Patents

Literature

68results about How to "Saving process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

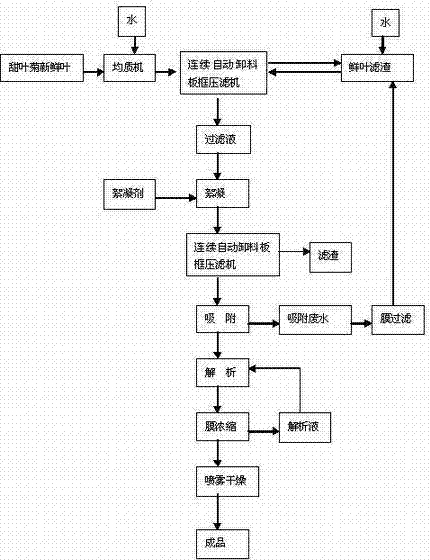

Method for extracting stevioside from fresh stevia rebaudiana leaves

InactiveCN102127129AReduce drying processLow costSugar derivativesSugar derivatives preparationFlocculationEngineering

The invention discloses a method for extracting stevioside from fresh stevia rebaudiana leaves, which comprises: crushing fresh stevia rebaudiana leaves with homogenizing crushing equipment under a condition of water, performing pressure filtration in continuous automatic discharge filtering equipment, subjecting the filtrate to flocculation by mixed flocculating agent; and absorbing by resin, analyzing, desalting and decolorizing by resin, concentrating and spray drying to obtain the stevioside product. In the invention, time and working procedures are saved, a long-distance transport process is avoided, raw material cost is lowered, discharge of waste water is reduced greatly, and clean production can be realized basically.

Owner:LIAONING QIANQIAN BIOLOGICAL TECH

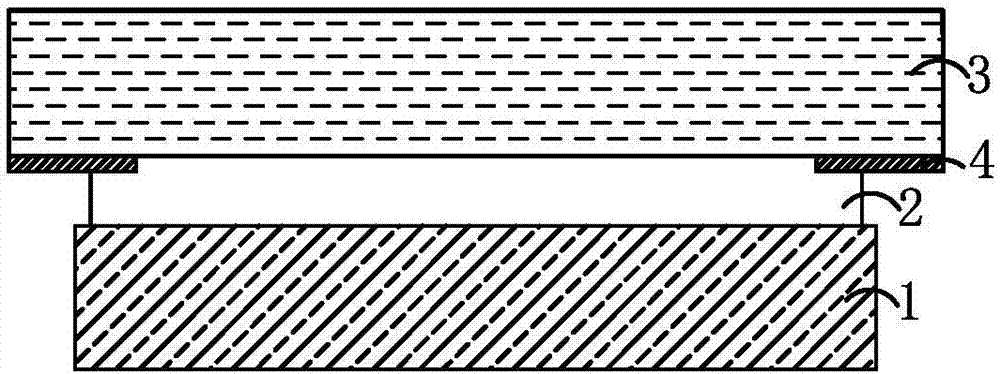

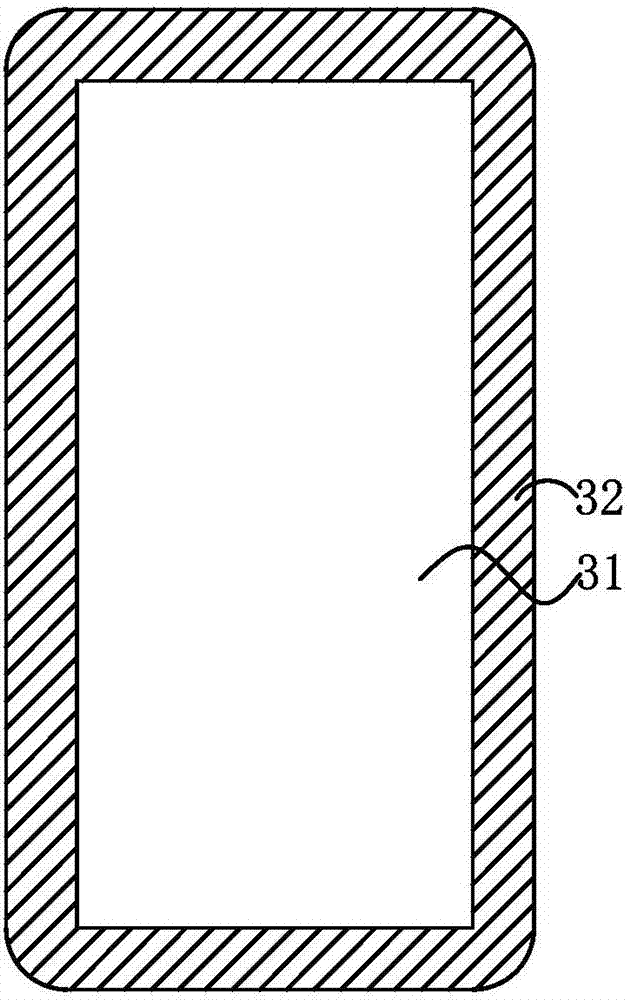

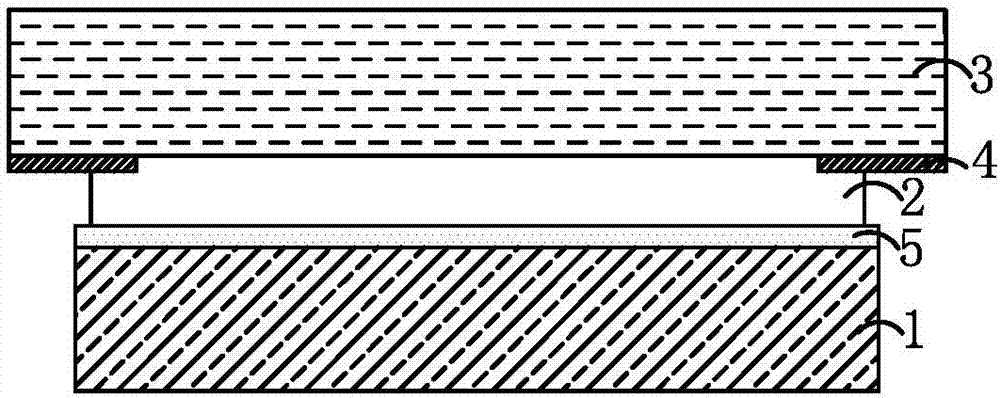

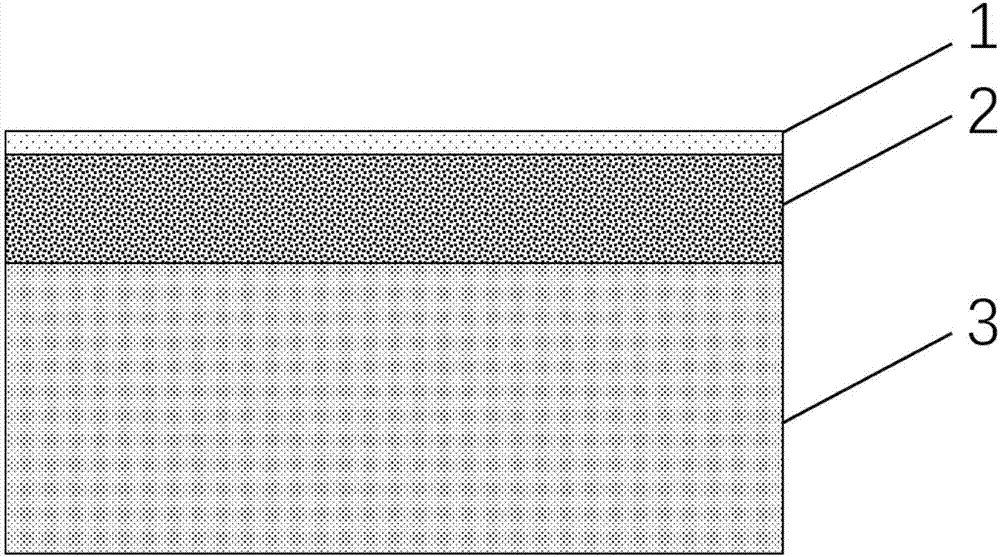

OLED display screen and manufacturing method thereof

ActiveCN106941132AImpact strength is not affectedAchieve one blackSolid-state devicesSemiconductor/solid-state device manufacturingTransmittanceEngineering

The present invention relates to the technical field of electronic equipment displays and particularly relates to an OLED display screen and a manufacturing method thereof. The manufacturing method of the OLED display screen comprises the steps of preparing a display module and a cover plate glass; machining the cover plate glass to enable the visible light transmittance of the cover plate glass to be less than or equal to 65%; printing: printing a black ink layer on the surface partial region of the cover plate glass, so as to form a visual area in the cover plate glass and a non-visual area with the black ink layer; laminating: laminating the cover plate glass above a display module, and enabling the surface of the cover plate glass, printed with the black ink layer, to be opposite to the display module. According to the display screen manufactured by the above manufacturing method, the one-piece black of the display screen can be truly realized. Meanwhile, the strength of the cover plate glass is given consideration to at the same time.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

