Patents

Literature

30results about How to "Quick water removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

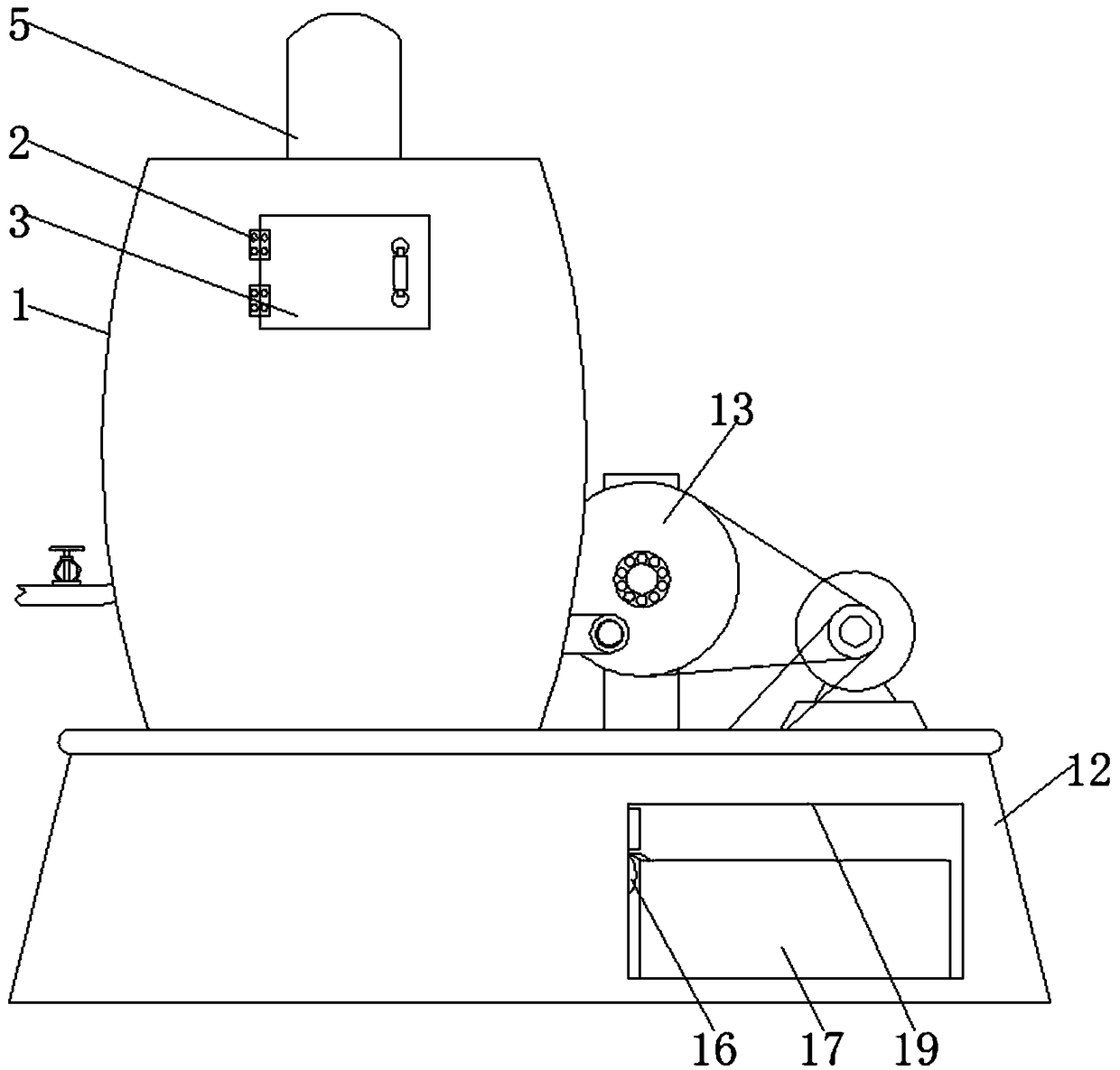

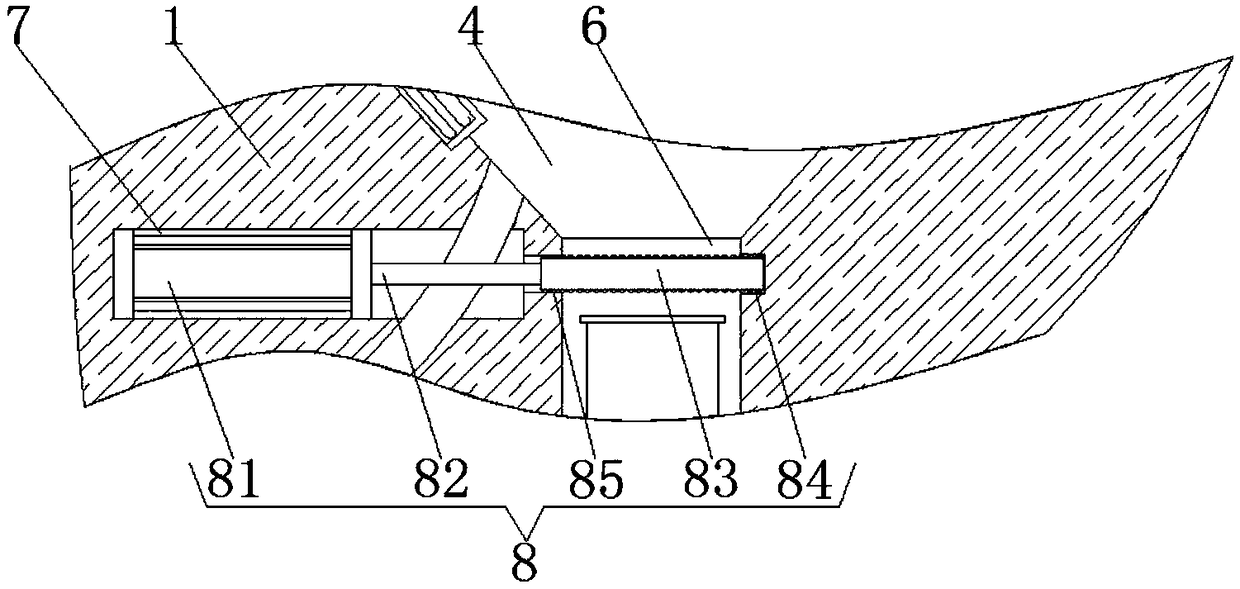

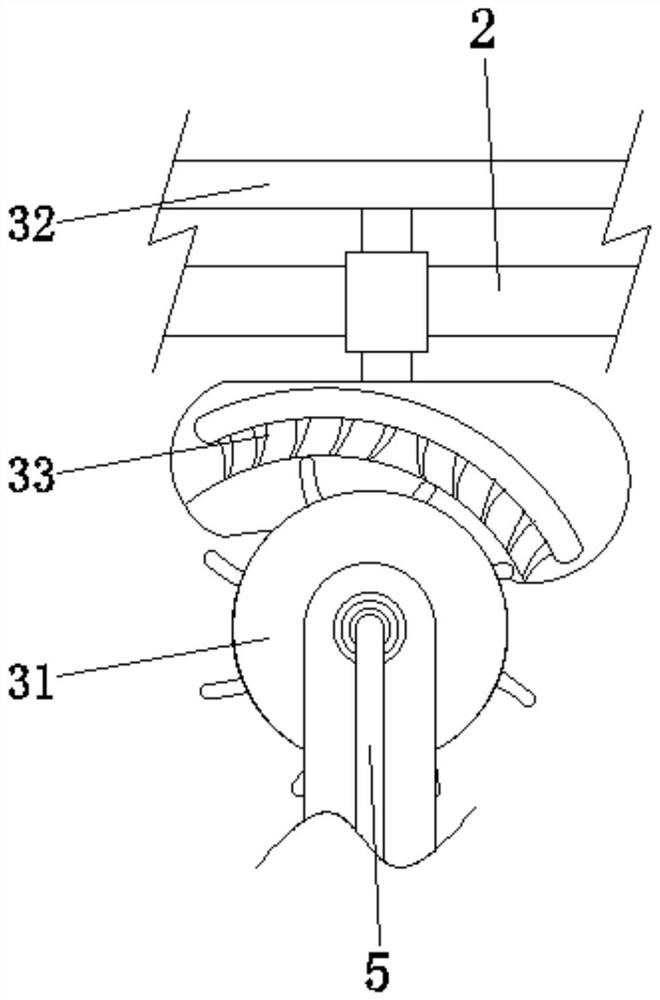

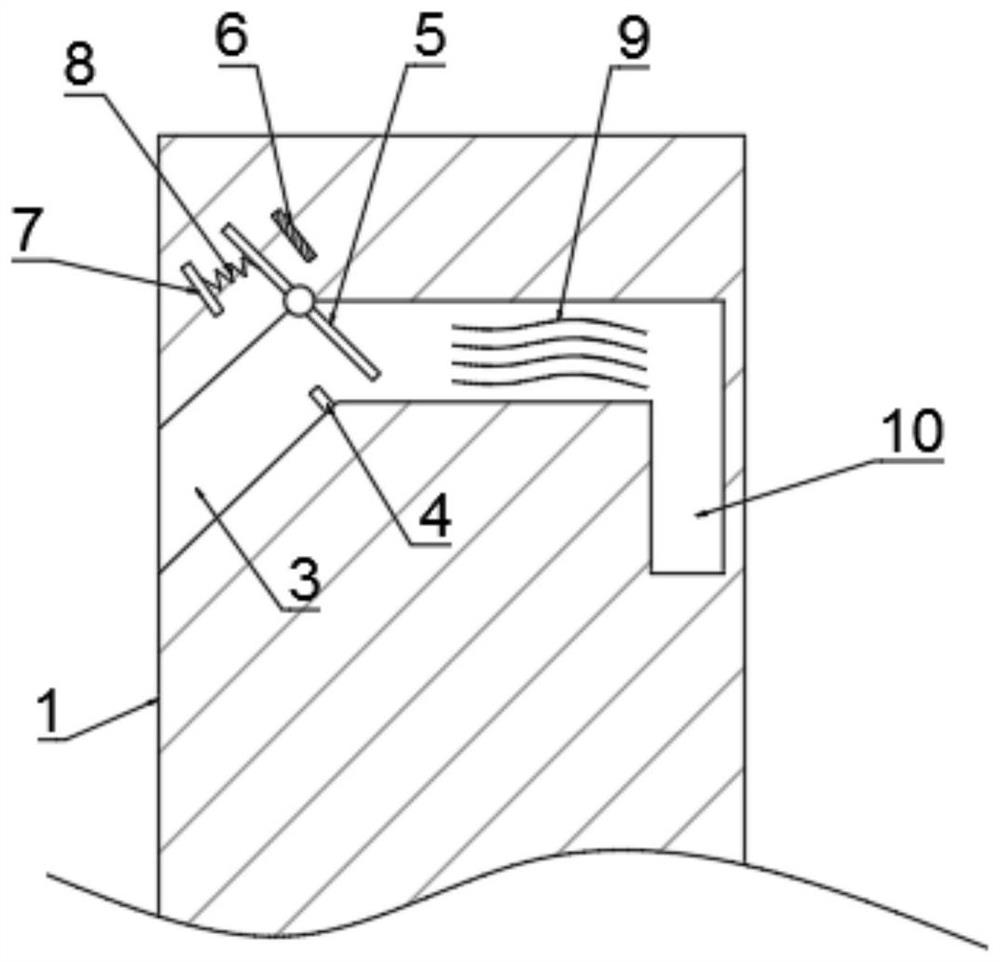

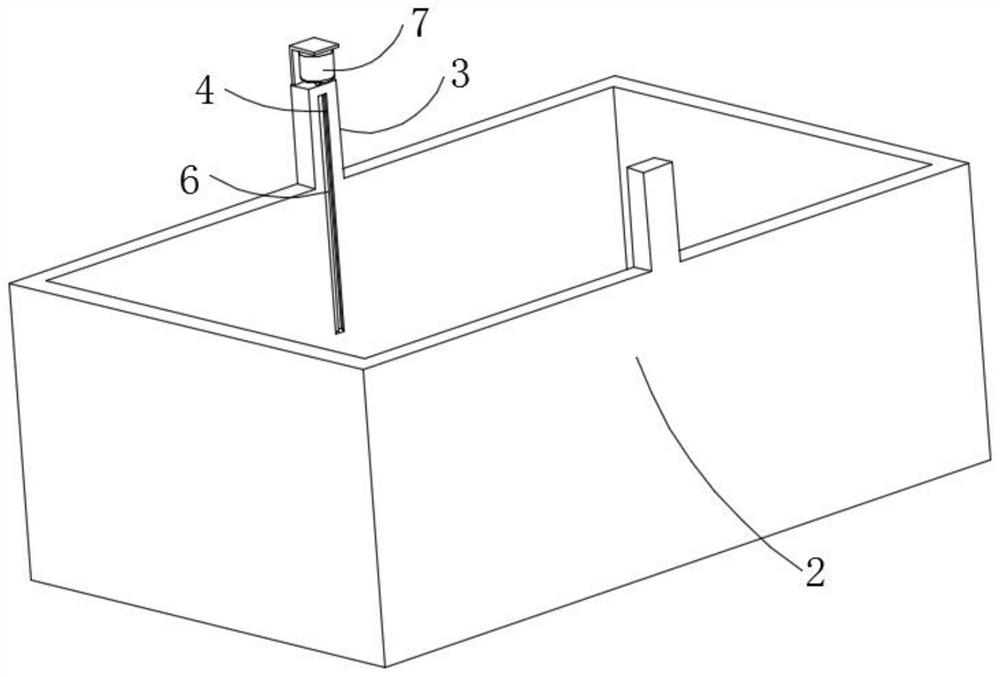

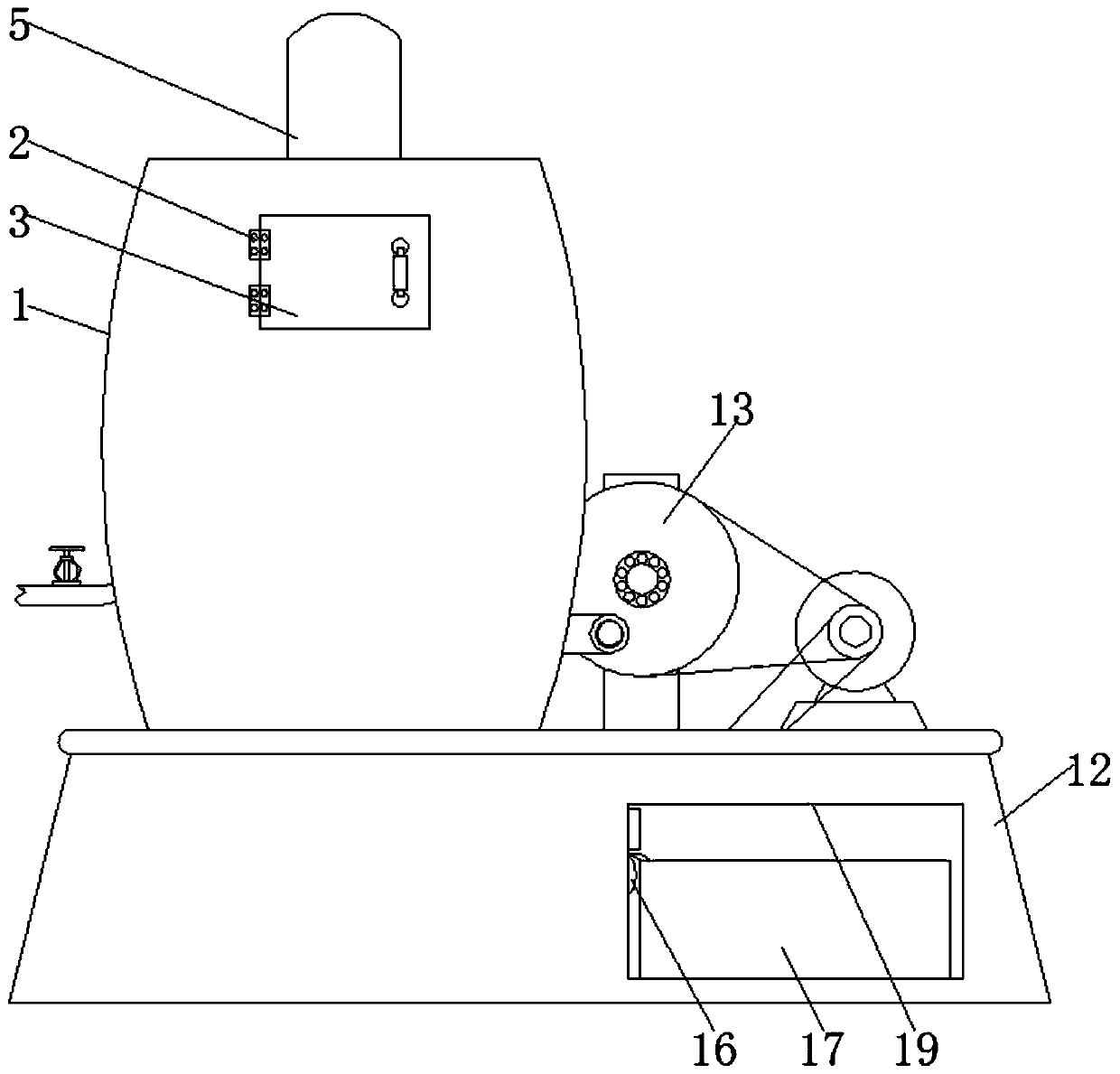

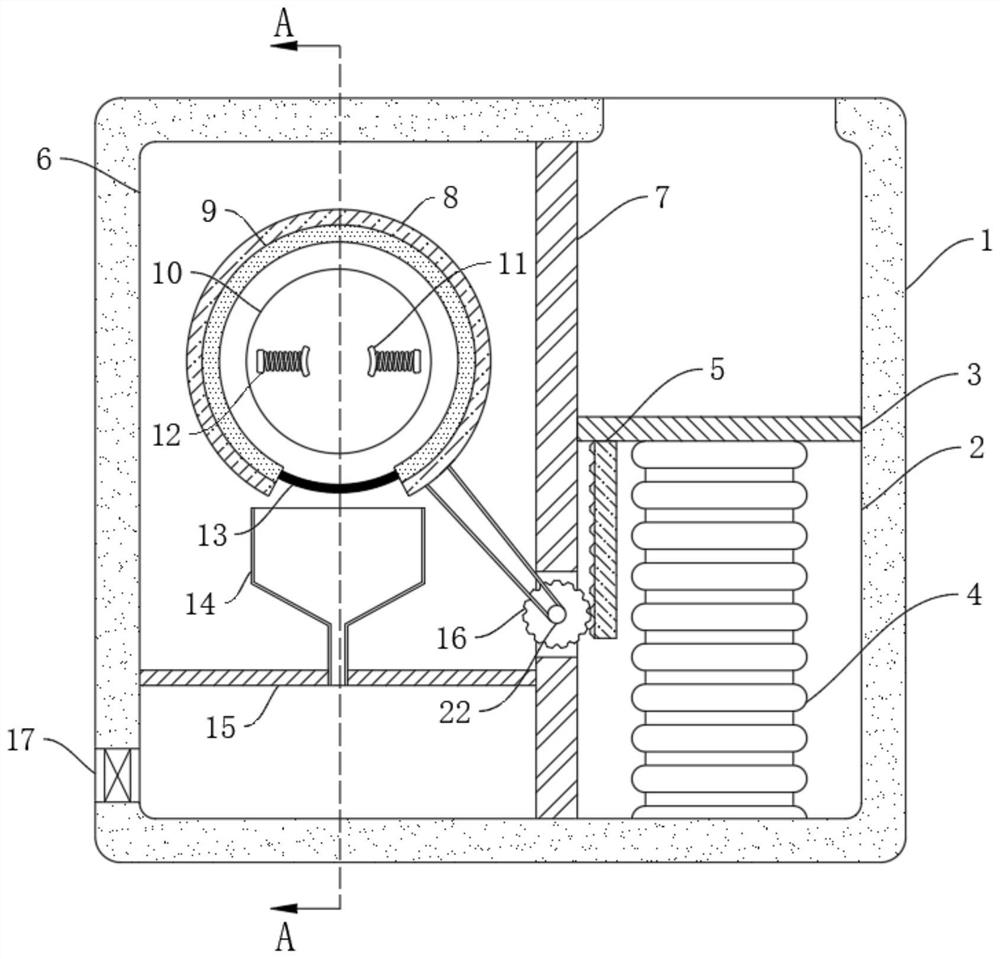

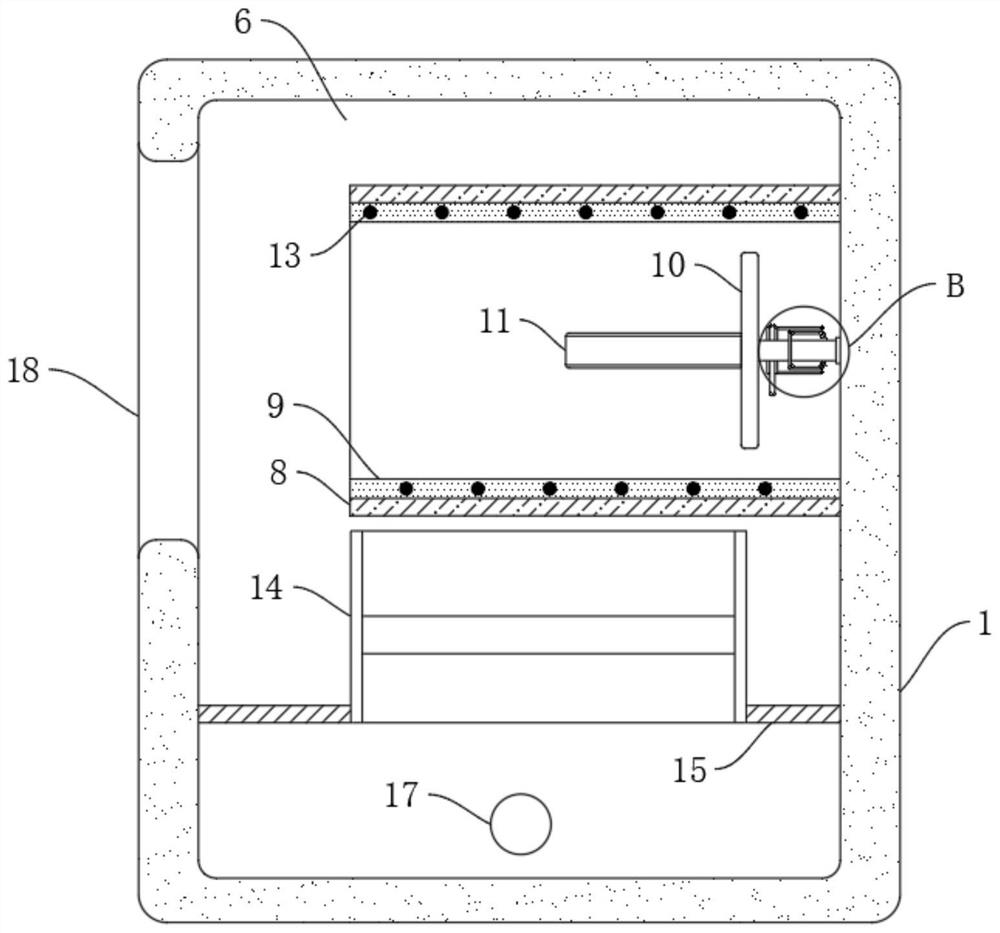

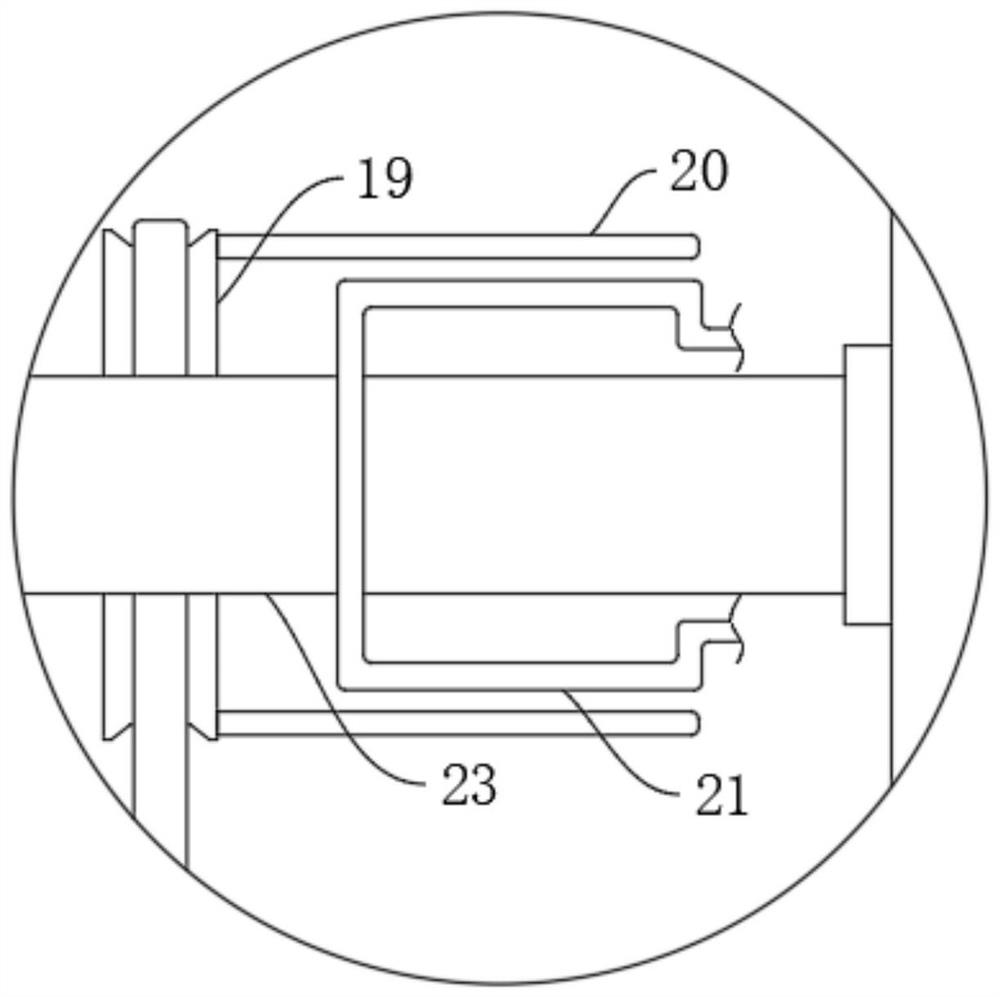

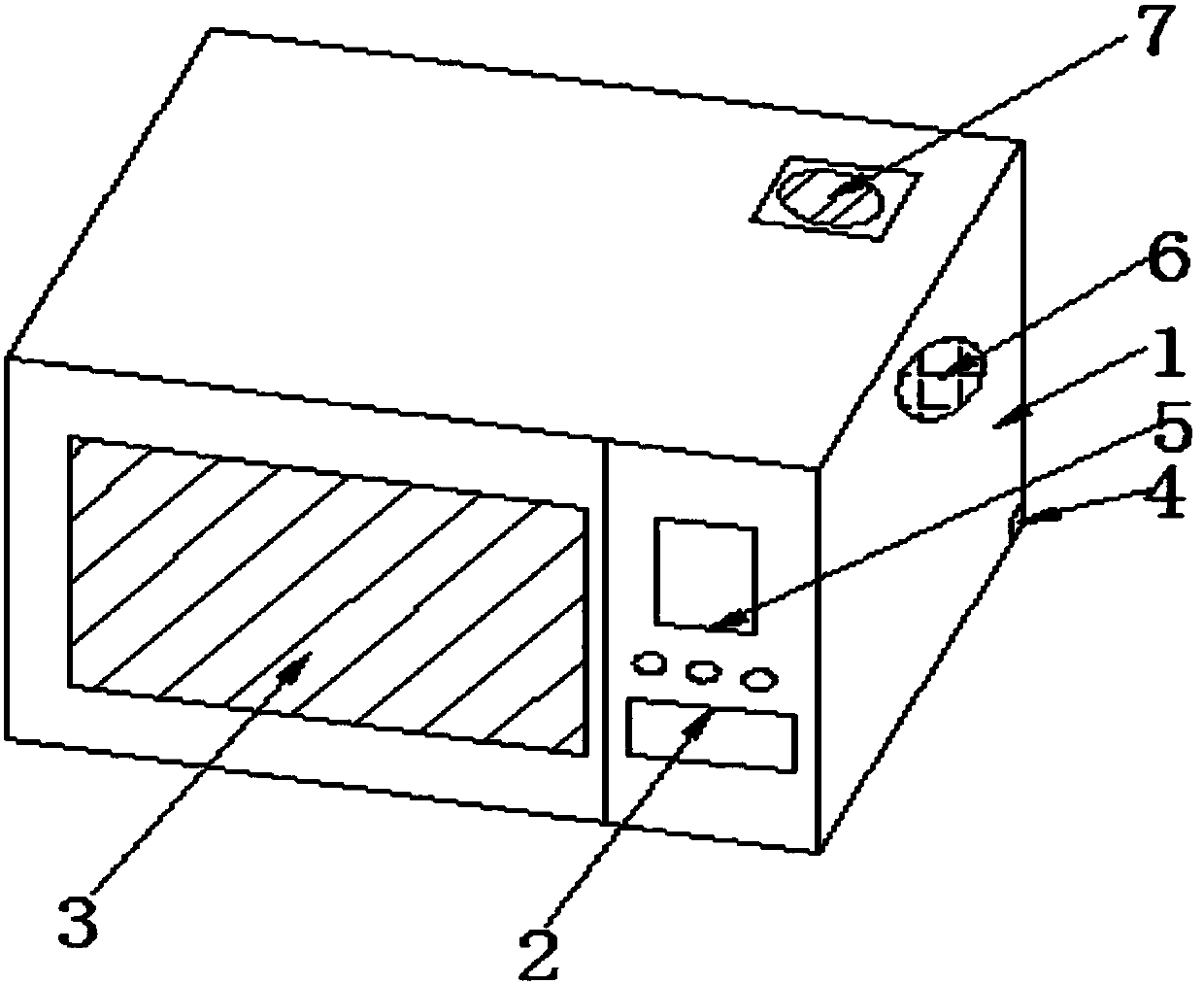

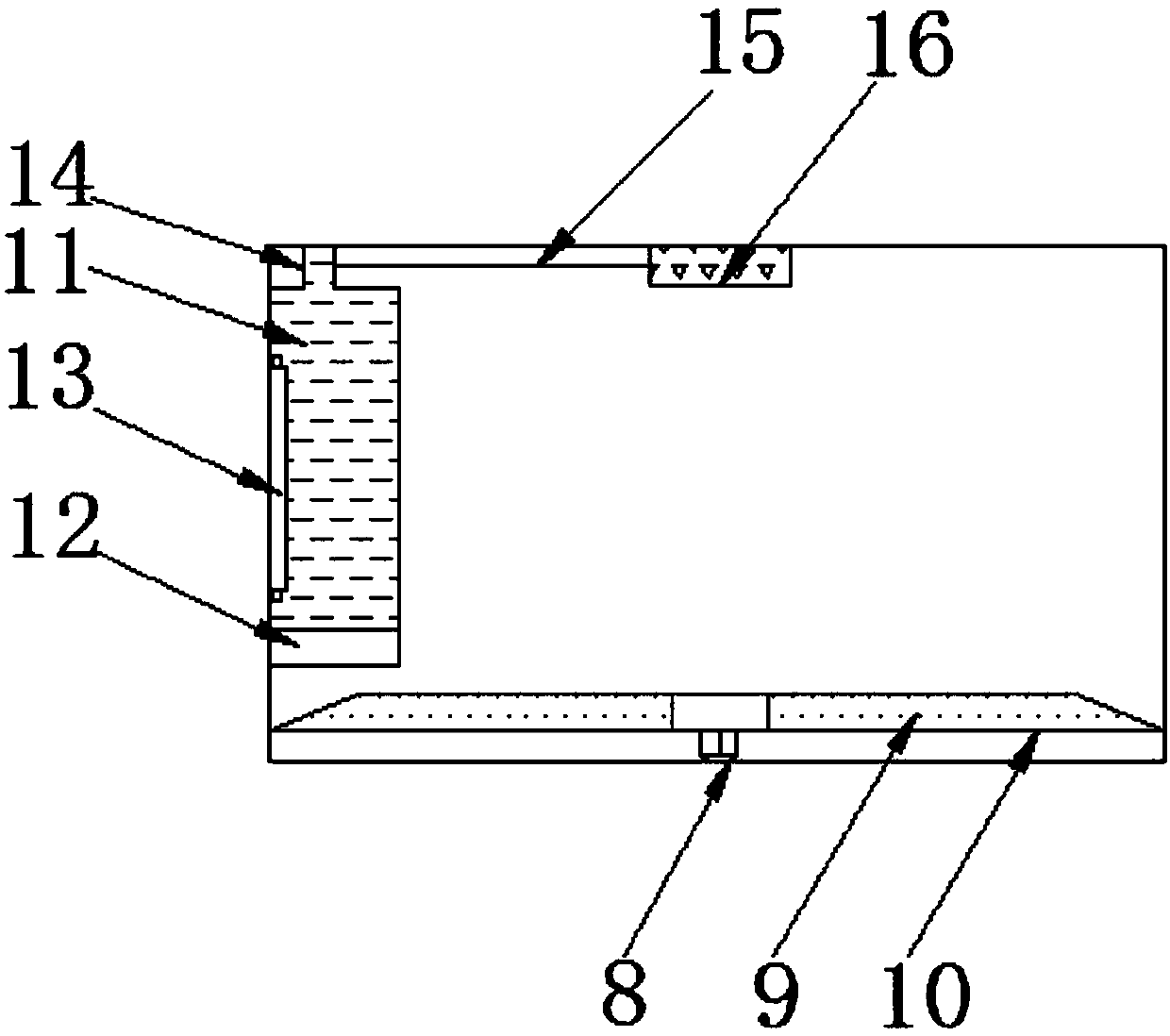

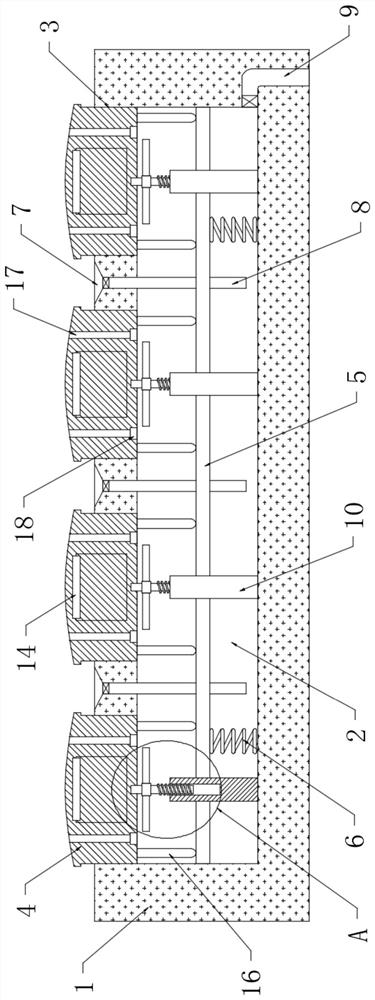

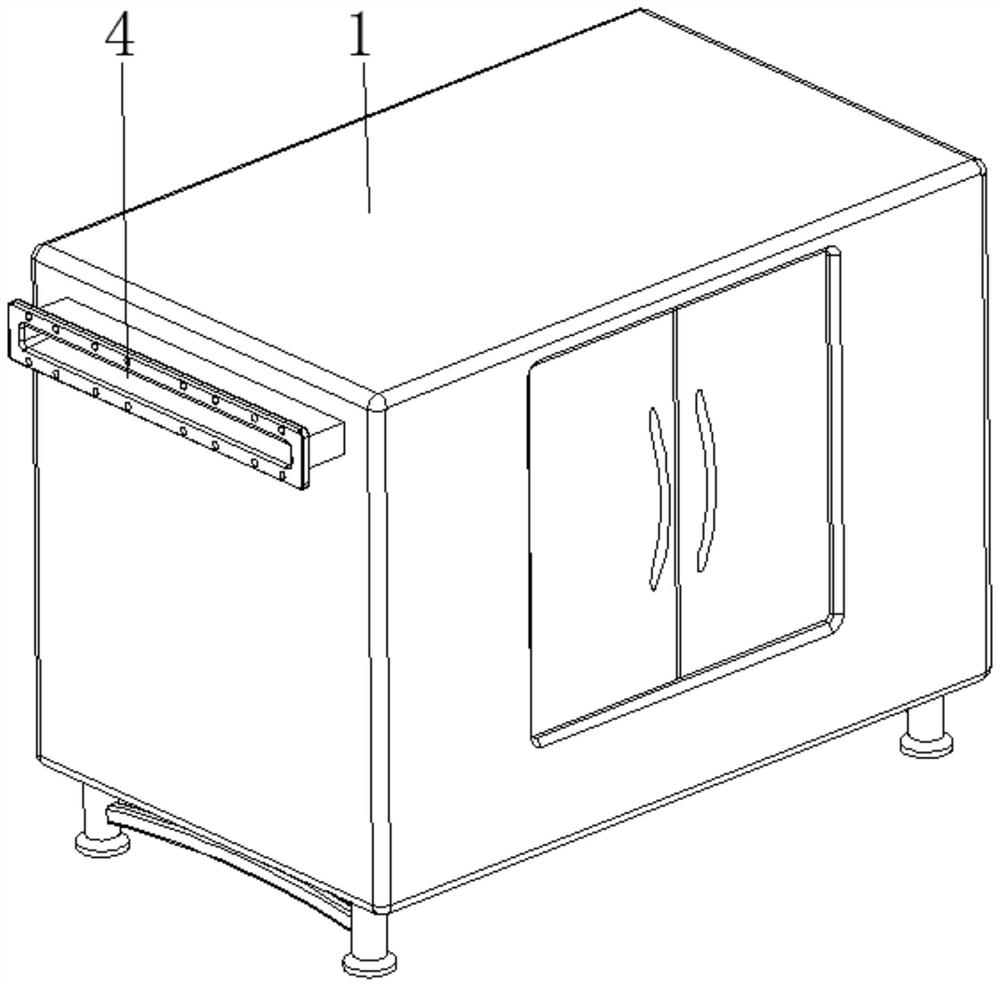

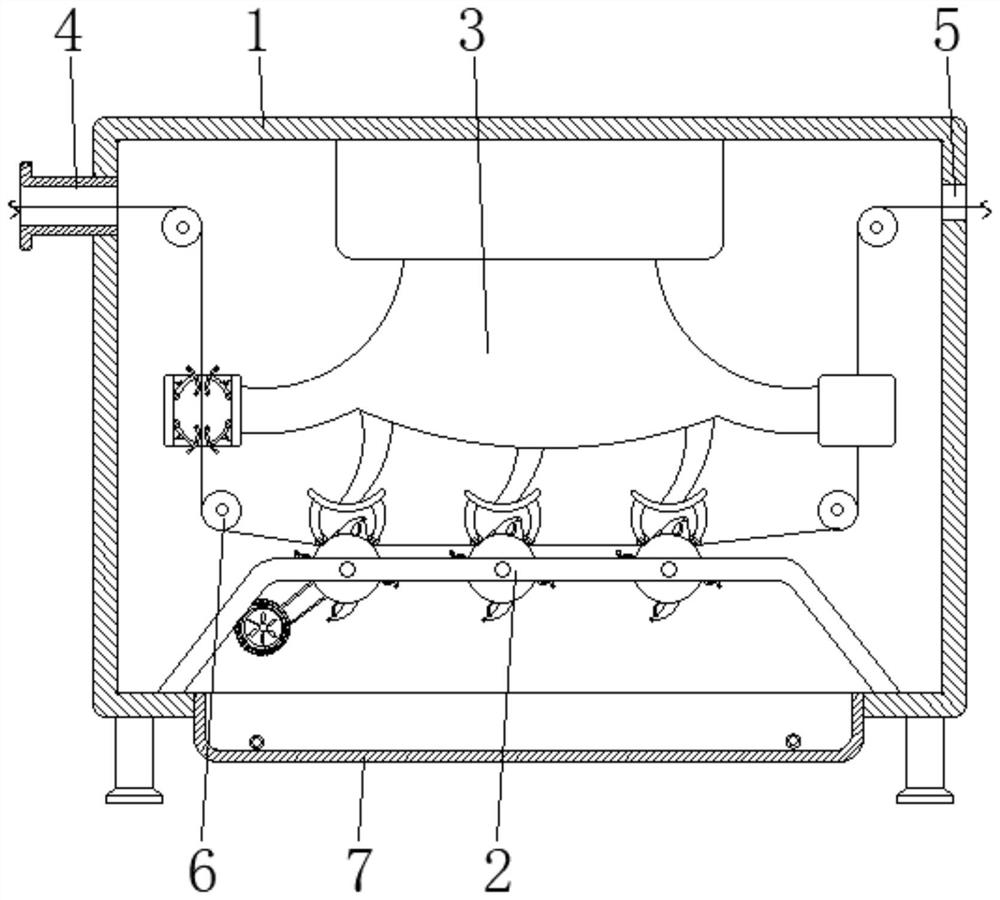

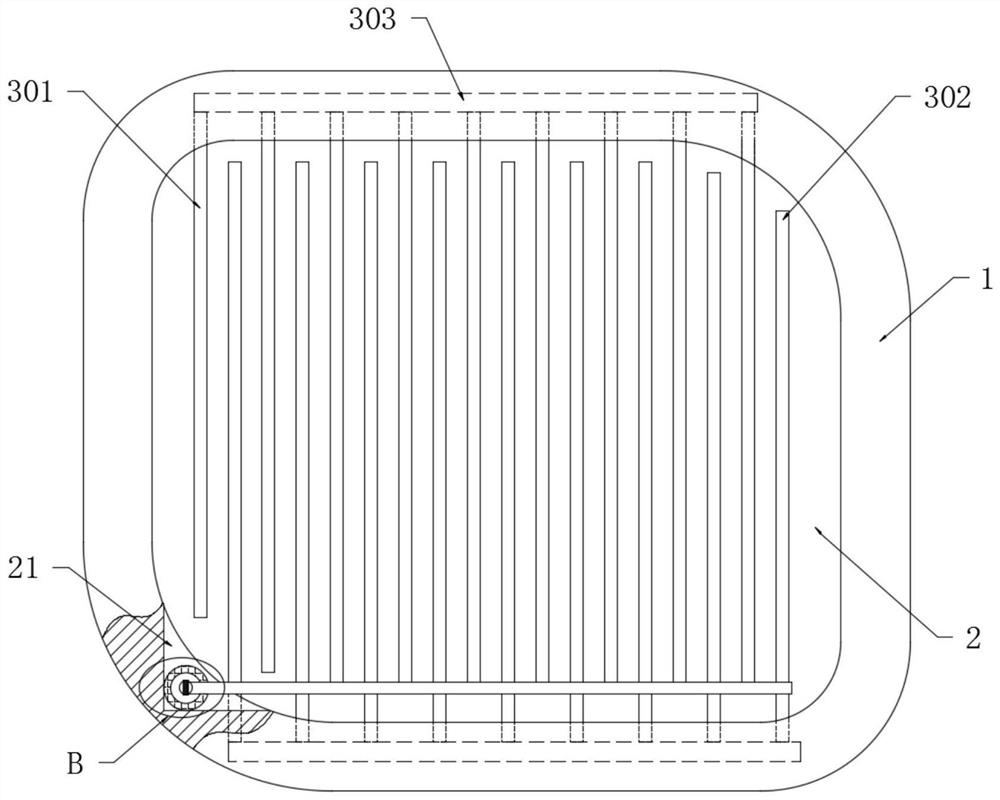

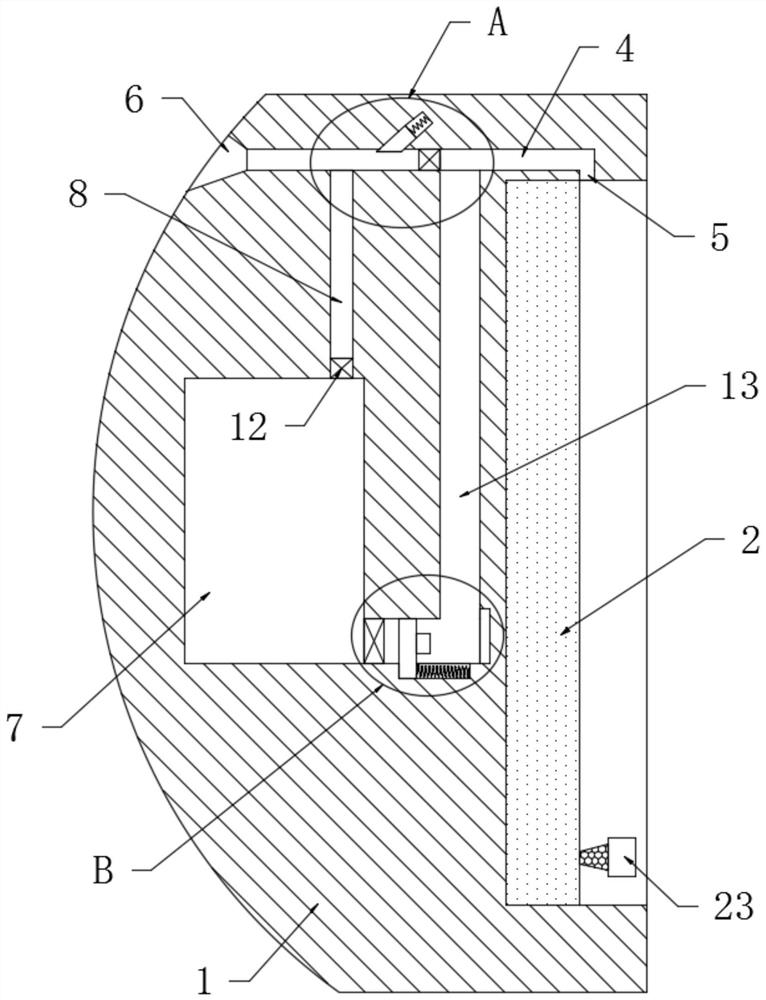

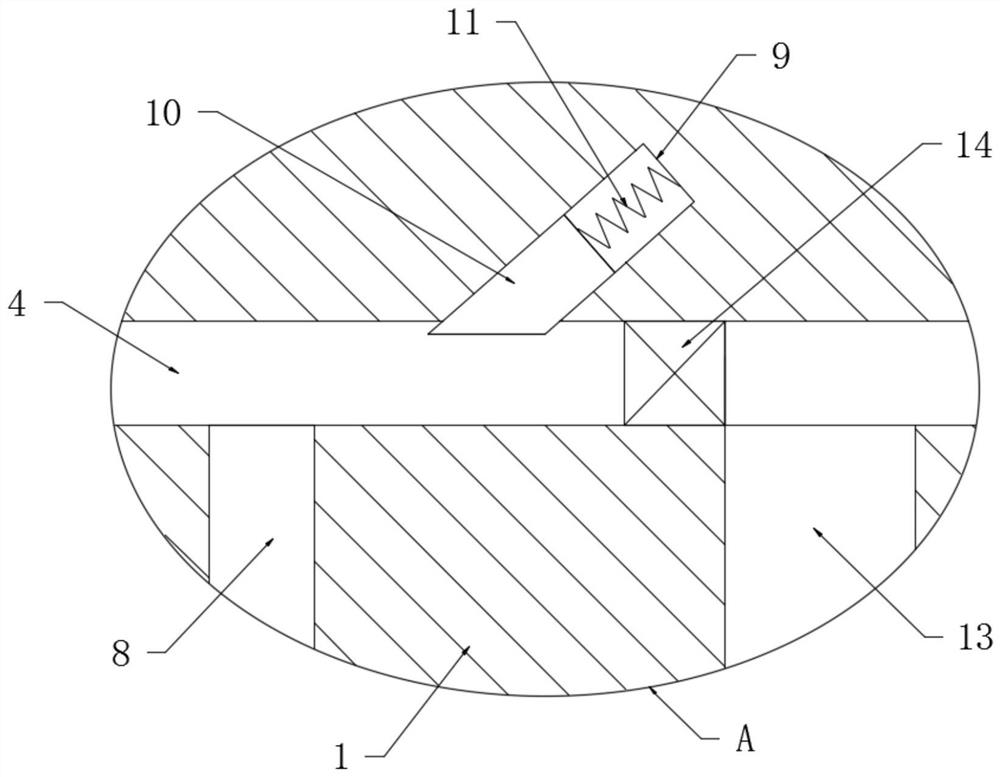

