Electric wire extrusion molding production line

A production line and wire technology, which is applied in the manufacture of circuits, electrical components, cables/conductors, etc., can solve the problems of prolonged water cooling time of wires, affecting production efficiency, and reducing production efficiency, so as to achieve strong adaptability to ambient temperature, improve efficiency, and quickly The effect of water removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

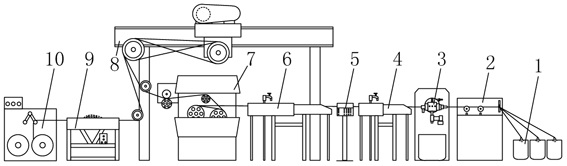

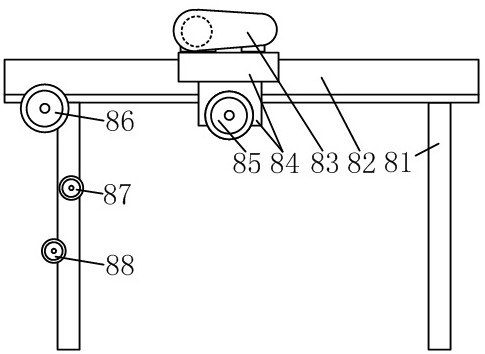

[0020] Such as figure 1 As shown, the wire extrusion production line of the present invention includes a core barrel, a dryer, an extruder, a first cooling water tank, a caliper, a second cooling water tank, a vacuum eliminator, an oiler, A coiling and winding machine and a drying rack arranged above the second cooling water tank and the vacuum suction machine.

[0021] There are multiple core barrels, and the center of the top cover of the core barrel is provided with an outlet hole. The core wire barrel is used to place the coiled copper wire, and the core wire of the electric wire has multiple strands of copper wire. A roll of copper wire is placed in each core wire barrel, and each strand of copper wire is drawn out from each core wire barrel to form a core wire.

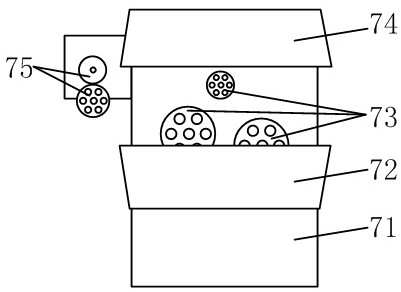

[0022] The top of the dryer is equipped with a paralleling plate, a par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com