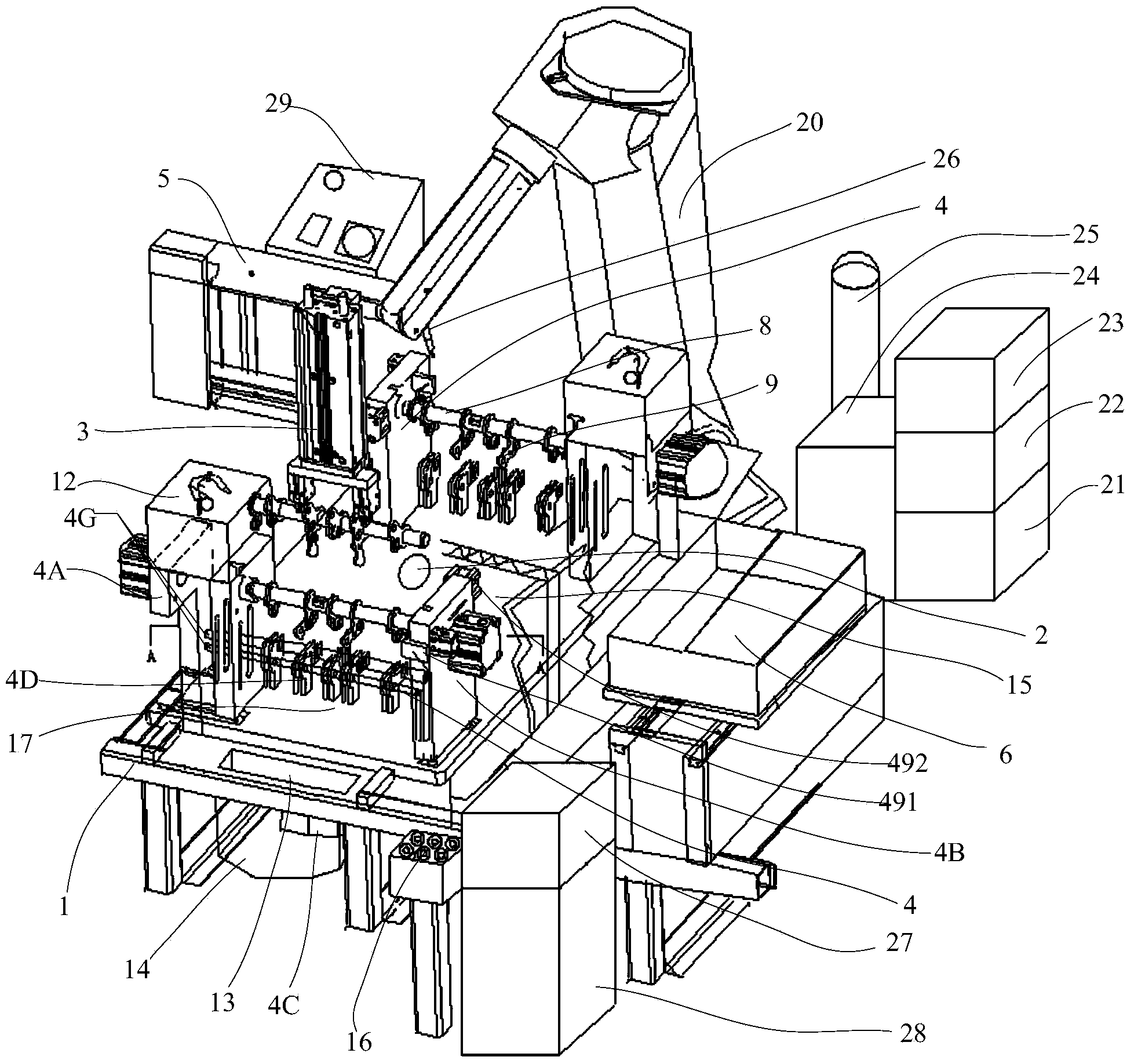

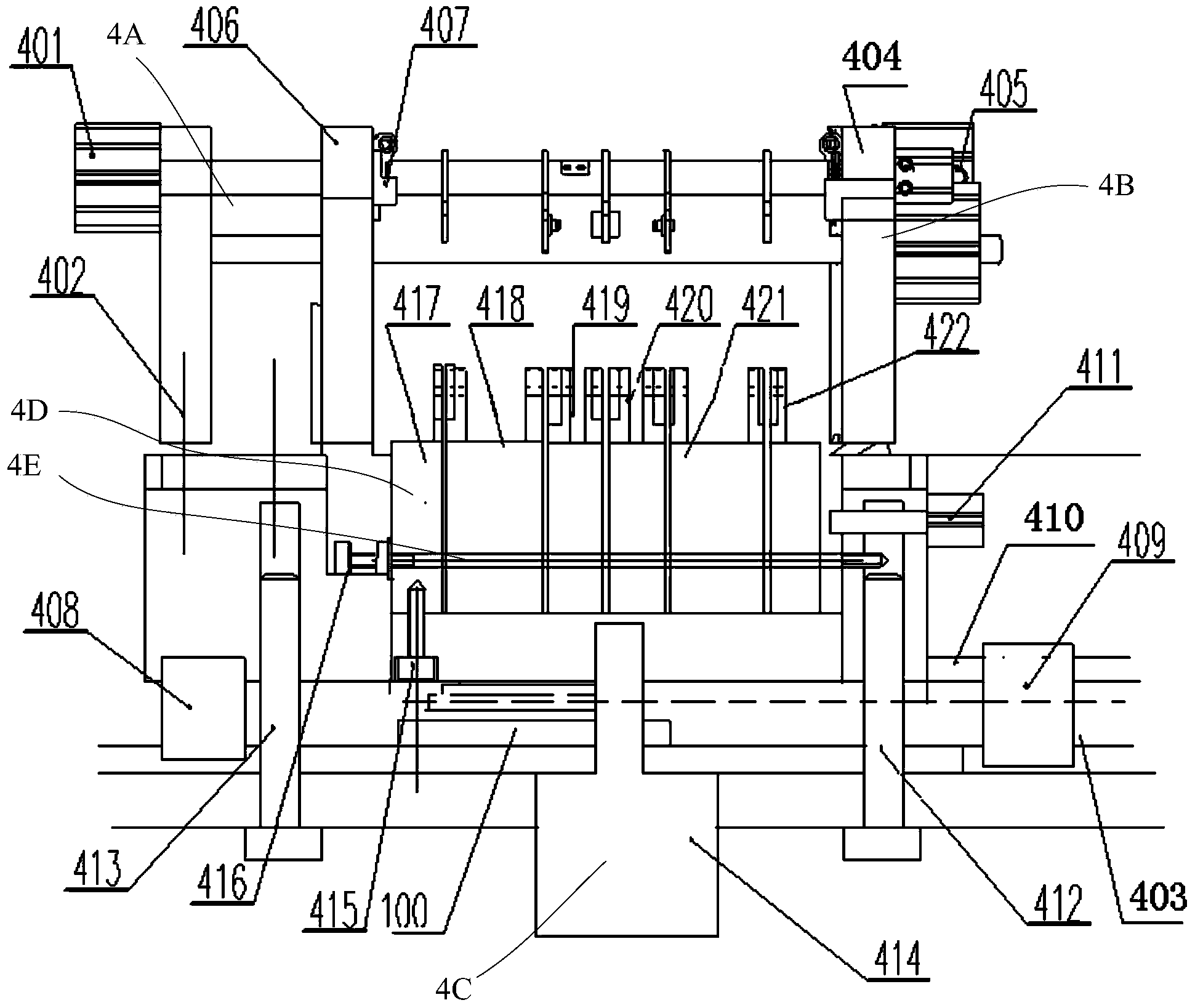

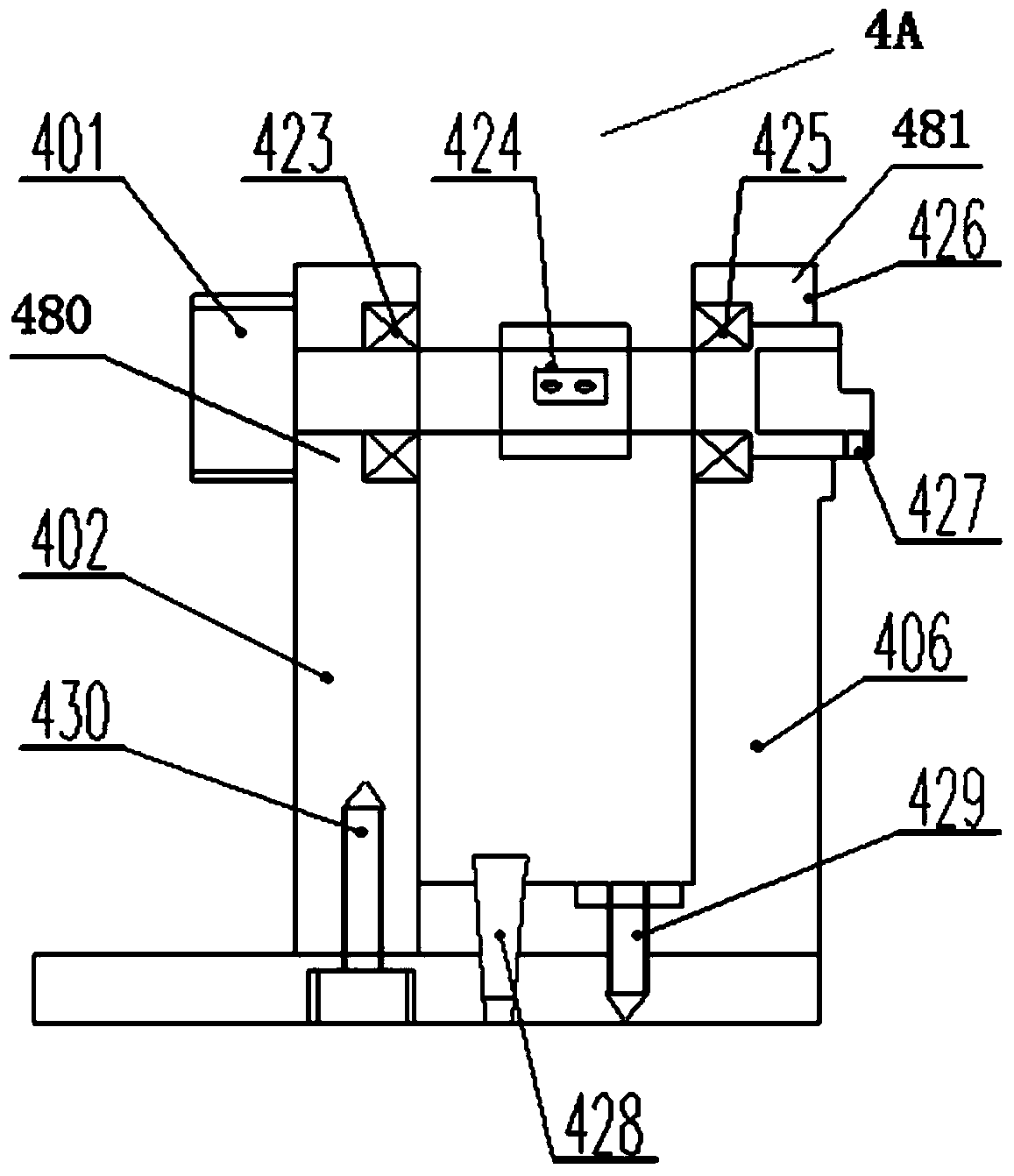

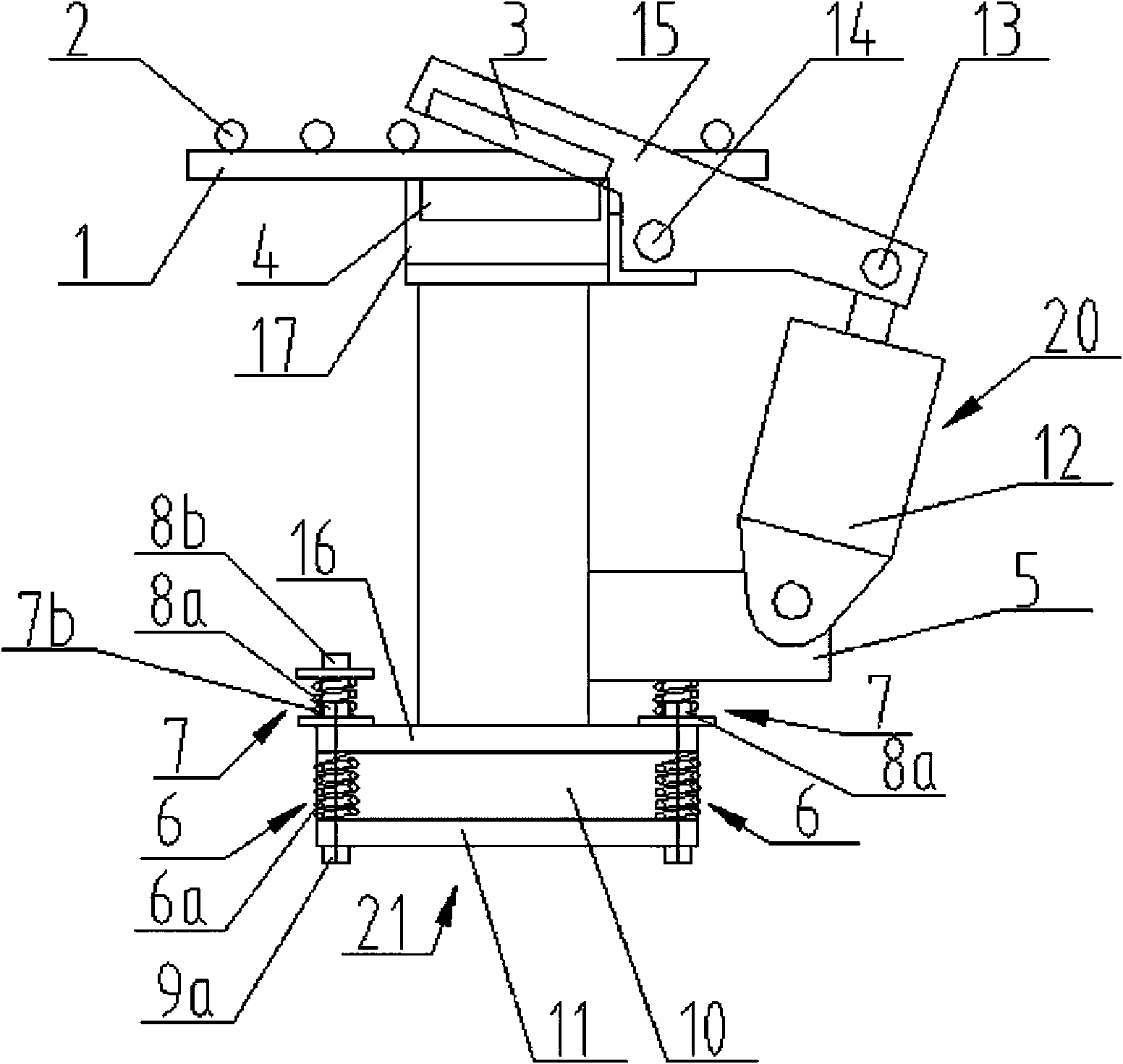

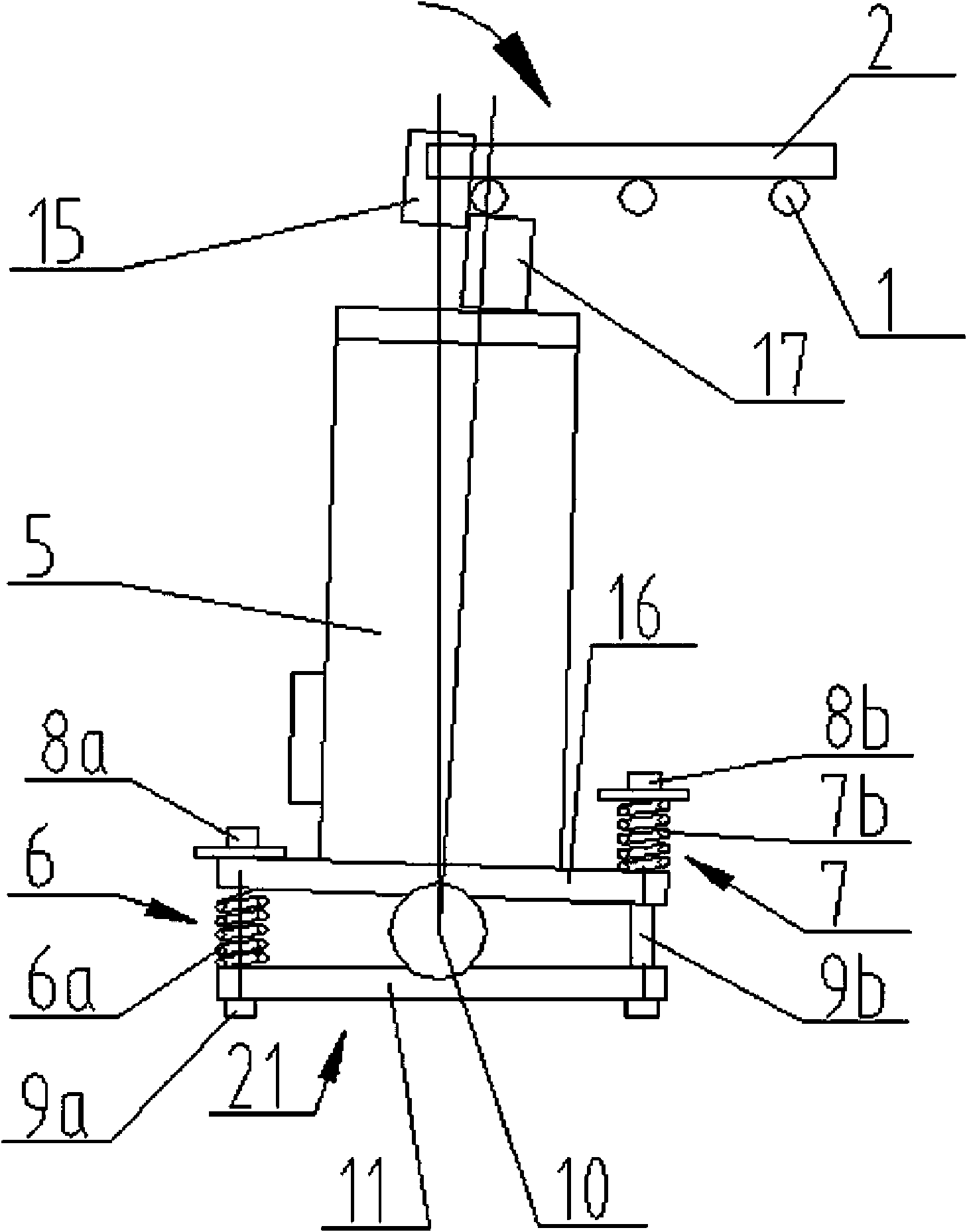

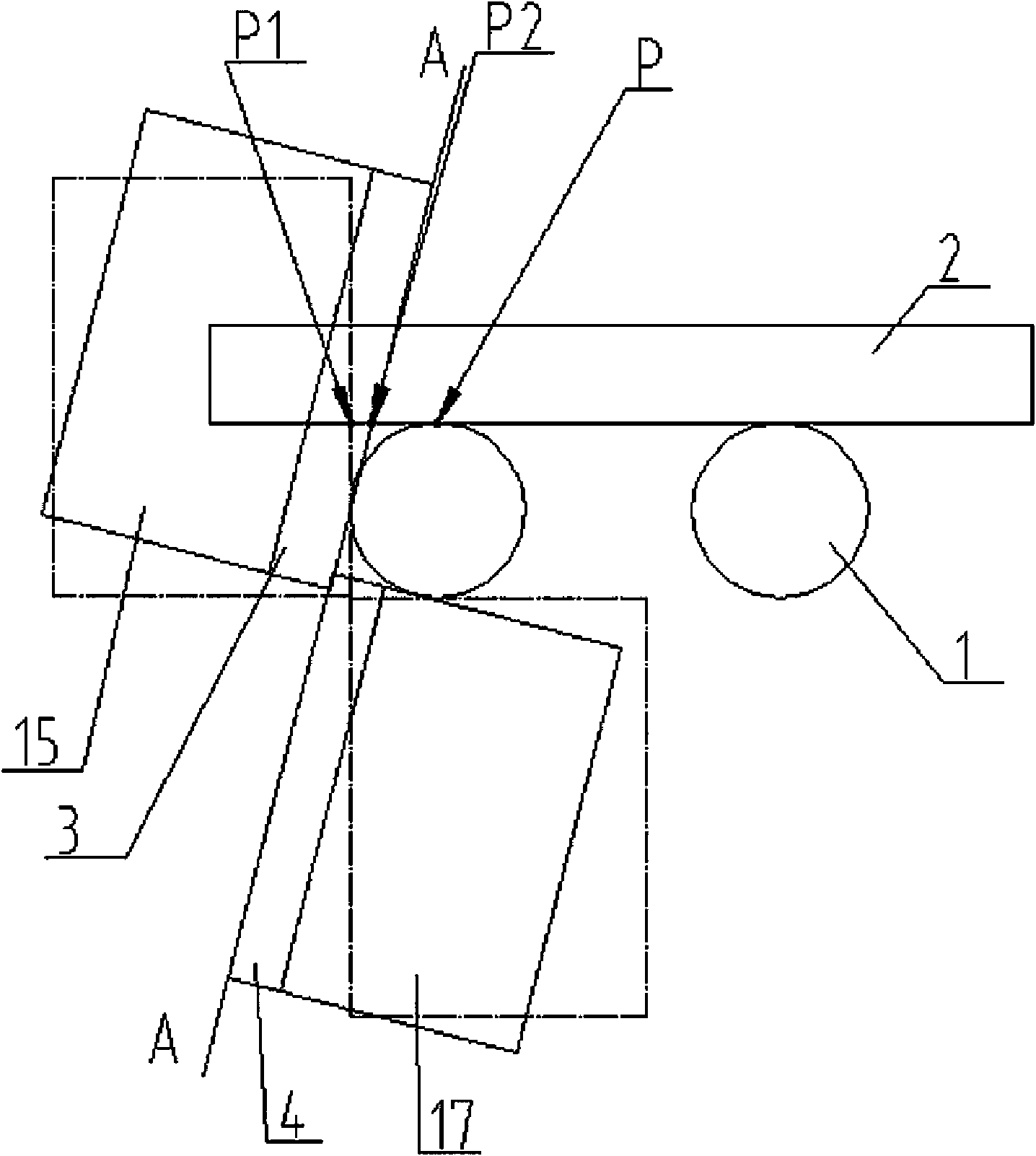

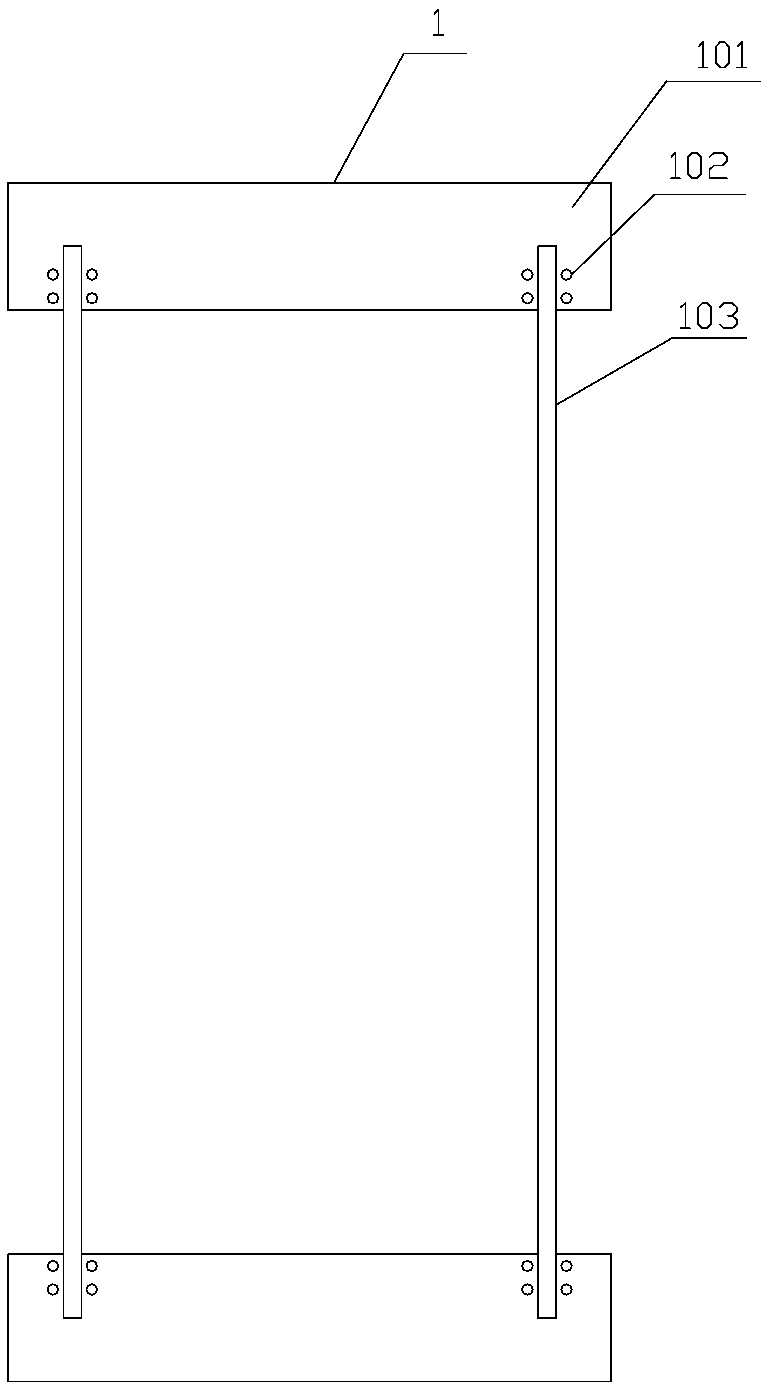

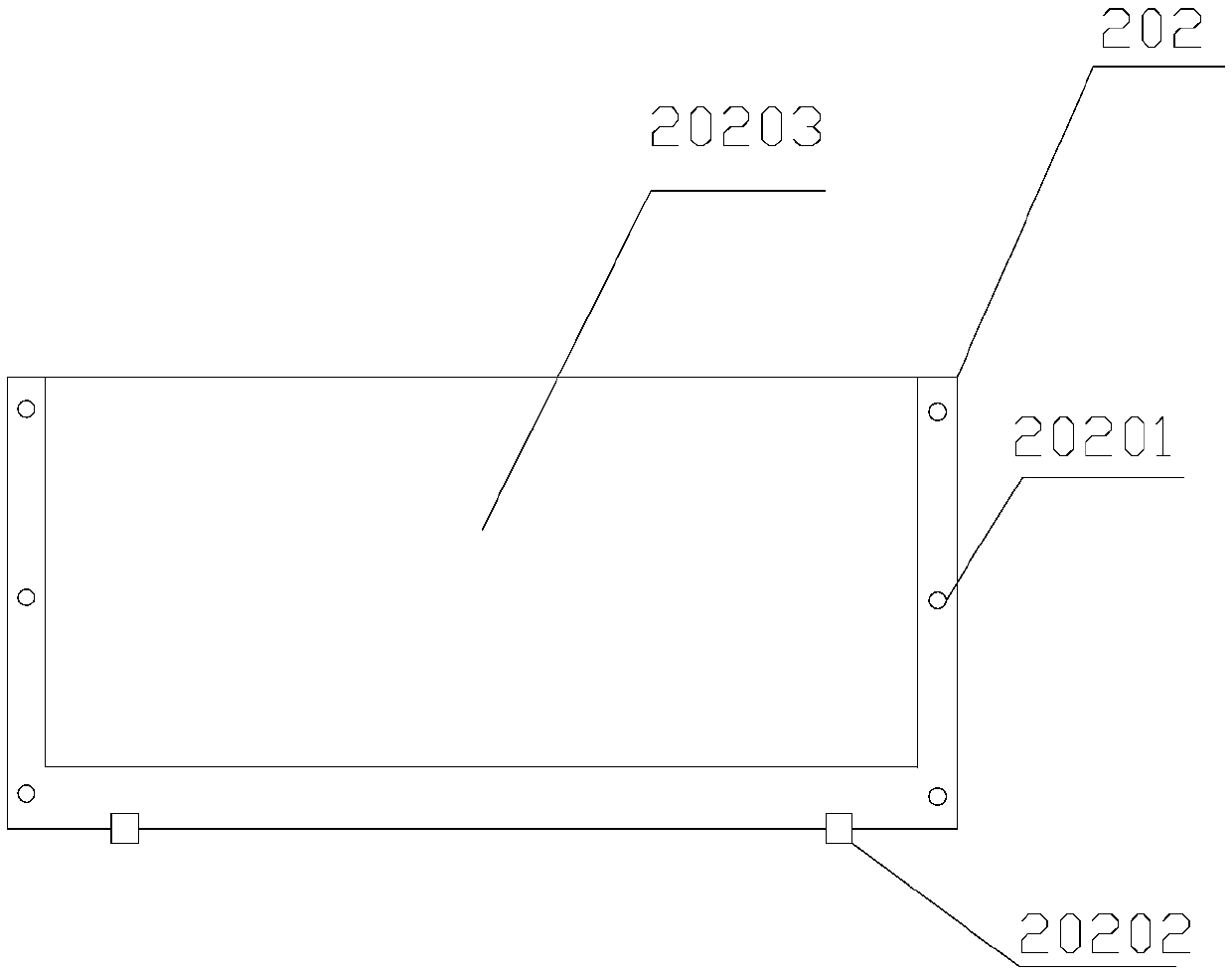

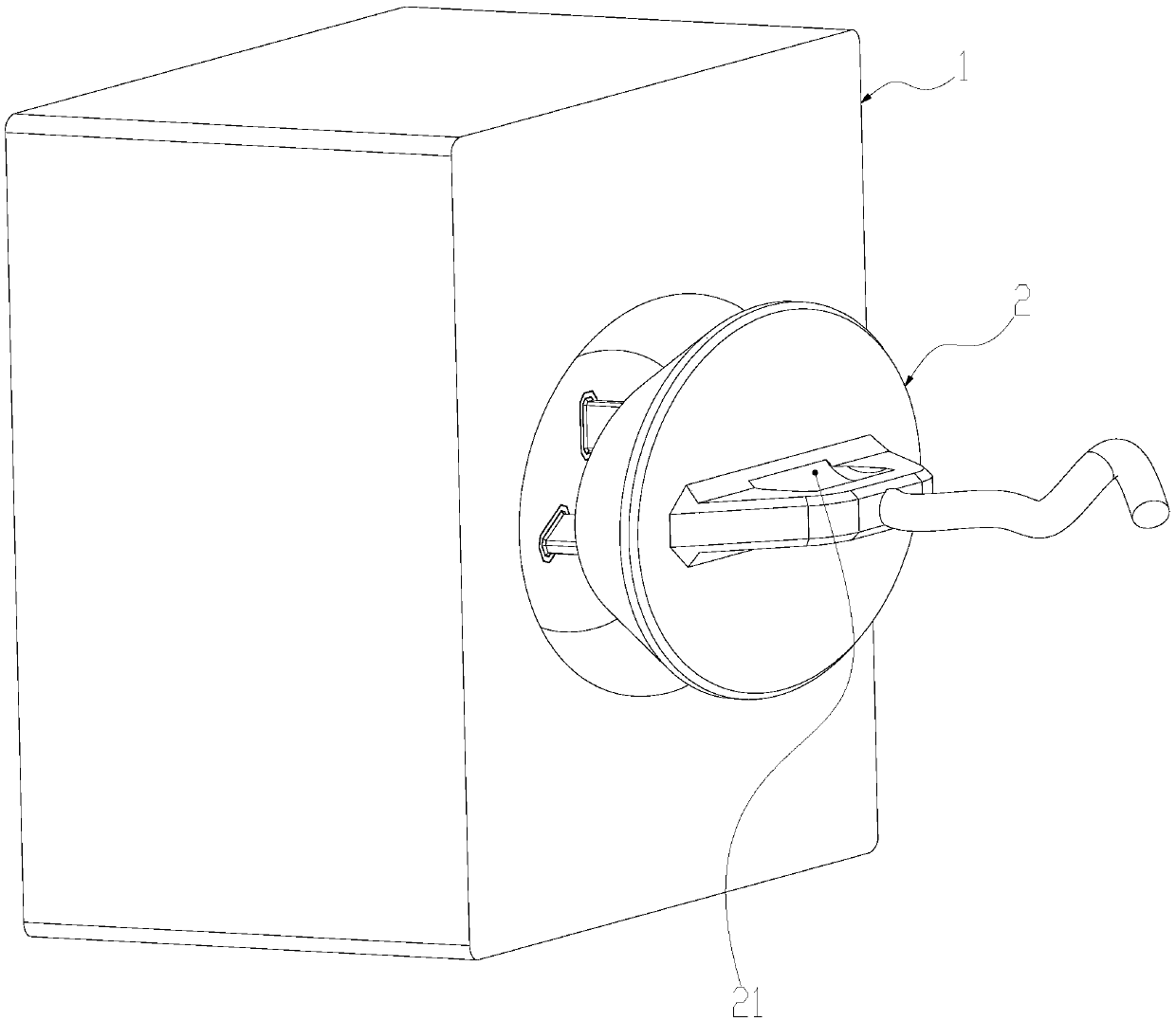

Rotating shaft welding jig, rotating shaft welding worktable and automatic rotating shaft welding system

ActiveCN103506797ASimple structurePrecise control of shape and positionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a rotating shaft welding jig, a rotating shaft welding worktable and an automatic rotating shaft welding system. The rotating shaft welding jig comprises a rotating shaft clamp and a component fixing device, wherein the rotating shaft clamp is used for clamping a rotating shaft, and the component fixing device is used for fixing a rotating shaft component which needs to be welded to the rotating shaft. The rotating shaft clamp comprises a rotating shaft supporting and rotating mechanism and a rotating shaft supporting and clamping mechanism, wherein the rotating shaft supporting and rotating mechanism and the rotating shaft supporting and clamping mechanism are used for clamping the two ends of the rotating shaft respectively. The component fixing device