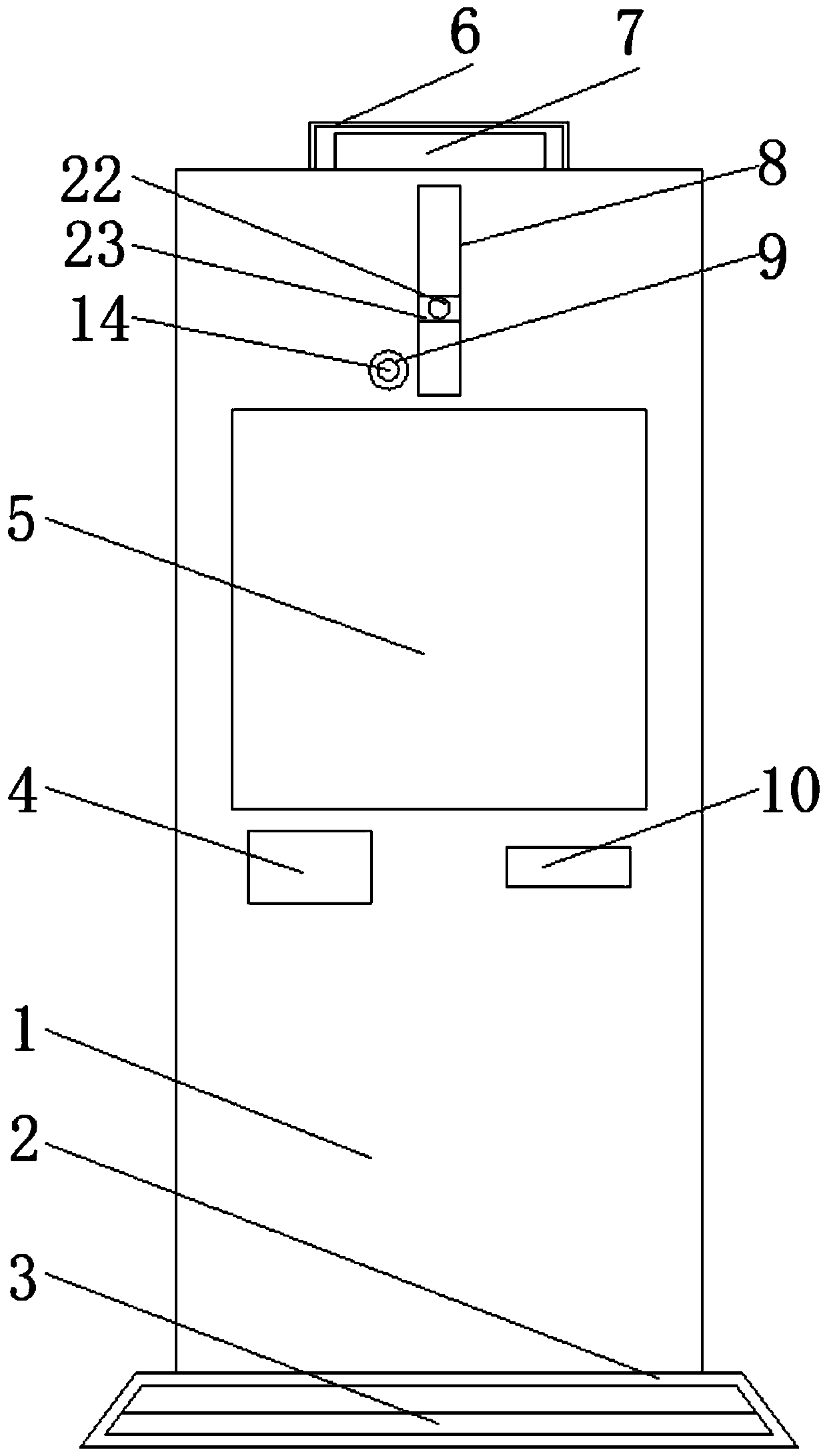

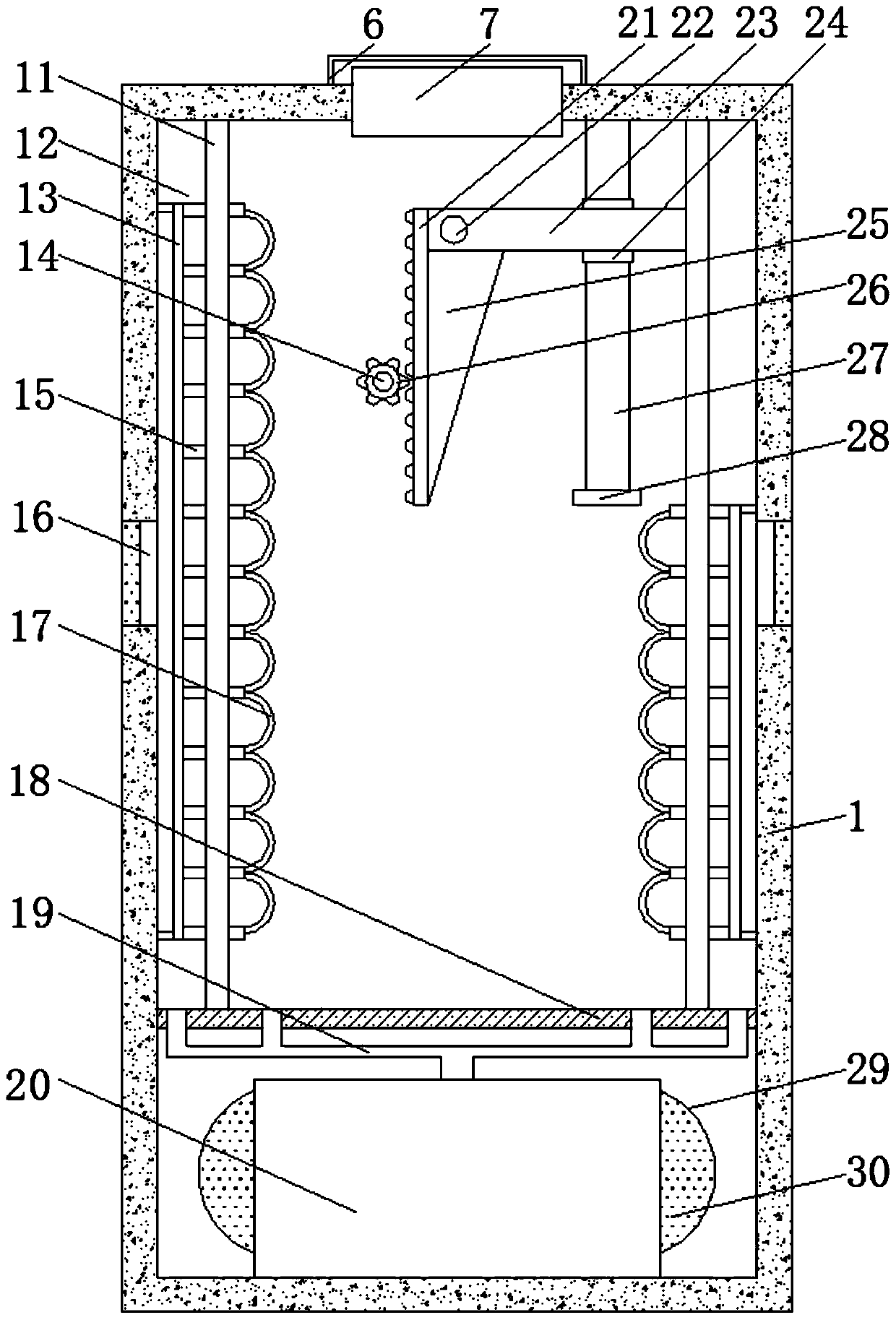

Ground potential overhead line foreign matter removing device

PendingCN114172071AEasy to removeTimely removalApparatus for overhead lines/cablesForeign matterElectric machine