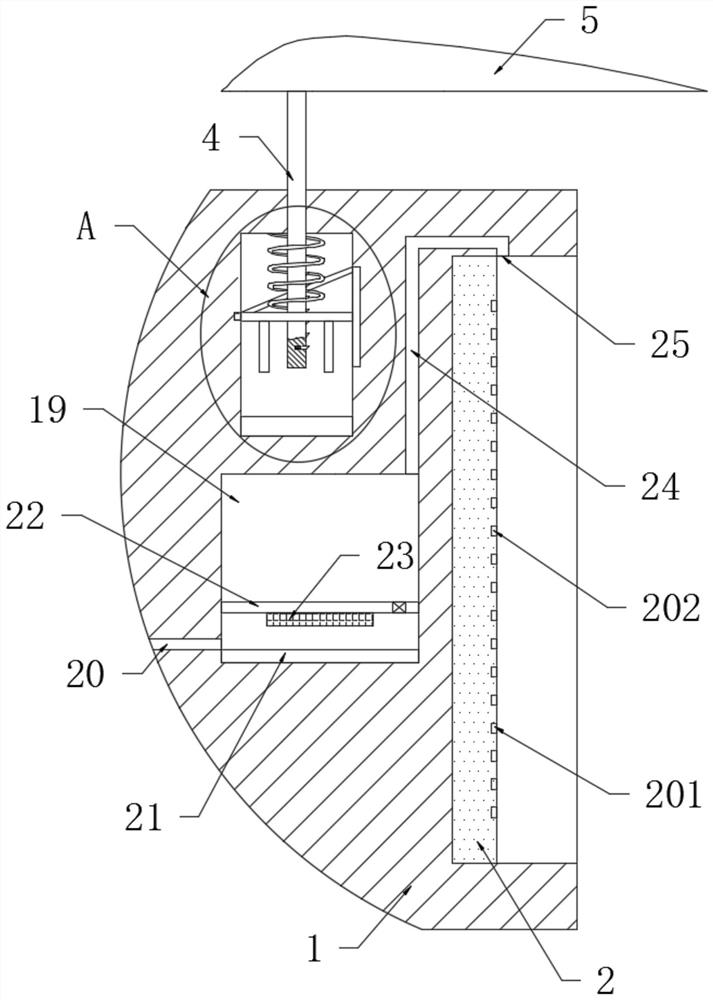

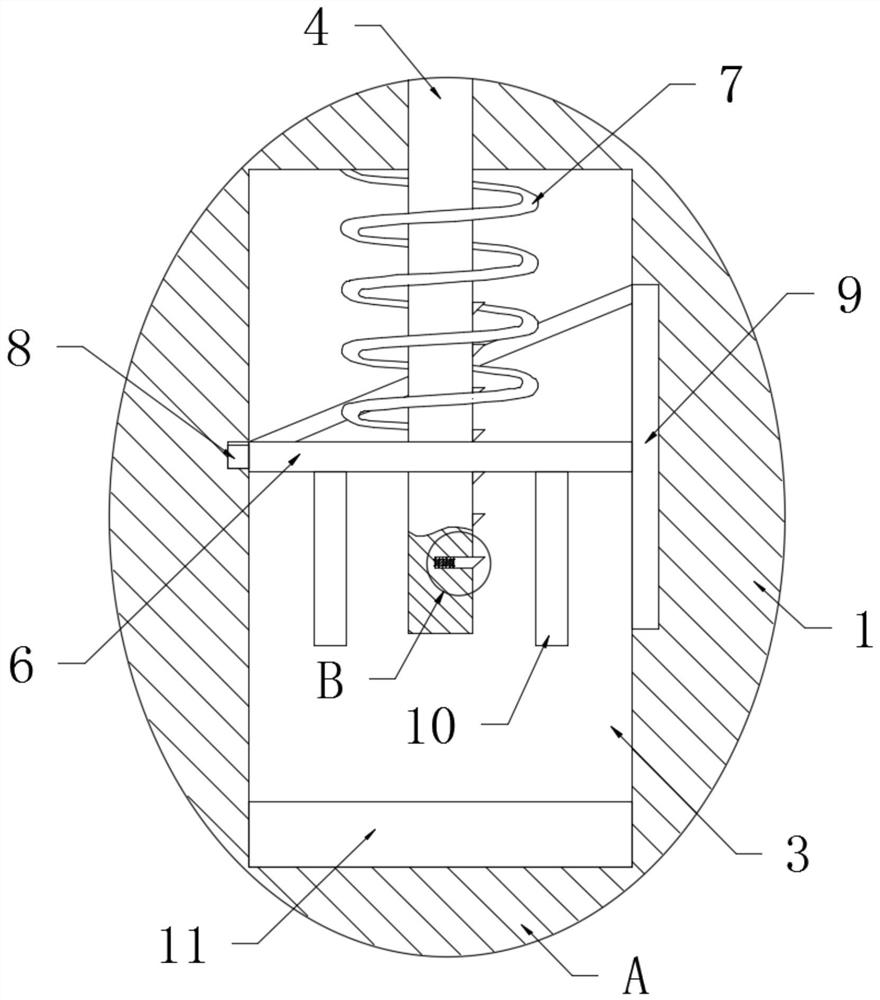

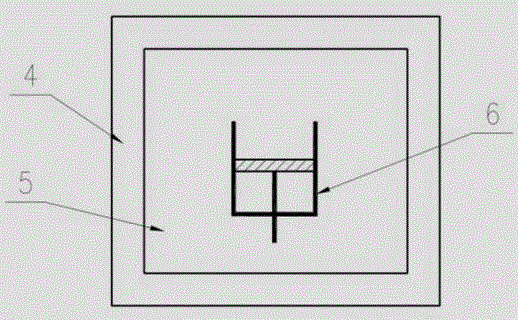

Umbrella water removing device for shopping mall

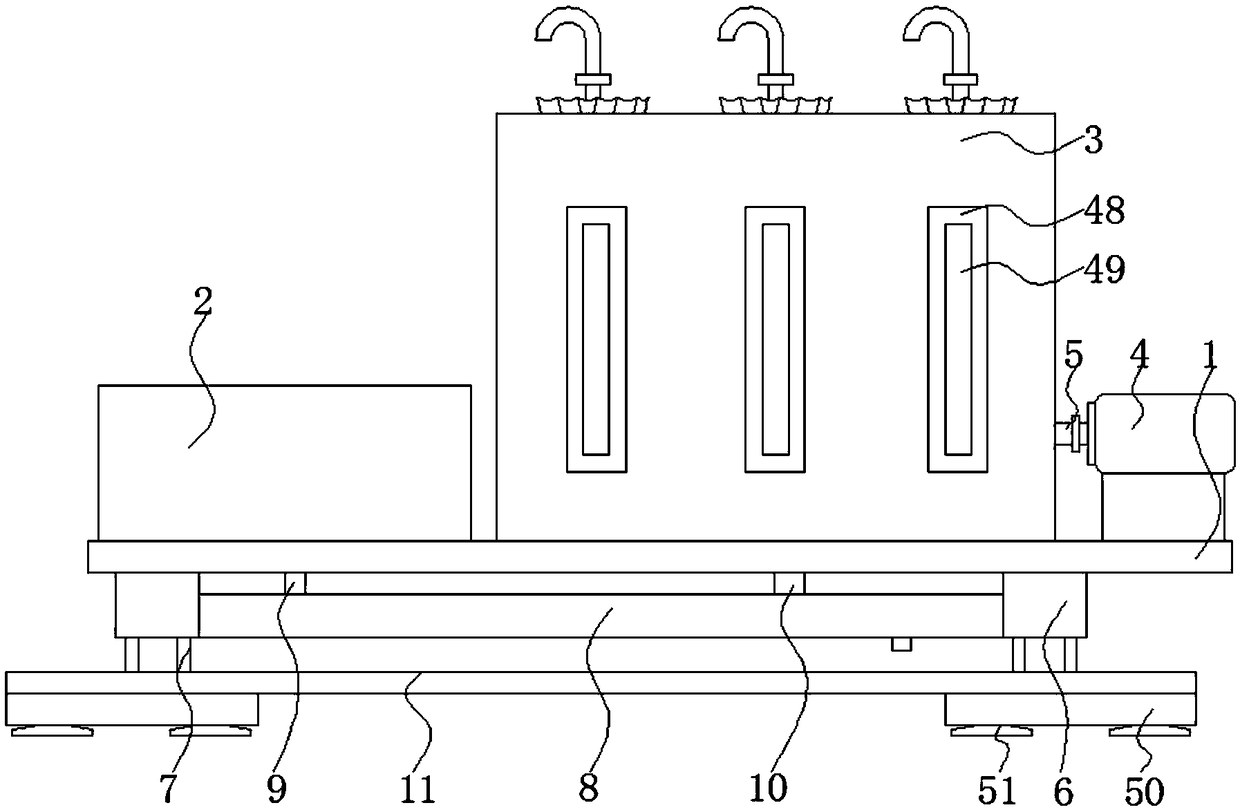

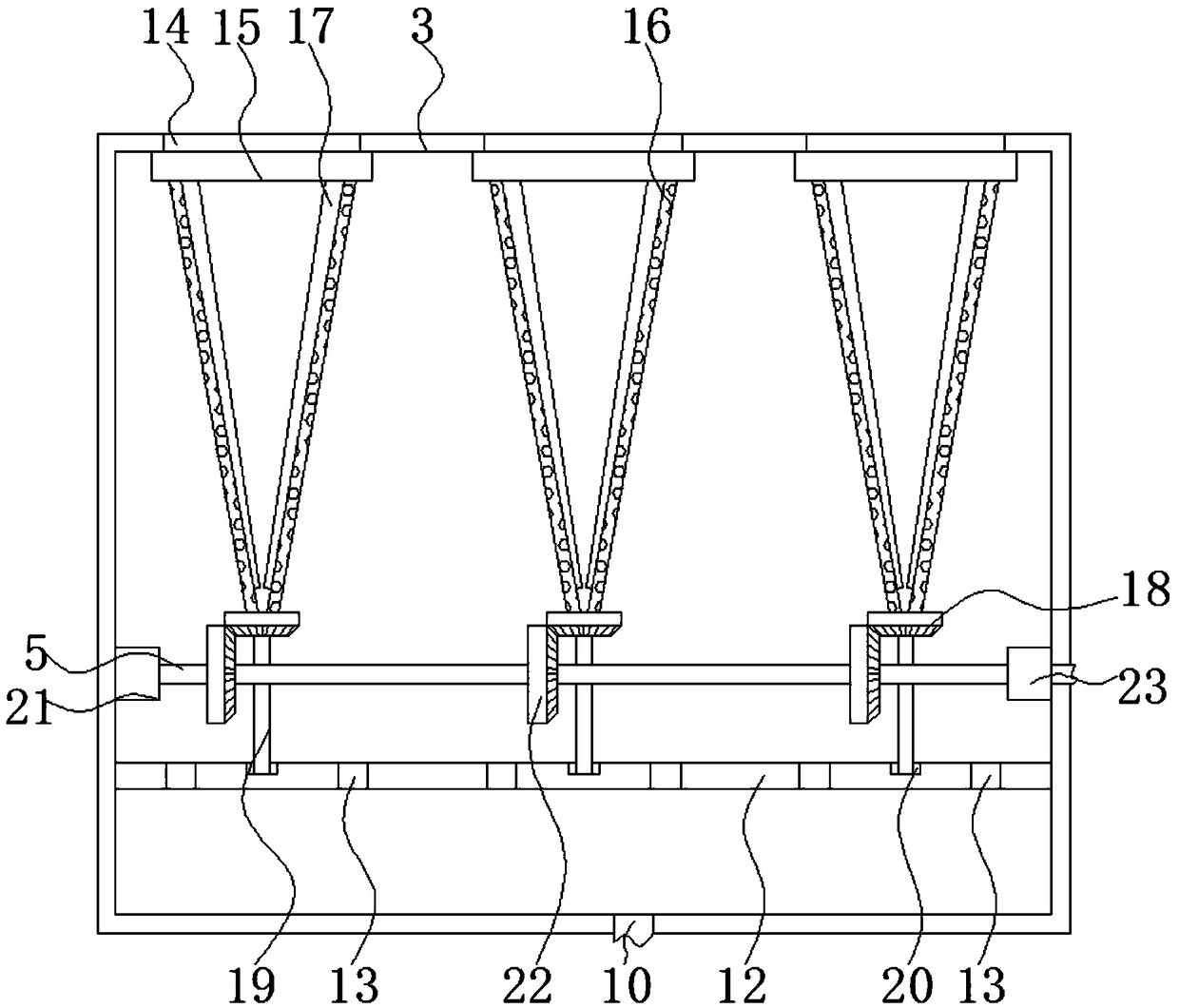

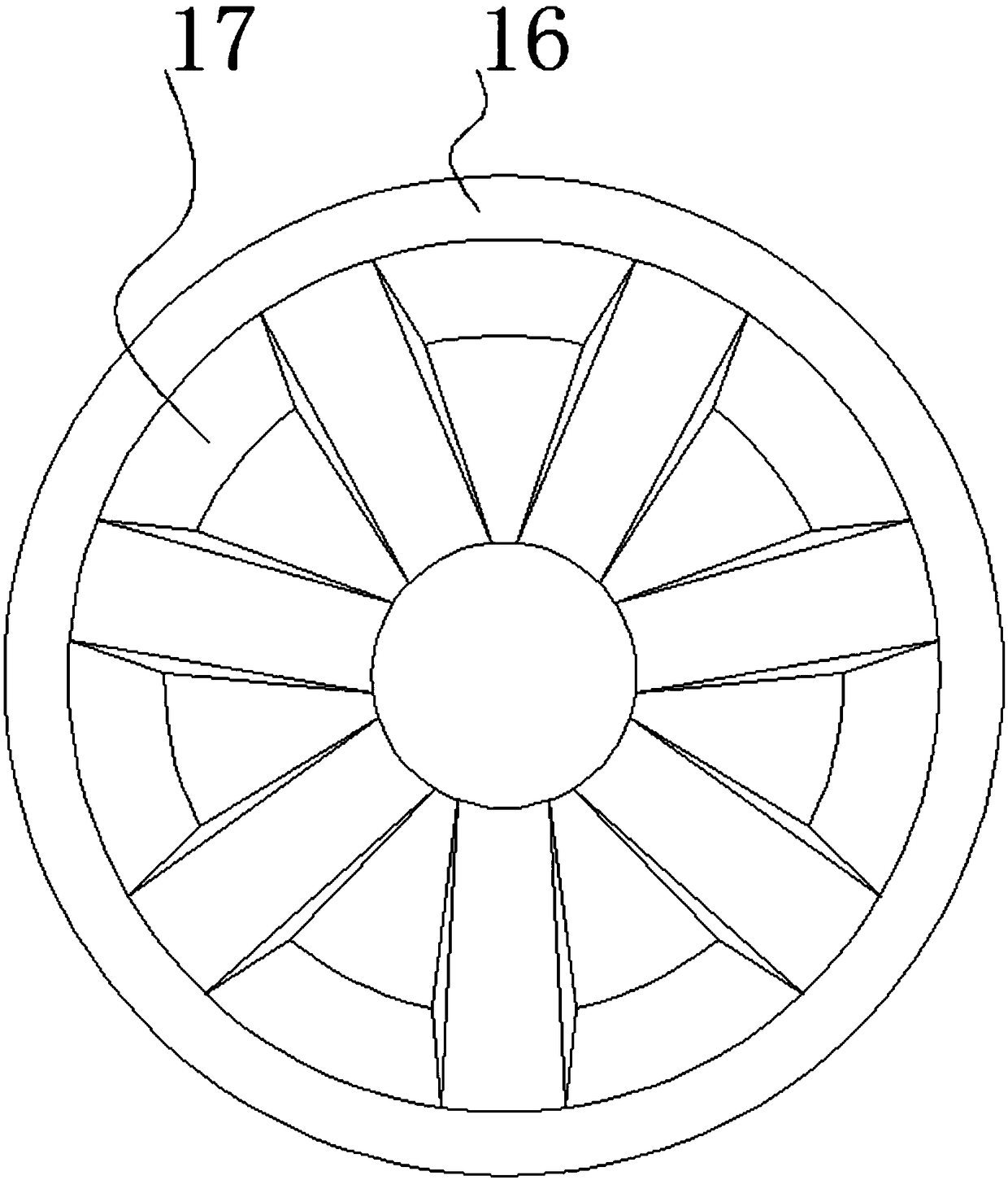

The invention provides an umbrella water removing device for a shopping mall, and relates to the field of umbrella water removing. The umbrella water removing device for the shopping mall comprises asupporting base. A shoe drying mechanism is arranged on the top of the supporting base, a water removing mechanism is arranged on the portion, on the top of the supporting base, of the right side of the shoe drying mechanism, a motor is arranged on the portion, on the top of the supporting base, of the right side of the water removing mechanism, a rotary rod is arranged on an output shaft of the motor, the end, away from the output shaft of the motor, of the rotary shaft penetrates through one side of the water removing mechanism and stretches into the water removing mechanism, a buffer box isarranged at the bottom of the supporting base, and two supporting rods are inserted into the side, away from the supporting base, of the buffer box. According to the umbrella water removing device for the shopping mall, by means of the technical scheme, through the arrangement of the water removing mechanism of the device, multiple umbrellas can be conveniently inserted into the water removing mechanism, water on the umbrellas is conveniently thrown away, and therefore the water on the umbrellas is rapidly removed conveniently.