is arranged between the rotating shaft supporting and rotating mechanism and the rotating shaft supporting and clamping mechanism and comprises a rotating shaft component clamping part and a clamping driving part. The rotating shaft component clamping part comprises a plurality of bases which are arranged on a base plate side by side, wherein the bases include at least one fixed locating base and a plurality of sliding bases. The clamping driving part is connected with the rotating shaft component clamping part and can drive the sliding bases to slide towards the locating base so that the adjacent bases can clamp and loosen the rotating shaft component. The rotating shaft welding jig can clamp the rotating shaft and the rotating shaft component at a time.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

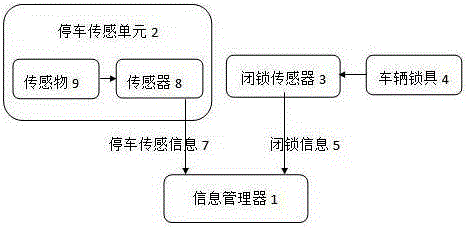

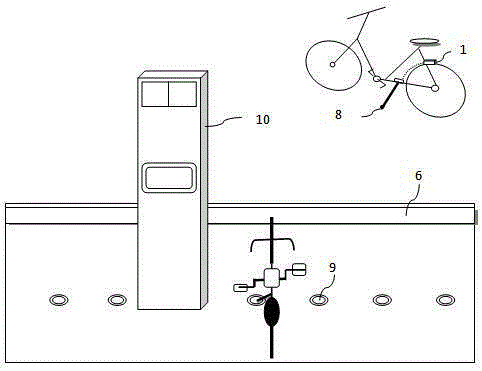

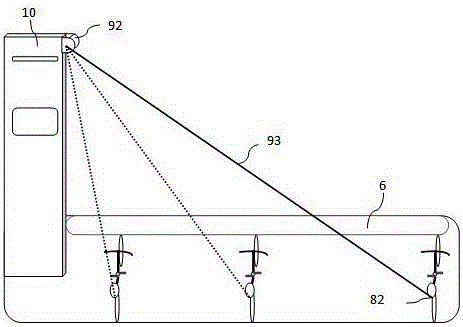

Pile-site-free type parking management system and method

InactiveCN105270507ASolve bottlenecksConvenient travelAnti-theft cycle devicesCycle standsParking sensorsEngineering

The invention discloses a pile-site-free type parking management system and a method. The system comprises an information manager, a lockout sensor, a bicycle lock and at least one set of parking sensor units. Each parking sensor unit is composed of a