The invention relates to the technical field of power distribution line maintenance, in particular to a ground potential overhead line foreign matter removing device which is characterized in that a telescopic mechanism is connected to the upper portion of a bottom support and comprises a telescopic operating rod, a control mechanism is arranged at the fixed end of the telescopic operating rod, and a foreign matter removing mechanism comprises a bionic gripper and an opening and closing motor for controlling the bionic gripper to act; the end part of the extending end of the telescopic operating rod is connected with a rotating support, the rotating support is connected with a foreign matter removing mechanism, and a rotating motor capable of driving the rotating support to rotate is arranged on the rotating support; the control mechanism is electrically connected with the telescopic motor, the rotating motor and the opening and closing motor. The device is light and easy to carry, can be carried by inspectors on a vehicle, improves the operation timeliness, and greatly reduces the working cost.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

Detection method, device, computer equipment and storage medium of cached data

ActiveCN112540811BImprove detection efficiencyUnderstand in timeExecution paradigmsCode generationParallel computing

Owner:PING AN TECH (SHENZHEN) CO LTD

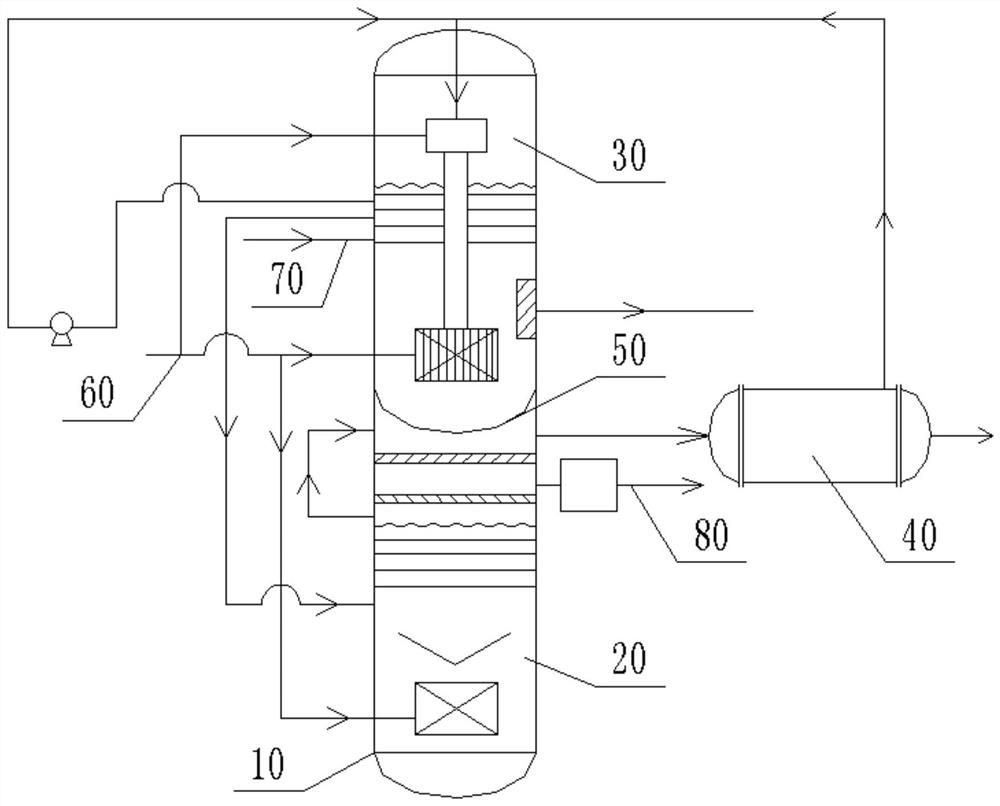

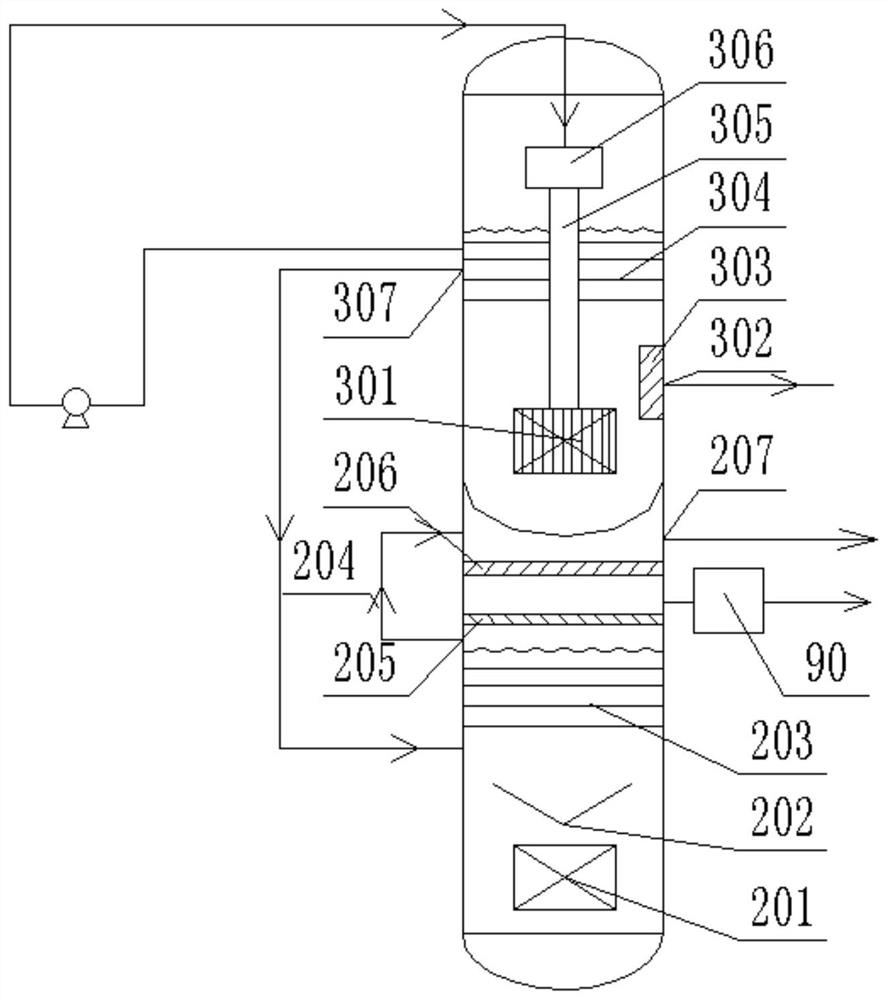

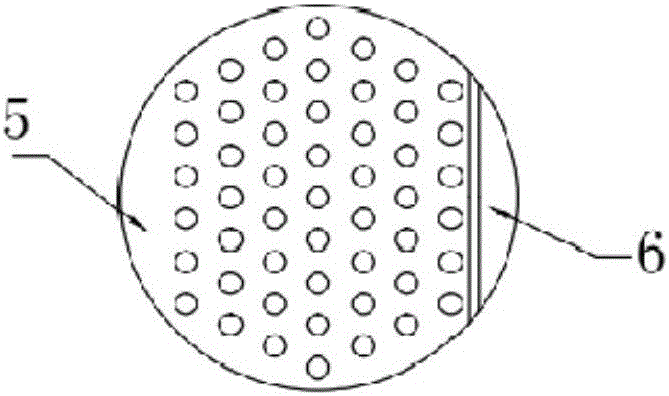

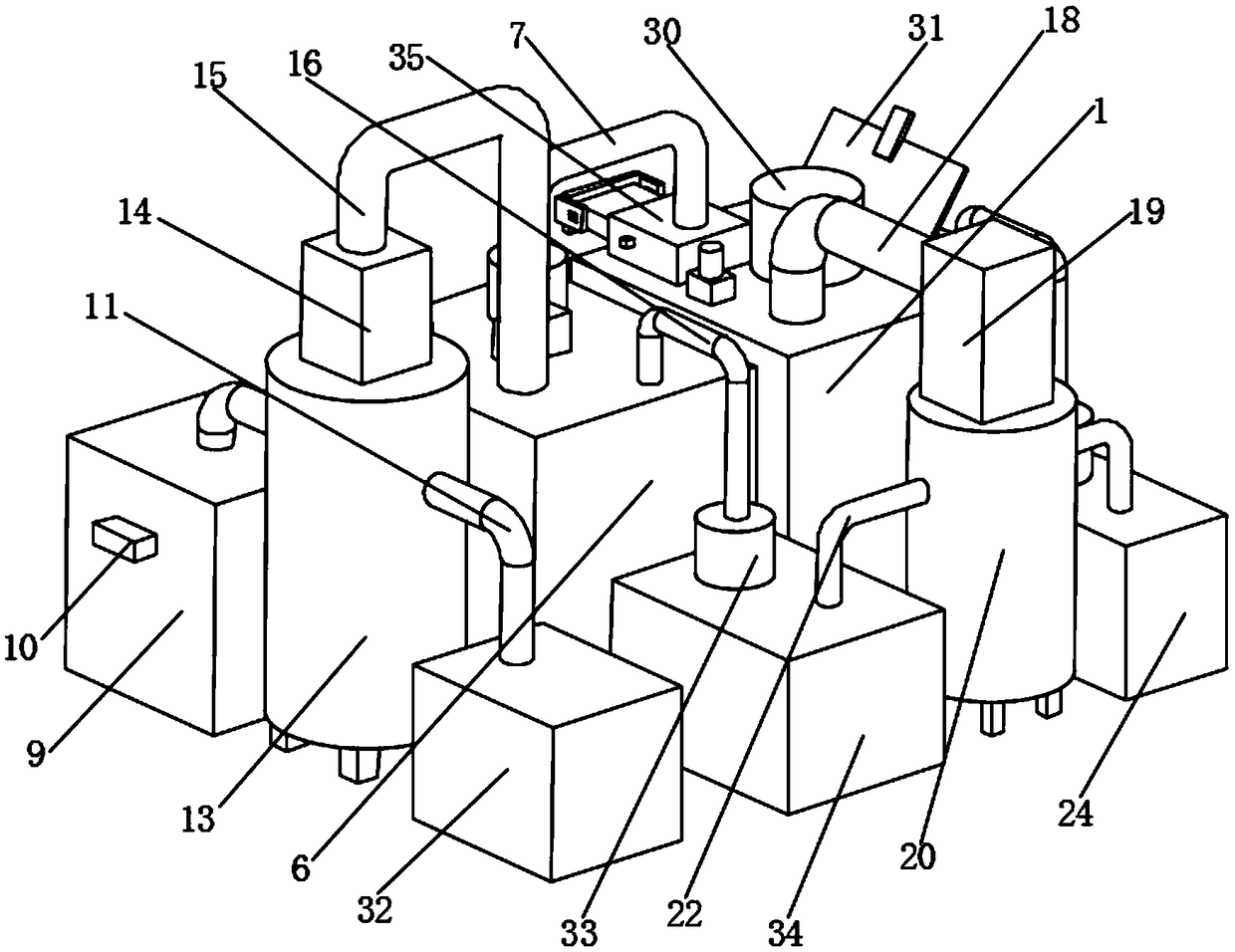

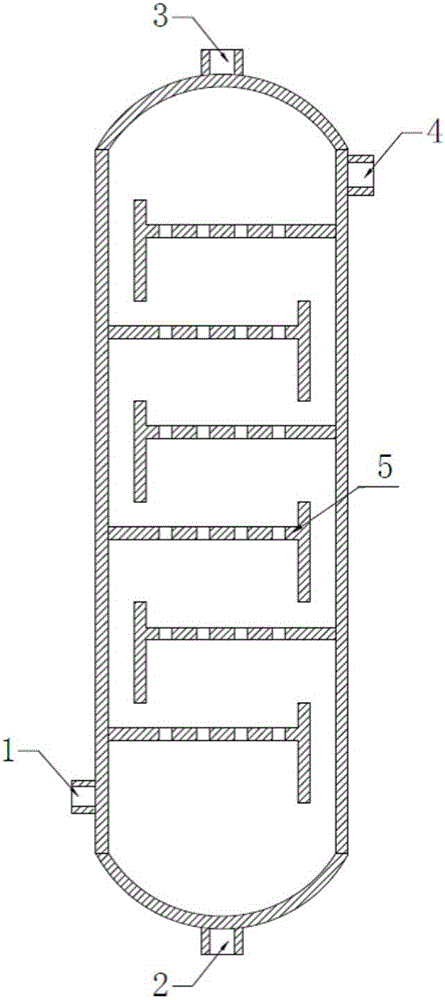

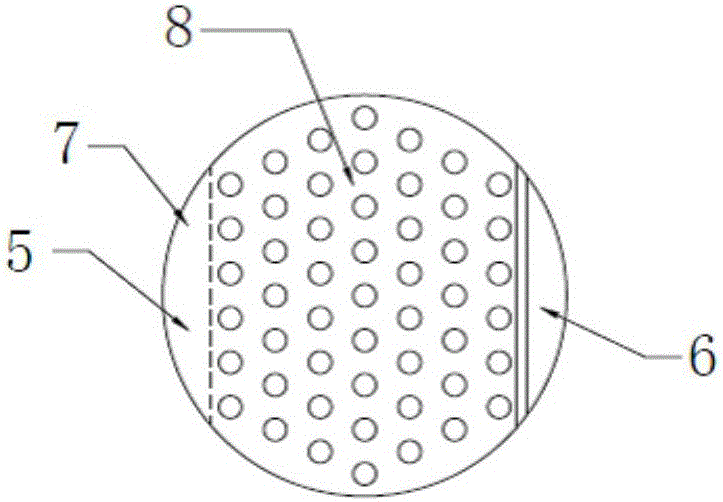

Reaction system and method for preparing ethylene by means of slurry bed reactor

ActiveCN105879792ATimely removalSimple methodHydrocarbon by hydrogenationChemical/physical processesComing outFiltration

