Power battery module based on coupling cooling of loop heat pipe and phase change material

A technology of phase change materials and loop heat pipes, which is applied in the field of power batteries, can solve the problems of difficult manufacturing of spiral coils, low convective heat transfer coefficient, high cost, and high maintenance costs, so as to avoid excessive local temperature and compact overall structure , Efficient and uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

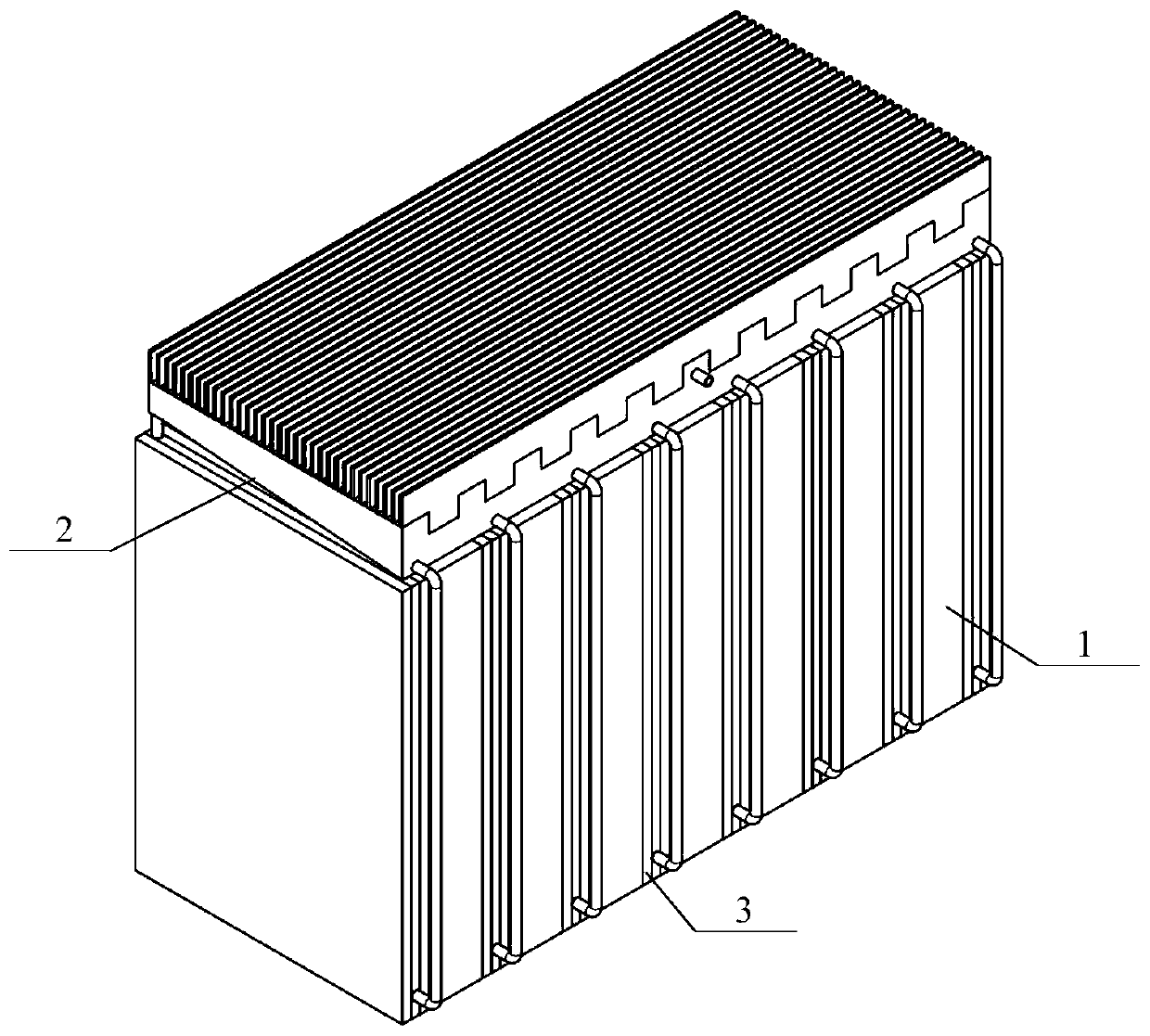

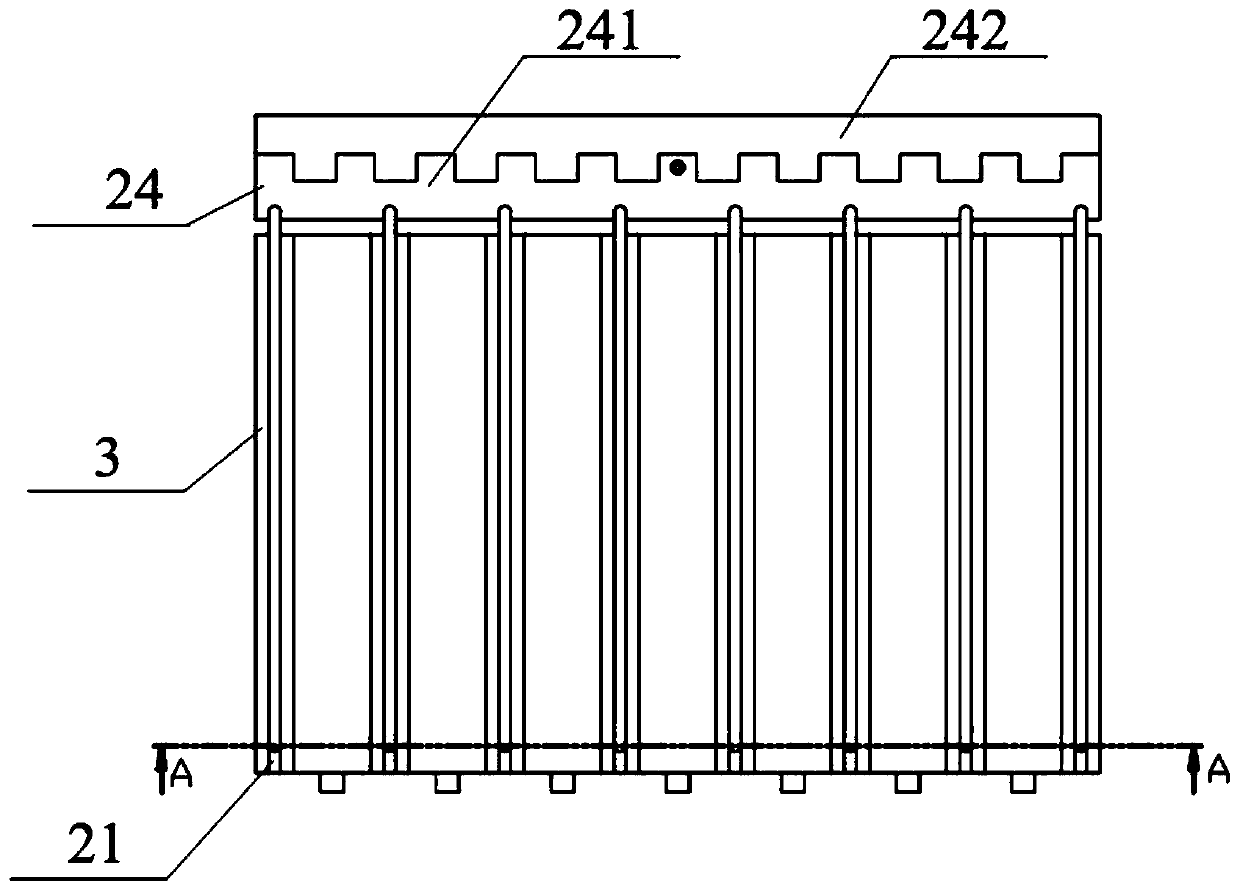

[0039] Such as Figure 1 to Figure 5 , Figure 8 As shown, the power battery module based on the coupled cooling of the loop heat pipe and the phase change material includes a battery module, a cooling system 2 and a phase change system;