pair of sensors and a sensing member. The sensors and the sensing member are respectively arranged on any one of a bicycle or the ground. The parking sensor unit supplies the parking sensor information to the information manager. The lockout sensor supplies the lockout information to the information manager. The information manager is arranged on a ground machine station or a bicycle, and the parking state can be managed. According to the technical scheme of the invention, no bicycle locking pile is arranged at a bicycle rental station, so that the space is greatly saved. Through arranging more than one parking sensor unit, bicycles, returned and automatically parked in the bicycle rental station by users, can be orderly and neatly arranged in the unattended manner. Therefore, the operation cost is effectively reduced, and the labor cost investment is lowered. the aesthetic property of the city appearance is improved.

Owner:谢瑞初

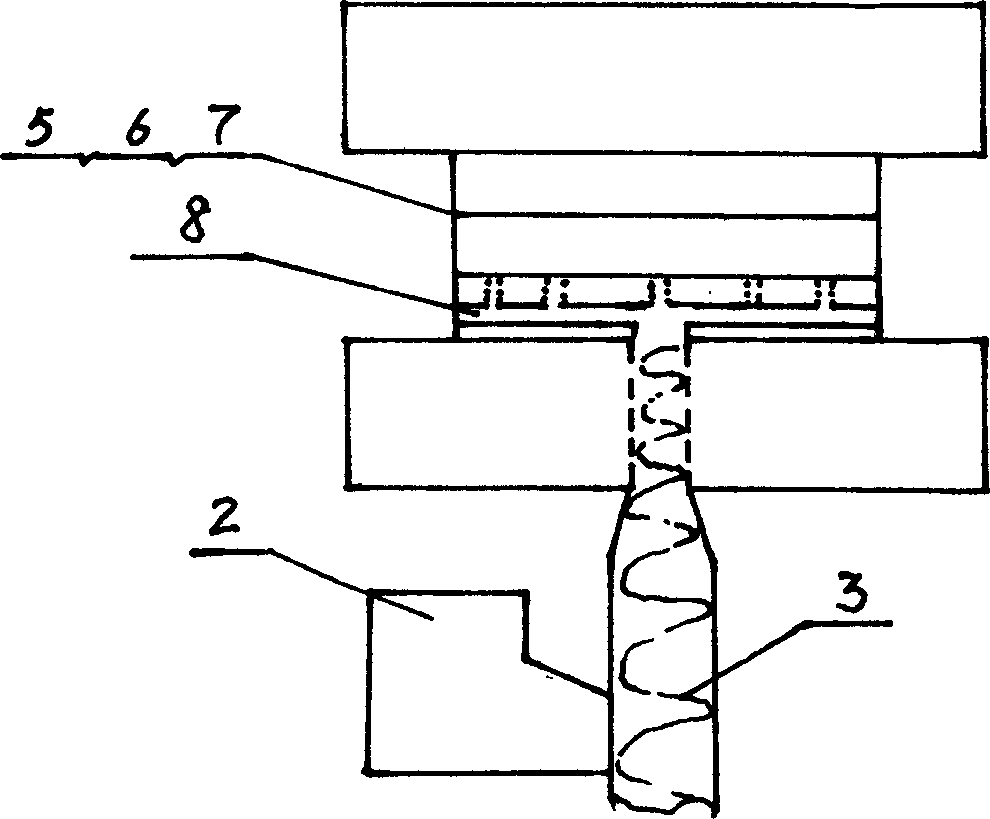

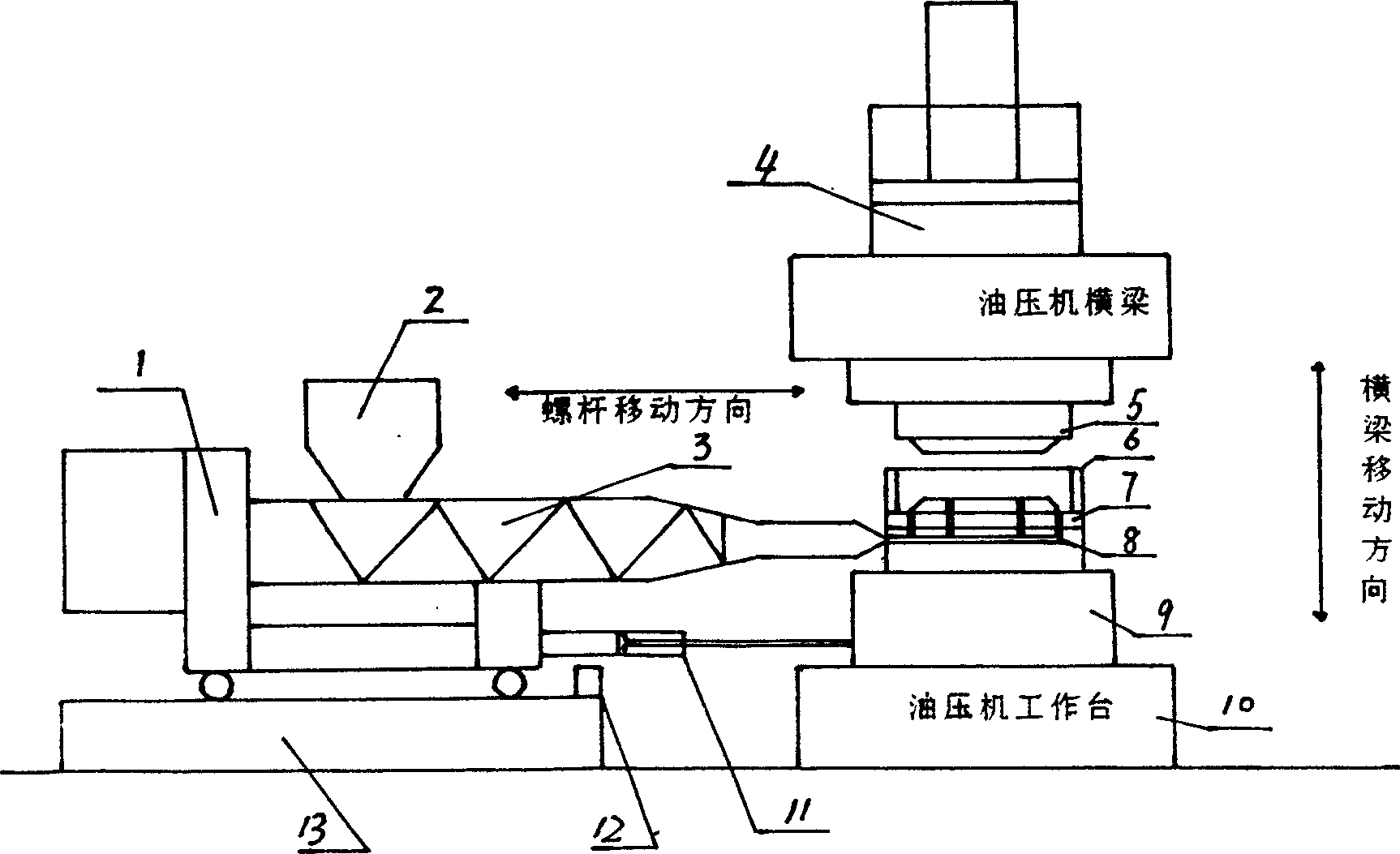

Plastic filtering board or board forming process

A process for preparing the plastic filter plate or plastic plate features that its mould is controlled by hydraulic press, its heat channel is positioned at the bottom of lower mould and communicated with said lower mould, and the plasticized plastics is injected in said mould via heat channel.