The invention relates to a reaction system and method for preparing ethylene by means of a slurry bed reactor. The system comprises the slurry bed reactor, a condenser, a condensate separator, a condensate liquid storage tank, a solvent pump, a tower bottom solvent storage tank, filtration equipment, a green oil removal system, a high-temperature heating device and a catalyst reduction device; the slurry bed reactor comprises a shell, a heater and a sieve plate; the lower portion of the shell is provided with a reaction gas inlet, a liquid solvent inlet and a liquid outlet; the upper portion of the shell is provide with a gas outlet and a liquid inlet; the heater is arranged on the lower portion inside the shell; the sieve plate is located inside the shell and fixed on the inner wall of the shell. The invention further provides a method for preparing ethylene by means of the system. The method comprises the steps that mixed gas of acetylene and hydrogen is fed into the slurry bed reactor for a reaction; the reacted gas is subjected to condensation separation, and ethylene is obtained; a catalyst obtained through filtration can be recycled. By means of the reaction system and method for preparing ethylene by means of the slurry bed reactor, the problems that for ethylene prepared in the prior art, internal heat is not prone to come out, and the utilization rate of the catalyst is low can be effectively solved.

Owner:SHENWU TECH GRP CO LTD

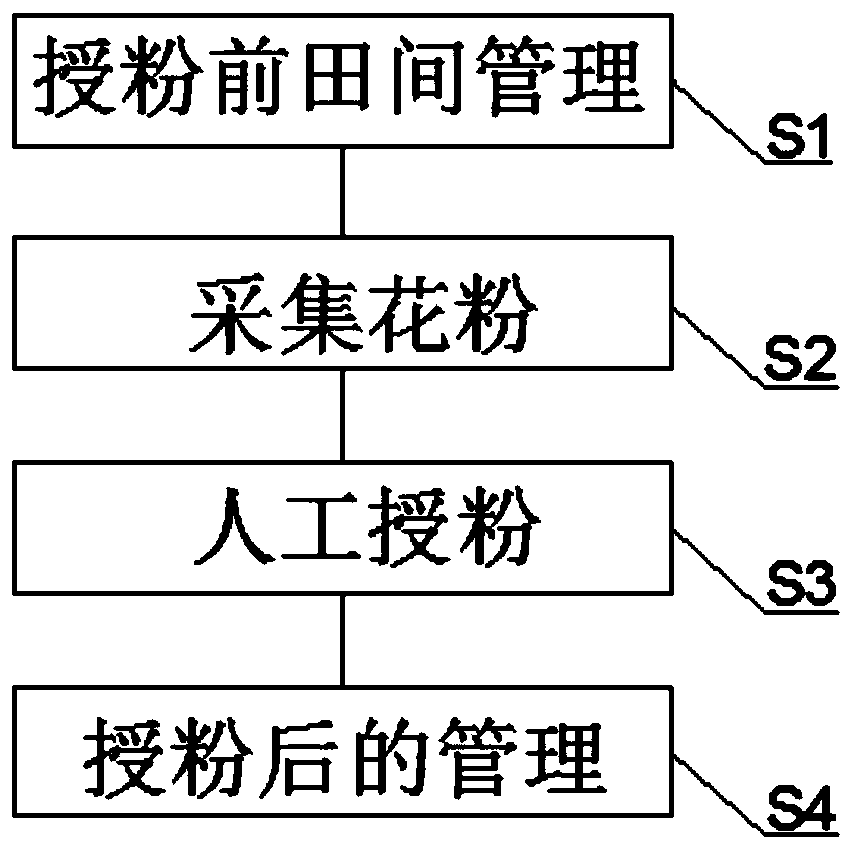

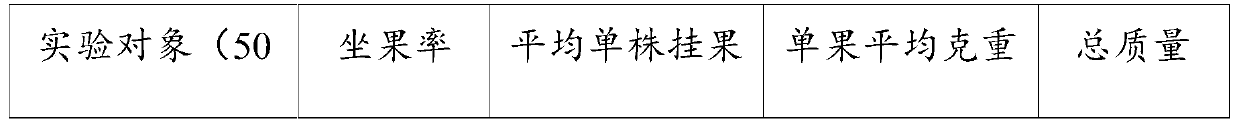

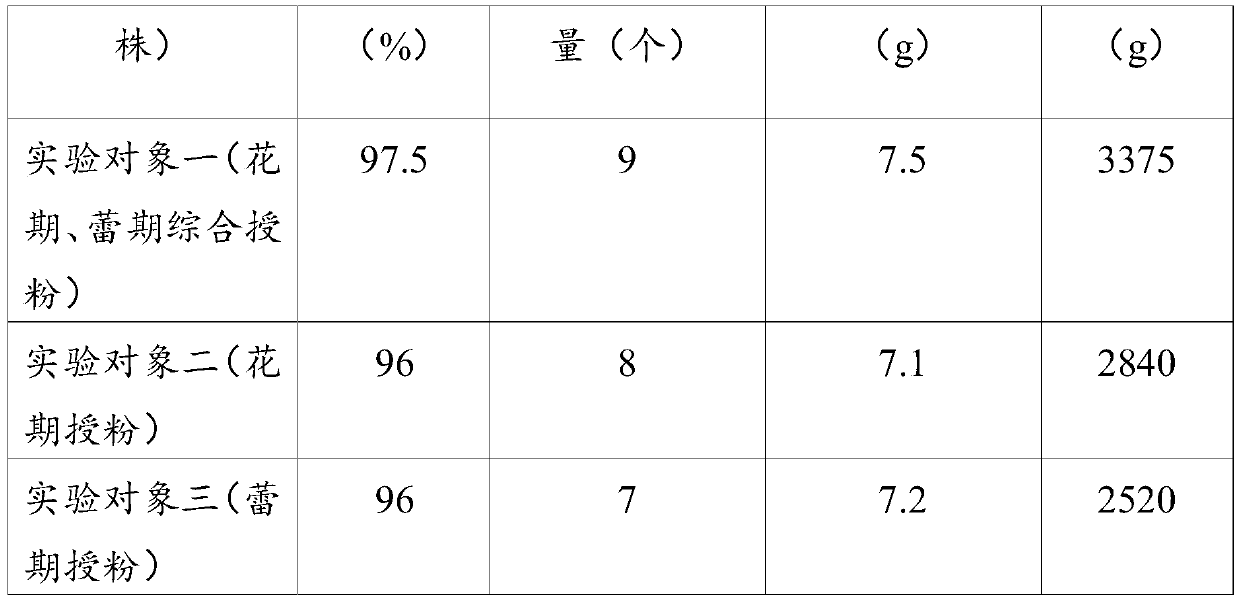

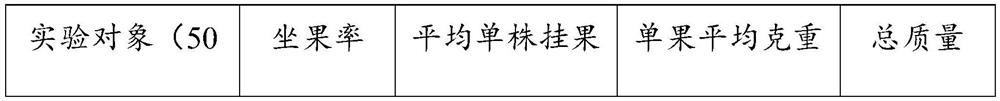

Pollination method capable of increasing yield of amomum villosum

ActiveCN111512957AImprove fruit setting rateTimely removalPlant genotype modificationFruit setAnthesis

