Mold and method for manufacturing flexible robot

A technology of robots and molds, applied in the manufacture of tools, manipulators, etc., can solve the problems of slow deformation of flexible fingers, inability to adapt to fast grasping, insufficient strength, etc., and achieve the effect of low cost, simple structure, and fast deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the examples, but it should not be understood that the scope of the subject of the present invention is limited to the following examples. Without departing from the above-mentioned technical ideas of the present invention, various replacements and changes made according to common technical knowledge and conventional means in this field shall be included in the protection scope of the present invention.

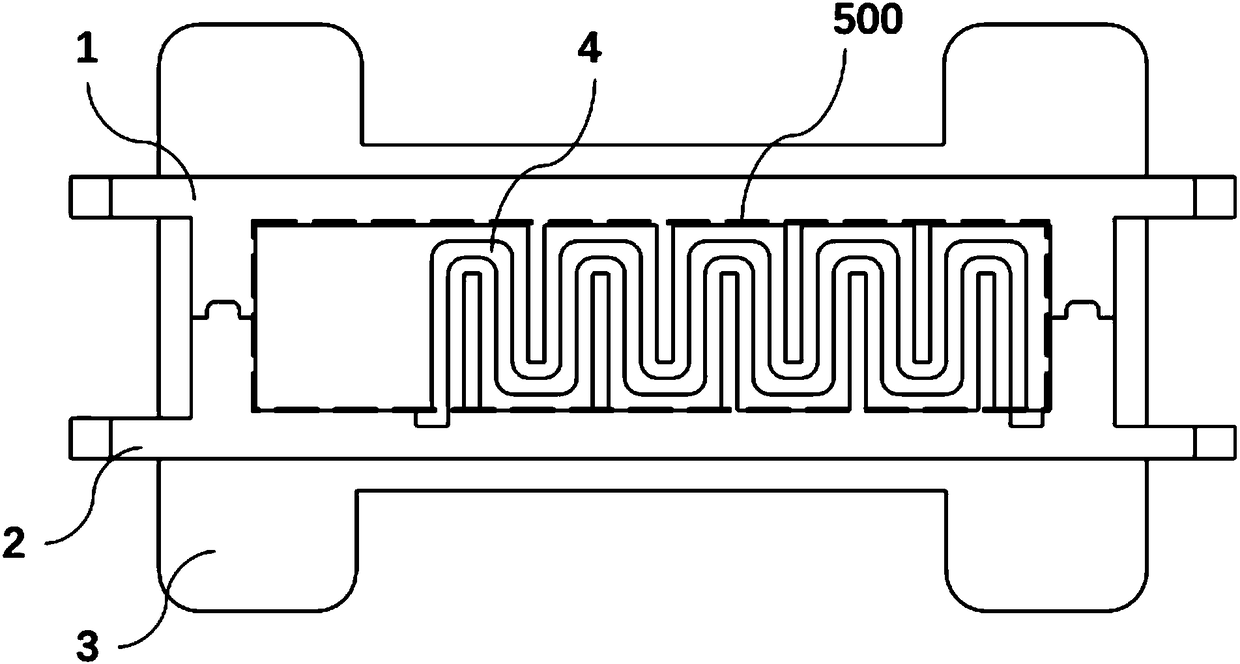

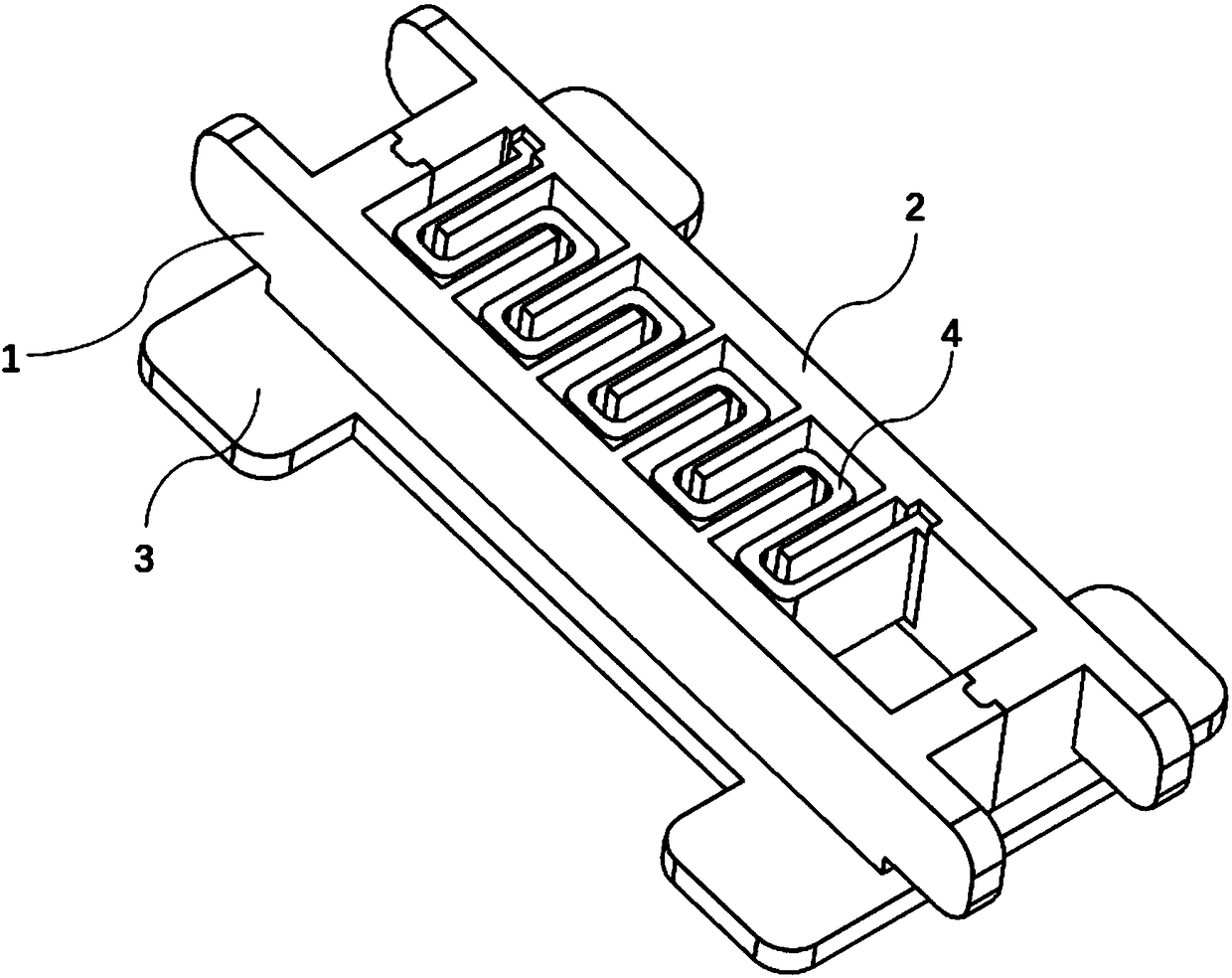

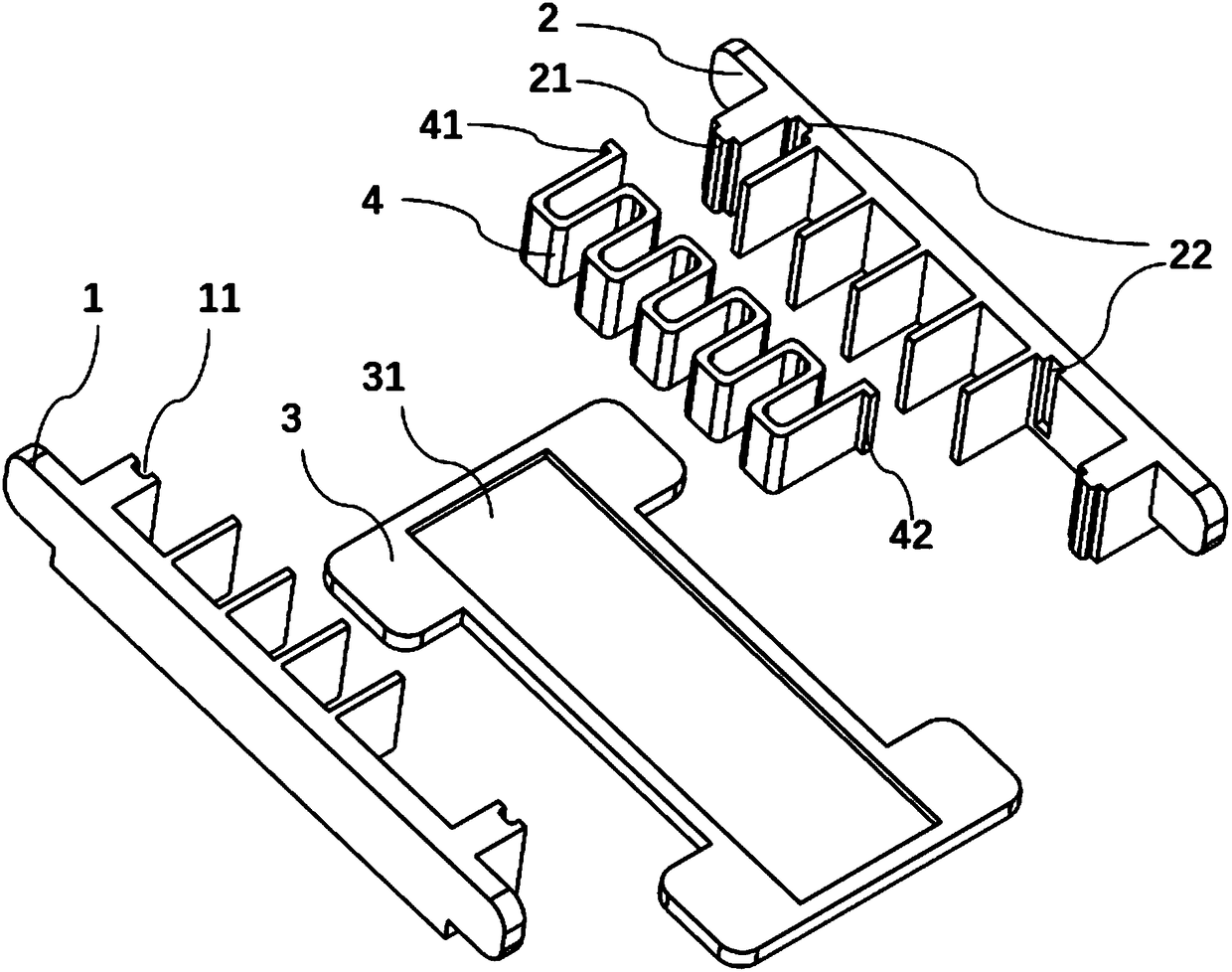

[0021] Such as figure 1 , 2 As shown in and 3 , this embodiment discloses a mold for manufacturing a soft robot, including an upper mold 1 , a lower mold 2 , a bottom mold 3 and a wave-shaped part 4 . The upper mold 1 and the lower mold 2 are of the same height, the upper mold 1 is provided with a positioning groove 11 , and the lower mold 2 is provided with a positioning protrusion 21 matching with the positioning groove 11 . The wave-shaped part 4 is provided with two left and right positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com