Owner:ZHEJIANG LONGYUAN ENVIRONMENTAL TECH CO LTD

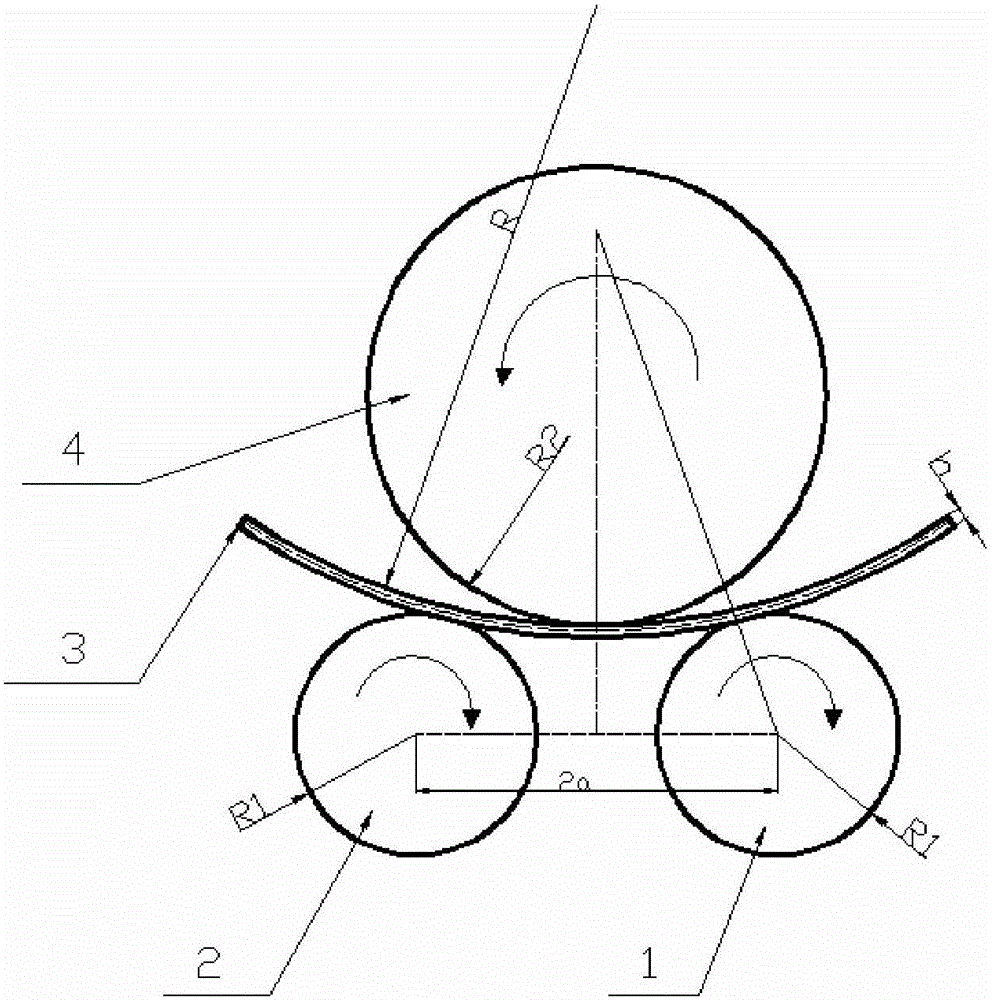

Forming method of titanium alloy oil tank shell

InactiveCN105033568AImproved precision forming processAchieving Precise FormingDrive wheelButt welding

The invention belongs to the field of precise panel machining, and discloses a forming method of a titanium alloy oil tank shell. The forming method comprises the following steps that firstly, the shape of an unfolded material of a component is calculated according to the theoretical diameter of the neutral plane of the titanium alloy oil tank shell, blanking is carried out in the direction of fiber of a rolled blank, and a panel material is obtained; secondly, the cold roll bending diameter of the oil tank shell is determined according to the structural parameters of a cold roll machine; thirdly, roll bending forming is carried out on the panel material through the cold roll machine according to the cold roll bending diameter of the oil tank shell; fourthly, butt welding is carried out on the panel material formed through roll bending; and fifthly, thermal correcting and stabilizing processing are carried out on a cylindrical piece formed through welding. The technology allowance and machining procedures needed by the thermal forming technology are greatly saved through unfolded material calculation, drive wheel pressing displacement compensation calculation, electron beam butt welding and the composite technology of thermal correcting and stabilizing processing; and according to the precise forming technology of the whole oil tank shell, the production efficiency is greatly improved, and the producing and manufacturing cost is reduced.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

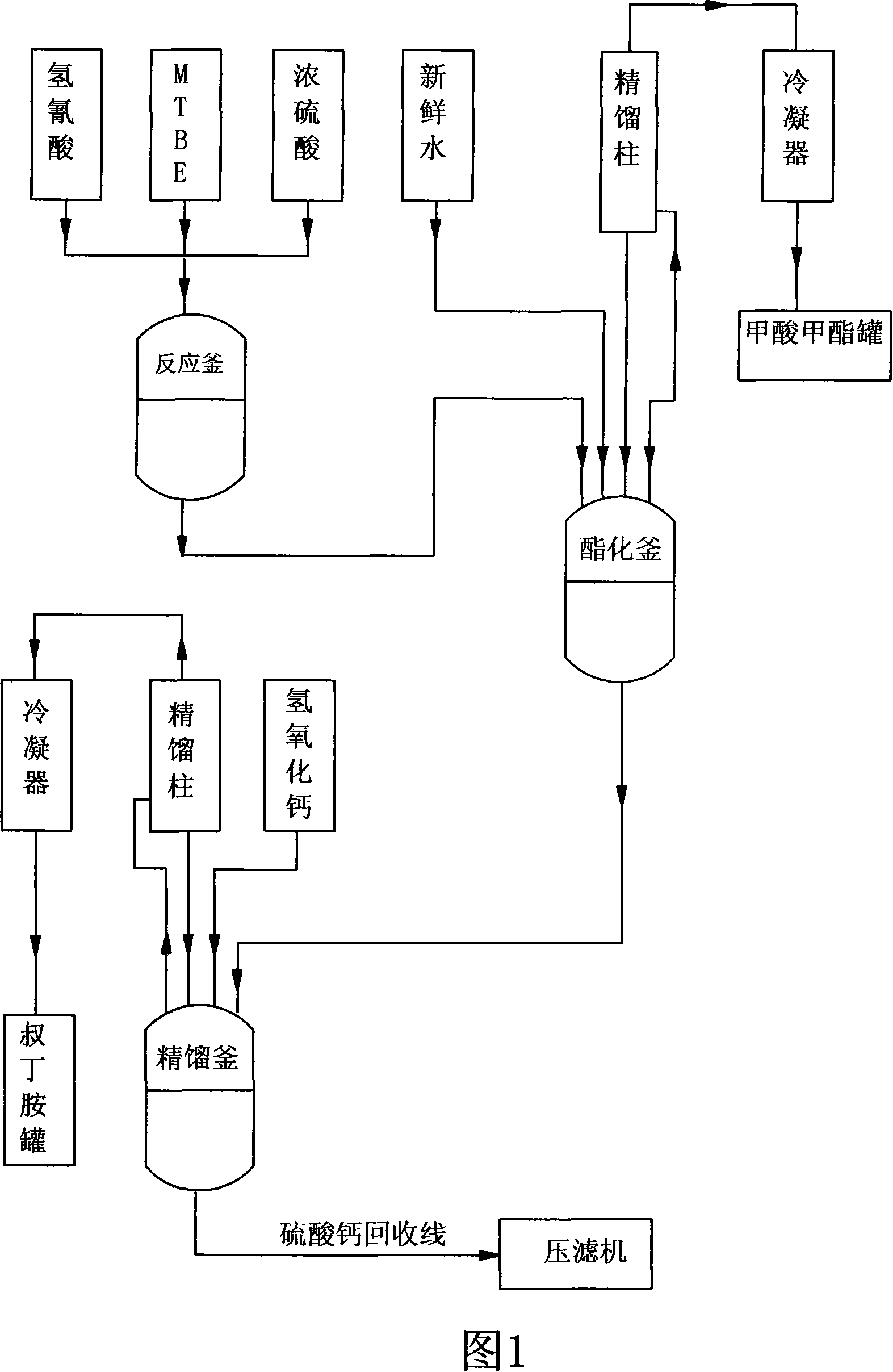

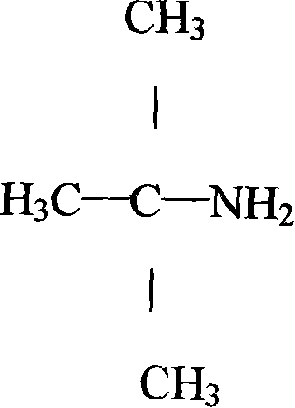

Technique for synthesizing tert-butylamine

ActiveCN101108806APromote hydrolysisPromote esterification reactionOrganic compound preparationAmino compound preparationTert-ButylamineCALCIUM HYDROXIDE SOLUTION

The invention belongs to the fine chemical field, which is mainly used for the synthesis of rubber accelerator NS and the intermediate raw material of the rifampicin-tert-butylamine. The invention is characterized in that: the methyl tert-butyl ether-hydrocyanic acid method is adopted to produce tert-butylamine; under normal pressure, the methyl tert-butyl ether is added with hydrocyanic acid and is added with concentrated sulphuric acid to carry out fully catalytic reaction; the methanol produced in the catalytic reaction is fully adopted and is added with water to perform hydrolysis, deep hydrolysis and esterification, and methyl formate and methanol without react completely are distilled; sulphates in calcium hydroxide solution and the butylamine to replace the butylamine to gain the butylamine through rectification and produce the byproduct calcium sulfate. The invention adopts the water instead of the methanol to carry out the hydrolysis and esterification and neutralizes the raw materials and adopts the calcium hydroxide to produce butylamine, which has the advantages of simple process, short production period, high yield, stable product quality, low production cost and small environment pollution.

Owner:ZIBO LUHUA HONGJIN NEW MATERIAL CO LTD

Ecological restoration method for metal mine waste lands

InactiveCN108207158AReduce poisonReduce the impactSoil-working methodsRestoration methodPlanting seed

The invention relates to the field of mine ecological restoration, in particular to an ecological restoration method for metal mine waste lands. The method mainly comprises the following steps that (1) surface soil of a site is loosened with a rake, and holes are punched at a one-meter interval; (2) compounds are prepared from charcoal, quick lime and bentonite, water is added into the compounds to prepare slurry, and the slurry is evenly sprayed on the site surface, permeated gradually and dried for 1-2 days; (3) the surface soil of the site is raked again, then plant seeds, organic fertilizers, water retention agents and calcium magnesium phosphate fertilizer are mixed, then water is added, the mixture is evenly stirred, and sprays on the surface soil with special spraying equipment, wherein the plant seeds comprise blechnoid, sticktight and paulownia kawakamii; lastly, after non-woven cloth is covered for conservation and management for 1 month, mulberry seedlings are planted. The ecological restoration method for the metal mine waste lands can realize the improvement of original soil and ecological restoration of the metal mine waste lands, the operation is convenient and effective, and the cost is saved.

Owner:SHENZHEN WENKE GARDENING IND

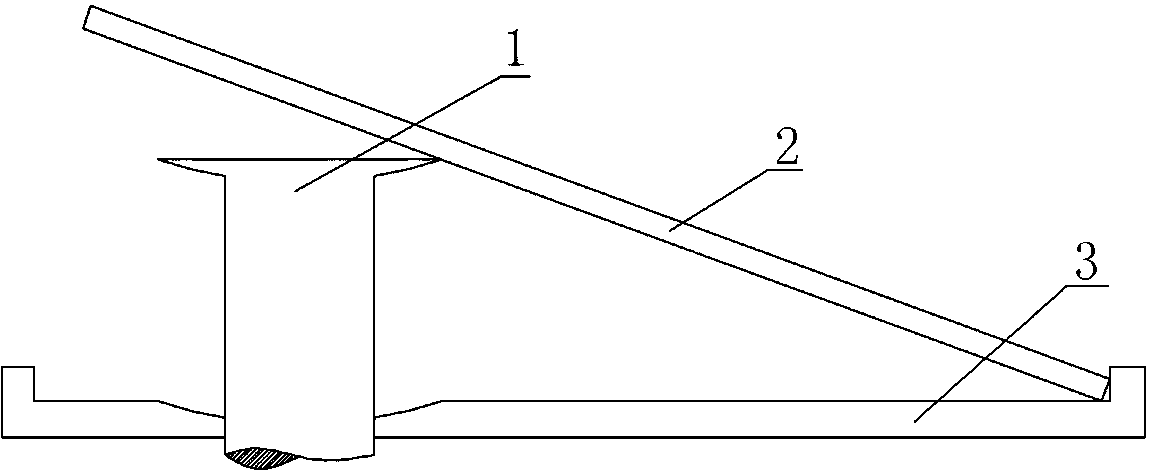

Online shearing device of mesh sheet burr of mesh welding machine

ActiveCN101664791AAvoid skin phenomenaEnsure safetyWire networkMetal working apparatusProduction rateEngineering

The invention discloses an online shearing device of mesh sheet burr of a mesh welding machine, the structure of which comprises an upper cutter holder, a lower cutter holder, a bracket, a lever driving mechanism driving the upper cutter holder to swing, wherein one end of the upper cutter holder is connected with the driving mechanism, and the other end thereof is connected with an upper cutter;a hinged shaft of the lever driving mechanism is arranged between two ends of the upper cutter holder; the hinged shaft is fixed on the bracket and hinged with the upper cutter holder; and the bottomof the bracket is provided with an inclined mechanism which drives the side surface of the upper cutter to cling to a bus of a longitudinal bar so as to lead the shearing line between the upper cutterand a lower cutter to be inclined towards the direction of a welding point between the longitudinal bar and a transverse bar. The online shearing device has the beneficial effects that: the inclinedmechanism drives the shearing line between the upper cutter and the lower cutter to be inclined towards the direction of the welding point between the longitudinal bar and the transverse bar, and shear the burr towards the side of the welding point, thus avoiding the phenomenon that the burr protrudes too long to scratch the skin of an operation staff, and protecting the safety of the operation staff. By the invention, the mesh sheet after completing welding realizes online shearing, saves manpower and improves the production efficiency.