The invention discloses a pollination method capable of increasing the yield of amomum villosum. The pollination method capable of increasing the yield of the amomum villosum comprises the following steps: 1, field management before pollination; 2, pollen collection; 3, artificial pollination; and 4, management after pollination. The pollination method has the beneficial effects as follows: a manner combining pollination at a flowering stage and pollination at a bug stage is adopted, artificial pollination is performed on the amomum villosum, the pollination success probability is increased ina repeated point pollination means, meanwhile pollen-free or dense stock plants and male plants are timely removed to increase the fruit setting rate of the amomum villosum, nitrogen, phosphorus andpotassium fertilizer is timely supplemented to guarantee nutrients required for growth of fruits of the amomum villosum, and the yield of the amomum villosum is further increased.

Owner:石相怡

A kind of pollination method to improve the yield of spring Amomum

ActiveCN111512957BImprove fruit setting rateTimely removalPlant genotype modificationFruit setAnthesis

The invention discloses a pollination method for increasing the yield of spring Amomum, and the pollination method for increasing the yield of Amomum comprises the following steps: 1. field management before pollination, 2. collecting pollen, 3. manual pollination, 4. pollination after pollination manage. Beneficial effects: artificially pollinate the spring amomum by combining pollination at the flowering stage and pollination at the bud stage, using repeated spot pollination to increase the probability of successful pollination, and remove pollen-free or dense female plants and male plants in time , to improve the fruit setting rate of Amomum sativa, and supplement nitrogen, phosphorus and potassium fertilizers in time to ensure the nutrients needed for the growth of Amomum sativa fruit, thereby increasing the output of Amomum sativa.

Owner:石相怡

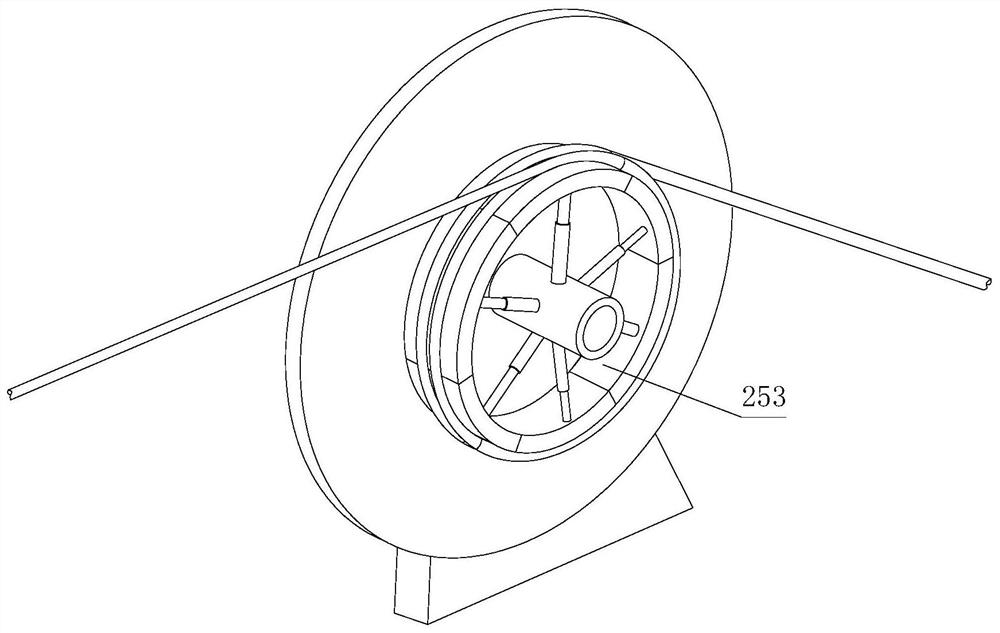

A high-power fiber laser indicating light protection device and its implementation method

ActiveCN111596408BFree from damageEffective strippingCoupling light guidesFibre mechanical structuresErbium lasersMaterials science

The invention discloses a high-power optical fiber laser indicating light protection device and its implementation method, belonging to the field of optical fiber lasers, comprising an indicating light laser, an optical fiber winding mechanism and a cladding light stripping mechanism, an optical fiber connected to the indicating light laser and two sets of The fiber winding mechanism is connected with the cladding optical stripping mechanism. The fiber winding mechanism is used to change the diameter of the fiber coil and the angle of the fiber bending. The core light in the fiber enters the cladding from the core, and the fiber winding mechanism takes the fiber The core light is converted into cladding light; through the cladding light stripping mechanism twice, the stripping can be carried out step by step, which can effectively strip the reverse core light and cladding light of the high-power fiber laser, and protect the pointing light laser from damage. But it will not cause the attenuation of the indicated light intensity.

Owner:GW (SHANGHAI) LASER TECH CO LTD

Method for preparing long-chain dicarboxylic dialkyl ester

InactiveCN1212304CEasy to separateLess side effectsOrganic compound preparationCarboxylic acid esters preparationAlcoholDistillation

The method for preparing long-chain dicarboxylic acid dialkyl ester uses dicarboxylic acid of C8-C18 and excess C6-C18 monobasic alcohol as raw material, adopts proper acidic resin as catalyst, and makes them implement esterification reaction at higher temp., at the same time of esterification the formed water content is evaporated out, the conversion rate of reaction can be raised, and the reaction liquid can be undergone the processes of distillation, etc. and can be purified. Said invention has the advantages of short process, high esterification rate, short operation period, and low energy consumption, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