Owner:温州枫艇网络科技有限公司

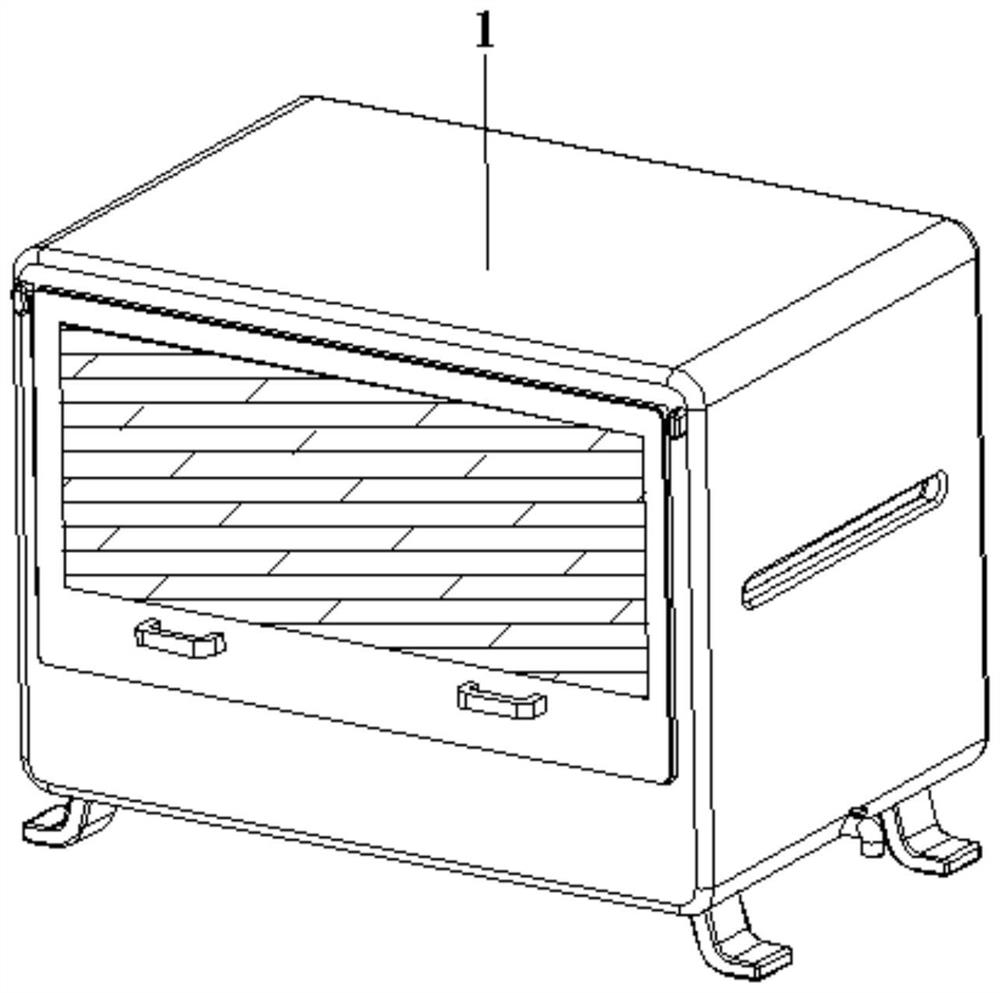

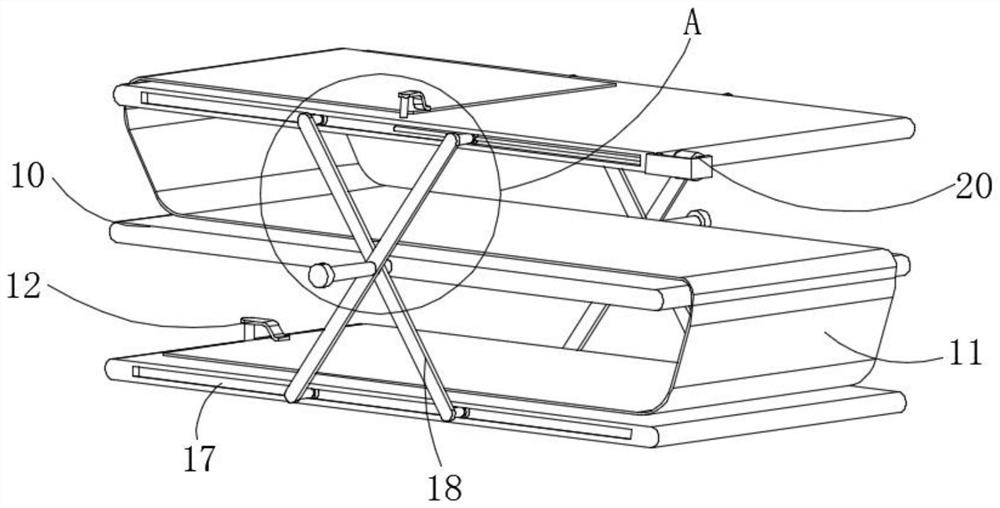

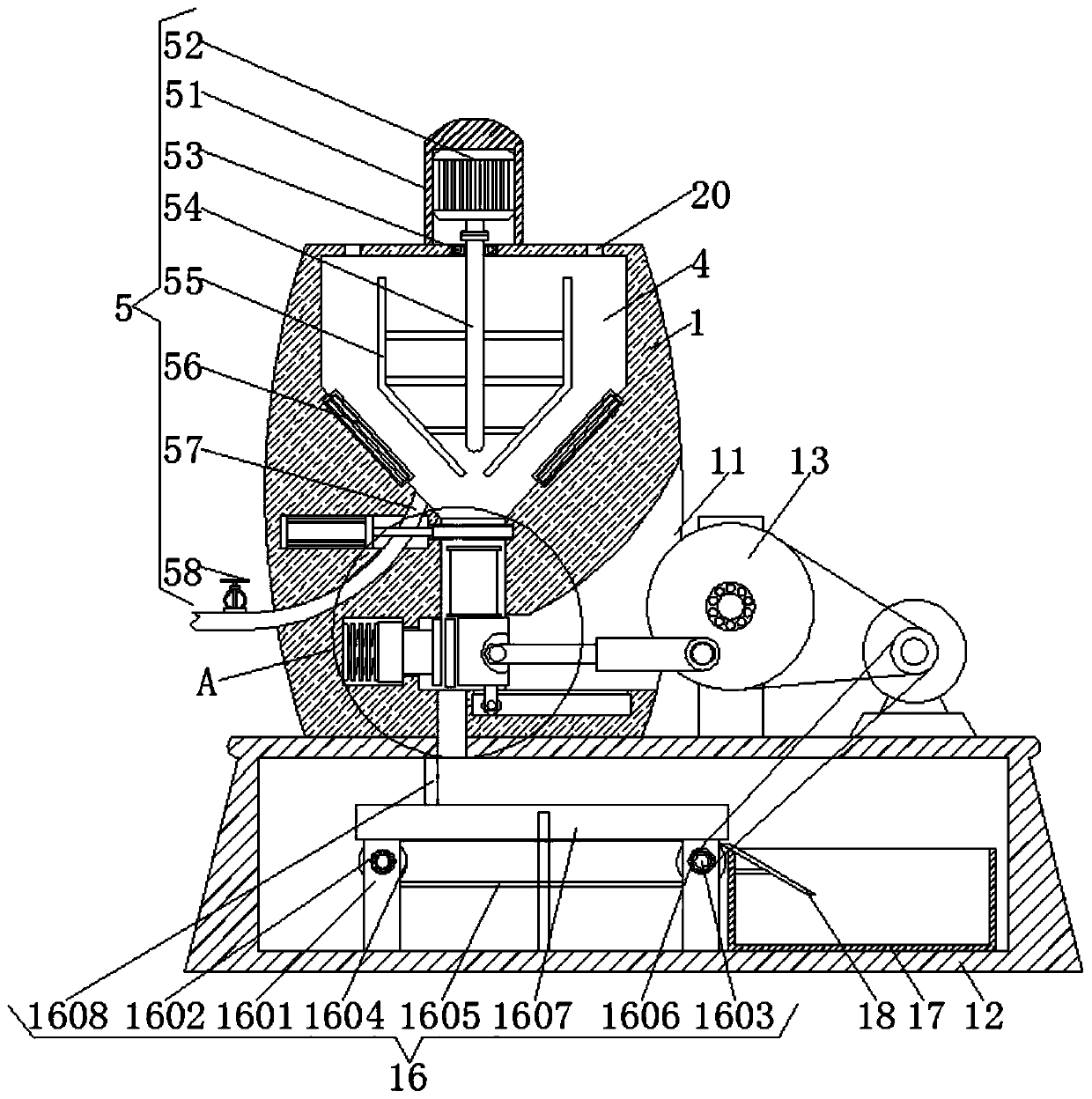

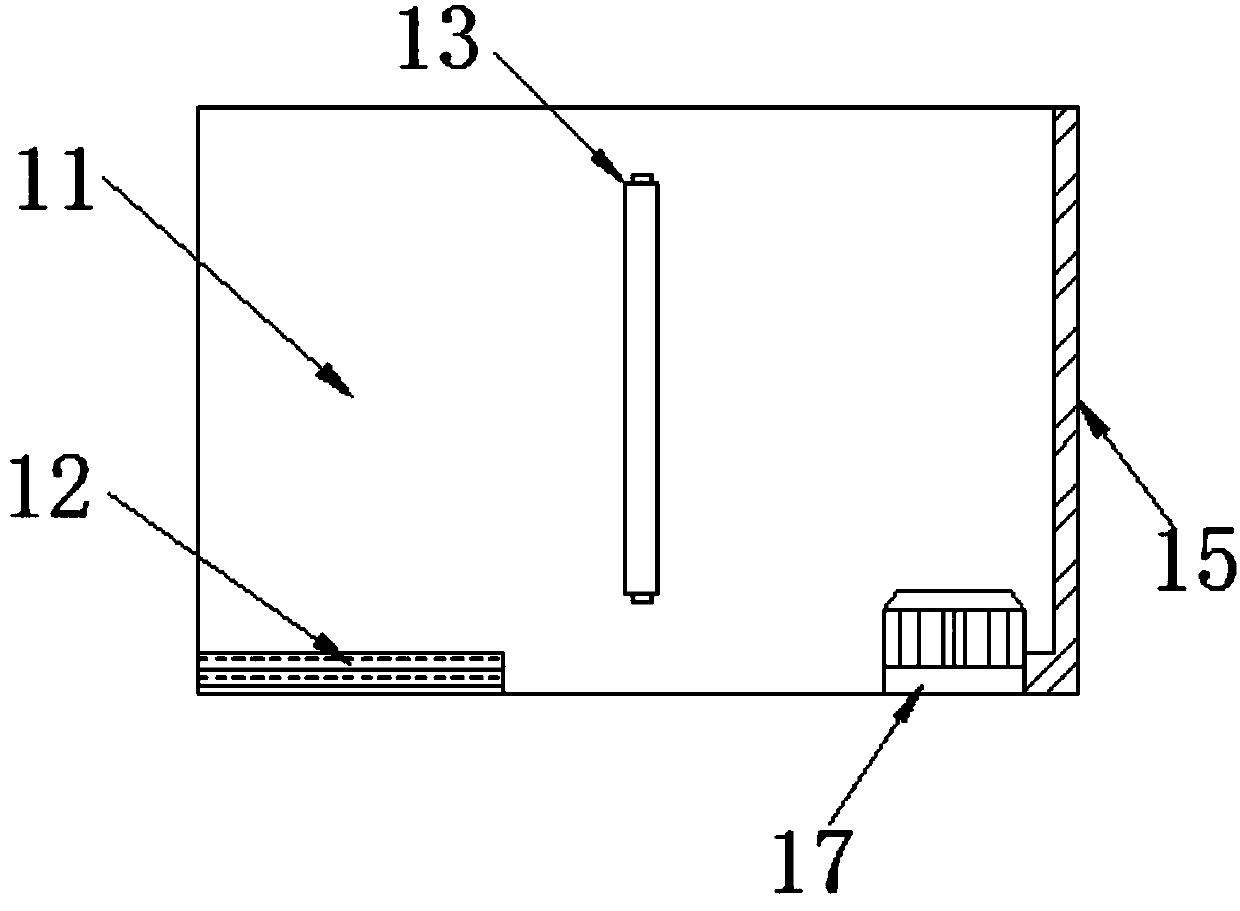

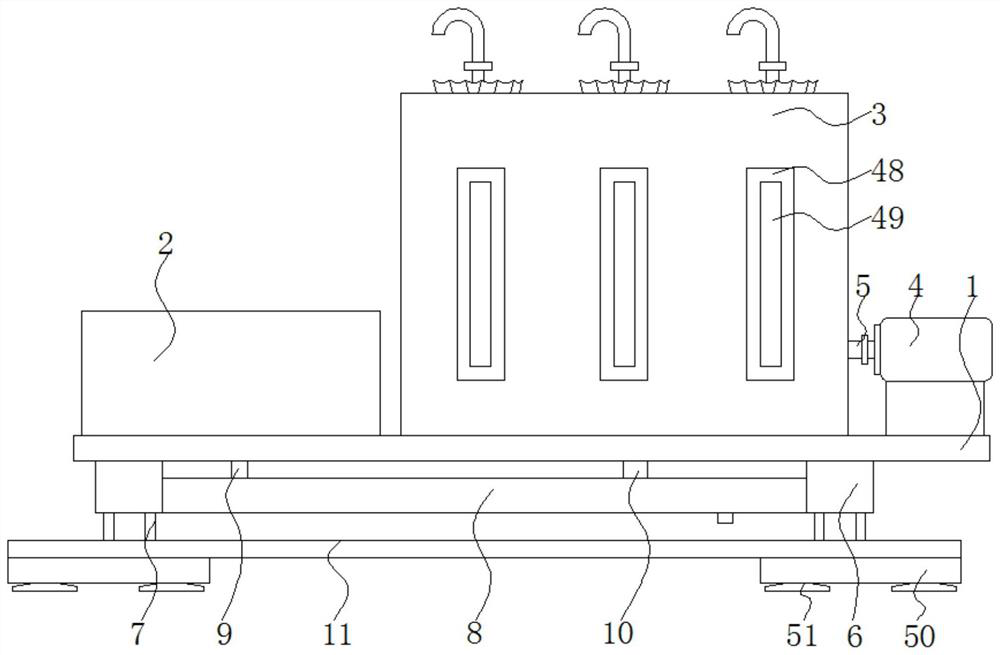

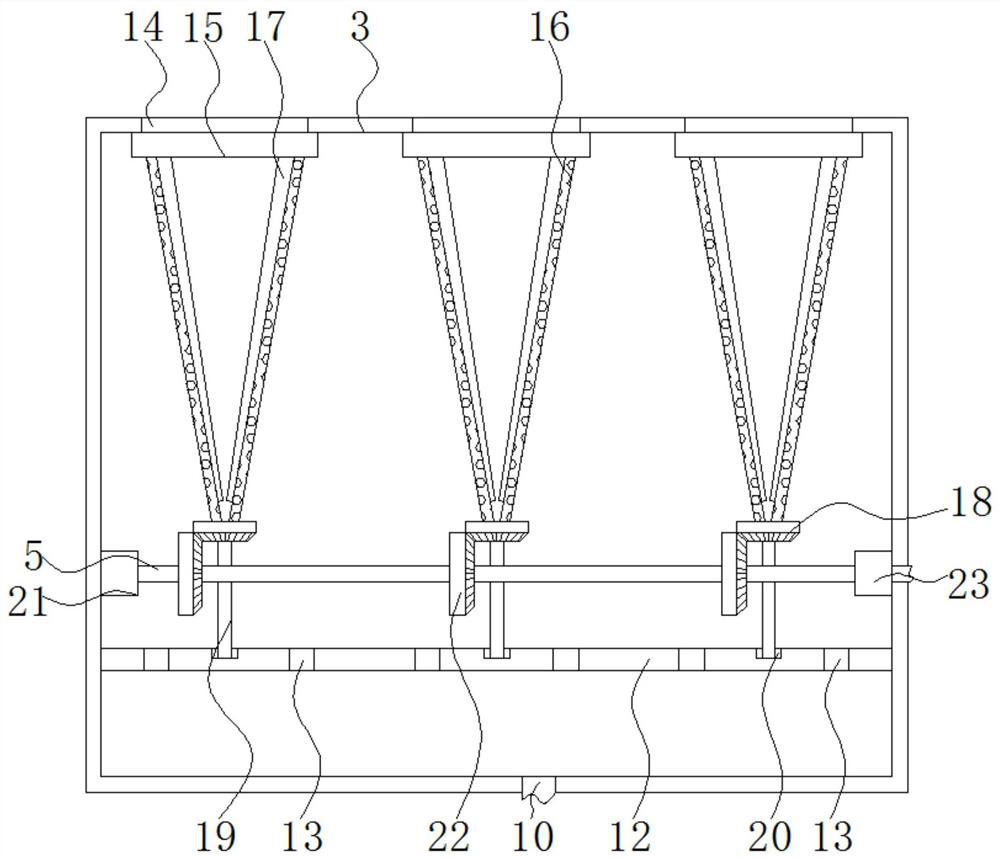

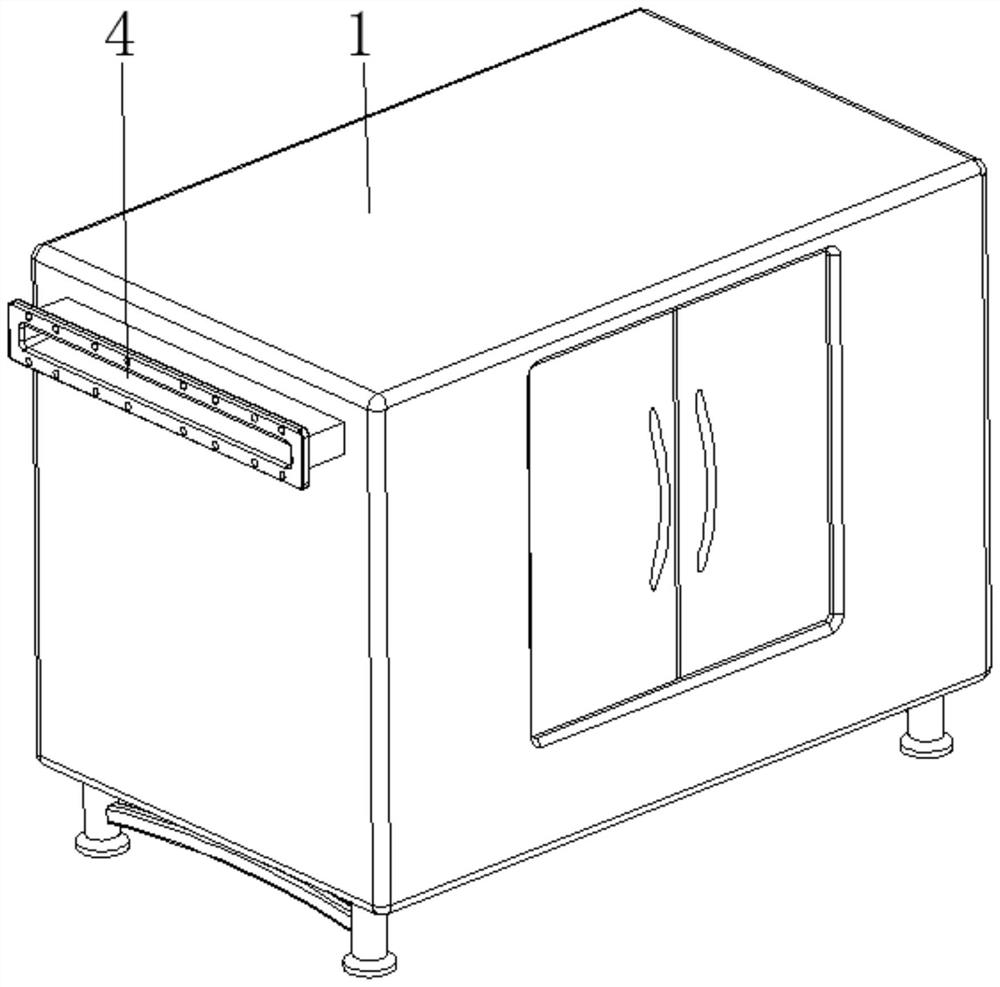

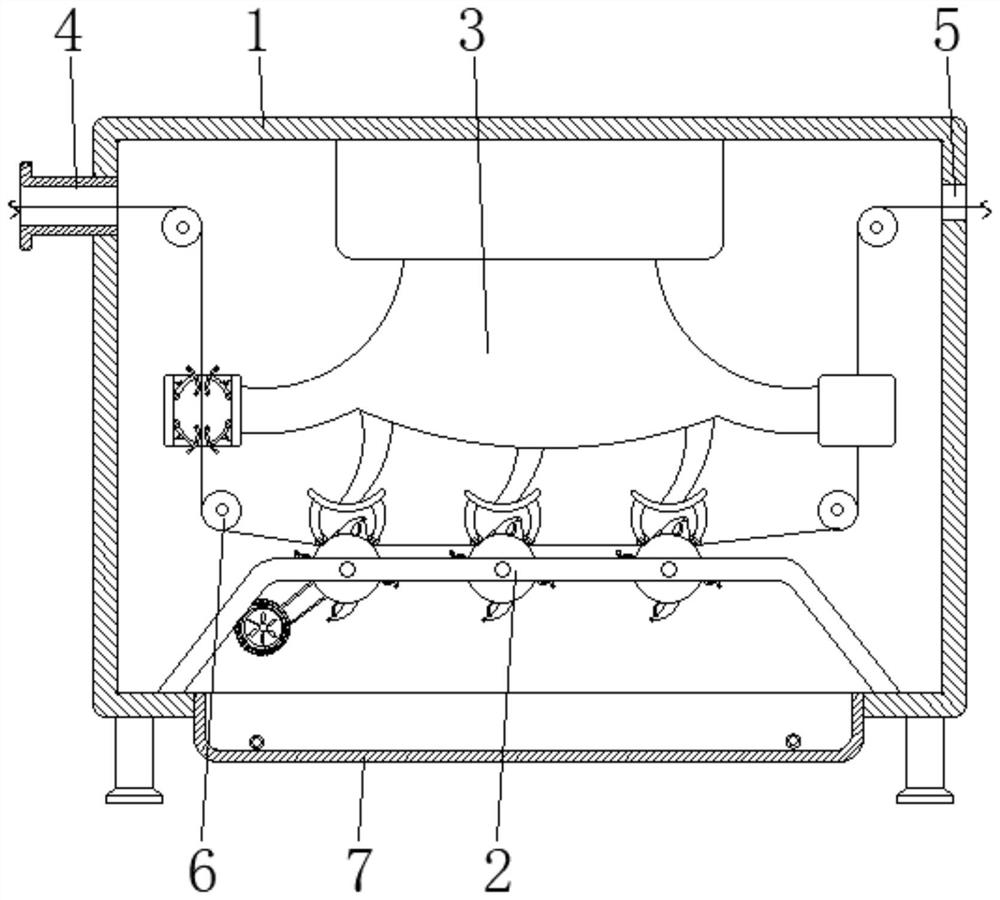

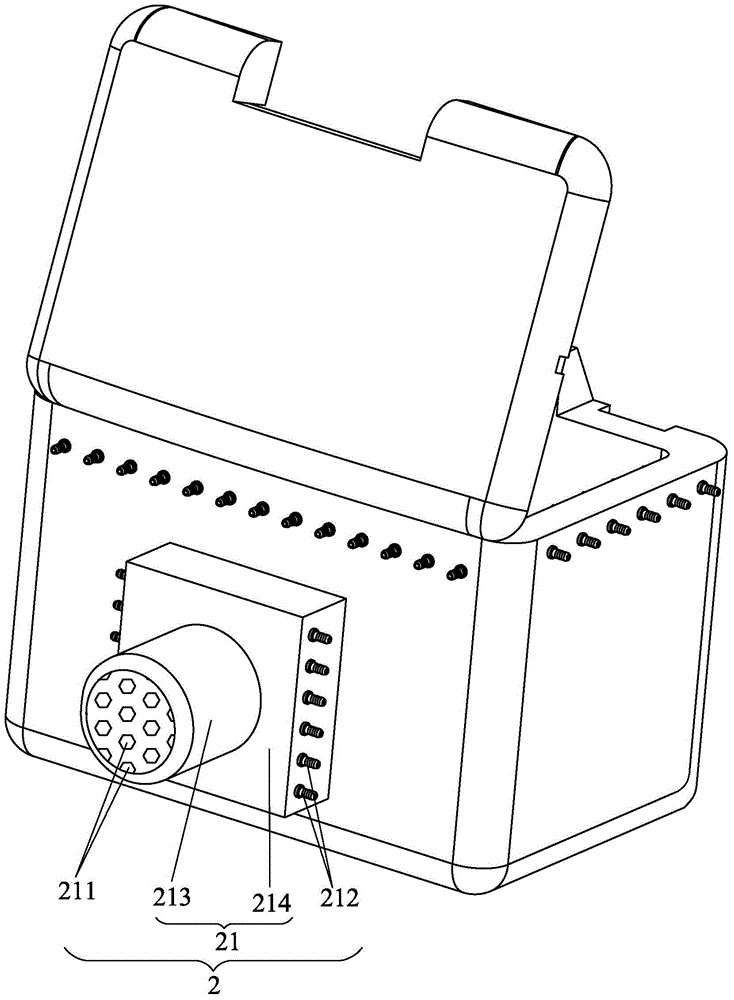

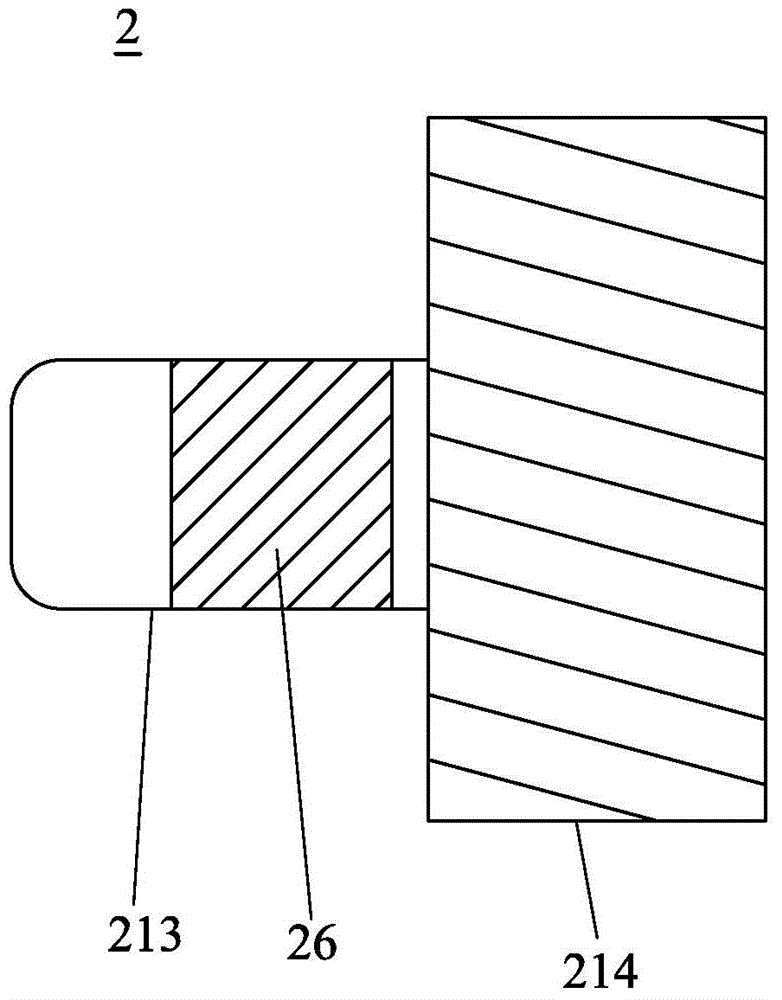

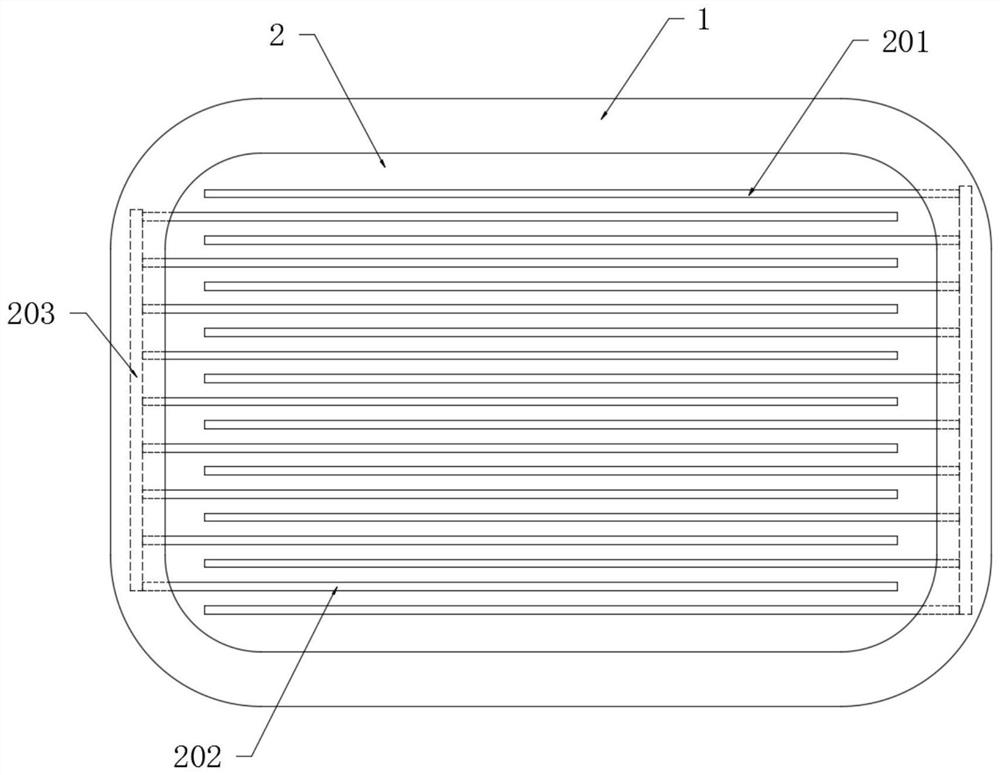

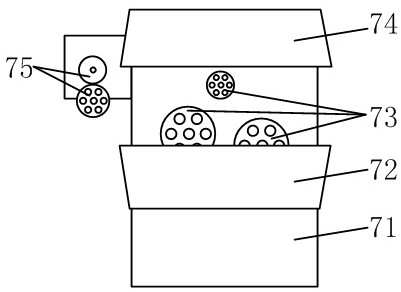

Flattening equipment for zip-top can waste recycling and capable of cleaning away waste liquid

ActiveCN109291494AEasy to throw outEasy dischargeDrying solid materials without heatDrying machines with non-progressive movementsLiquid wasteWaste product

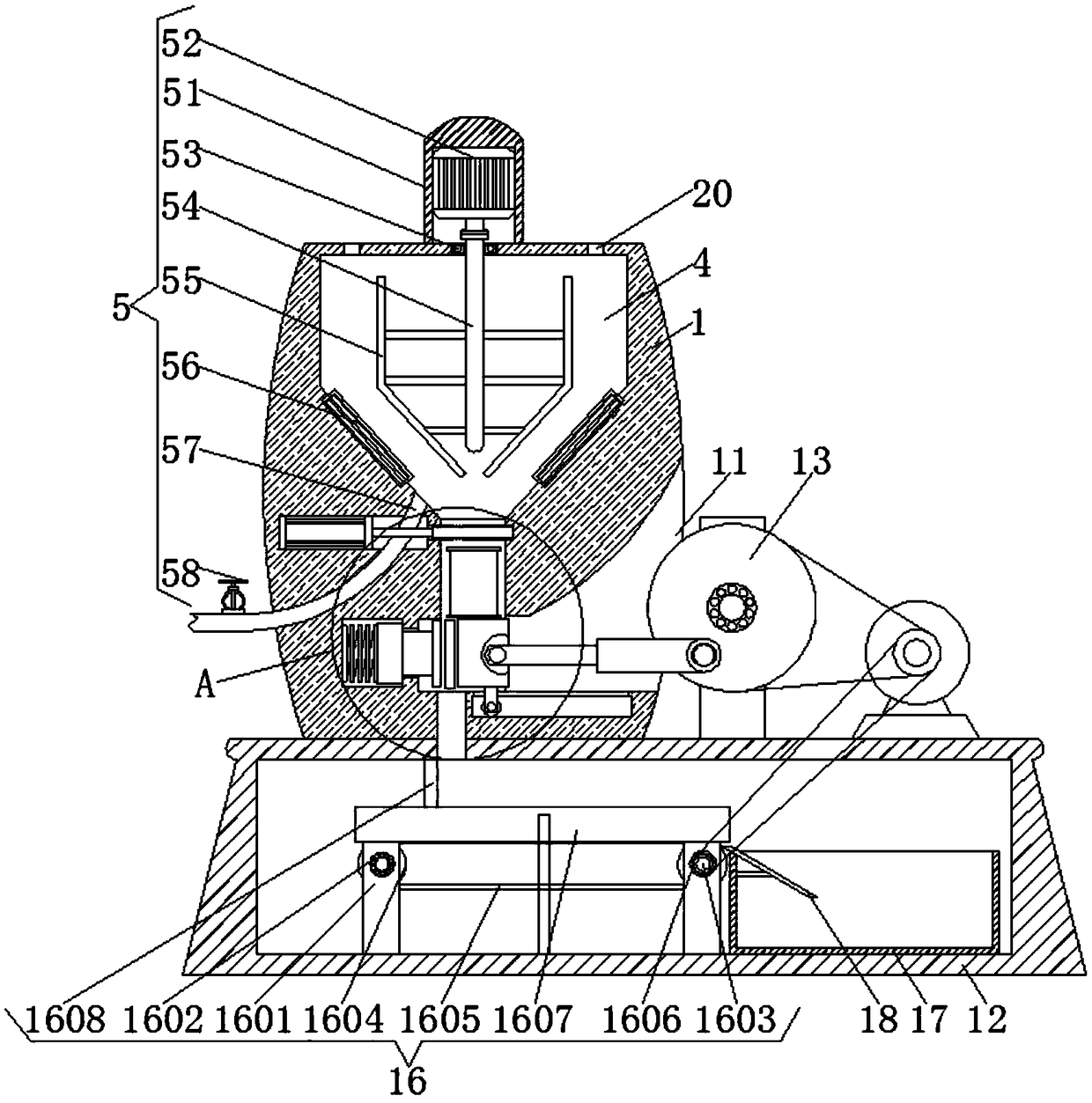

The invention discloses flattening equipment for zip-top can waste recycling and capable of cleaning away waste liquid and relates to the technical field of environment protection. The zip-top can flattening equipment comprises a machine body. Two hinges are hinged to the part, located at the left end of the machine body, of the top of the front face of the machine body. Object holding doors are hinged to the ends, away from the machine body, of the two hinges. A drying chamber is formed in the top end of the machine body. Dewatering devices are arranged in the drying chamber and on the top face of the machine body correspondingly. A transfer groove is formed in the part, located at the bottom of the drying chamber, of the bottom end of the machine body. According to the flattening equipment for zip-top can waste recycling and capable of cleaning away the waste liquid, through matched use of the dewatering devices, a discharge device, a return device, a flattening device and a conveying device, liquid in zip-top cans can be cleaned out conveniently, normal operation of the zip-top can flattening equipment is facilitated, meanwhile work efficiency of the machine body is further improved, and long-time use and practicability of the machine body are improved.