Owner:林振伦

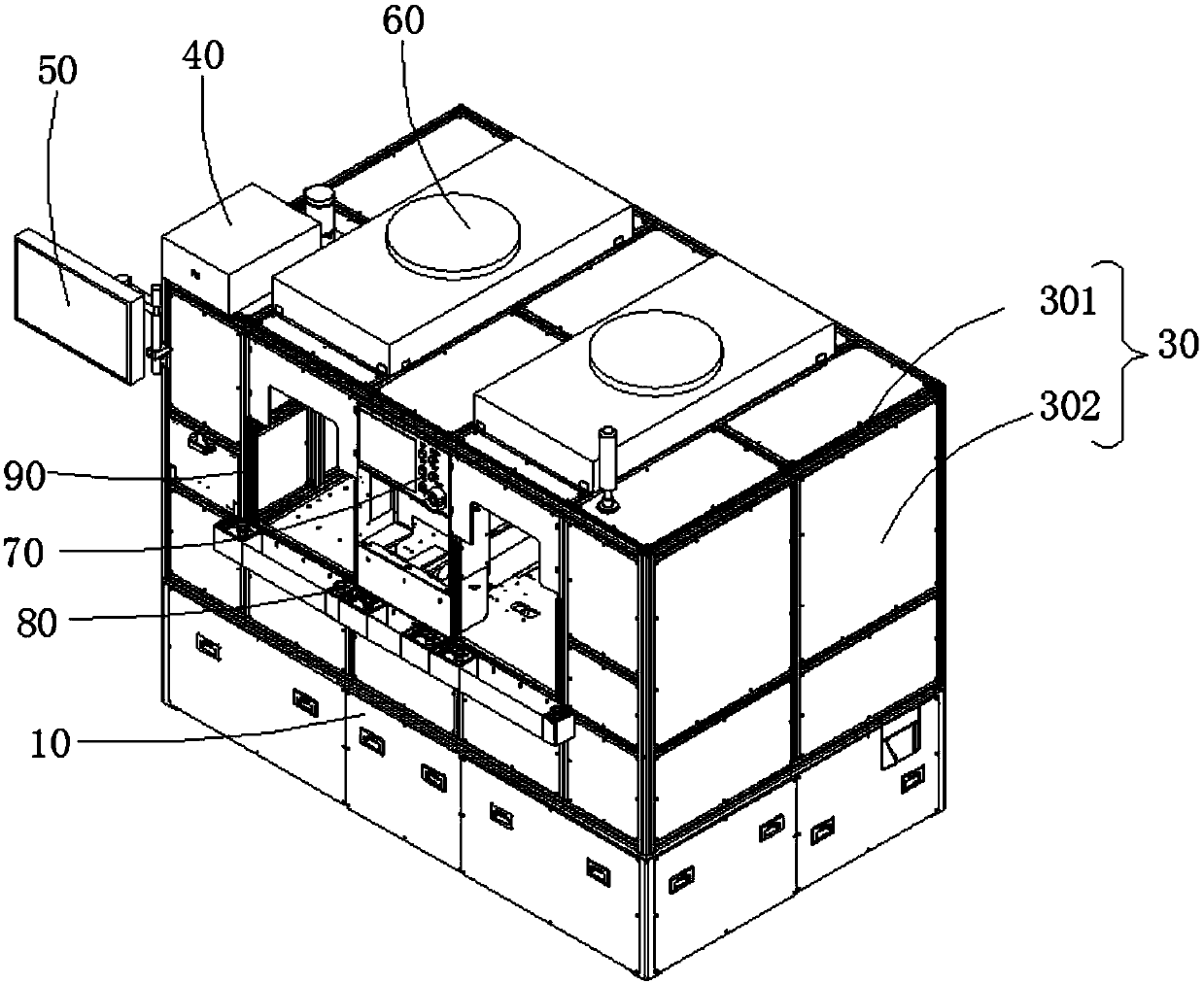

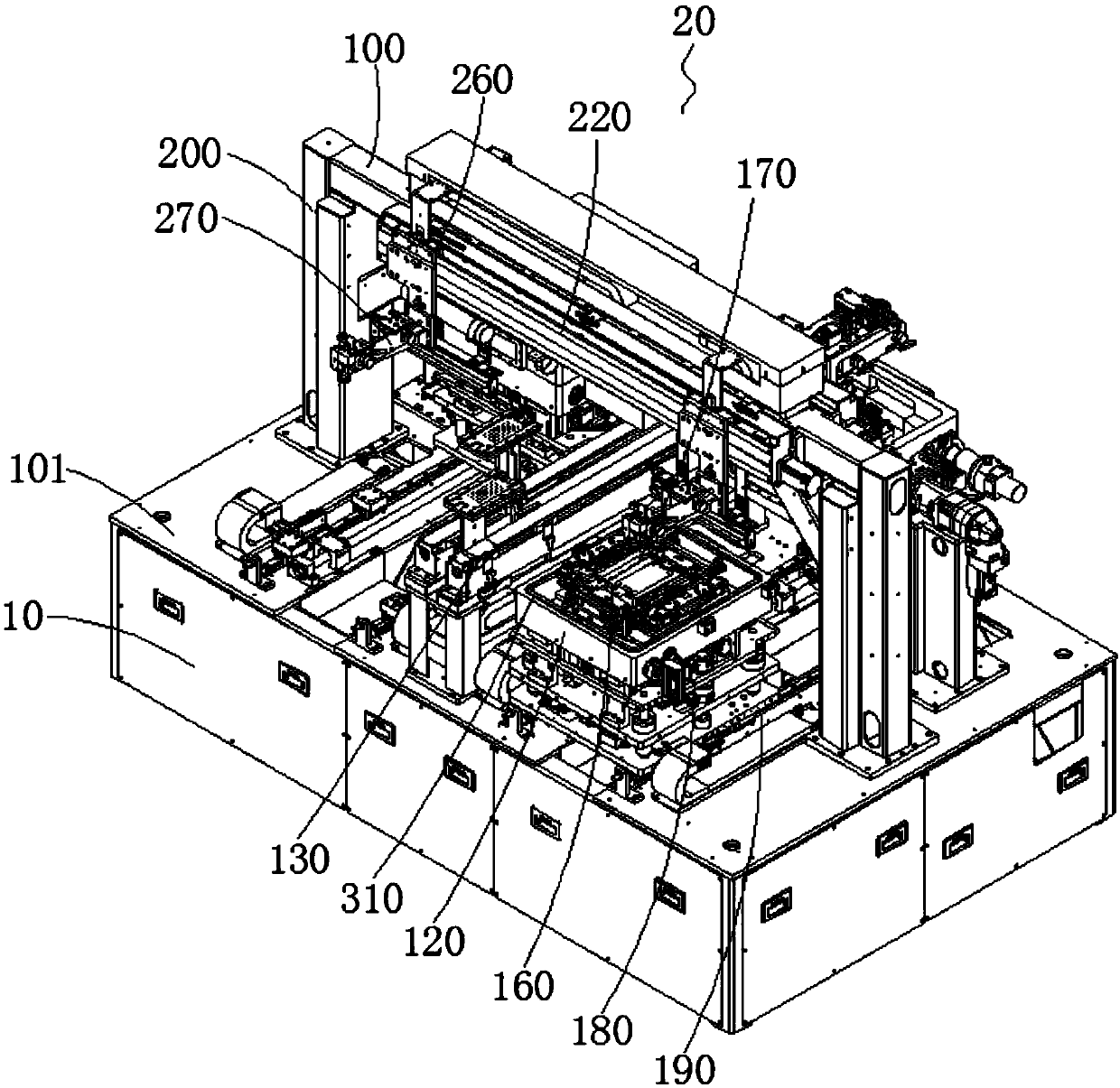

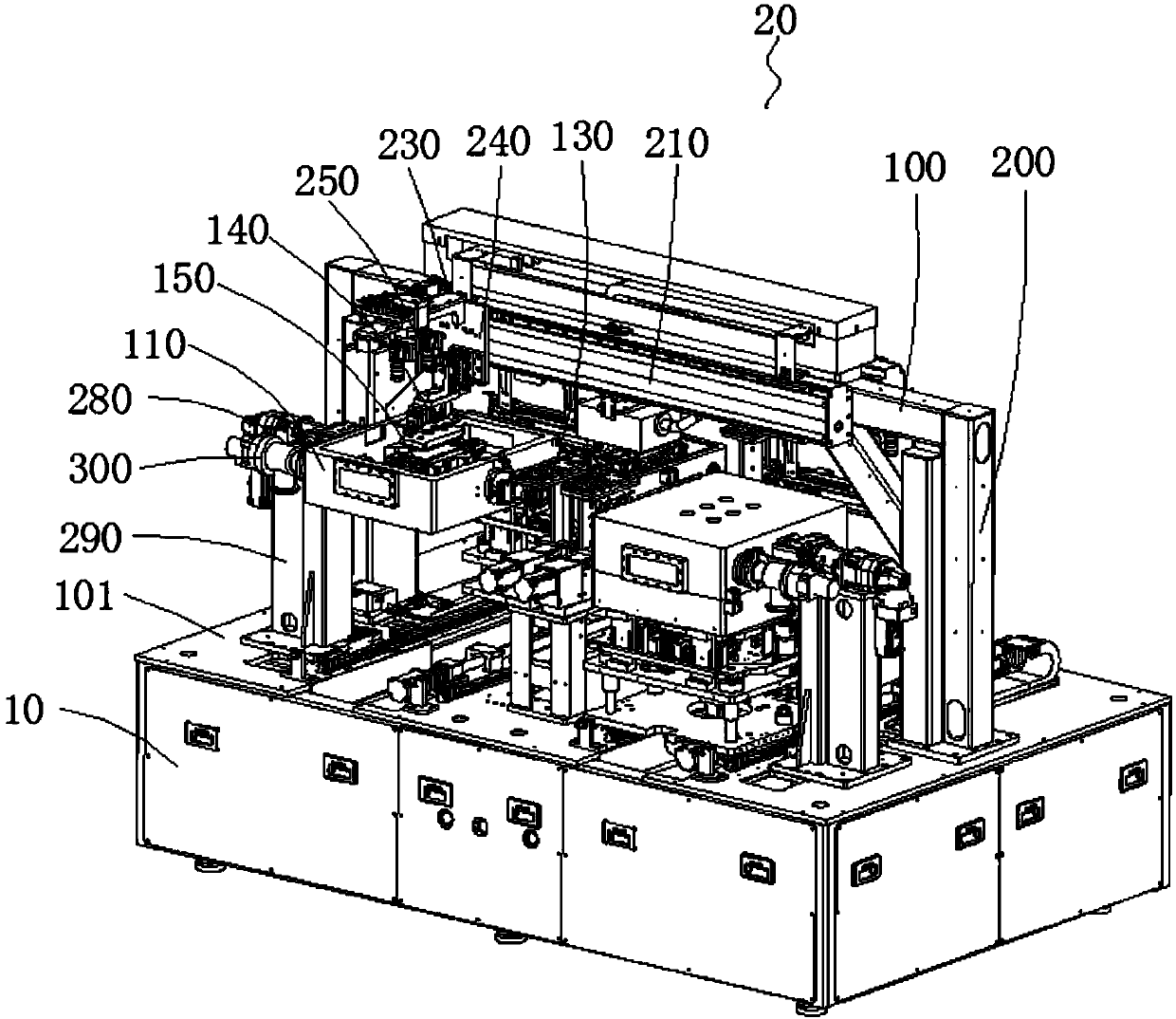

Vacuum laminating fixture and method for 3D curved surface glass and explosion-proof film

The invention discloses a vacuum laminating fixture and method for 3D curved surface glass and an explosion-proof film. The vacuum laminating fixture comprises a machine frame base and a 3D curved surface glass laminating device arranged above the machine frame base, an outer cover is arranged on the surface of the 3D curved surface glass laminating device in a sleeving mode, the outer cover is fixedly connected with the machine frame base, the 3D curved surface glass laminating device comprises a supporting cross beam, an overturning upper box body, a movable lower box body, a curved surfaceglass sheet conveying mechanism, a curved surface glass sheet grabbing mechanism, a curved surface glass sheet positioning mechanism, a silica gel soft mold bearing mechanism, a back adhesive anti-explosion film sheet positioning mechanism, a back adhesive anti-explosion film sheet laminating lifting mechanism and a back adhesive anti-explosion film sheet conveying mechanism. The vacuum laminatingfixture and method for the 3D curved surface glass and the explosion-proof film has the advantages that the structure is simple, the use is convenient, pasting of a back adhesive of the curved surface glass product can be quickly realized, the error is within + / -0.05 mm, no bubbles and wrinkles exist between the back adhesive explosion-proof film sheet and the attaching surface of the curved surface glass sheet, so that the quality of the curved surface glass product is improved, meanwhile, the yield of the product is improved, and the production cost is greatly reduced.

