Bottle grabbing device and control method thereof

A technology for grabbing devices and bottles, which is applied in the direction of manufacturing tools, transportation and packaging, manipulators, etc., can solve the problems of slow grabbing speed and unstable grabbing, and achieve high efficiency, good grabbing effect, and high stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

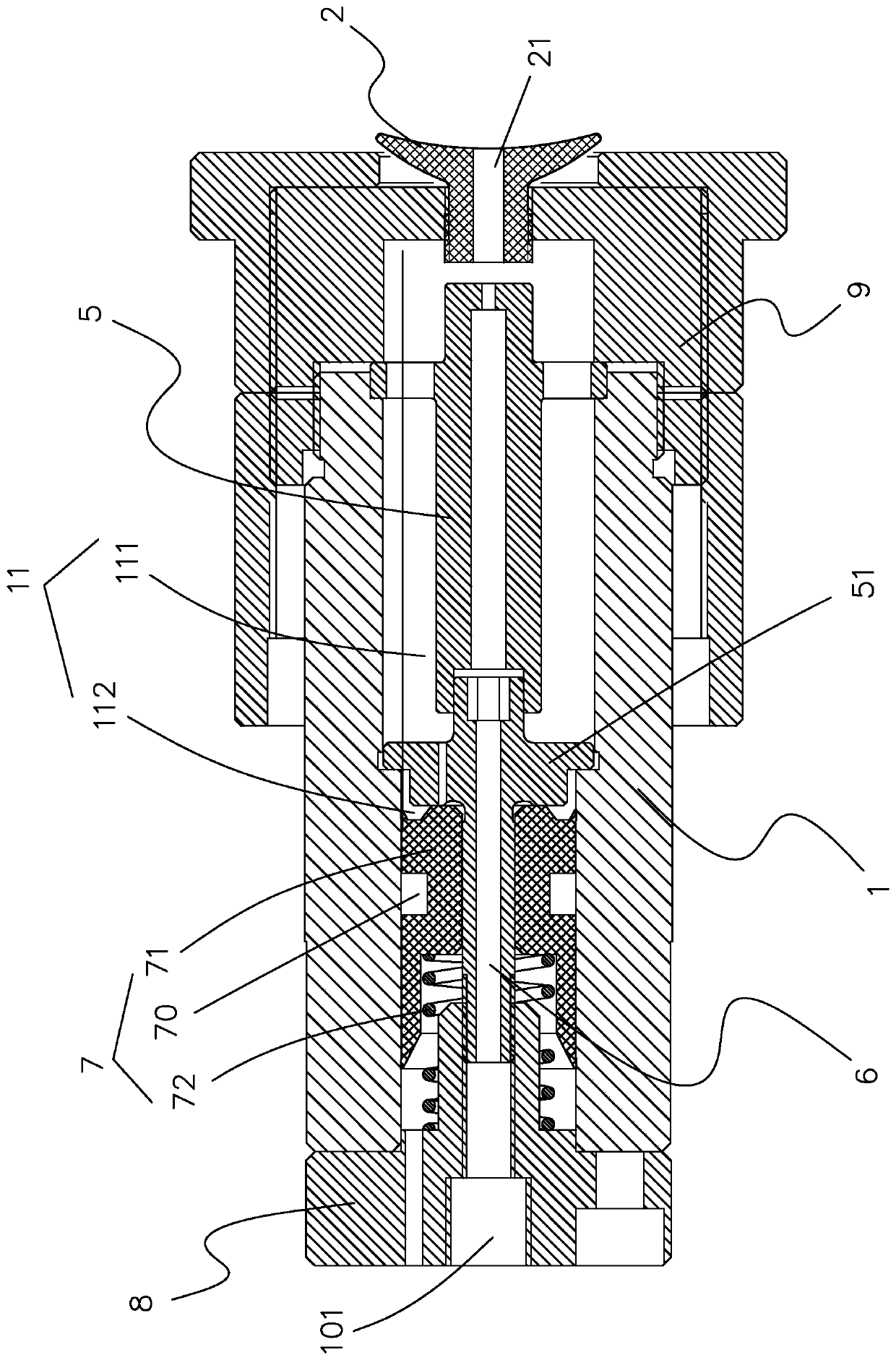

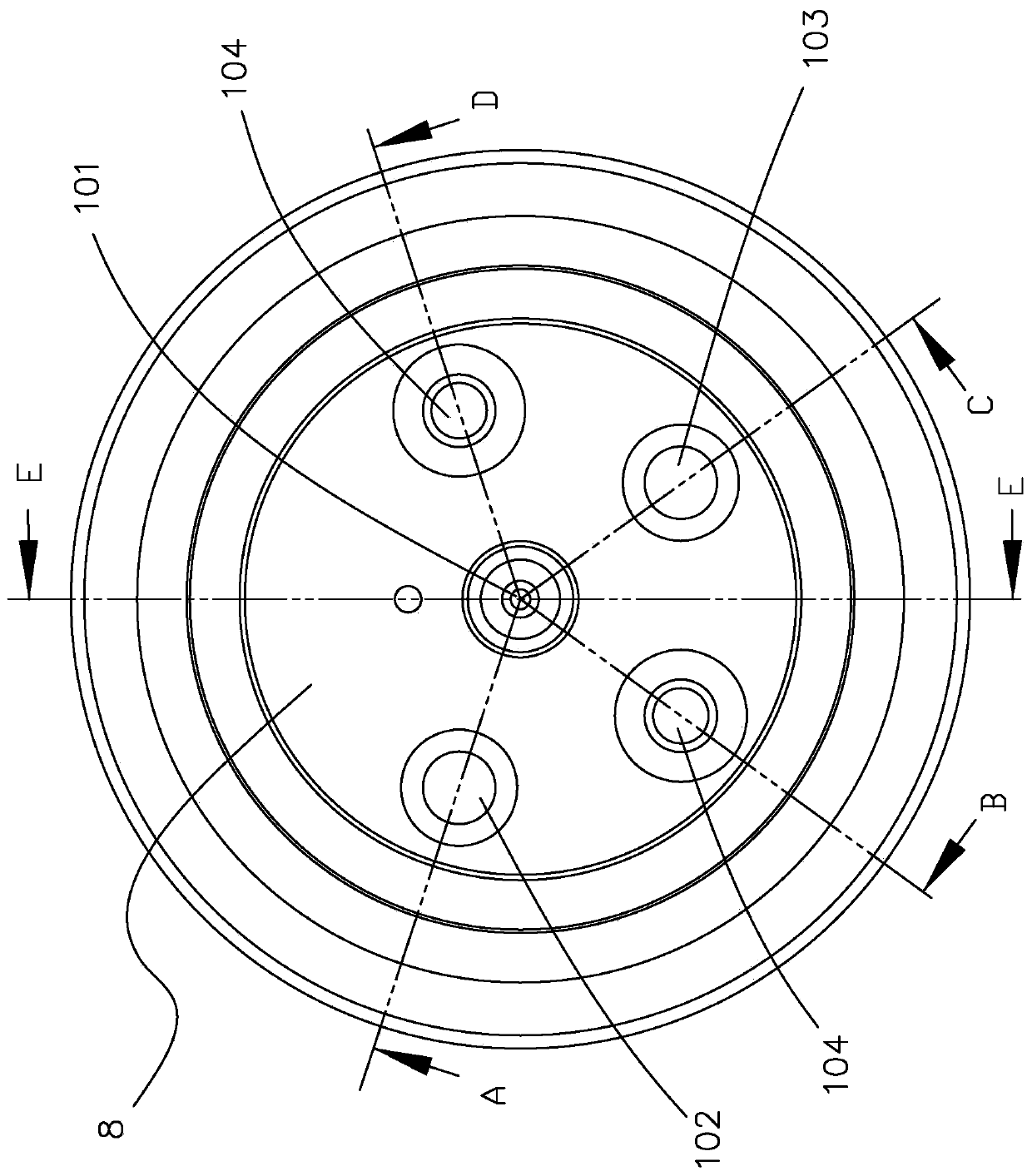

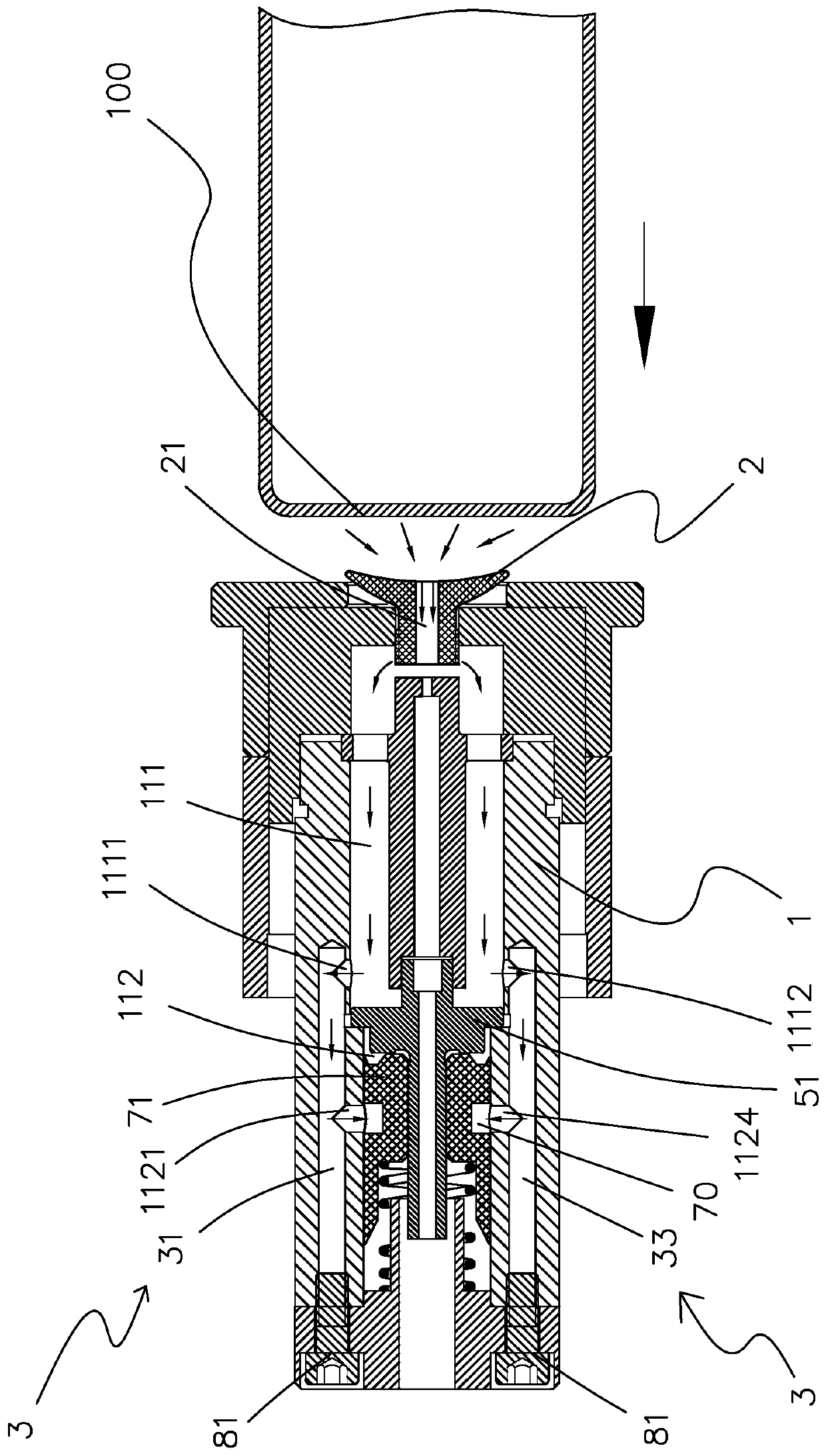

[0034] A bottle grabbing device, comprising a base body 1 and a suction cup 2 arranged at the front end of the base body 1, the suction cup 2 is provided with a vent hole 21, and the interior of the seat body 1 is provided with a cavity communicating with the vent hole 21 along its axial direction 11. A negative pressure channel 3 and a positive pressure channel 4 are respectively connected to the cavity 11 in the circumferential direction. The negative pressure channel 3 communicates with the vent hole 21 so that the vent hole 21 forms a negative pressure and the suction cup 2 can suck the bottom 100 of the bottle. In order to grab the bottle, the cavity 11 is provided with a mandrel 5 along its axial direction for blocking the positive pressure passage 4 from communicating with the vent hole 21, and the mandrel 5 is provided with an exhaust passage 6 communicating with the vent hole 21 for use In order to restore the normal air pressure in the vent hole 21 and release the suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com