Owner:嘉兴市建美轻体建材有限公司

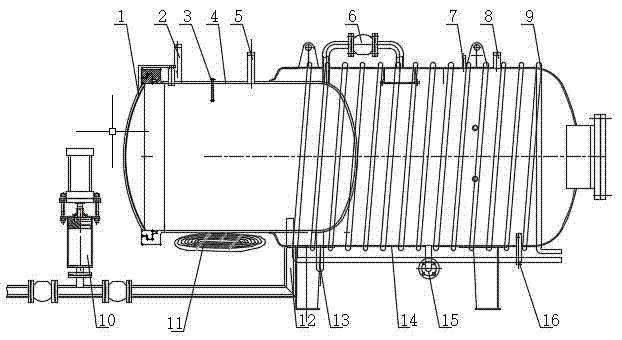

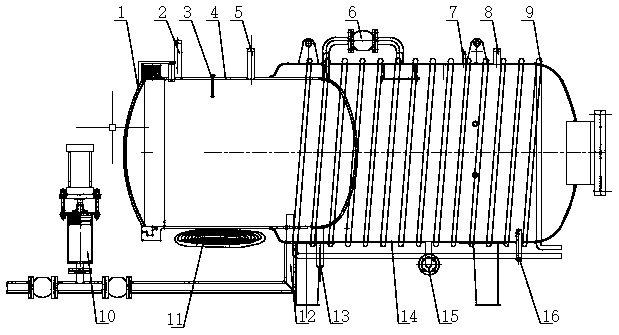

High-frequency induction type dewaxing kettle with wax-water separation function

The invention discloses a high-frequency induction type dewaxing kettle with a wax-water separation function. According to the technical scheme, the high-frequency induction type dewaxing kettle comprises a steam generating tank, a dewaxing cavity, a steam inlet control valve, aluminum silicate heat preservation materials and a high-frequency induction heating device. The steam generating tank communicates with the dewaxing cavity through the steam inlet control valve, and steam is controlled by the steam inlet control valve to enter the dewaxing cavity. The corresponding aluminum silicate heat preservation material is arranged on the outer layer of the steam generating tank. A high-frequency electromagnetic induction coil is evenly wound on the heat preservation material. The dewaxing cavity is also covered with the corresponding aluminum silicate heat preservation material. A high-frequency electromagnetic induction coil is arranged below the dewaxing cavity and used for heating the dewaxing cavity so as to separate water. An exhaust valve is arranged on the dewaxing cavity and used for exhausting water steam when the pressure is reached. A wax pumping device is connected with a wax outlet of the dewaxing cavity. The dewaxing kettle is heated through the electromagnetic induction principle, the heating speed is high, the heating efficiency is high, the dewaxing kettle has the rapid water removing function, so that further treatment of wax liquid is omitted, and after being pumped into a standing barrel through the wax pumping device and then is subjected to standing, the dewatered wax liquid can be directly used.

Owner:东营福浩精铸科技有限公司

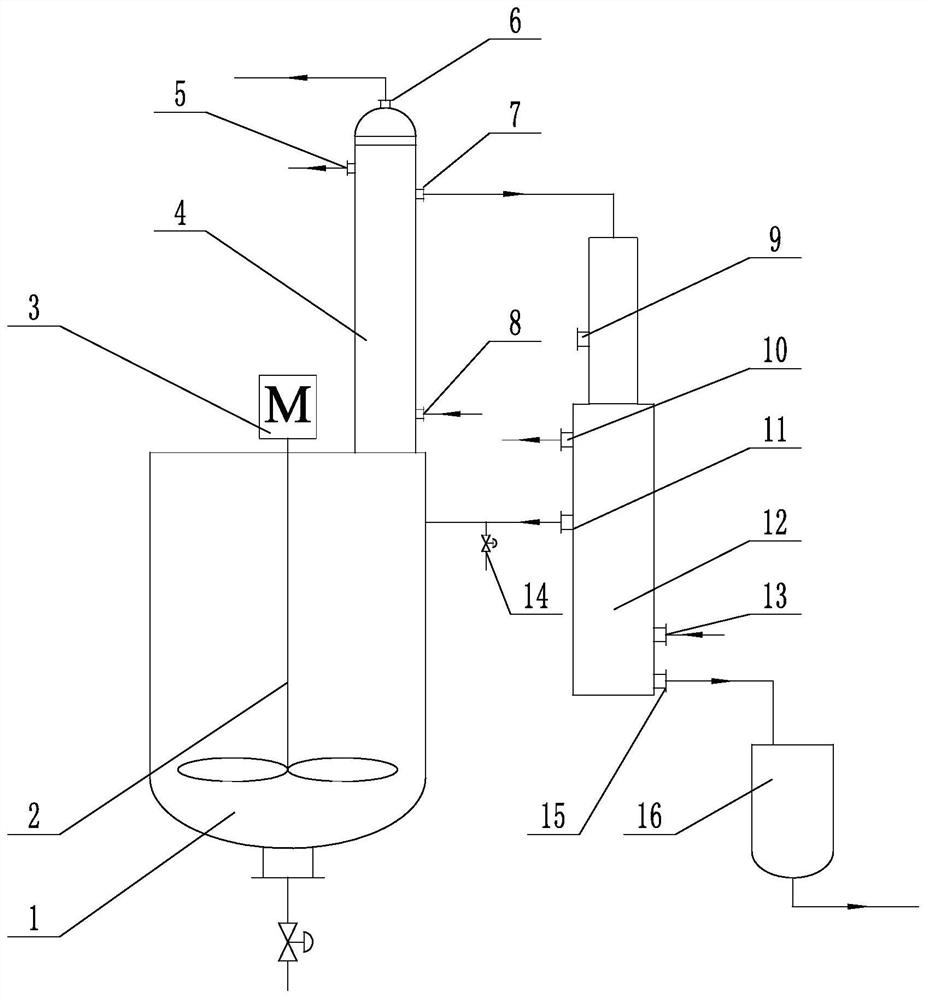

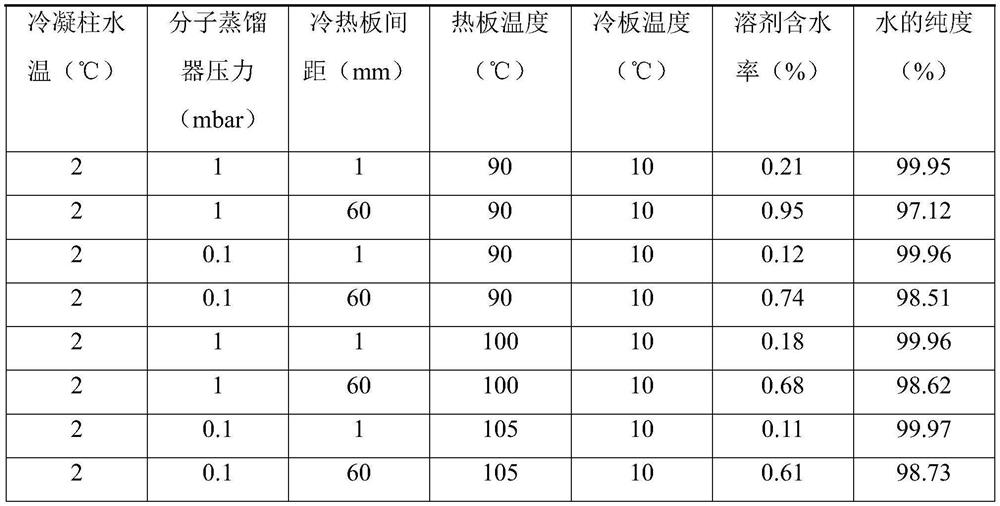

Polysulfone series resin polymerization dehydration process

The invention belongs to the technical field of high polymer materials, and particularly relates to a polysulfone series resin polymerization dehydration process. A rapid dehydration process is adopted in the polymerization process, and the system is heated to the boiling point of a solvent and is dehydrated in an azeotropic manner of the solvent and water. An ultralow-temperature condenser is matched with a novel molecular distiller, the mixed solution is quickly subjected to short-range separation, water and a pure solvent are recovered respectively, the almost anhydrous pure solvent is directly returned to the polymerization kettle, the solvent consumption for dehydration can be reduced by 30-50 wt%, no pollution is caused to the product, no dehydrating agent is left, the process is green and environmentally friendly; meanwhile, the production period can be shortened from 14-16 h to 10-12 h through the rapid and efficient dehydration process and the high dehydration temperature, andthe polymerization period is shortened by 25-28%. The obtained polysulfone polymer material has the advantages of high purity, low ash content, stable performance, low cost, no pollution and the like, and can be applied to the fields of medical instruments, aerospace, automobile parts, electronic components and the like.

Owner:FUHAI (DONGYING) ADVANCED MATERIAL TECH CO LTD

High frequency induction dewaxing and wax water separation dewaxing kettle

ActiveCN107282878BImprove purityImprove efficiencyFoundry mouldsFoundry coresExhaust valveAluminum silicate

The invention discloses a high-frequency induction type dewaxing kettle with a wax-water separation function. According to the technical scheme, the high-frequency induction type dewaxing kettle comprises a steam generating tank, a dewaxing cavity, a steam inlet control valve, aluminum silicate heat preservation materials and a high-frequency induction heating device. The steam generating tank communicates with the dewaxing cavity through the steam inlet control valve, and steam is controlled by the steam inlet control valve to enter the dewaxing cavity. The corresponding aluminum silicate heat preservation material is arranged on the outer layer of the steam generating tank. A high-frequency electromagnetic induction coil is evenly wound on the heat preservation material. The dewaxing cavity is also covered with the corresponding aluminum silicate heat preservation material. A high-frequency electromagnetic induction coil is arranged below the dewaxing cavity and used for heating the dewaxing cavity so as to separate water. An exhaust valve is arranged on the dewaxing cavity and used for exhausting water steam when the pressure is reached. A wax pumping device is connected with a wax outlet of the dewaxing cavity. The dewaxing kettle is heated through the electromagnetic induction principle, the heating speed is high, the heating efficiency is high, the dewaxing kettle has the rapid water removing function, so that further treatment of wax liquid is omitted, and after being pumped into a standing barrel through the wax pumping device and then is subjected to standing, the dewatered wax liquid can be directly used.

Owner:东营福浩精铸科技有限公司

Textile cloth drying equipment

ActiveCN112944862AReduce lossDry evenlyDrying gas arrangementsDrying chambers/containersProcess engineeringMechanical engineering

The invention discloses a textile cloth drying equipment. The equipment comprises a drying box, wherein a lifting mechanism is arranged in the center of the top of the inner wall of the drying box, a drying device is arranged among the bottom of the inner wall of the drying box and two corresponding sides of the bottom of the lifting mechanism, a heater is fixed to a position, close to the top, of one side of the inner wall of the drying box, one end of a curve pipe communicates with the air outlet end of the drying device, a gas dryer is fixed to a position, close to the bottom, of one side of the inner wall of the drying box, the air inlet end of the gas dryer communicates with the end, away from the drying device, of the curve pipe, and the air outlet end of the gas dryer communicates with the air inlet end of the heater. The invention relates to the technical field of textile drying. According to the textile cloth drying equipment, purposes of heat cyclic utilization and rapid drying are achieved, moisture can be extruded out in time, auxiliary time is shortened, drying is rapid and convenient, meanwhile, heat can be recycled, heat loss is reduced, and drying efficiency and the performance are improved.

Owner:湖北新耀实业有限公司

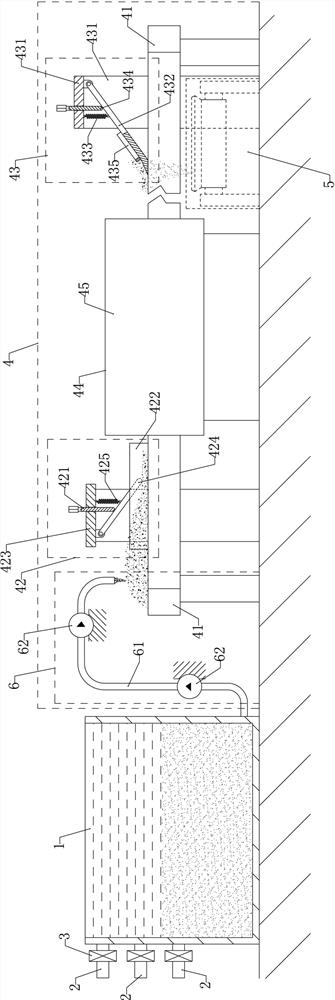

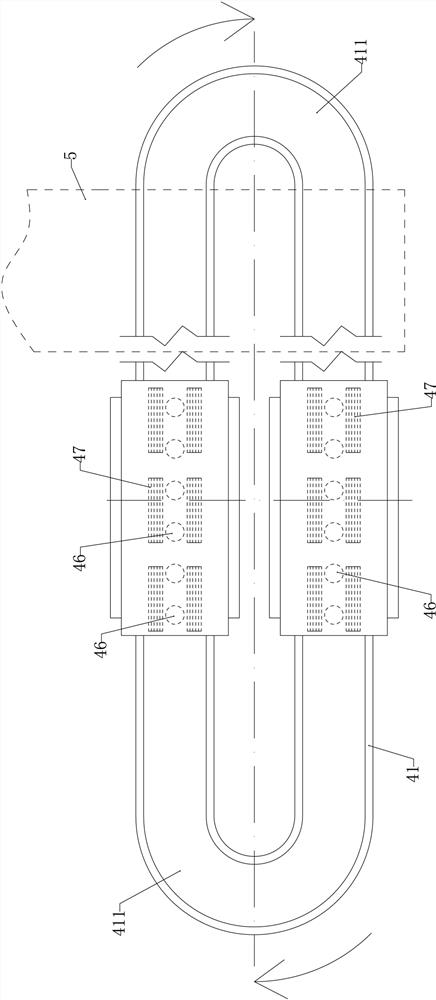

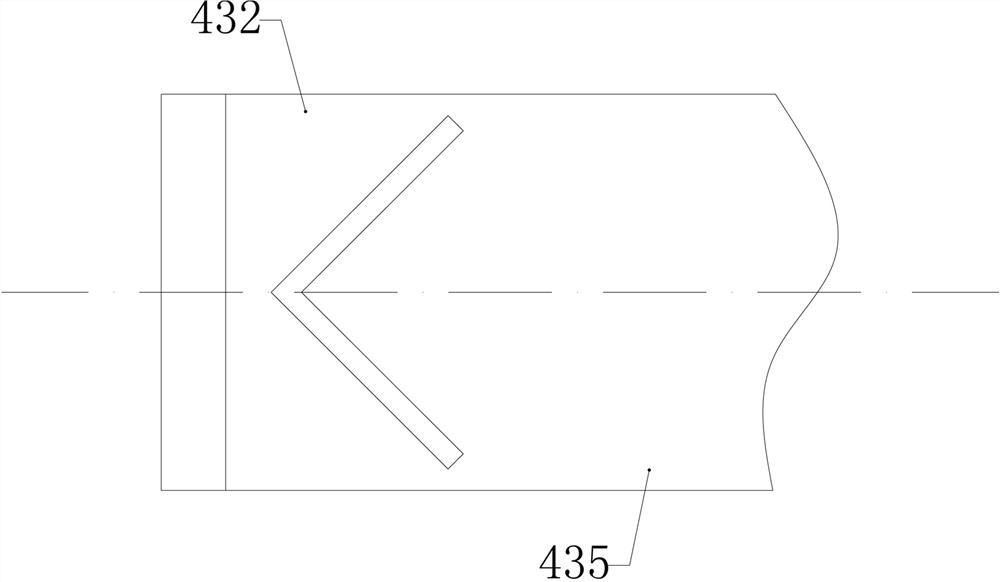

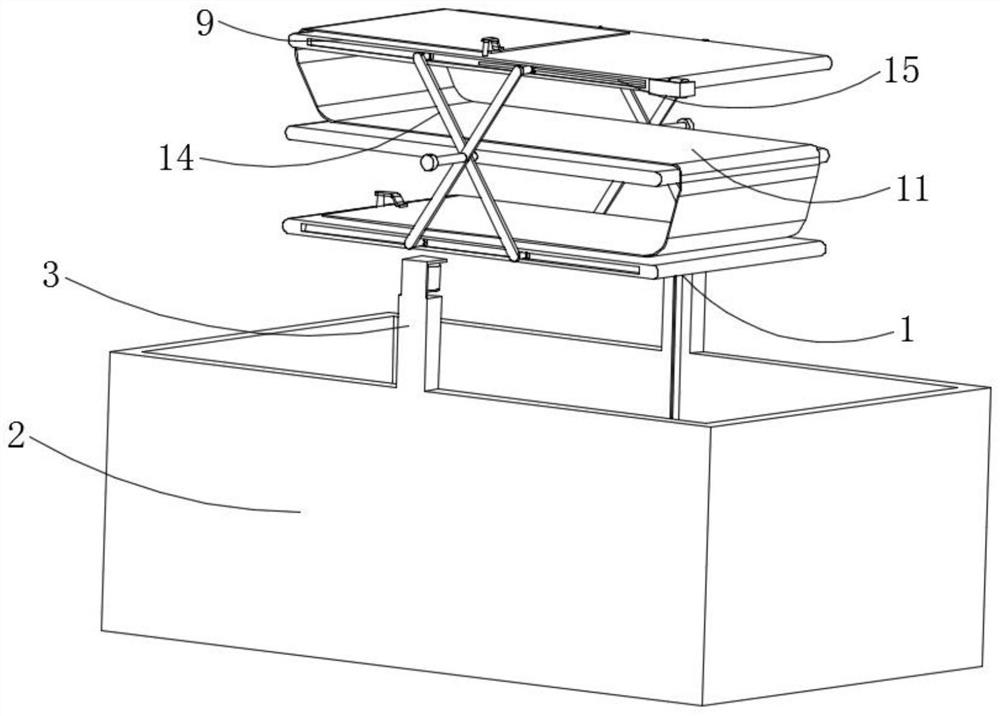

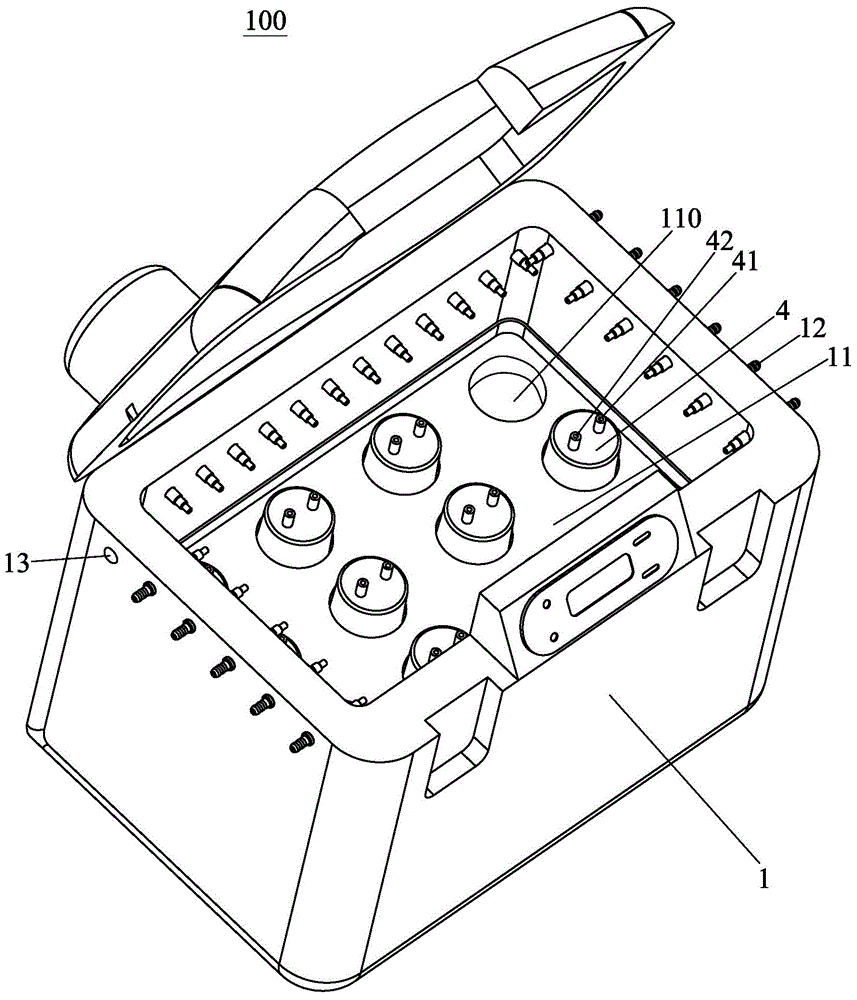

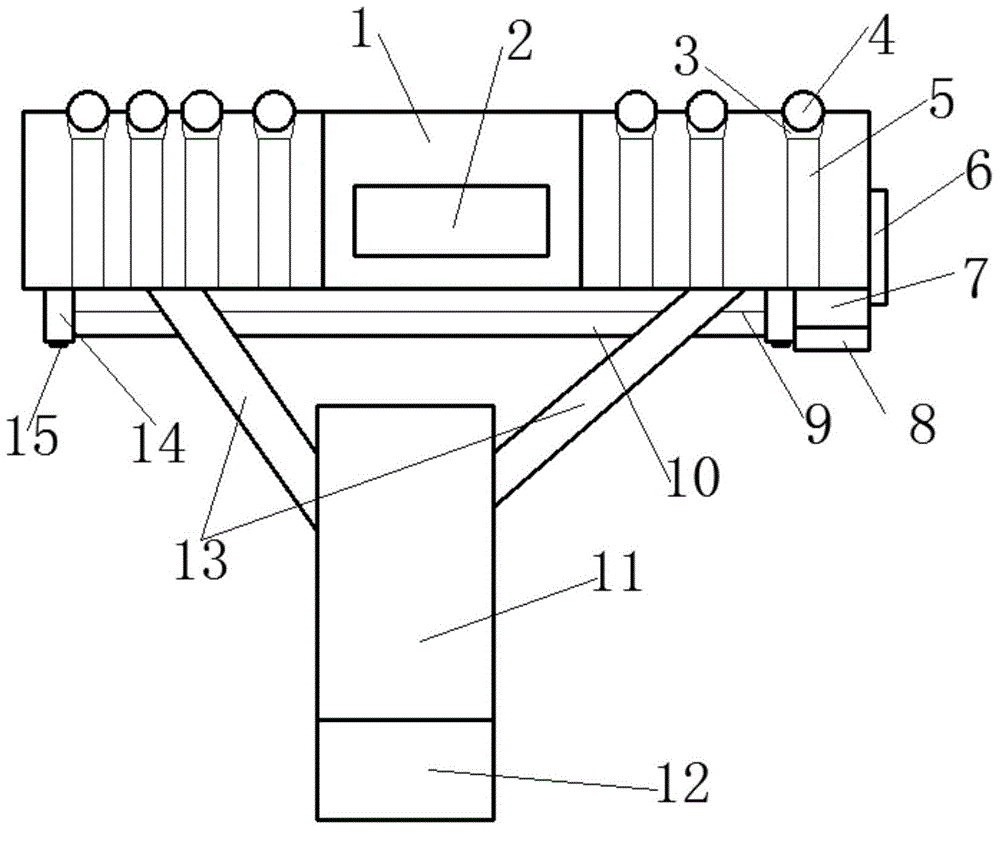

Sludge treatment method and matched treatment device

ActiveCN112174482AQuick water removalEasy to drySludge treatment by de-watering/drying/thickeningWater contaminantsSludgeProcess engineering

The invention relates to the technical field of sludge treatment, in particular to a sludge treatment method and a matched treatment device, and the method comprises the following steps: a, collectingwater-containing sludge into the sludge treatment device; b, beating and spraying the interior of the sludge; c, naturally settling; d, separating mud from water; e, performing sludge drying treatment; and f, pressing the semi-dry sludge into building blocks. According to the treatment method, the water-containing sludge can be quickly dewatered and dried, and the sludge treatment effect can be effectively guaranteed; when the sludge is treated, the uniform spreading of the sludge can be effectively realized, and finally, the sludge drying efficiency is improved; the paving thickness of the sludge and the shoveling thickness of the semi-dry sludge can be automatically adjusted, so that the high efficiency of the sludge drying treatment process is further ensured; the sludge is treated toobtain semi-dry sludge, and the semi-dry sludge is finally utilized to form a building block, so that the recycling rate of the sludge can be effectively improved, and the environmental friendliness of sludge treatment is guaranteed.

Owner:明洋(山东)环境科技有限公司

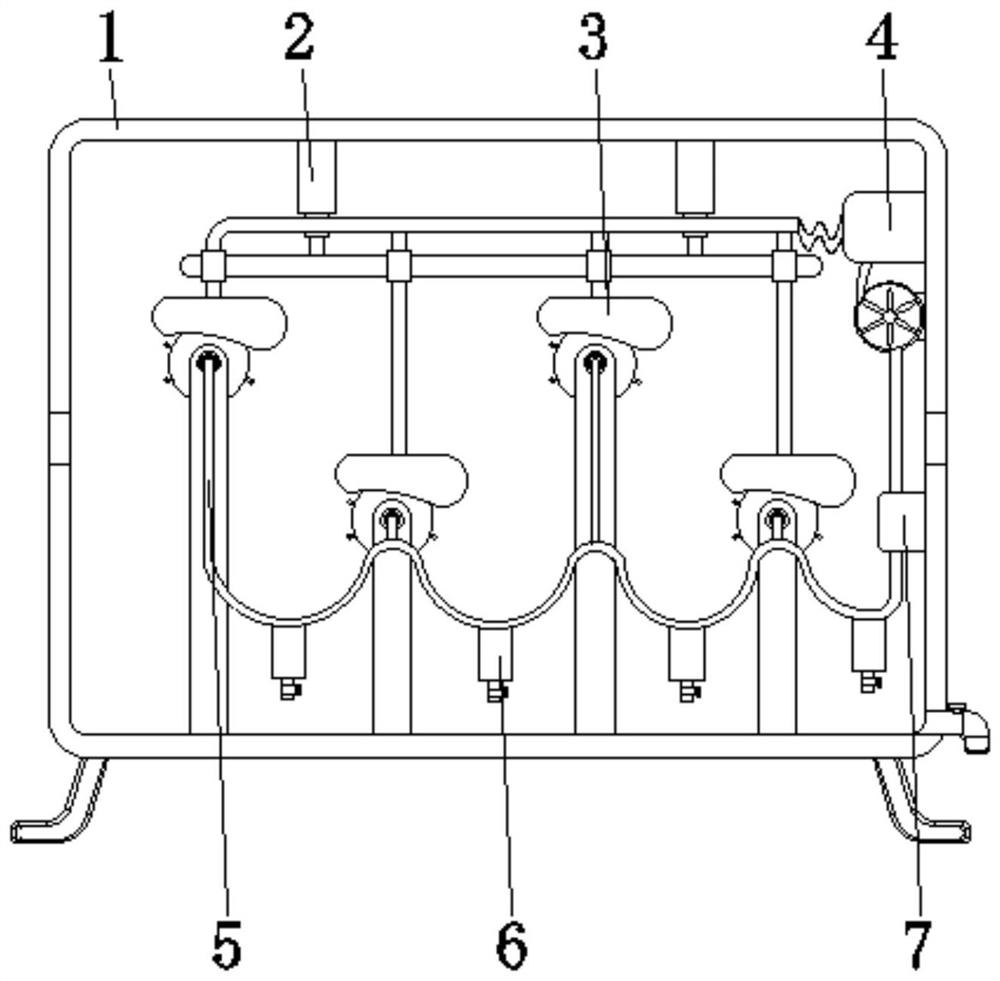

Energy-saving cleaning machine

InactiveCN107695015AEfficient removalReduce wasteDrying gas arrangementsCleaning using liquidsWater cyclingRinse water

The invention relates to an energy-saving cleaning machine, which includes a cleaning component, a drying component, a power component and a water circulation component; the cleaning component is installed at the front end of the drying component; the power component is installed under the cleaning component and the drying component; The water circulation component is connected to the cleaning component through a pipeline; the cleaning component includes a lotion high-pressure spray cleaning compartment, a lotion ultrasonic cleaning compartment, a spray rinsing compartment and a water cutting compartment; the lotion high-pressure spray compartment, lotion ultrasonic The cleaning chamber, the spray rinsing chamber and the water cutting chamber are assembled in sequence. The drying assembly includes a heating box, a hot air fan, a tunnel hot air circulation drying chamber, and a temperature sensing and alarm device; the heating tank is installed in the tunnel hot air circulation In the drying chamber; the hot air fan is installed above the tunnel hot air circulation drying chamber.