Owner:深圳市义鹏技术有限公司

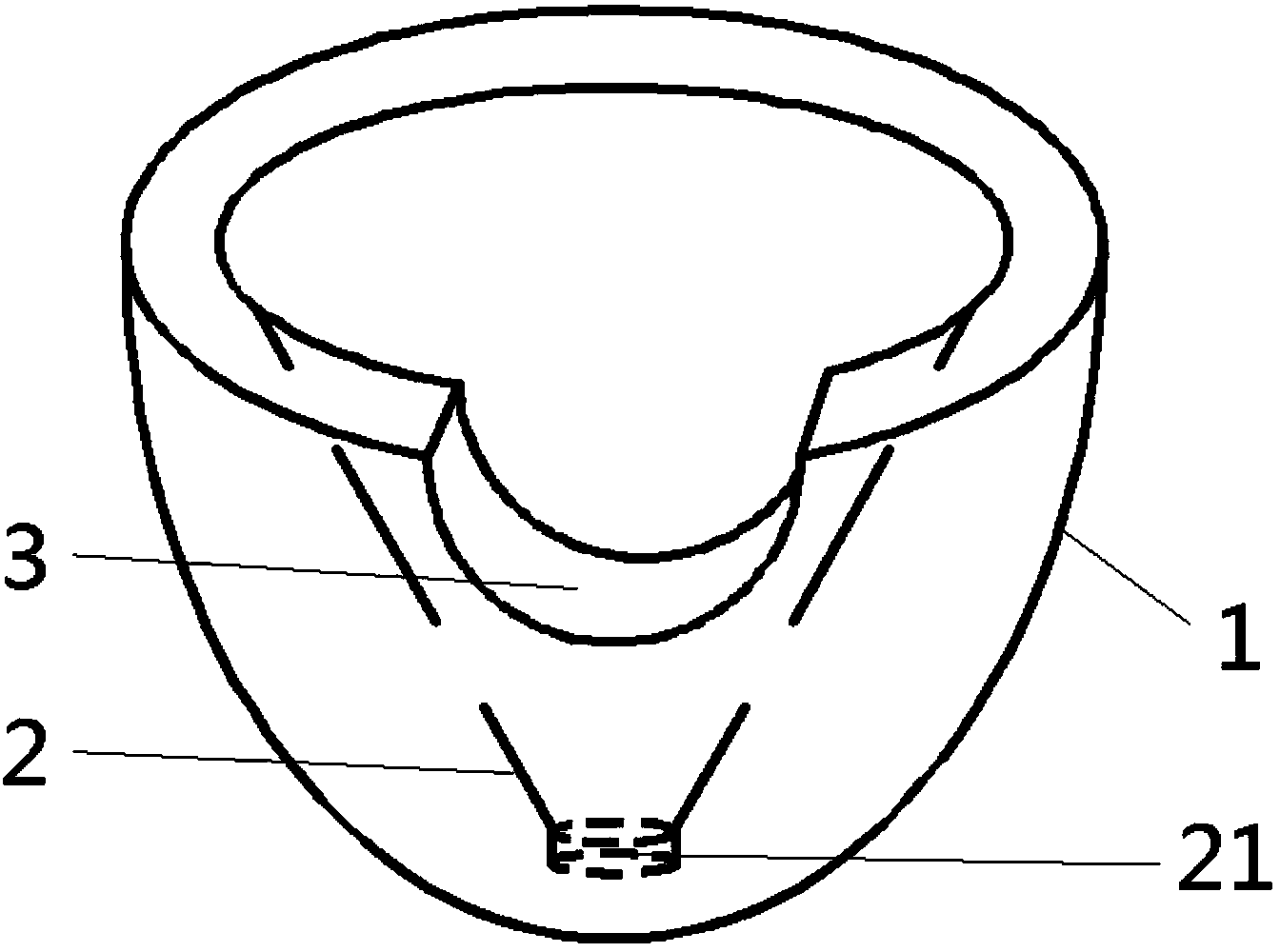

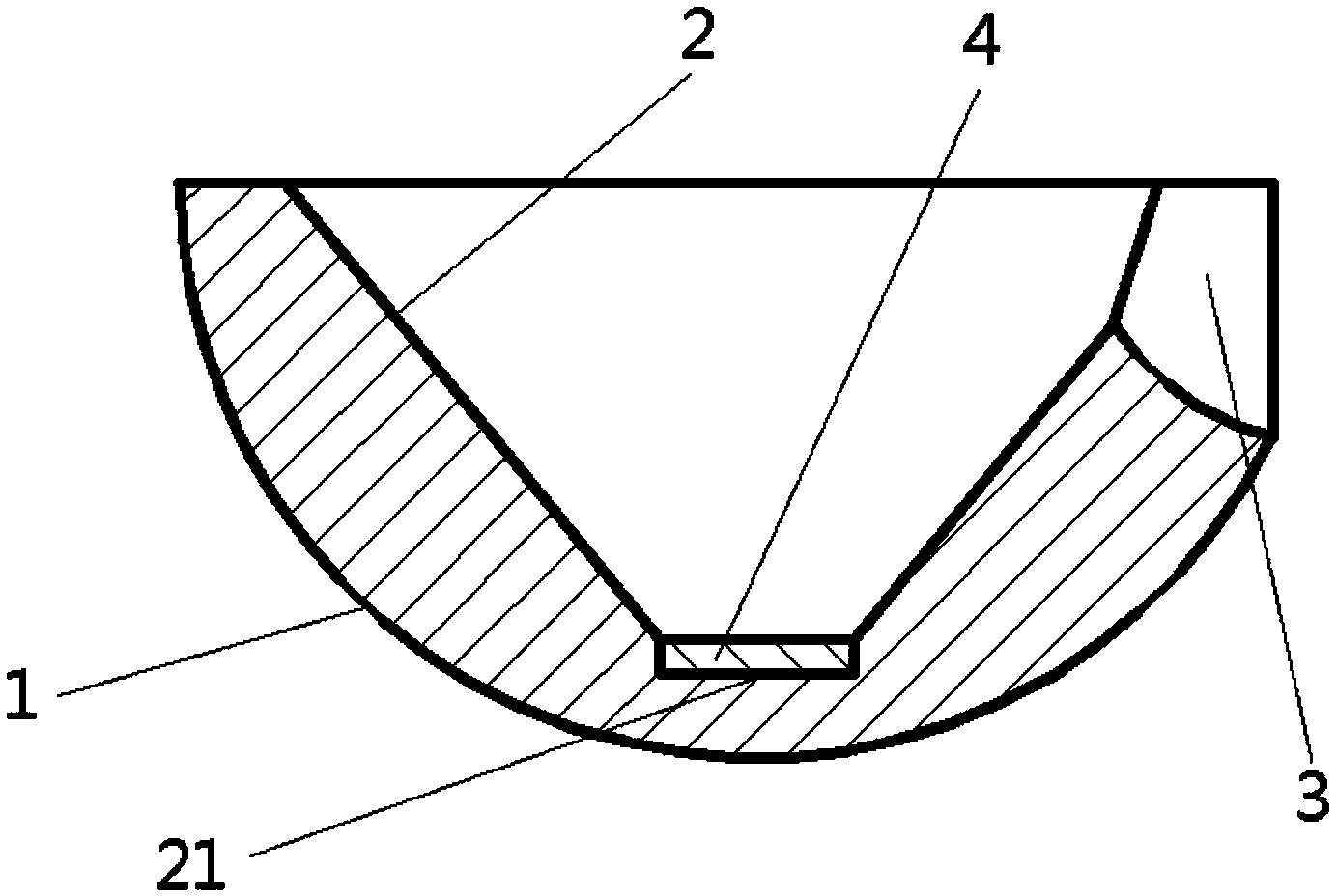

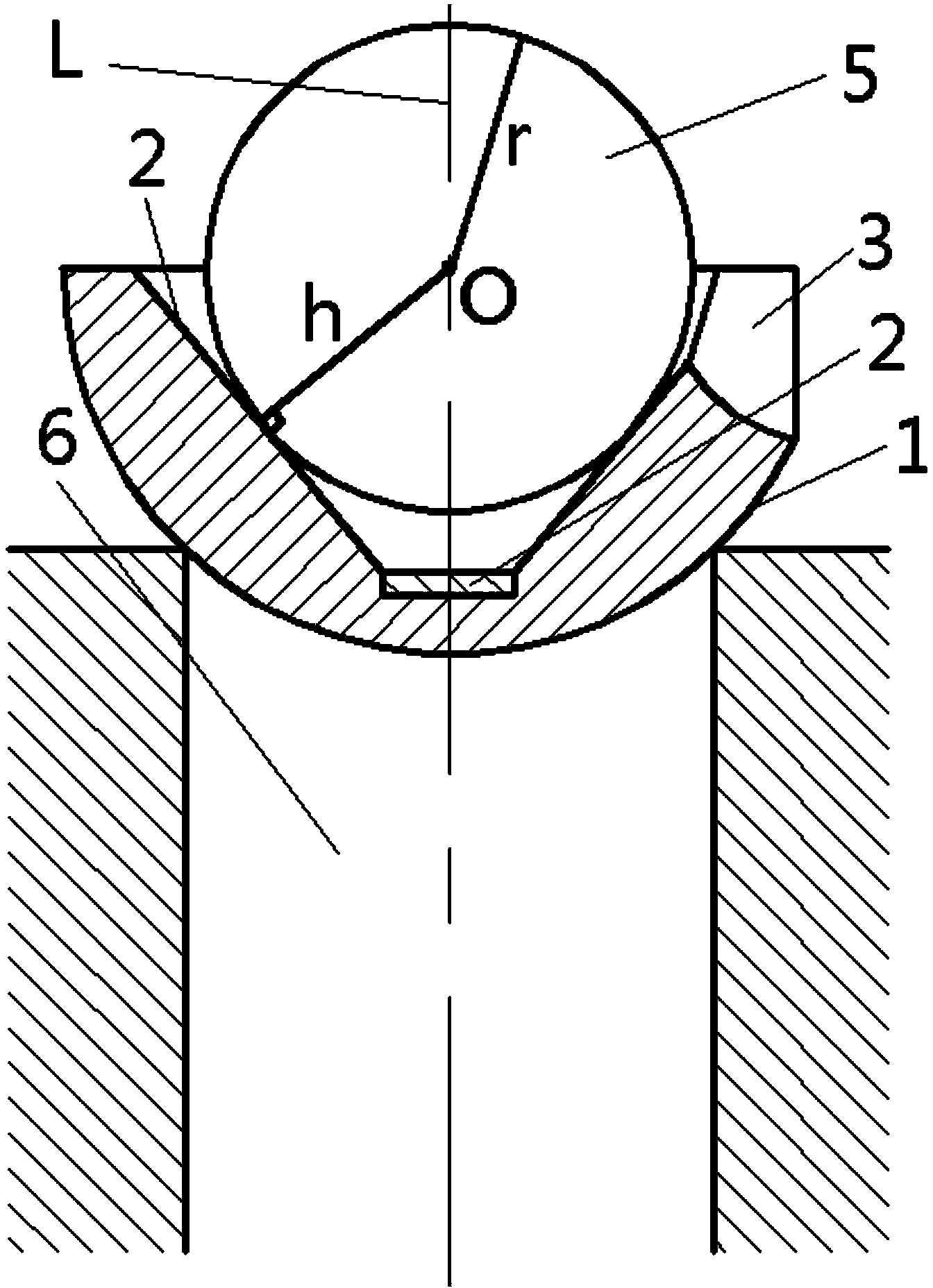

Spherical prism sleeve base for measuring center coordinates of round hole

ActiveCN103940338AAvoid the problem of inaccurate measurement resultsReduce investmentSurveying instrumentsUsing optical meansCircular coneArchitectural engineering

The invention provides a spherical prism sleeve base for measuring the center coordinates of a round hole. The spherical prism sleeve base for measuring the center coordinates of the round hole aims to solve the problems that according to a traditional adjustment and measurement method, a large amount of time is consumed, and the accuracy is low. The spherical prism sleeve base for measuring the center coordinates of the round hole is of an inward-concave structure with an opening facing upwards, the outer surface of the sleeve base is hemispherical, the inner surface of the sleeve base is in the shape of a cone with a conical tip facing downwards, the central axis of the inner surface of the sleeve base and the central axis of the outer surface of the sleeve base coincide, the distance between the centre of sphere of the hemispherical surface of the sleeve base and the conical surface of the conical inner surface of the sleeve base is the same as the radius of a spherical prism placed in the sleeve base, a groove is formed in the upper end of the sleeve base and penetrates through the inner surface and the outer surface of the sleeve base, and the opening is located in the upper surface of the sleeve base. When the sleeve base is used for measuring the center coordinates of the round hole in a device, operation processes can be simplified, labor investment is reduced, the measurement efficiency and the measurement accuracy are improved, as a result, the construction quality is improved, the construction period is shortened, and the working efficiency is improved.