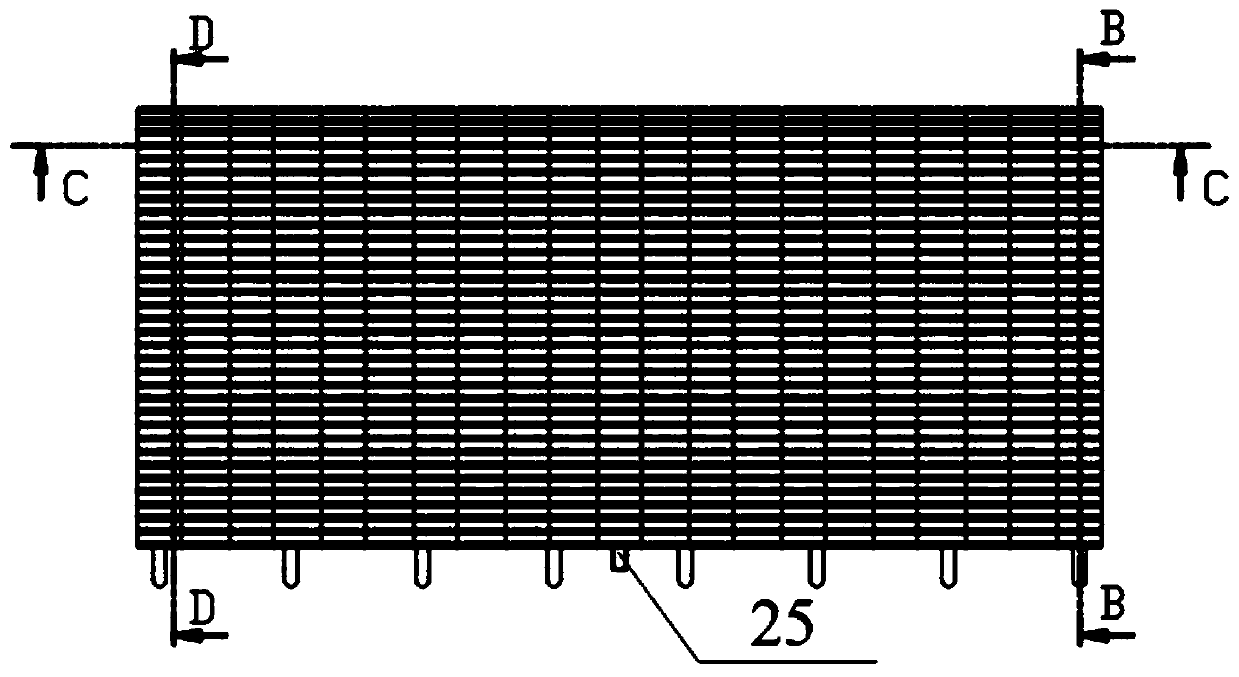

[0040] The cooling system 2 includes an evaporating plate 21 and a condenser 24; there are multiple evaporating plates 21, and the multiple evaporating plates 21 are arranged side by side with gaps left and right;

[0041] The phase change system includes a solid-solid phase change plate 3, and there are multiple solid-solid phase change plates 3, which are correspondingly arranged on the left and right sides of each evaporation plate 21;

[0042] The battery module includes a plurality of battery cells 1; each battery cell 1 is arranged between adjacent solid-solid phase change plates 3;

[0043...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com