Owner:江苏盛锐光电科技有限公司

Efficient water removal structure of automobile rearview mirror

PendingCN111660939AEfficient water removal structureGuaranteed dewatering and demisting effectVehicle cleaningOptical viewingGear wheelEngineering

The invention discloses an efficient water removal structure of an automobile rearview mirror. The efficient water removal structure comprises a mirror body and a mirror surface connected with the mirror body; a plurality of air inlet ducts and a ventilating duct are formed in the outer wall of the mirror body; fan blades are mounted in the ventilating duct; an incomplete gear is fixedly connectedto the outer walls of the fan blades; a toothed plate meshed with the incomplete gear is arranged in the ventilating duct; a magnet frame is fixedly connected into the ventilating duct; a conductingrod located in the magnet frame is fixedly connected to the outer wall of the toothed plate; a U-shaped rod is fixedly connected to the lower side wall of the magnet frame; a groove is formed in the lower end of the toothed plate; and the end of the U-shaped rod is inserted into the groove. According to the efficient water removal structure of the automobile rearview mirror of the invention, airflow generated in the running process of an automobile drives the fan blades to rotate to generate current, and the current is collected; and when mirror surface water and mist removal needs to be conducted, a scraper plate rotates, the heated airflow is sprayed to make contact with the mirror surface, so that a mirror surface water and mist removal effect is guaranteed.

Owner:孟祥权

Tandem type constant power ribbon heater processing technology

InactiveCN106455168AImprove structural strengthAvoid direct contactHeating element shapesHeating element materialsGlass fiberConstant power

The invention discloses a tandem type constant power ribbon heater processing technology. The technology includes the following steps: 1. wrapping a glass fiber braid ply on the outside of an alloy heating core, arranging one layer of inorganic lubrication powder, extruding one layer of busbar insulating layer, coating a silicone oil, cooling the alloy heating core in the air and immersing the alloy heating core in water for performing cooling, scraping the silicone oil on the surface of the busbar insulating layer and recycling the silicone oil, and obtaining the constant power heating busbar; 2. coating one layer of heat conductive silica gel on the surface of the constant power heating busbar, such that the silica gel fills the gaps between each constant power heating busbar in a heating busbar group, curing the heat conductive silica gel which is filled in the heating busbar group; 3. adopting an extruding pipe extrusion die to extrude one layer of total insulating layer on the outside of the heating busbar which is processed by the step 2, then coating one layer silica oil on the outside of the total insulating layer, cooling the total insulating layer in the air and immersing the total insulating layer in water for performing cooling, taking the total insulating layer from a cooling water tank, scraping the silica oil on the surface of the total insulating layer and recycling the silica oil.

Owner:WUHU XUHUI ELECTRIC NEW MATERIAL

Cleaning machine provided with induction system

InactiveCN107716421AEfficient removalReduce wasteDrying gas arrangementsCleaning using liquidsFiltrationSlow rotation

The invention relates to a cleaning machine equipped with an induction system, the cleaning machine includes a cleaning assembly, a drying assembly, a power assembly and a water circulation assembly; the cleaning assembly is installed at the front end of the drying assembly; the power assembly is installed at the cleaning assembly and the drying assembly Below the assembly; the water circulation assembly is connected to the cleaning assembly through a pipeline; the cleaning assembly includes a lotion high-pressure spraying chamber, a lotion ultrasonic cleaning chamber, a spray rinsing chamber and a water cutting chamber; the lotion high-pressure spraying chamber, The spray rinsing bin and the water cutting bin are assembled together in sequence, and the drying components include a heating box, a hot air fan, and a tunnel hot air circulation drying bin; the floating ball induction system in this scheme can control the dirt load per unit of filter paper. If the liquid contains a lot of impurities, move the position of the floating ball down so that the filter cloth can rotate faster, thereby increasing the filtration rate of the entire filtration system, reducing the deposition of liquid in the dirty liquid chamber, and avoiding the slow rotation of the liquid due to the filter cloth overflow from the cavity.

Owner:江苏盛锐光电科技有限公司

Mite-killing processing method for heat-moisture comfortable bio-based fiber cloth

InactiveCN113215829AGood antibacterial and mite removal effectLong-lasting and highly effective antibacterial effectBiochemical fibre treatmentFibre typesBiotechnologyFiber

The invention discloses a mite-killing processing method for heat-moisture comfortable bio-based fiber cloth. The mite-killing processing method comprises the steps of antibacterial agent preparation, bio-based fiber antibacterial fabric preparation and secondary antibacterial treatment of cloth; through antibacterial treatment in the cloth spinning process, the internal structure of the cloth can contain antibacterial components, so that the antibacterial effect is more durable and efficient; the surface of the fabric is provided with an antibacterial layer through surface soaking antibacterial treatment, so that bacteria and mites are more difficult to survive in the fabric, and the antibacterial and acarus killing effects of the fabric are better and more efficient through combined use of the antibacterial treatment and the soaking antibacterial treatment.

Owner:安徽迪惠新材料科技有限公司

Quick water removal rearview mirror of new energy automobile

ActiveCN112172678APlay a dust-proof effectHigh electric heating efficiencyVehicle cleaningOptical viewingNew energyProcess engineering

The invention discloses a quick water removal rearview mirror of a new energy automobile, which comprises a rearview mirror body and a mirror surface embedded on the rearview mirror body, a heating device is arranged on the mirror surface, a breather pipe is embedded at the top of the rearview mirror body, a horn-shaped air inlet is formed in the outer wall of the side, away from the mirror surface, of the rearview mirror body, one end of the ventilation pipe is communicated with an air inlet, a row of uniform air outlet holes are formed in a mirror frame, located above the mirror surface, ofthe rearview mirror body, and the end, away from the air inlet, of the ventilation pipe is communicated with the multiple air outlet holes. The quick water removal rearview mirror has the advantages that when an automobile travels, stored energy of gas is used for generating electricity, external power supply is not needed, energy conservation and environmental protection are achieved, mirror surface heating, mechanical rainwater wiping and gas storage water blowing are used in cooperation for water removal of the rearview mirror, and the water removal effect is improved while the water removal efficiency is improved.

Owner:湖州力卓机械设备技术开发有限公司

A flattening device that can clean up waste liquid for recycling cans

ActiveCN109291494BEasy to throw outEasy dischargeDrying solid materials without heatDrying machines with non-progressive movementsWaste productEnvironmental engineering

The invention discloses a squishing device capable of cleaning waste liquid for recycling can waste products, and relates to the technical field of environmental protection. The can crushing device includes a body, the top of the front of the body is hinged with two hinges at the left end of the body, and the ends of the two hinges away from the body are hinged with a storage door, and the inside of the top of the body A drying chamber is provided, and a water removal device is provided inside the drying chamber and on the top surface of the machine body, and a transmission tank is opened inside the bottom end of the body and at the bottom of the drying chamber. The squashing equipment for can waste recycling that can clean up waste liquid can conveniently clean out the liquid inside the cans through the cooperation of the dewatering device, the discharge device, the return device, the squashing device and the conveying device, and promotes the production of cans. The normal operation of the flattening device further improves the working efficiency of the body, and increases the long-term use and practicability of the body.

Owner:嘉兴市建美轻体建材有限公司

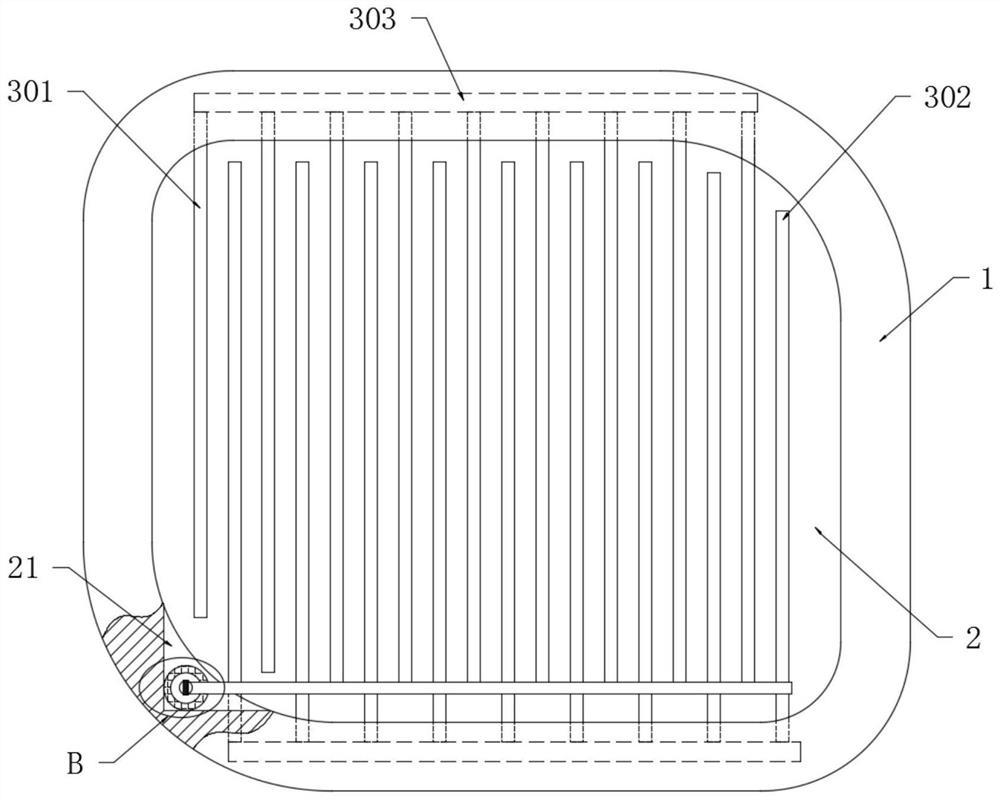

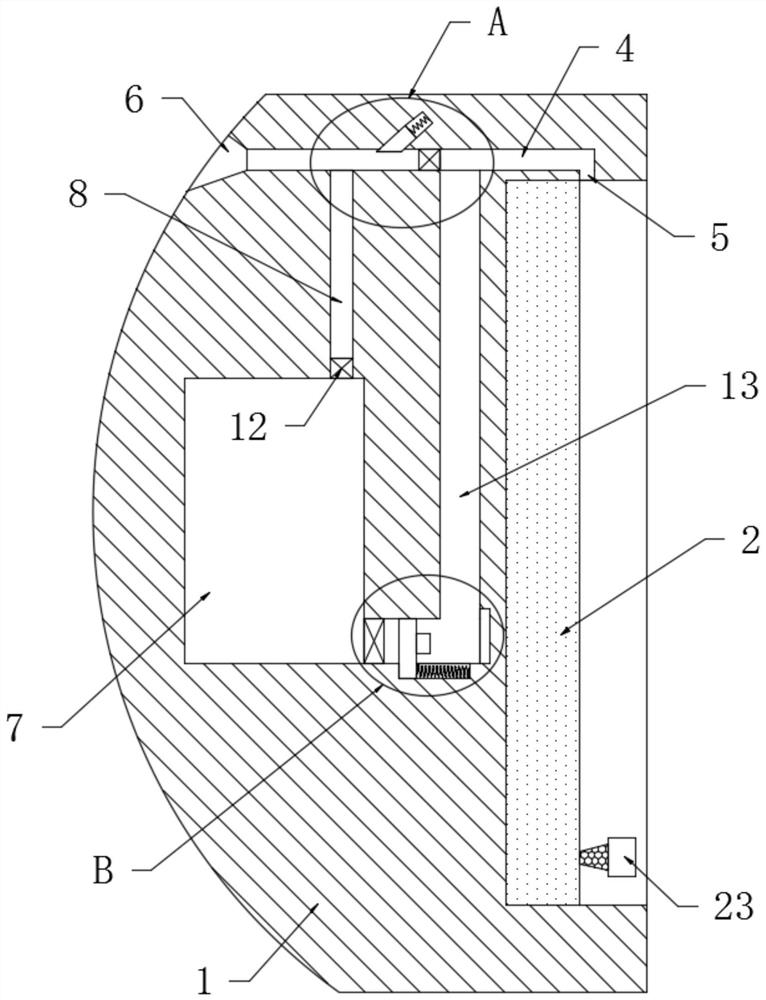

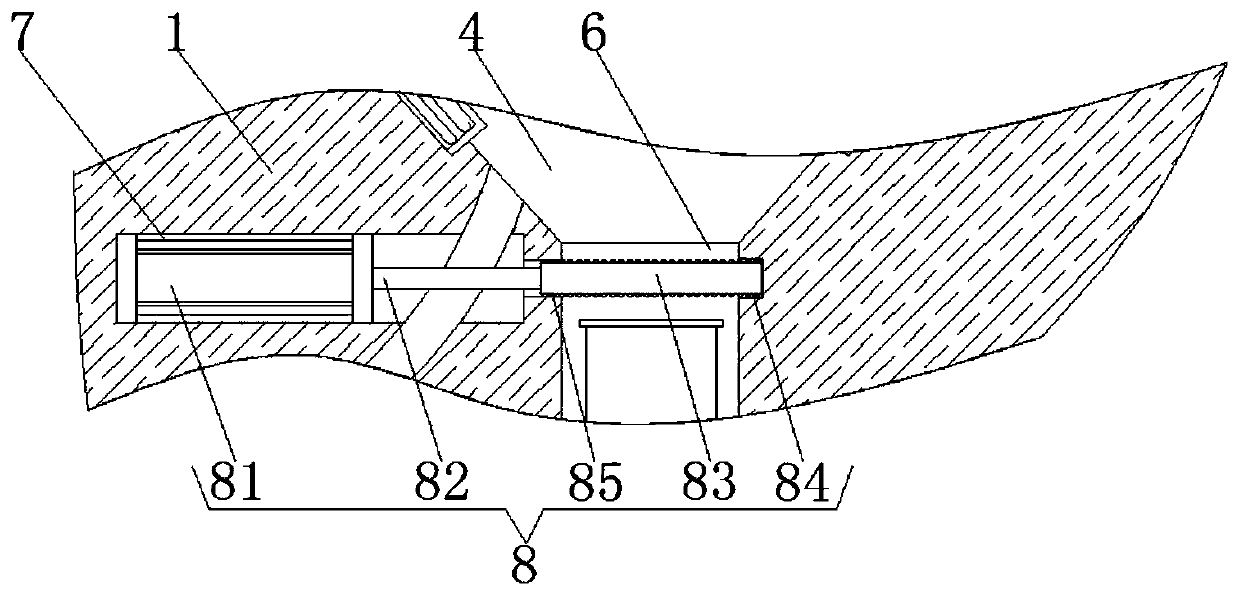

An umbrella water throwing device

InactiveCN111271942BQuick water removalEasy to useDrying solid materials without heatDrying chambers/containersWater storageStructural engineering

The invention discloses an umbrella water throwing device, which comprises a casing, the inner wall of the casing is fixedly connected with a partition, and the partition divides the inside of the casing into an operation chamber on the left and a control chamber on the right. The upper wall of the control chamber is provided with a communication port, the side wall of the operation chamber is provided with a placement port, the interior of the control chamber is provided with a control mechanism, and the interior of the operation chamber is provided with an operating mechanism and a water storage mechanism. The installation board is fixedly connected to the inner wall of the operation chamber, the side wall of the installation board is provided with a water-absorbing sponge, the inner wall of the operation chamber is connected to a placement board through the rotation of the first rotating shaft, and the placement board is provided with a clamping piece, so There is a water squeezing mechanism inside the operation chamber. The invention can quickly remove water from the umbrella without using plastic bags, which will not cause waste, and can also prevent the water on the soles from touching the ground, making the ground slippery and causing people to slip.

Owner:南京溧水高新产业股权投资有限公司

Novel dishwasher

InactiveCN107898418ASafe and convenient to killEasy to killTableware washing/rinsing machine detailsMicroorganismUv disinfection

The invention discloses a novel dishwasher. The dishwasher comprises a water tank, an ultraviolet lamp, a waterproof outer shell, a rotary motor, rotary blades, an air inlet and heaters, the ultraviolet lamp is installed in the middle of the inner side of the water tank, the waterproof outer shell is arranged at the bottom inside a dishwasher body, the rotary motor is arranged at the bottom of thewaterproof outer shell, the rotary blades are arranged at the top of the rotary motor, the air inlet is formed in the left side inside the dishwasher body, the heaters are arranged at the bottom inside the water tank and on the left side of a fan. The novel dishwasher has the advantages of being scientific and reasonable in structure and safe and convenient in use; users can conveniently eliminate harmful microorganisms in the water tank by arranging the ultraviolet sterilizing lamp, the users can rapidly and conveniently remove water inside the dishwasher by arranging the rotary blades, theusers can conveniently heat the water, chopsticks and bowls by arranging the heaters, and conveniences are provided for the users to use the dishwasher.

Owner:玉林市玉州区万通华信科技服务部

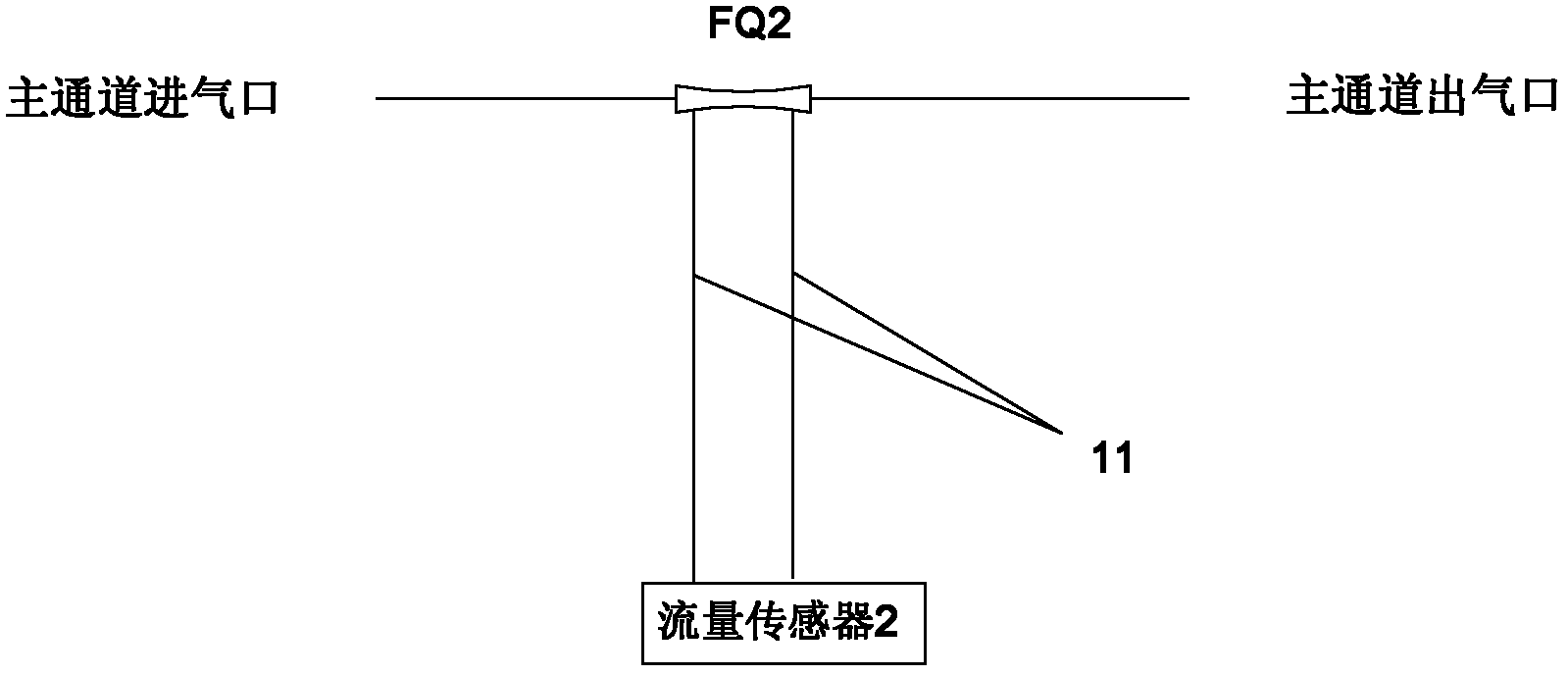

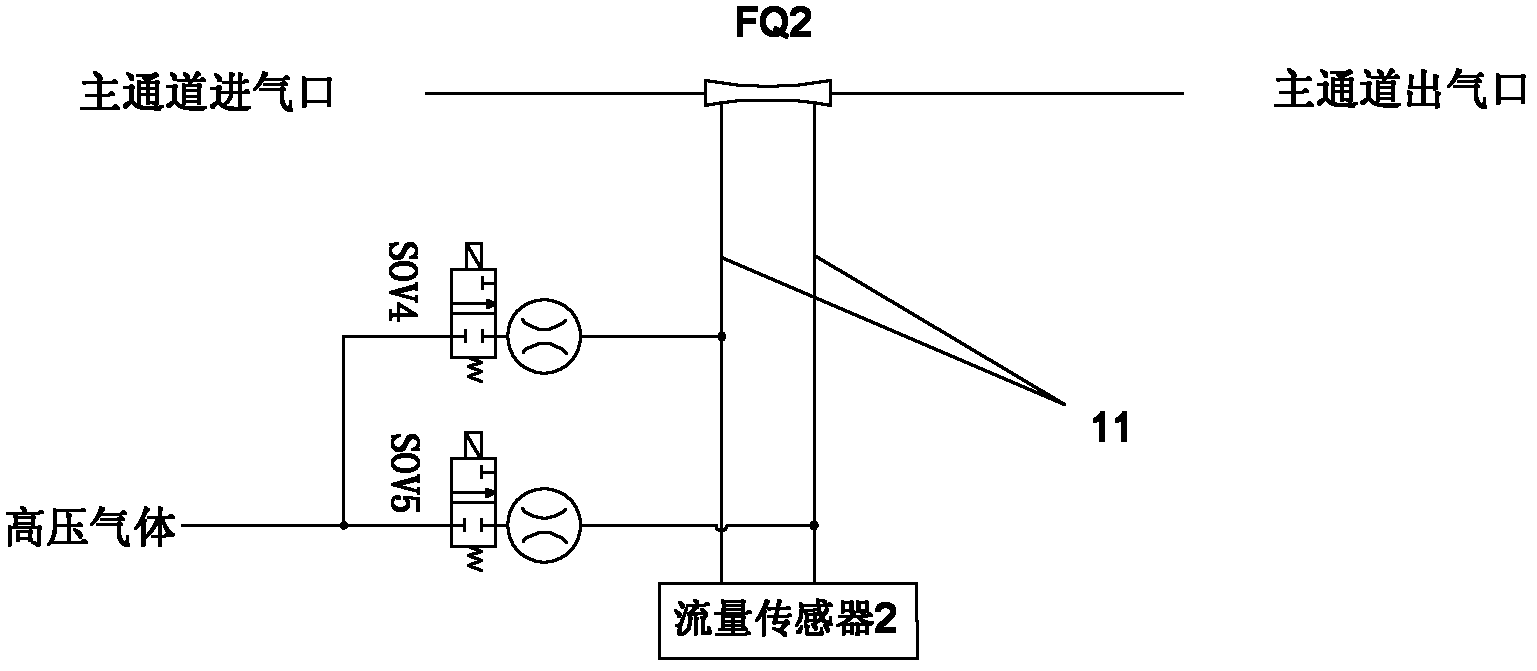

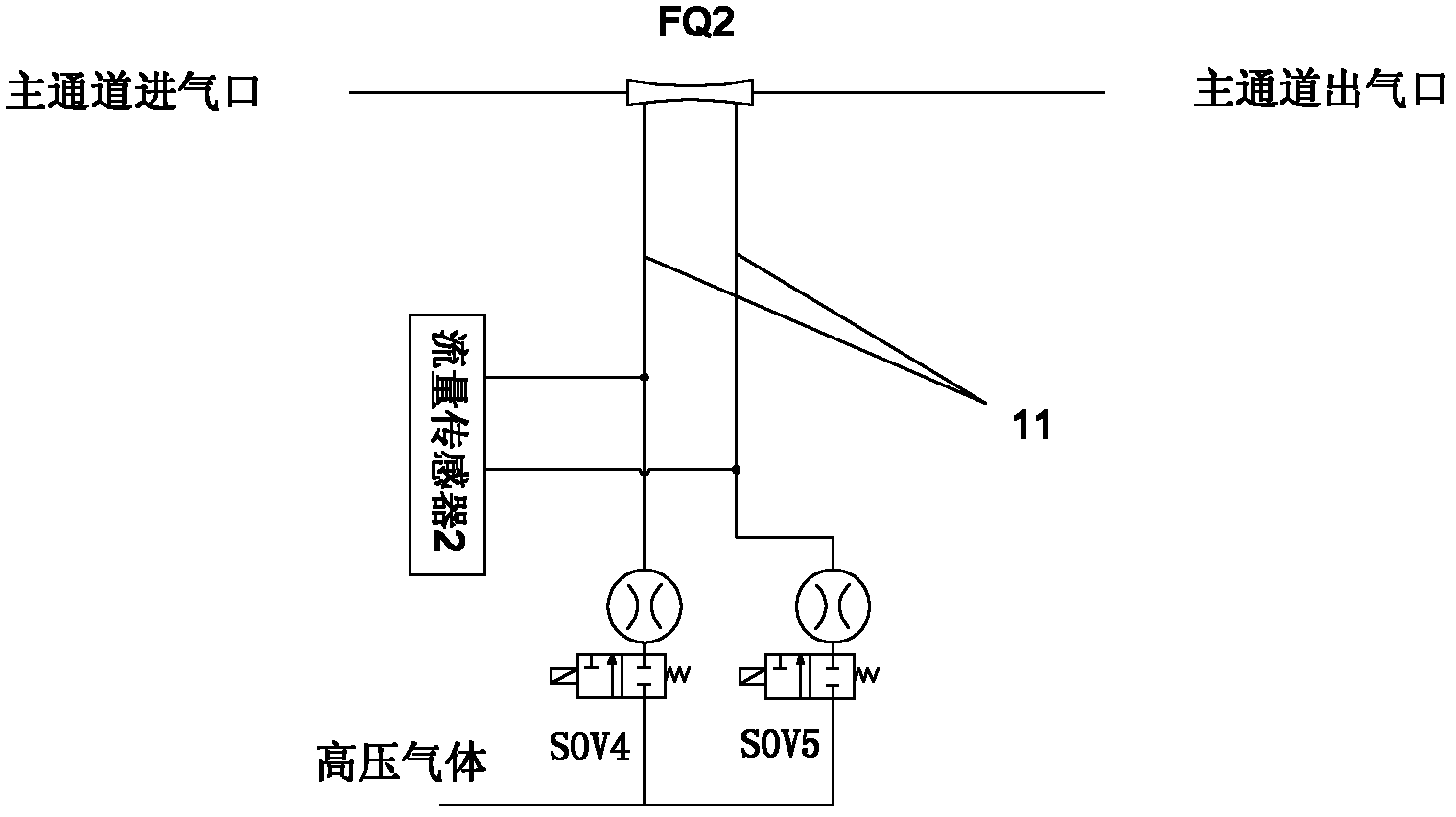

Water removal system of flow sensor

InactiveCN102506954AQuick water removalWork reliablyVolume meteringVolume/mass flow by differential pressureEngineeringHigh pressure

The invention relates to a water removal system of a flow sensor; an air channel is communicated with a flow sensor(2) and a flow sensor probe (FQ2), the water removal system of the flow sensor comprises a first electromagnetic valve (SOV4) and a second electromagnetic valve (SOV5), and a control unit, wherein bypass air channels at one ends of the first electromagnetic valve and the second electromagnetic valve are communicated with a corresponding detection branch air channel (11) between the flow sensor and the flow sensor probe (FQ2), an air channel at the other ends of the first electromagnetic valve and the second electromagnetic valve is connected with high-pressure air; the control unit which is electrically connected with control ends of the first electromagnetic valve and the second electromagnetic valve and is used for controlling the first electromagnetic valve and the second electromagnetic valve to be closed for performing the flow detection or controlling the first electromagnetic valve and the second electromagnetic valve to be opened for performing water removal or dredging by utilizing the high-pressure air. The water removal system of the flow sensor can be used for removing the condensed water in the detection branch air channel, and the flow sensor is accurate in detection, is reliable in usage and is long in service life.

