A deep drying method and an amplitude-modulated vacuum drying oven

A drying method and drying technology, which is applied in the direction of drying solid materials, local agitation dryers, and static material dryers, etc., which can solve the bottlenecks in the production of the electronics industry, the poor drying effect of battery pole pieces, and the inability to meet higher requirements, etc. problem, to achieve the effect of accelerating the desorption and desorption process, good water removal effect, and good water removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

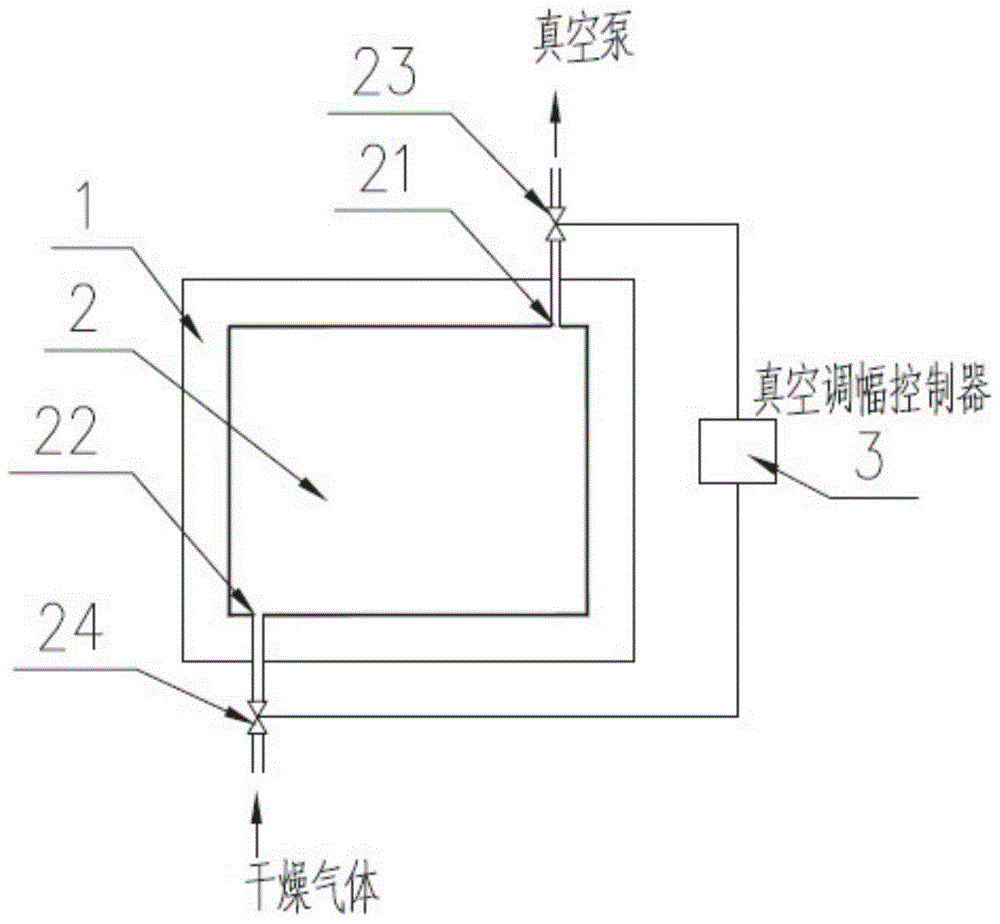

[0033] An amplitude-modulated vacuum drying oven, comprising a drying oven box body 1 and a drying inner chamber 2 arranged in the box body, and a vacuum air conditioning controller 3, and the drying oven box body 1 is provided with a drying inner chamber 2 The vacuum port 21 connected with the vacuum pump, and the air inlet 22 connected with the drying inner cavity 2 and used for connecting the dry gas; a vacuum port valve 23 is provided between the vacuum port 21 and the vacuum pump, and the air inlet An air inlet valve 24 is provided between the port 22 and the dry gas source, and the vacuum air conditioning controller 3 is connected to the vacuum interface valve 23 and the air inlet valve 2 respectively, and is controlled to open or close.

[0034] The vacuum air conditioning controller is composed of a precise pressure sensor, a precision solenoid valve and a flow meter. The precision pressure sensor measures the vacuum degree in the inner cavity of the oven. The valve co...

Embodiment 2

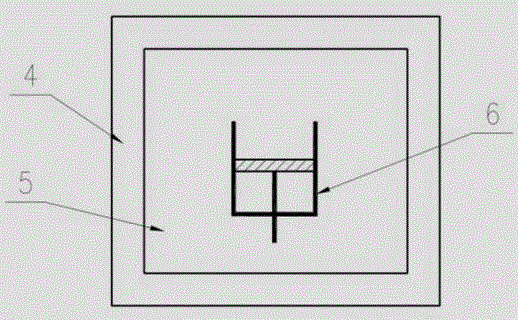

[0039] An amplitude-modulated vacuum drying box, comprising a drying box body 4 and a drying inner cavity 5 arranged in the box body, and also includes a piston device 6 that can be stretched inside the drying box, and the piston device can be telescopically reciprocated in the drying box The back and forth movement of the device, the piston movement of the device, makes the volume in the container increase and decrease regularly, so that the gas pressure in the container changes regularly. Through regular vibration, the water molecules are accelerated to detach from the micropores on the surface of the material, and then they are effectively drawn out of the drying container, so as to speed up the desorption and desorption process of the absorbed water in the dried material, so as to achieve faster water removal, more thorough drying, and dehydration. Water effects better technical effects.

[0040] After testing with a moisture meter, and recording the time required to dry t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com