Cleaning machine provided with induction system

An induction system and cleaning machine technology, applied in the field of cleaning machines, can solve the problems of large water consumption, environmental pollution and low efficiency of cleaning machines, and achieve the effects of facilitating rapid advancement, increasing dirt load, and reducing deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

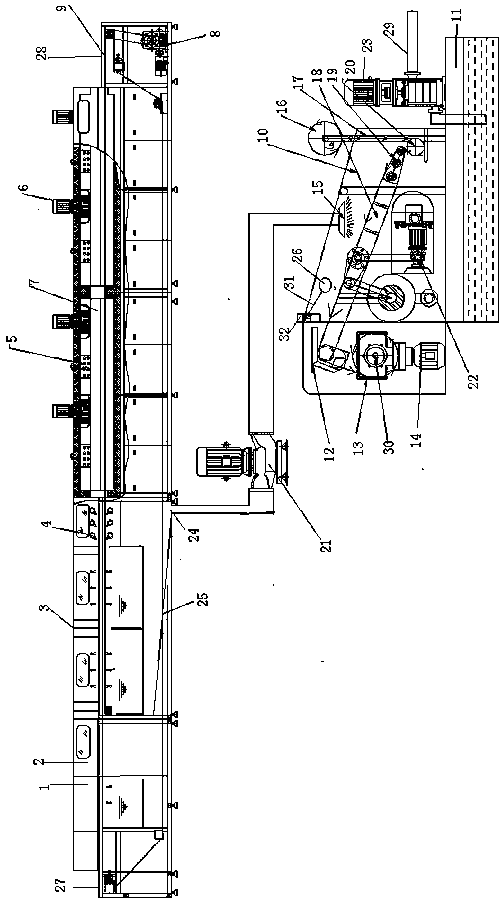

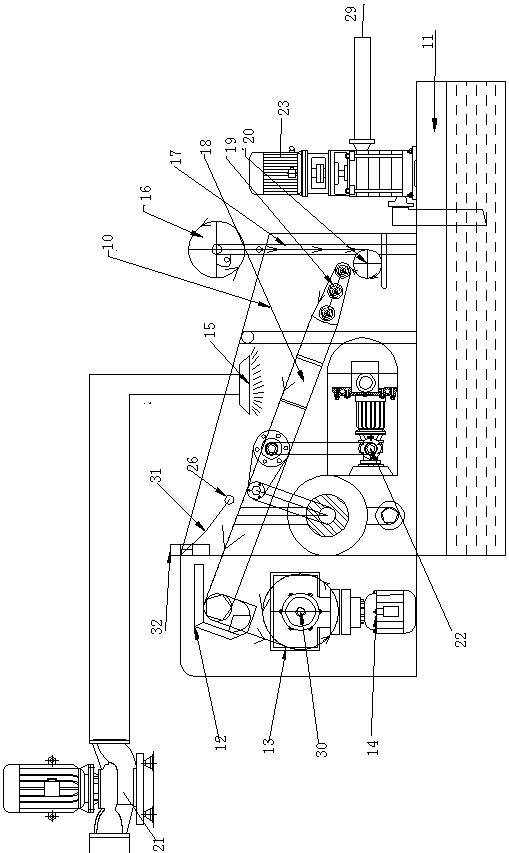

[0018] Embodiment 1: see Figure 1-Figure 2, a cleaning machine provided with an induction system, the cleaning machine provided with the induction system includes a cleaning assembly, a drying assembly, a power assembly and a water circulation assembly; the cleaning assembly is installed at the front end of the drying assembly; the power assembly is installed at the cleaning Below the component and the drying component; the water circulation component is connected with the cleaning component through a pipeline. The design structure is simple and clear, the components are closely connected and do not affect each other, the required parts are easy to replace, and the product is easy to maintain during use in the future. The cleaning components include lotion high-pressure spraying chamber 1, lotion The ultrasonic cleaning chamber 2, the spray rinsing chamber 3 and the water cutting chamber 4; the lotion high-pressure spraying chamber, the lotion ultrasonic cleaning chamber, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com