Owner:于邦仲

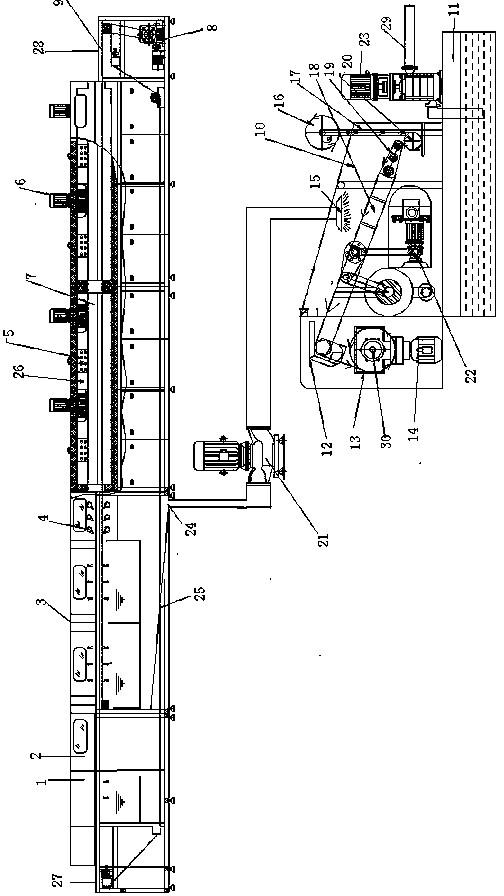

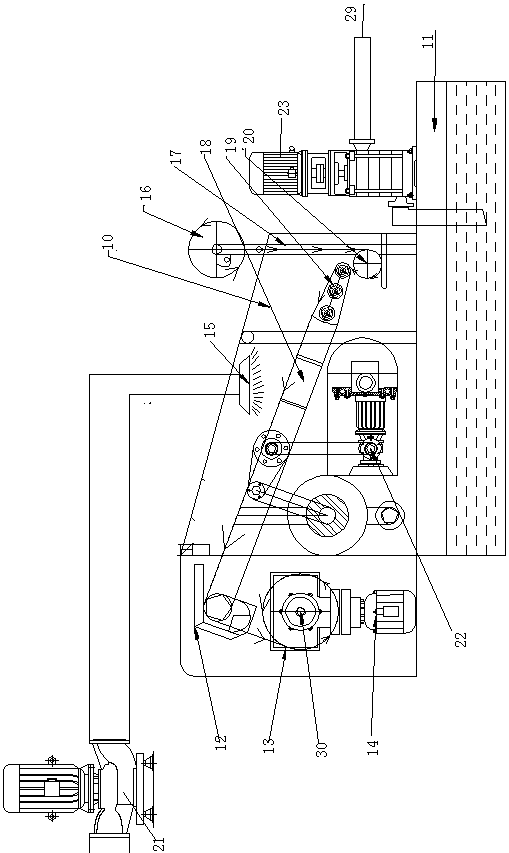

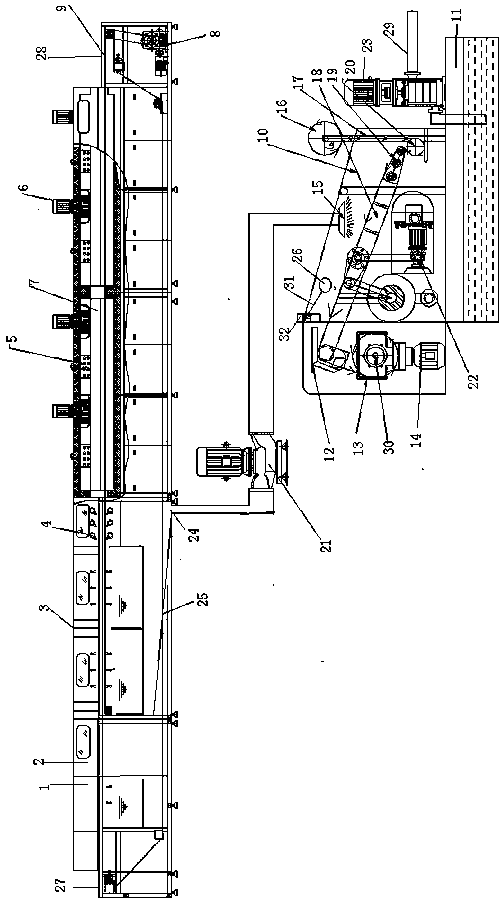

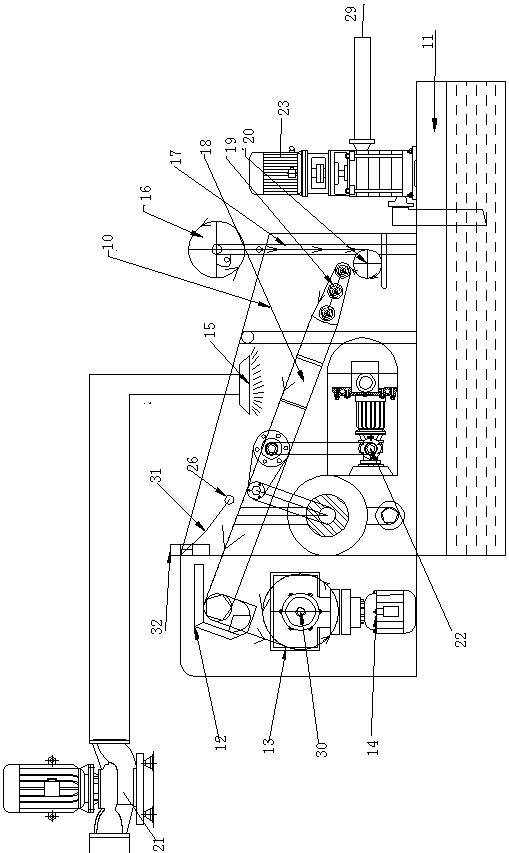

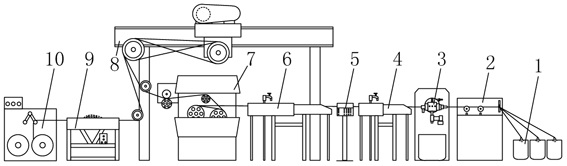

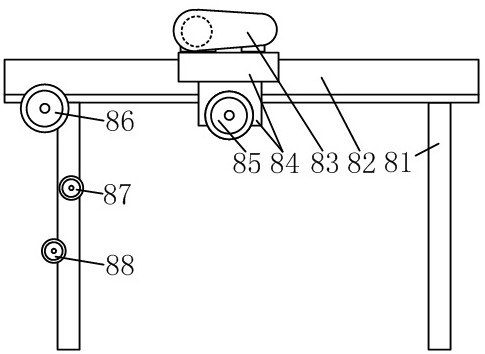

Wire extrusion production line

ActiveCN113205925BImprove the efficiency of extrusion productionImprove temperature adaptabilityInsulating conductors/cablesWinding machineProduction line

Owner:郴州市伟强科技有限公司

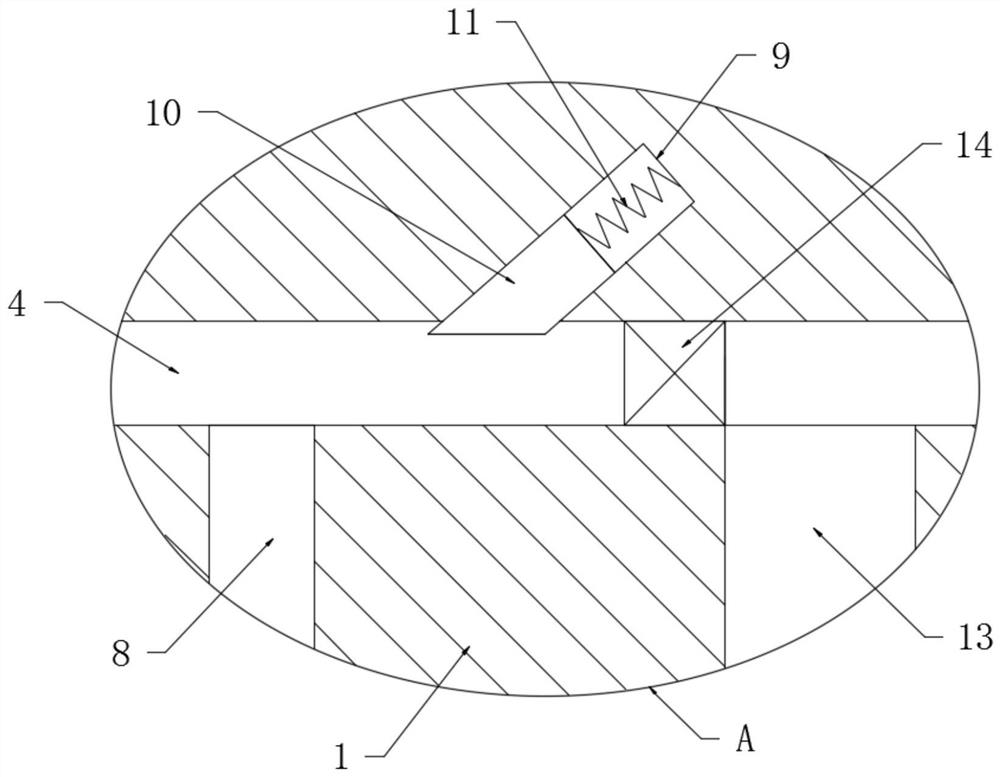

Anti-skid floor tile capable of quickly removing water

InactiveCN112942724AAnti-skid effectPlay a role in anti-slipCovering/liningsResiliently-mounted floorsSurface moistureConvex structure

The invention discloses an anti-skid floor tile capable of quickly removing water. The anti-skid floor tile comprises a floor tile body, wherein a cavity is formed in the floor tile body; a plurality of sliding grooves which are arranged in order are formed in the upper end surface of the floor tile body; the plurality of sliding grooves communicate with the cavity; a brick is connected to each sliding groove in a sliding manner; a horizontal partition plate is connected in the cavity in a sealing and sliding manner; a plurality of springs are welded to the lower end surface of the partition plate; and the lower ends of the plurality of springs are fixedly connected with the bottom cavity wall of the cavity. The anti-skid floor tile has the advantages that the surface of the floor tile body is of a concave-convex structure, so that a preliminary anti-skid effect can be achieved; meanwhile, negative pressure is formed by utilizing the difference of volume changes of air, and certain suction force is generated to soles on the bricks, so that an anti-skid effect is further achieved; and in the process of descending the bricks, induction current is generated by utilizing cutting magnetic induction lines to electrify heating blocks to work, so that the temperature of the bricks is increased, the volatilization speed of surface moisture is accelerated, and water on the surface of the floor tile is quickly removed.

Owner:饶秀支

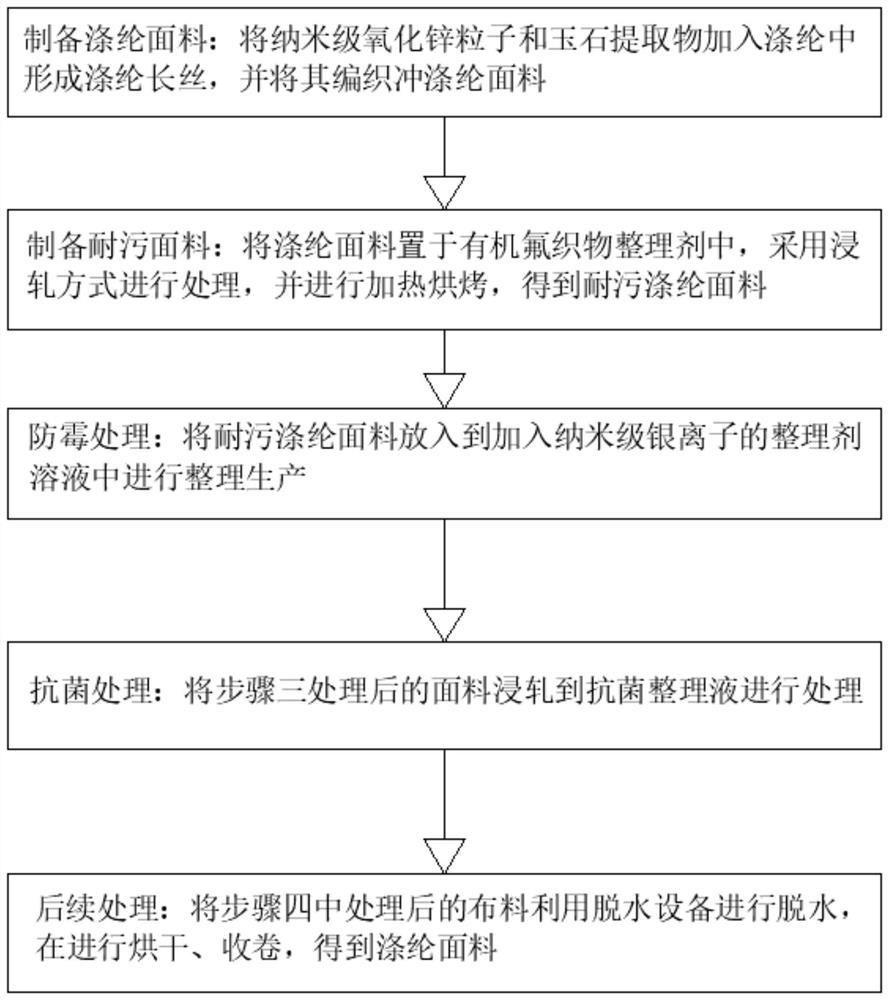

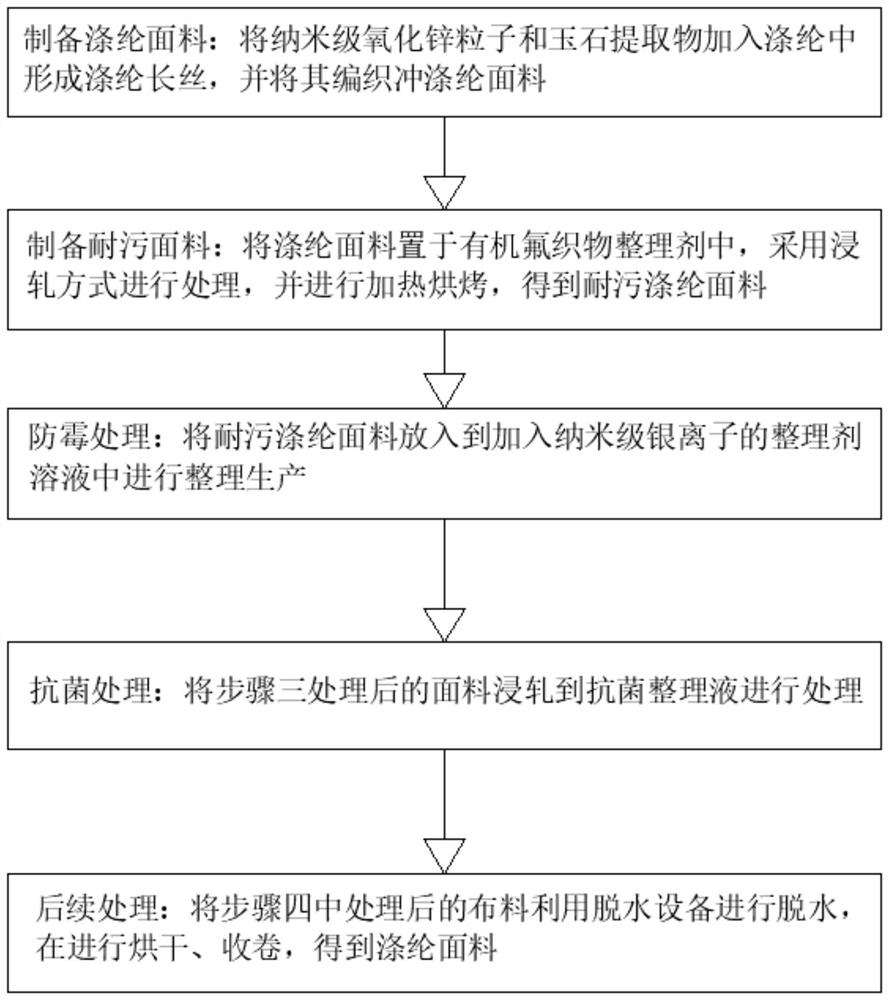

Production process of mildewproof and stain-resistant polyester fabric

ActiveCN113882147AEasy to useReduce breedingStain/soil resistant fibresBiochemical fibre treatmentPolyesterPolymer science

The invention discloses a production process of a mildewproof and stain-resistant polyester fabric. The production process comprises the following steps of preparing a polyester fabric; preparing a stain-resistant fabric: putting the polyester fabric into an organic fluorine fabric finishing agent, treating in a padding manner, and heating and baking to obtain the stain-resistant polyester fabric; performing mildewproof treatment: putting the stain-resistant polyester fabric into a finishing agent solution added with nanoscale silver ions for finishing production; performing antibacterial treatment: padding the fabric treated in the third step into antibacterial finishing liquid for treating; and performing subsequent treatment: dehydrating the cloth treated in the step 4 by utilizing dehydration equipment. The invention relates to the technical field of fabric production. According to the production process of the mildewproof and stain-resistant polyester fabric, the mildew-proof and stain-resistant effects are achieved, the high-quality fabric with the antibacterial, mildew-proof and stain-resistant functions and the like can be obtained, bacterium breeding is reduced, peculiar smells are not prone to occurring, personal life and environmental sanitation are not affected, and the use performance of the fabric is improved.

Owner:绍兴达伽马纺织有限公司

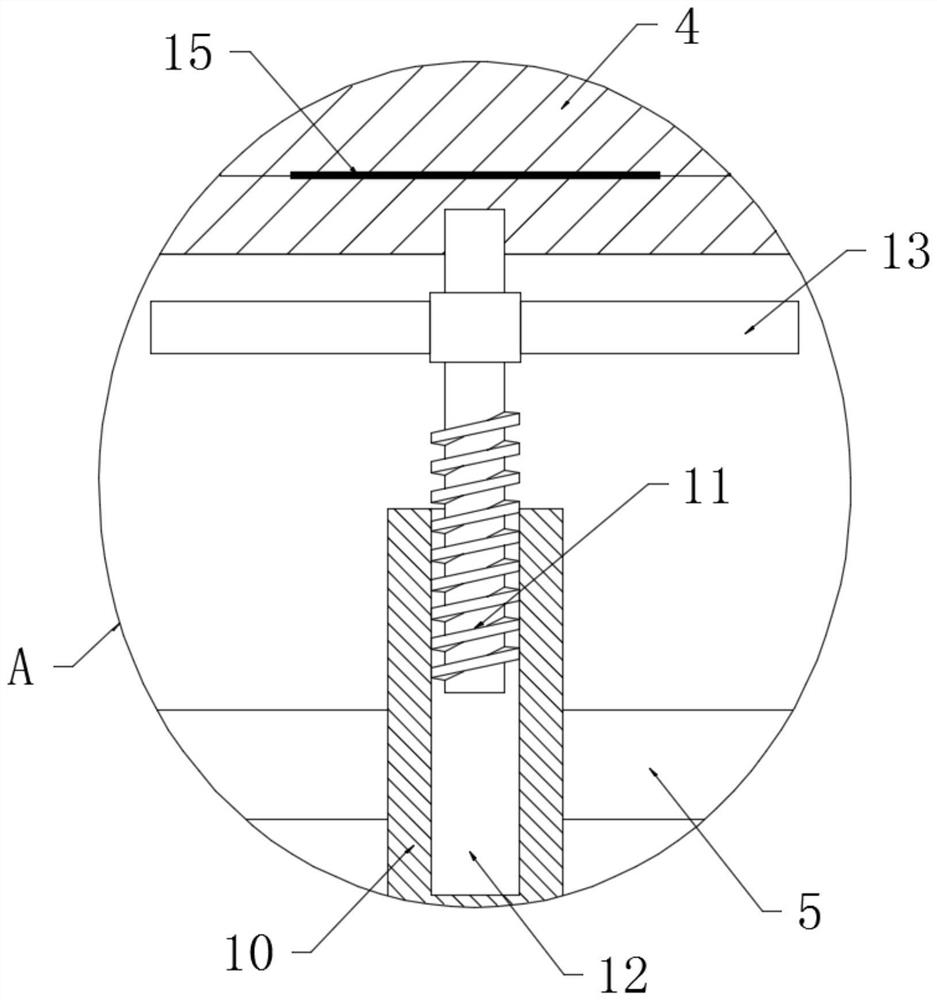

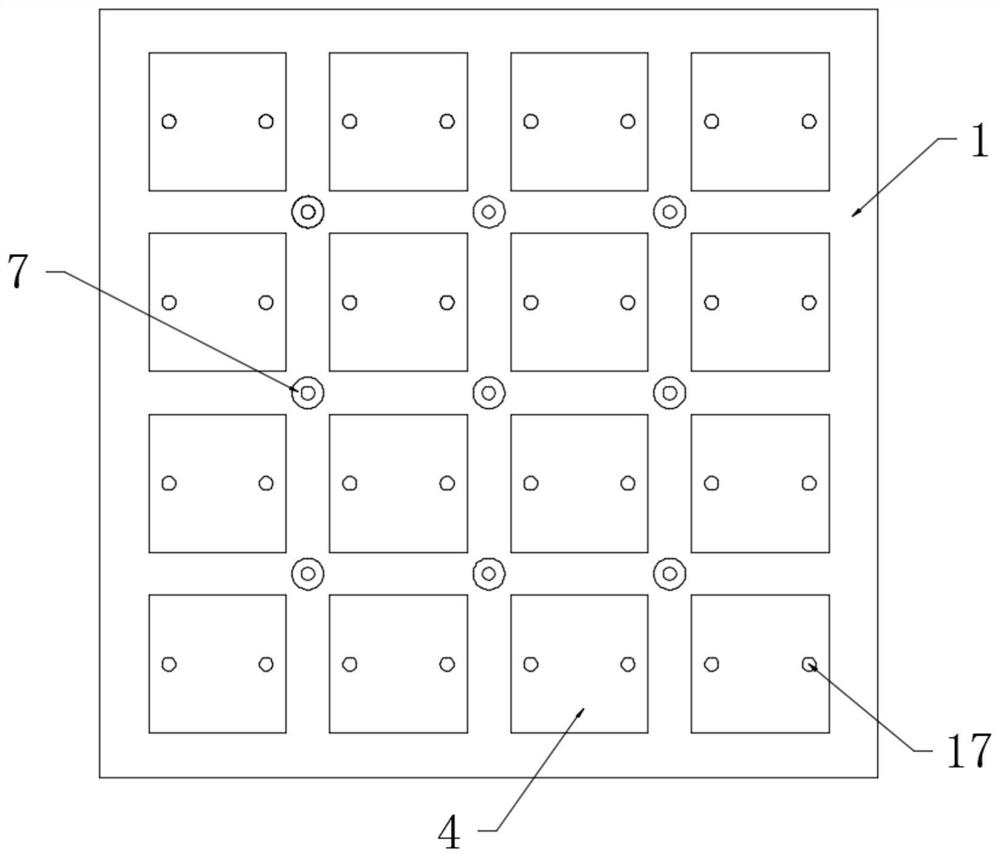

Umbrella dewatering device for shopping malls

ActiveCN109431024BEasy to remove waterQuick water removalWalking sticksApparel holdersAgricultural engineeringElectric machinery

The invention provides an umbrella dewatering device for shopping malls, and relates to the field of umbrella dewatering. The umbrella dewatering device for shopping malls includes a support base, a shoe drying mechanism is provided on the top of the support base, and a dewatering mechanism is provided on the top of the support base and on the right side of the shoe drying mechanism, and the top of the support base is provided with a water removal mechanism. A motor is provided on the right side of the dewatering mechanism, and a rotating rod is provided on the output shaft of the motor, and the end of the rotating rod away from the output shaft of the motor runs through one side of the dewatering mechanism and extends to the inside of the dewatering mechanism. A buffer box is provided at the bottom of the support seat, and two support rods are interspersed on the side of the buffer box away from the support seat. The umbrella water removal device for shopping malls is a kind of umbrella water removal device for shopping malls made by the technical solution of the present invention. This device is convenient for inserting multiple umbrellas into the water removal mechanism by setting the water removal mechanism, which is convenient. The umbrella quickly shakes water, thereby facilitating the rapid water removal of the umbrella.

