Scrap iron collecting vehicle

A technology for collecting vehicles and iron filings, applied in road cleaning, construction, cleaning methods, etc., can solve the problems of iron filings not being cleaned well, low efficiency, and potential safety hazards, achieving continuous collection, avoiding the process of dismantling, The effect of flexible and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

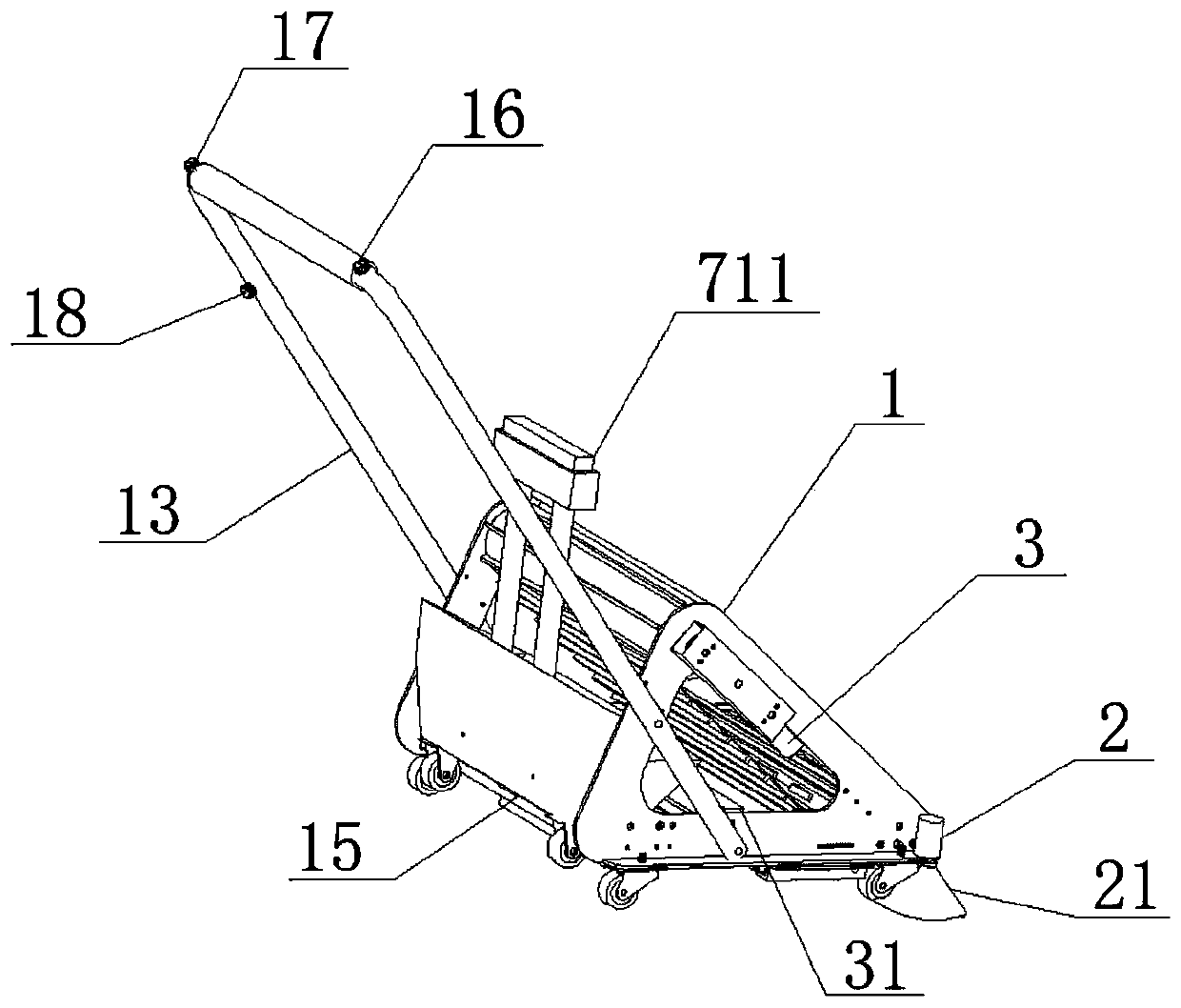

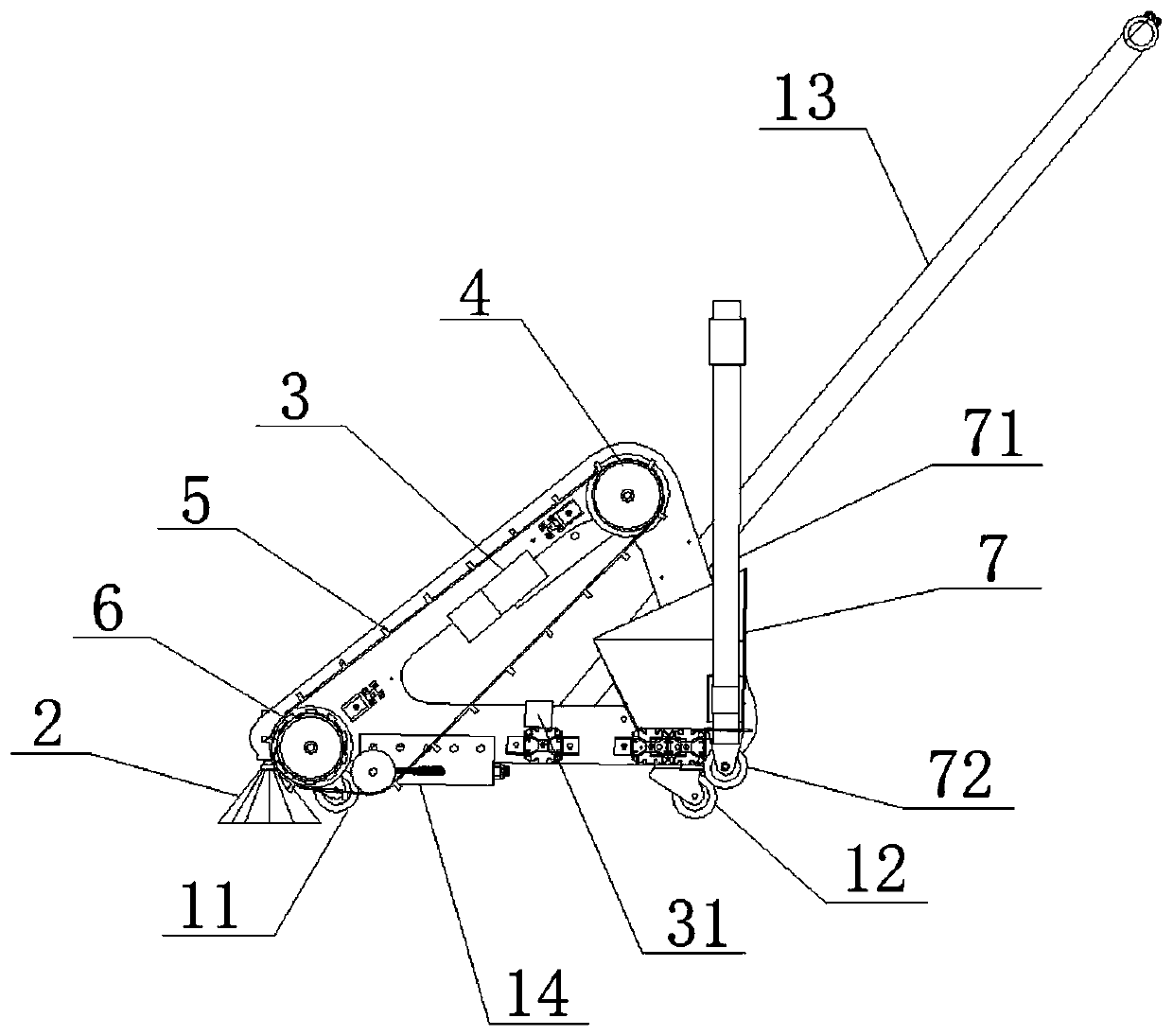

[0022] Such as Figure 1-2 As shown, the present invention discloses a chip collecting vehicle, which includes a frame 1, a cleaning device 2, a motor drive device 3, a driving roller 4, a transmission belt 5, an electromagnetic driven roller 6, and a chip box 7. The frame 1 is a horizontal triangular prism frame, the top of the frame body of the frame 1 is horizontally equipped with the driving roller 4, and the end of the driving roller 4 is connected with the motor drive device 3, the A power storage device 31 is installed on the bottom of the frame 1, and the power storage device 31 is electrically connected to the motor drive device 3. An electromagnetic driven roller 6 is installed horizontally on the bottom of the front end of the frame 1, and the transmission belt 5 is set on the On the driving roller 4 and the electromagnetic driven roller 6, the rear part of the frame 1 is provided with a horizontal fixed box frame 15, and the fixed box frame 15 is provided with a cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com