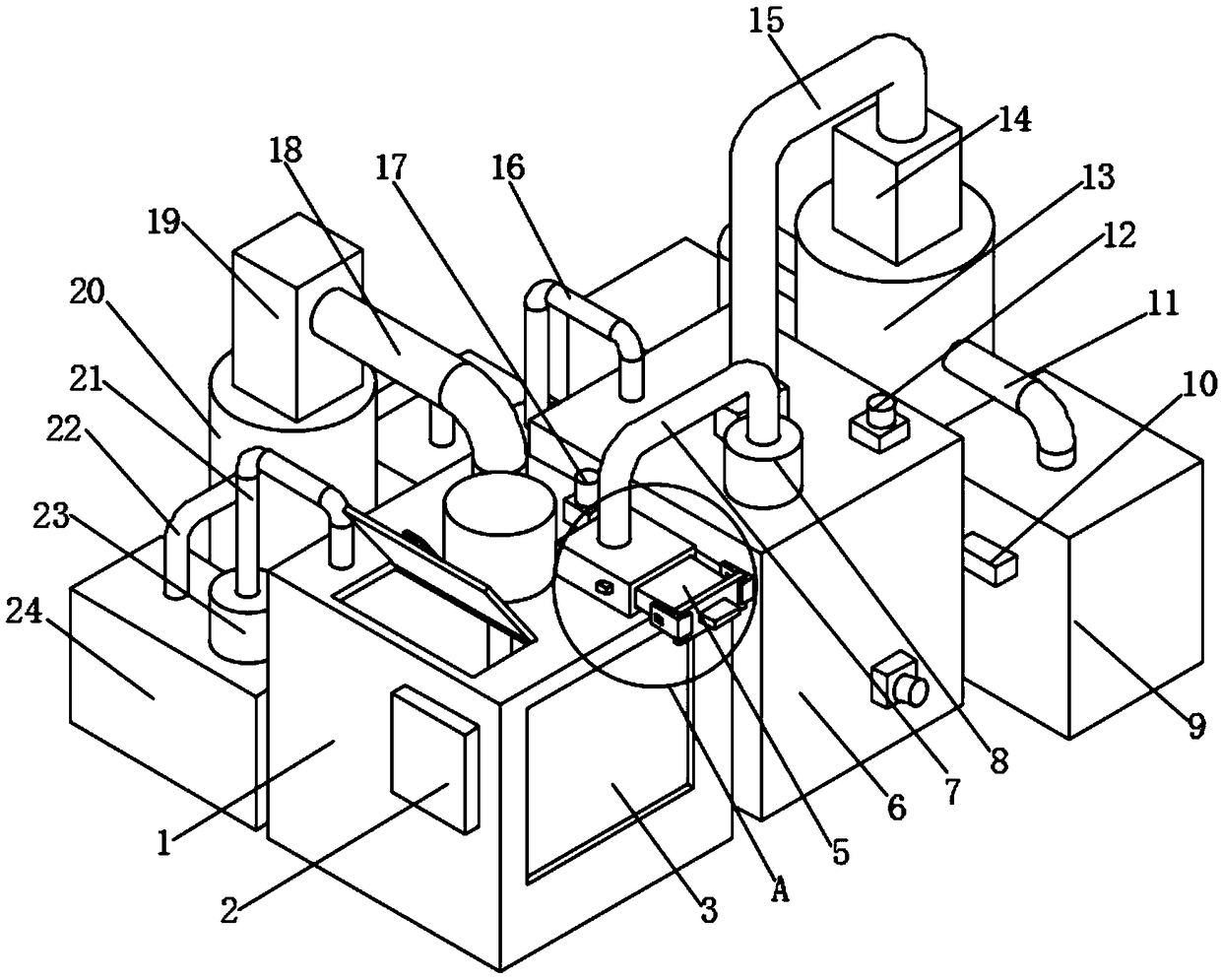

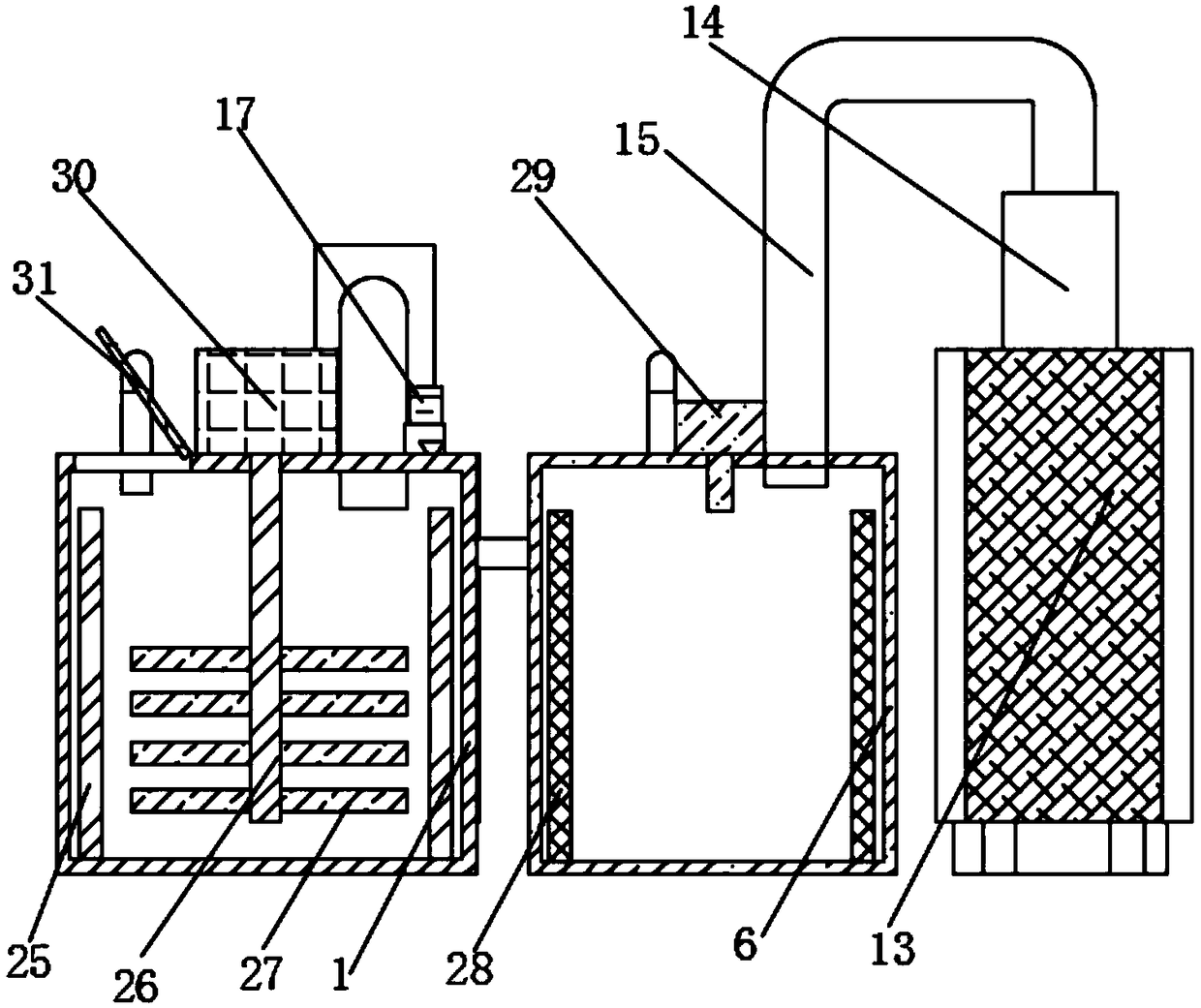

Device for making plasticizer DOTP

InactiveCN109012531ATimely removalStable structureGroup 5/15 element organic compoundsChemical/physical/physico-chemical stationary reactorsPlasticizerEngineering

The invention discloses a device for making a plasticizer DOTP. The device comprises a first reaction box, a motor and a second air outlet tube are arranged in a middle part of the upper surface of the first reaction box, two first heating tubes and a rotating shaft are disposed in the first reaction box, the first heating tubes are disposed on the left and right sides of the first reaction box, the output shaft of the motor is fixedly connected to the rotating shaft through the first reaction box, fixed axles are subjected to array distribution on the side surface of the rotating shaft, a second reaction tank is arranged on the right side of the first reaction tank, a first water pump is arranged on the upper surface of a second reaction tank, and a first connecting pipe is arranged at awater inlet of a first water pump. The device has a firm structure, is stable and durable, can be mass-produced, improves production efficiency, can reduce unit manufacturing cost, brings convenienceto the use, and can change a heat transfer mode, improves the mass and heat transfer during an esterification process, and removes the water in time during a production process.