Owner:温州枫艇网络科技有限公司

A kind of production technology of anti-mildew and anti-fouling polyester fabric

ActiveCN113882147BEasy to useReduce breedingStain/soil resistant fibresBiochemical fibre treatmentPolyesterPolymer science

Owner:绍兴达伽马纺织有限公司

A fast water-removing rearview mirror for new energy vehicles

ActiveCN112172678BPlay a dust-proof effectHigh electric heating efficiencyVehicle cleaningOptical viewingNew energyRear-view mirror

The invention discloses a fast water-removing rearview mirror for a new energy vehicle, which comprises a rearview mirror body and a mirror surface embedded on the rearview mirror body, a heating device is provided on the mirror surface, and a rearview mirror body has a A ventilation pipe is buried in the top position, and a trumpet-shaped air inlet is provided on the outer wall of the rearview mirror body away from the side of the mirror surface. One end of the ventilation pipe communicates with the air inlet, and the rearview mirror body is located at A row of uniform air outlets is provided on the frame above the mirror surface, and the end of the ventilation pipe away from the air inlet is connected with a plurality of air outlets. The advantage is that the present invention utilizes the energy storage of the gas to generate electricity when the vehicle is running, without external power supply, energy saving and environmental protection, and the combination of mirror surface heating, mechanical rain scraping and gas storage blowing is used to remove water from the rearview mirror, improving Improve the water removal efficiency while improving the water removal effect.

Owner:湖州力卓机械设备技术开发有限公司

Desiccant dewatering equipment

InactiveCN104568559AQuick water removalQuick and effective water removalPreparing sample for investigationDesiccantBottle

The invention discloses desiccant dewatering equipment which comprises a box, a heating device and a blower device, wherein a drying bottle is arranged in the box; a channel for connecting a gas inlet and a gas outlet of the drying bottle to the outside world is arranged in a side wall of the box; the heating device is arranged in the box to heat the drying bottle; the blower device comprises a shell, a fan, as well as an air inlet and an air outlet that are arranged in the shell; the outside air enters the shell from the air inlet and is discharged from the air outlet after pressurization by the fan; the air outlet is connected to the gas inlet by the channel and is connected to the outside world by the gas outlet. The desiccant dewatering equipment can rapidly dewater the desiccant in the drying bottle.

Owner:宁波市华测检测技术有限公司

Metastable mineral-amino acid preparations for food and beverage fortification

InactiveUS7175867B2Deterioration of flavorQuick water removalAnimal feeding stuffAccessory food factorsOrganic acidCoordination complex

The present invention is directed to metastable mineral-amino acid complexes that are formed by combining a mineral oxide, hydroxide, or carbonate an amino acid and an organic acid. The complexes may be used to fortify a variety of food and beverage products.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Self-water removal device for automobile rearview mirror

InactiveCN112193163AReduce line of sightQuick water removalVehicle cleaningOptical viewingAir compressionEngineering

The invention discloses a self-water removal device for automobile rearview mirror which comprises a rearview mirror body and a mirror surface embedded in the rearview mirror body; a heating water removal device is arranged on the mirror surface; a cylindrical cavity and a cavity are formed in the rearview mirror body; the cylindrical cavity is located above the cavity; a sliding rod is slidably connected to the center of the top of the cylindrical cavity in a penetrating mode, the upper end of the sliding rod penetrates through the top of the rearview mirror body and is welded with a wing plate, piezoelectric ceramic is fixedly connected to the bottom of the cylindrical cavity, and an energy storage device is arranged in the cylindrical cavity. The device has the advantages that after thepiezoelectric ceramic is impacted, an electromagnet is electrified to generate magnetism, air above a piston plate is compressed, and then high-speed airflow attached to the mirror surface is blown out from the air outlet hole in the upper portion of the mirror surface through an air guide pipe, so that water on the mirror surface is rapidly removed; meanwhile, circuits of a first conductive strip and a second conductive strip are conducted through water drops, so that the piezoelectric ceramic performs point heating on the water drops, and the water removal efficiency is improved.

Owner:德清之家纺织有限公司

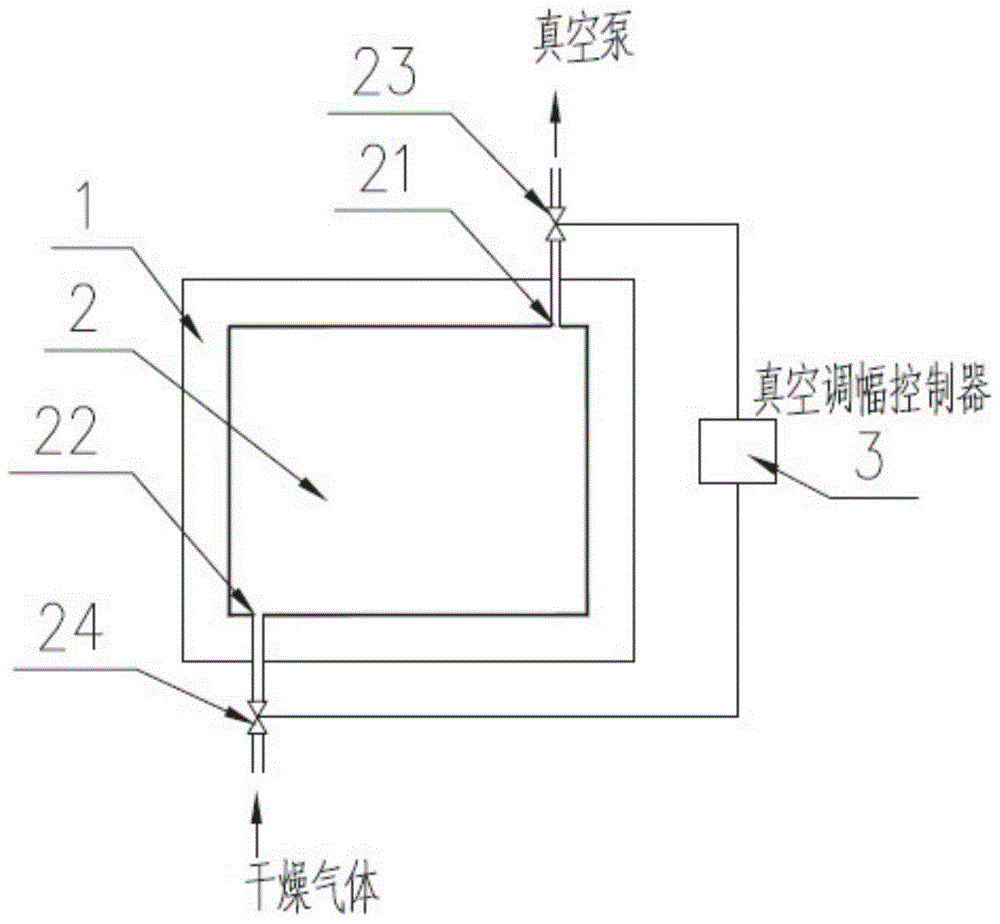

A deep drying method and an amplitude-modulated vacuum drying oven

ActiveCN103884156BAccelerated disengagementSpeed up the desorption and desorption processDrying solid materials without heatDrying machines with local agitationDesorptionPulp and paper industry

The invention discloses a deep drying method. By means of the method, the vacuum degree and / or air pressure intensity inside a container used for containing substances to be dried are changed regularly, the regular change of the vacuum degree and / or air pressure enables water molecules to break away from micro holes in the surfaces of the substances more rapidly, then the water molecules are pumped out of the drying container effectively, desorption of the absorbed water inside the substances to be dried is accelerated, and therefore the technical effects of being faster in water removal, more thorough in drying and better in water removal effect are achieved. The invention further discloses an amplitude-regulating type vacuum drying box. The deep drying method and the amplitude-regulating type vacuum drying box achieve the technical effects of being faster in water removal, more thorough in drying and better in water removal effect, can be applied to some electronic industries, and break through the bottleneck caused by water on the industries.

Owner:VIGOR GAS PURIFICATION TECHNOLOGIES (SUZHOU) CO LTD

Quick-dry bicycle saddle

The invention discloses a quick-dry bicycle saddle. The quick-dry bicycle saddle comprises a saddle body located on a bicycle. A hollow hole is arranged in the middle of the saddle body. A water sensor is arranged inside the hollow hole. Concave holes are formed in the periphery of the hollow hole. A through hole is formed in the bottom face of each concave hole. A massage ball is arranged on each concave hole. A heating pipe is arranged on the inner bottom of the saddle body. An electric heating wire is arranged inside the heating pipe. A fixing box is arranged at the tail end of the heating pipe and located behind the inner side of the saddle body. A storage battery is arranged inside the fixing box. A solar battery panel is arranged on the rear side of the saddle body. The solar battery panel is connected with the storage battery. A supporting frame is arranged below the saddle body and composed of three supporting rods and a supporting column. A fixing clamp is arranged at the bottom end of the supporting column. The saddle body can be mainly heated through the electric heating wire, and therefore rainwater on the saddle body is dried by distillation so as to achieve the purpose of rapid water removal.

Owner:泰州市建业车件制造有限公司

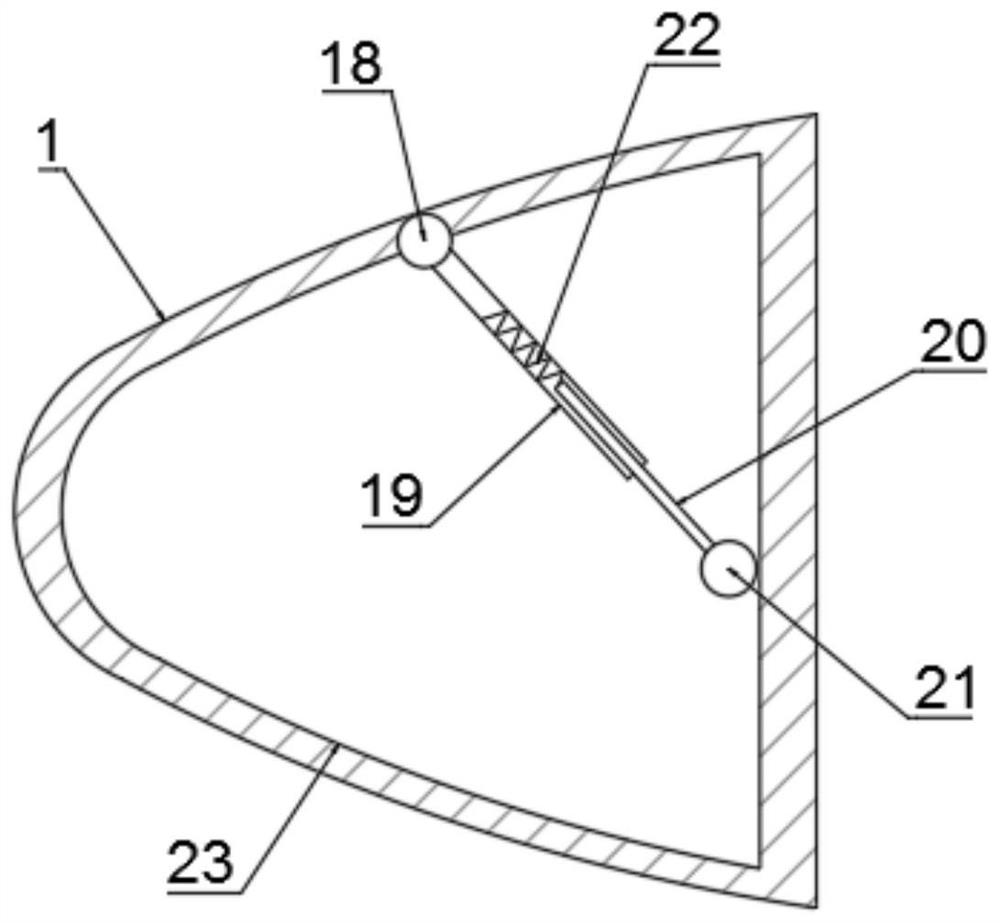

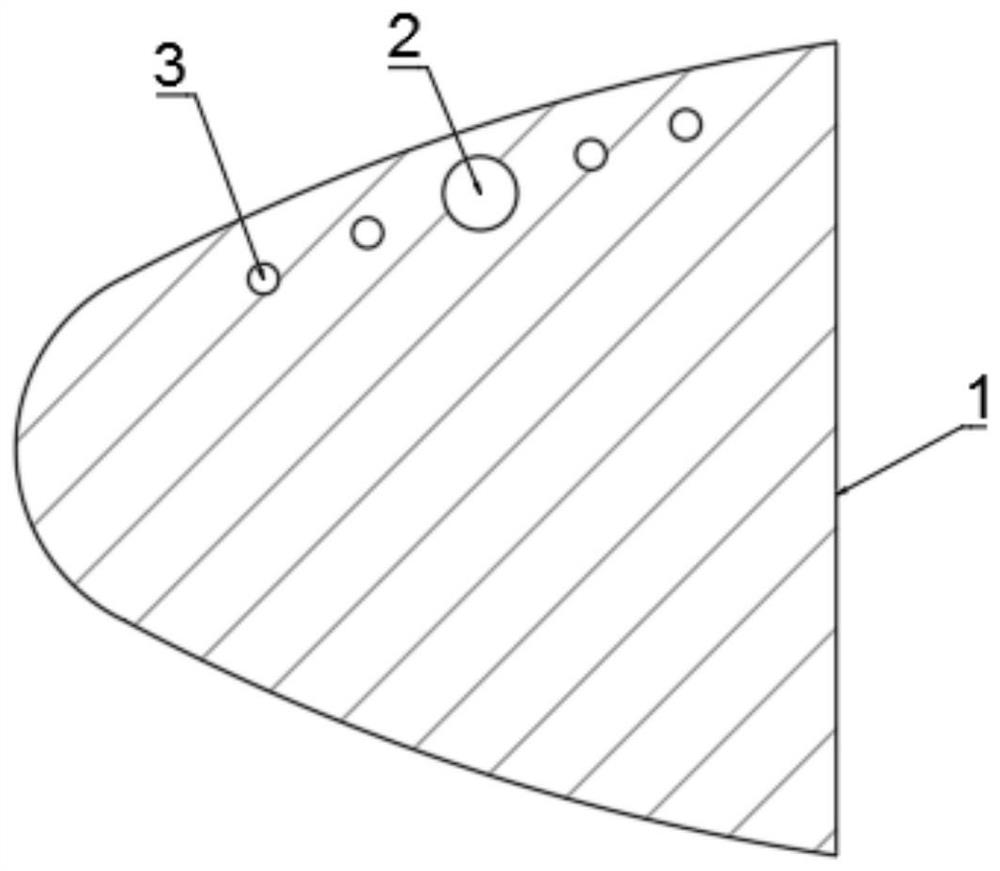

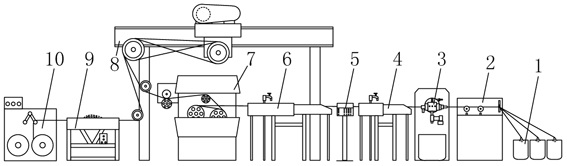

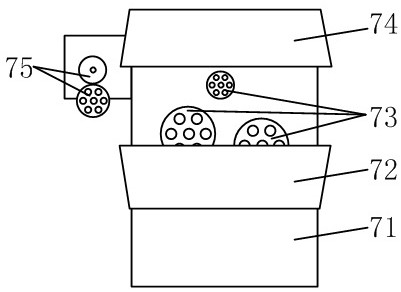

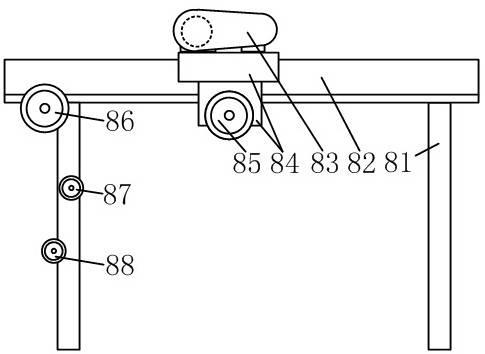

Electric wire extrusion molding production line

ActiveCN113205925AImprove the efficiency of extrusion productionImprove temperature adaptabilityInsulating conductors/cablesMolding machineElectric machinery

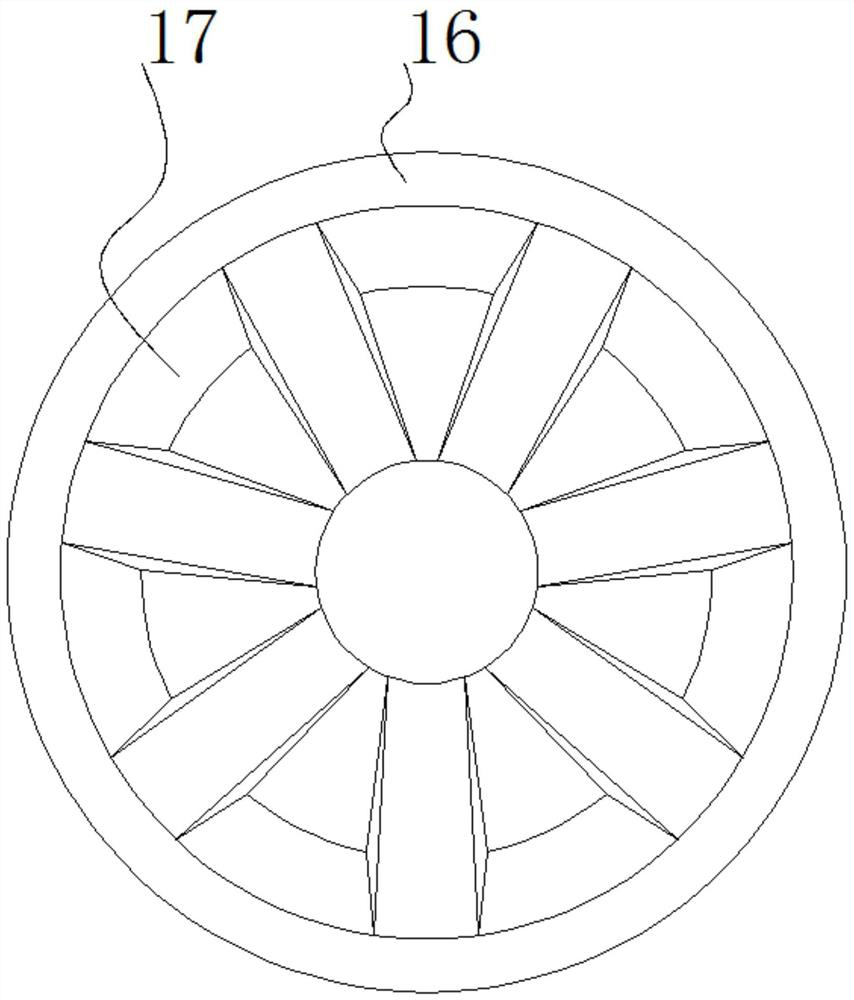

The invention provides an electric wire extrusion molding production line which comprises a core wire barrel, a drying machine, an extrusion molding machine, a first cooling water tank, a diameter measuring instrument, a second cooling water tank, a vacuum dehydrator, an oil passing machine, a winding take-up machine and an airing frame. The vacuum dehydrator comprises a case, an air inlet box, an air exhaust box, a water removal wheel set and a traction wheel set; a filtering water tank is arranged at the bottom of an inner cavity of the case, a water baffle, filtering sponge and a vacuum fan are sequentially arranged in the middle of the case from bottom to top, an air inlet box is communicated with the bottom of the case, an air exhaust box is communicated with the top of the case, and an opening of the air exhaust box and an opening of the air inlet box are vertically opposite and arranged on the front face of the case. The water removal wheel set is mounted on the front surface of the case between the air inlet box and the air outlet box, the water removal wheel set comprises three winding wheels which are triangularly arranged at intervals, and a plurality of circles of winding grooves are formed in the outer ring of each winding wheel; and the traction wheel set is arranged on the side portion of the machine box and comprises a pair of traction wheels abutting against each other and a traction motor driving the traction wheels to rotate.

Owner:郴州市伟强科技有限公司

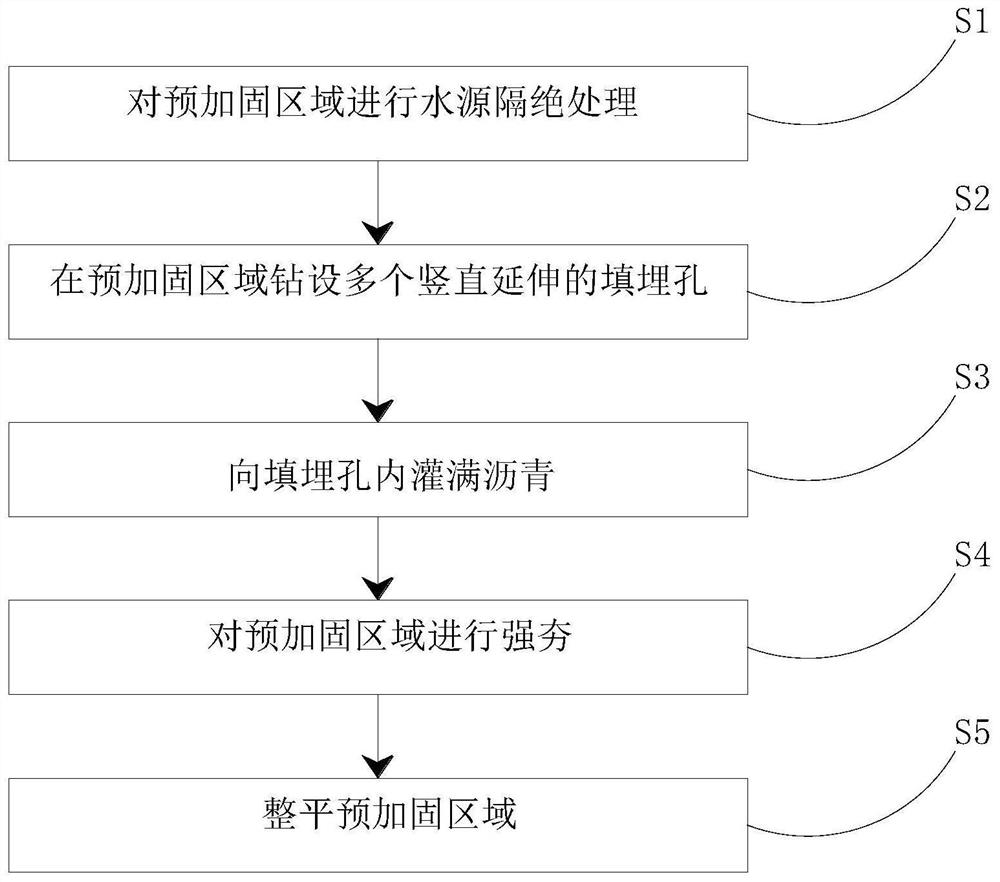

A ground reinforcement method

ActiveCN110904946BAvoid fluffyReduce moisture residueSoil preservationWater sourceArchitectural engineering

The present invention proposes a foundation reinforcement method, comprising the following steps: S1, performing water source isolation treatment on the pre-reinforcement area; S2, drilling a plurality of vertically extending landfill holes in the pre-reinforcement area; Filling with asphalt; S4, performing dynamic compaction on the pre-reinforcement area; S5, leveling the pre-reinforcement area. The invention prevents the external water source from infiltrating into the foundation and causing the foundation to be soft by isolating the water source of the foundation; opening a landfill hole in the foundation and pouring asphalt, and the asphalt has plasticity after cooling, which can make the foundation soil have certain ductility.

Owner:ANHUI SANLIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com