Owner:珠海市高栏联合新材料有限公司

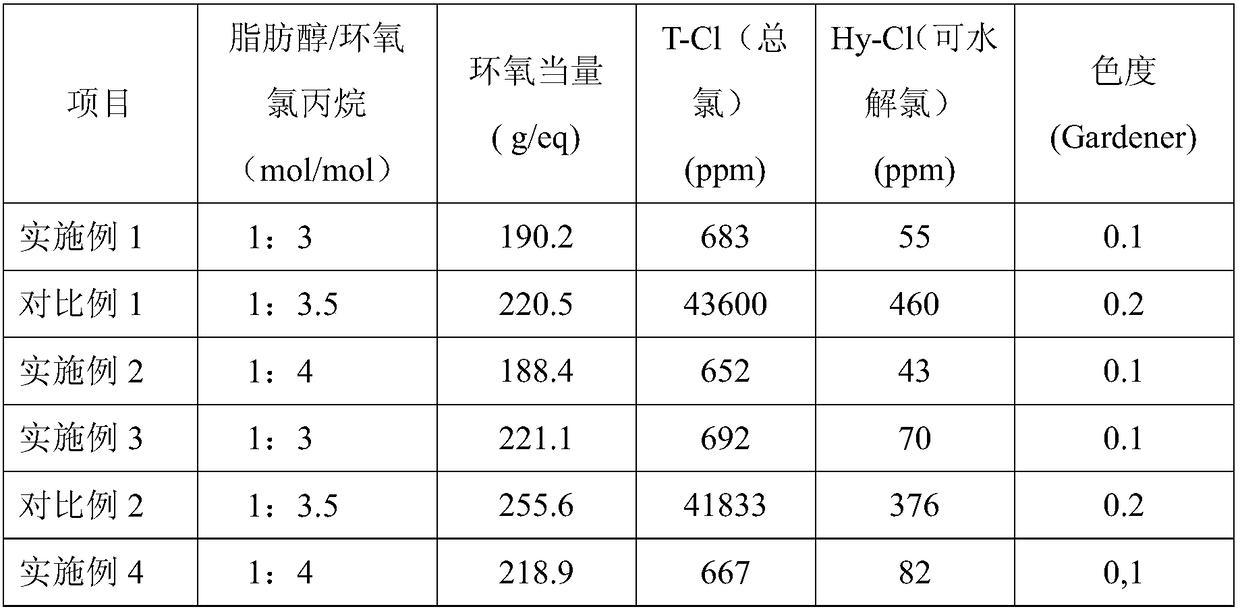

A kind of preparation method of reactive epoxy resin diluent with low total chlorine content

The invention belongs to the technical field of epoxy resin preparation, and particularly relates to a preparation method of an active epoxy resin diluent with the low total chlorine content. The method comprises the steps that a compound catalyst is adopted in an etherification open loop reaction to improve the reaction efficiency, an alkaline solution and a mixture of a special reducing agent tris(2-carboxyethyl)phosphine and Zn powder are continuously added into a reaction system of an obtained chlorohydrin ether intermediate to inhibit a side reaction, and mixed liquid of alkali metal hydroxides and quaternary ammonium salt is lastly added for refining. According to the preparation method, the technology is stable, few by-products are generated, material consumption and energy consumption are low, and a large amount of epoxy chloropropane is not needed in the epoxy resin preparation process, so that the production cost is reduced; the product is stable, low in hydrolyzed chlorine content and low in chrominance; the epoxy resin diluent prepared through the method has the advantages that the total chlorine content is lower than 700 ppm, the hydrolyzable chlorine content is lower than 100 ppm, the viscosity is lower than 6 mPa / s, and the epoxide equivalent ranges from 245 g / eq to 275 g / eq.

Owner:辽阳鑫宇化工有限公司

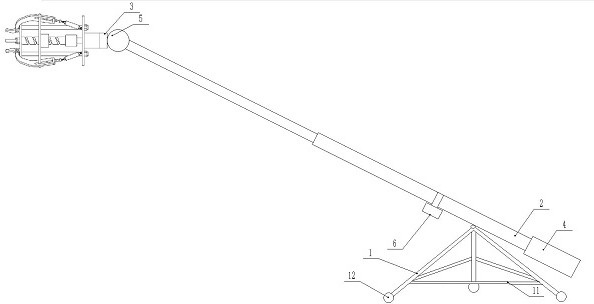

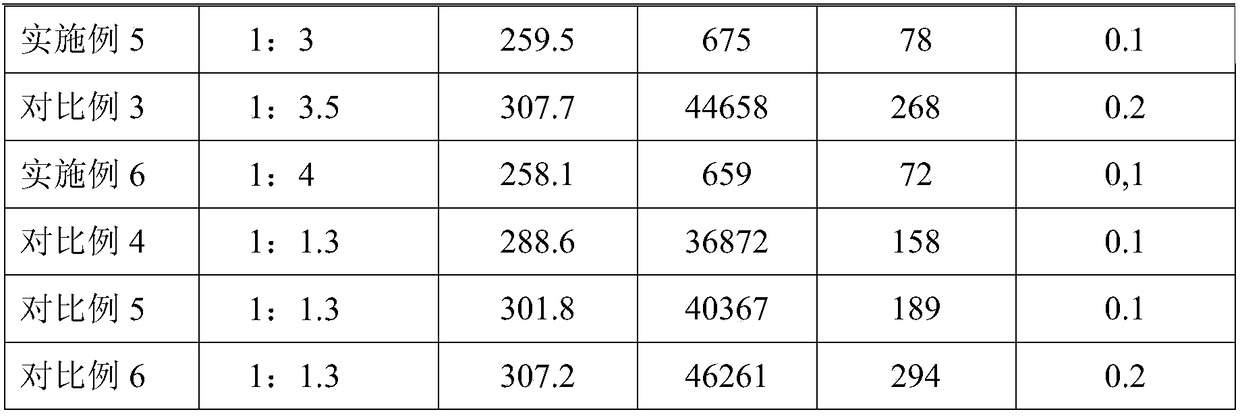

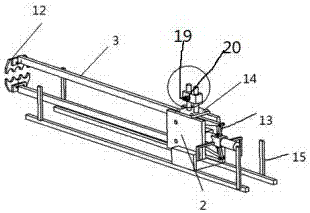

Scraper mechanism of cold-rolling emulsion magnetic filter

The invention relates to a scraper transmission mechanism of a cold-rolled emulsion magnetic filter, belonging to the technical field of cold-rolling equipment in the metallurgical industry. The technical solution is: including track (1), car body (2), upper scraper arm (3), lower scraper arm (4), upper top wire (5), lower top wire (6), cylinder (7) and scraper (12), the car body (2) is set on the track (1), the upper scraper arm (3) and the lower scraper arm (4) are respectively fixed on the car body (2) through pin shafts, the upper scraper arm (3) and One end of the lower scraper arm (4) is connected by a cylinder (7), and the other ends of the upper scraper arm (3) and the lower scraper arm (4) are respectively equipped with a scraper (12), the upper scraper arm (3) and the lower scraper arm ( 4) There are upper top wire (5) and lower top wire (6) respectively. The invention has the beneficial effects of avoiding the damage to the motor, the chain connection block and the pin shaft structure when the four-bar linkage mechanism in the prior art hits the block, and effectively improving the operating life of the scraper transmission mechanism.

Owner:HANGANG GRP HANBAO IRON & STEEL

A kind of preparation method of long carbon chain cyano acid

ActiveCN107325022BTimely removalOrganic compound preparationCarboxylic acid amides preparationPtru catalystOrganic synthesis

Owner:WUXI YINDA NYLON

Reaction system for preparing ethylene by inputting gas at different heights and method

InactiveCN105906470ATimely removalSimple methodHydrocarbon by hydrogenationHydrocarbon purification/separationHydrogenSlurry

The invention relates to a reaction system for preparing ethylene by inputting gas at different heights and a method. The system comprises a slurry state bed reactor, a condenser, a condensation separator, a condensate storage tank, a solvent pump, a tower bottom solvent storage tank, a filtering device, a green oil removing system, a high-temperature heating device and a catalyst reduction device. The slurry state bed reactor comprises a shell, a heater and a screen plate. The lower portion of the side face of the shell and the middle portion of the side face of the shell are provided with reaction gas inlets, and the lower portion of the shell is provided with a liquid solvent inlet and a liquid outlet. The upper portion of the shell is provided with a gas outlet and a liquid inlet. The invention further provides the method for preparing ethylene through the system. The method includes the steps of sending mixed gas of acetylene and hydrogen into the slurry state bed reactor for reaction, conducting condensation separation on reaction gas to obtain ethylene, and conducting filtering to obtain a catalyst which can be recycled. The problems that in the prior art, when ethylene is prepared, inner heat is not transmitted out easily, and the catalyst is low in utilization rate are solved.

Owner:SHENWU TECH GRP CO LTD

Reaction system and method for preparing ethylene by using slurry bed reactor

ActiveCN106045809ATimely removalSimple reactivityHydrocarbon by hydrogenationChemical/physical processesSolventChiller

The invention relates to a reaction system and method for preparing ethylene by using a slurry bed reactor. The system comprises the slurry bed reactor, a condenser, a condensation separator, a solvent pump, a solvent mixing tank, a solvent temperature control system, filter equipment, a green oil removing system, a high-temperature heating device and a catalyst reduction device, wherein the solvent temperature control system comprises a heater, a solvent bypass and a cooler; the solvent mixing tank communicates with the slurry bed reactor; the filter equipment communicates with the slurry bed reactor; the condenser communicates with the slurry bed reactor; the solvent temperature control system communicates with the slurry bed reactor; the condenser, the condensation separator and the solvent mixing tank communicate with one another successively; the solvent mixing tank, the solvent pump and the solvent temperature control system communicate with one another successively; the filter equipment, the high-temperature heating device, the catalyst reducing device and the solvent mixing tank communicate with one another successively; and the filter equipment, the green oil removing system and the solvent mixing tank communicate with one another successively. By the reaction system and method, the problems that heat inside prepared ethylene cannot be transferred out easily, and the utilization rate of a catalyst is low can be solved effectively.

Owner:北京锦泰诚瑞科技发展有限公司

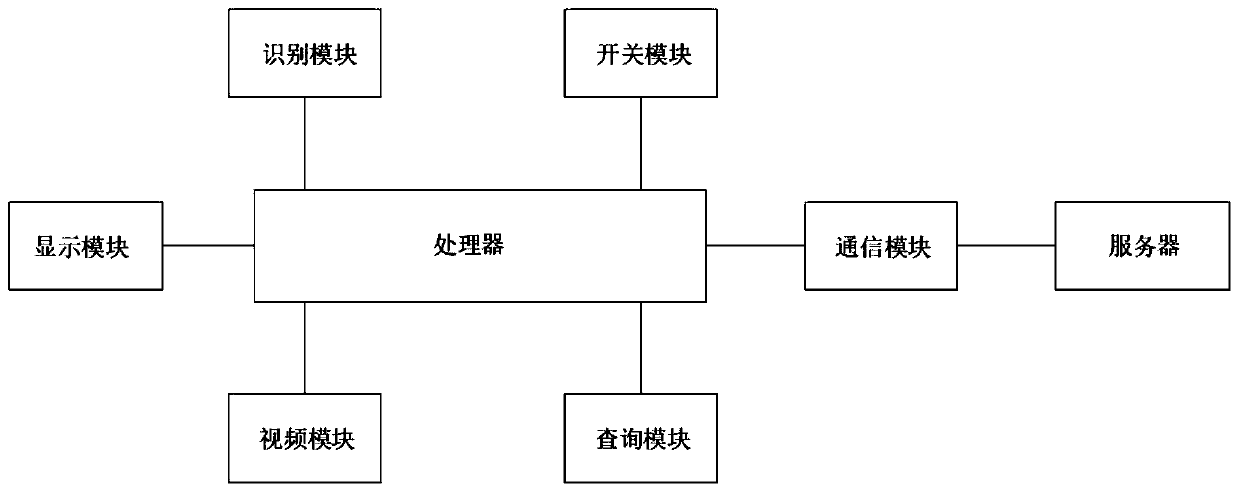

Internet-based business information query system

PendingCN110989784AImprove cooling effectTimely removalDigital data authenticationDigital processing power distributionCold airThe Internet

The invention discloses an Internet-based business information query system. The system includes an inquiry device body, the bottom of the query device body is fixedly connected with a base. A waterproof plate is fixedly connected to the bottom of the inner wall of the base, a touch display screen and a card recognizer are embedded in the front face of the query device body, the card recognizer islocated below the touch display screen, and a card inserting opening is formed in the position, located below the touch display screen, of the front face of the query device body. According to the Internet-based business information query system, the refrigerator is matched with the shunting air pipe for use, cold air is continuously conveyed into the query device body and the heat insulation cavity, thereby performing heat radiation and cooling on the inner part of the query device body; and through cooperative use of the first heat insulation plate and the heat insulation cavity, when external air and heat enter, the external air and the heat are limited in the heat insulation cavity, and the heat of the external air and the heat of the heat insulation cavity are reduced through cold air, so that the external heat can be effectively prevented from entering the query device body.

Owner:东营艾凡信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com