Owner:CHINA NUCLEAR IND 23 CONSTR

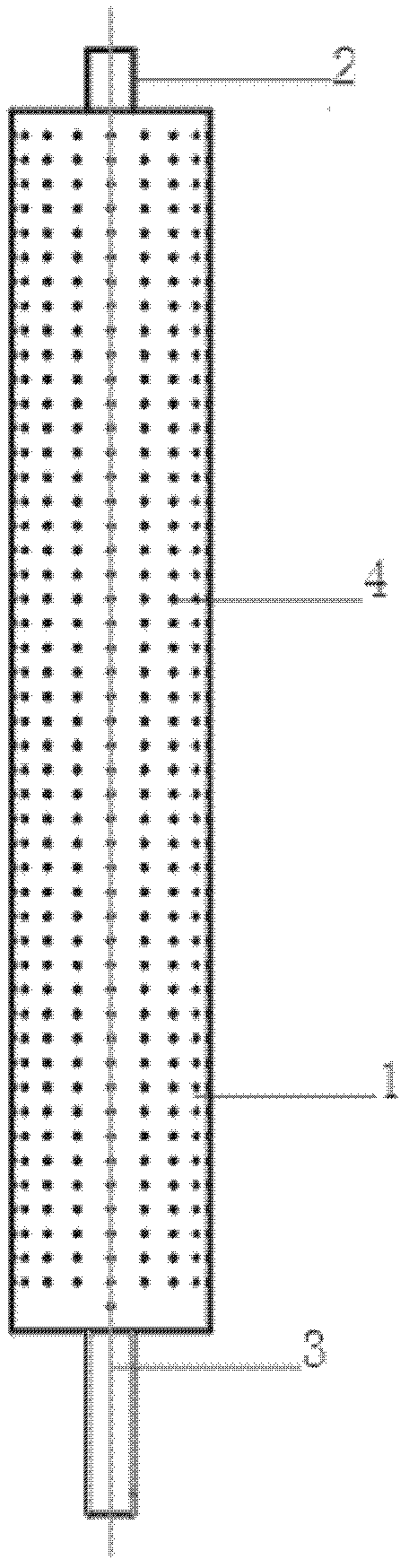

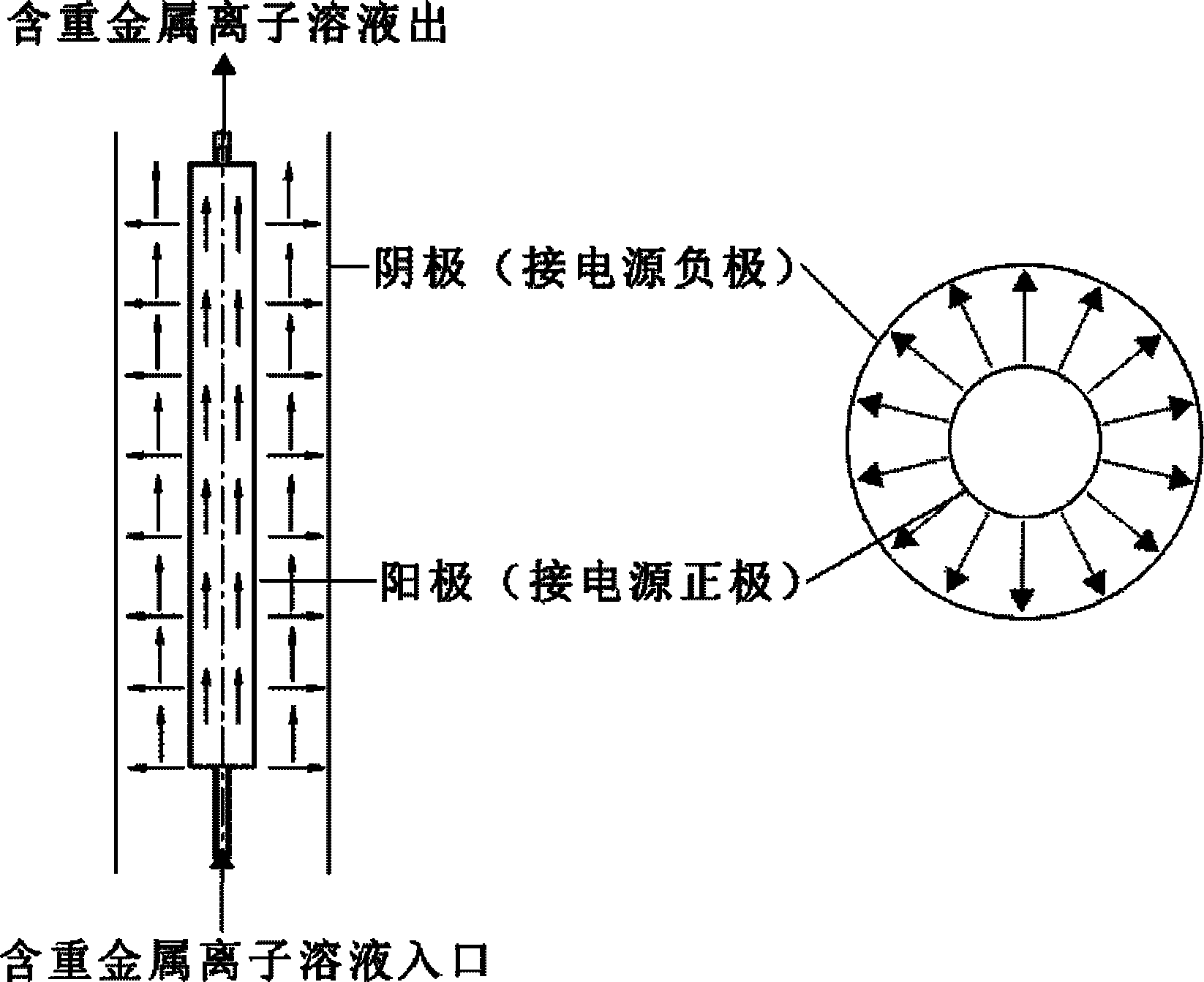

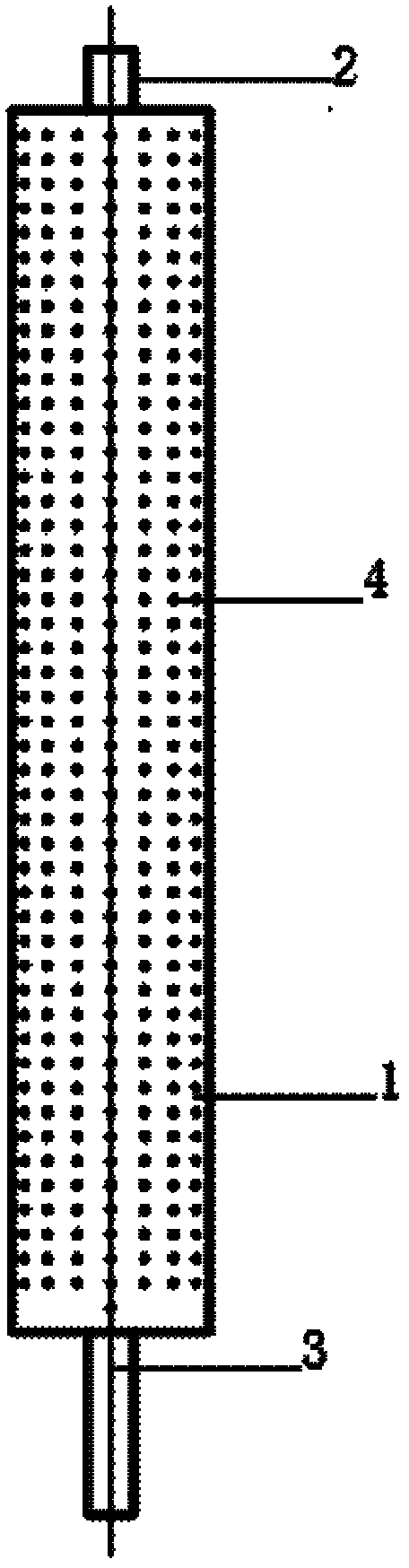

Anode for cylindrical jet-state direct electrodeposition devices

The invention discloses an anode for cylindrical jet-state direct electrodeposition devices, which comprises an anode tube, an upper coaxial positioning column and a lower coaxial positioning column, wherein the anode tube is a hollow cylinder, jet holes are uniformly distributed on the outer edge surface of the anode tube, and the lower coaxial positioning column is a hollow tube; one end of the anode tube is connected with the upper coaxial positioning column, and the other end of the anode tube is connected with the lower coaxial positioning column; the anode tube, the upper coaxial positioning column and the lower coaxial positioning column are coaxially arranged, and an inner-cylinder cavity of the anode tube is communicated with a hollow tube in the lower coaxial positioning column. The invention relates to one of core components of a cylindrical jet-state electrodeposition device, and the cylindrical jet-state electrodeposition device disclosed by the invention can effectively overcome the concentration polarization of a cathode surface, so that metal ions are successfully reduced and deposited on the cathode surface of a cathode. Therefore, compared with metal raw materials produced in previous modes, a metal raw material produced by the anode is more uniform in purity and better in surface effect.

Owner:工信华鑫科技有限公司

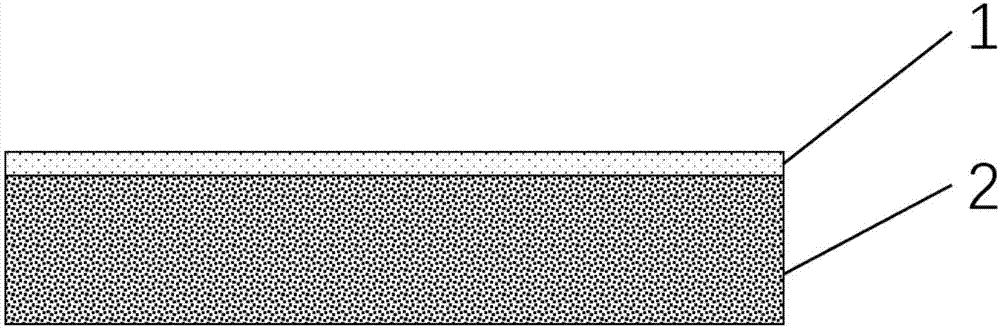

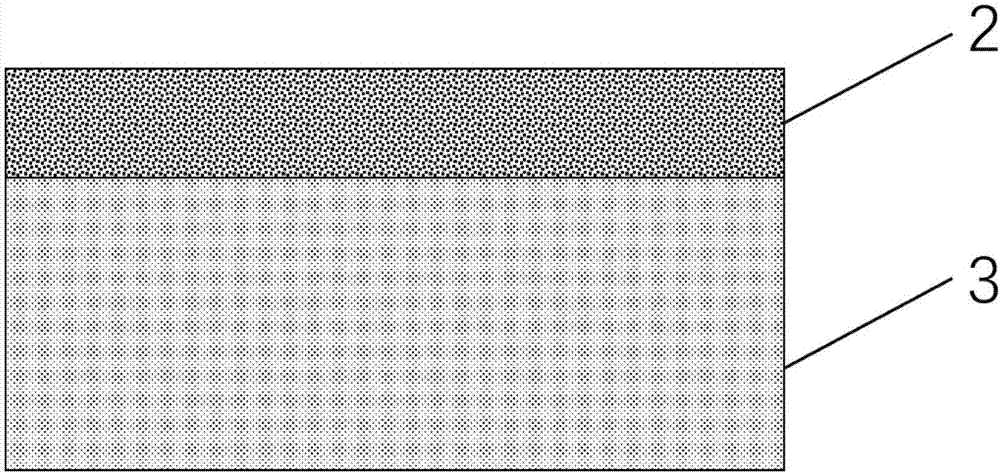

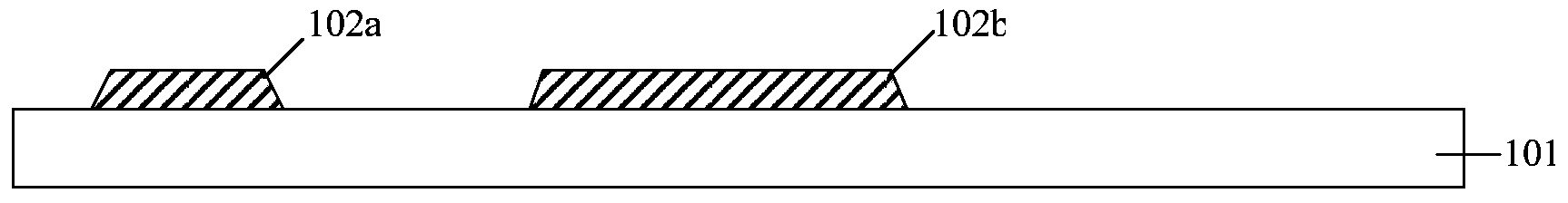

Process for direct imaging growth of graphene on insulation substrate

InactiveCN107012443AAvoid destructionSaving processChemical vapor deposition coatingCopper platingDirect imaging

The invention discloses a process for direct imaging growth of graphene on an insulation substrate, and belongs to the field of preparation of graphene materials. The graphene directly grows on the insulation substrate; and the imaging growth of the graphene is performed on the basis. A layer of copper is firstly plated on the insulation substrate as a catalyst; then, the graphene grows on the surface of the plated copper under catalyst of the copper; the high-temperature annealing is kept to volatilize the copper; and after the copper is volatilized, the graphene can fall to the surface of the insulation substrate to achieve the purpose of directly growing the graphene on the insulation substrate. Based on direct growth, the plated copper has a certain patterns through a photolithography process; and correspondingly, the graphene growing on the copper also has the same patterns to achieve the purpose of direct imaging growth of the graphene on the insulation substrate. The process prevents damage of the graphene in a graphene transfer process through the direct growth process, is lower in cost, and is suitable for large-scale batch production of the graphene.

Owner:BEIJING UNIV OF TECH

Optical glass cleaning and demisting method

InactiveCN105481268AWill not affect the subsequent processImprove cleanlinessCoatingsEnvironmental engineeringCleansing Agents

The invention discloses an optical glass cleaning and demisting method. The optical glass cleaning and demisting method comprises following steps: 1, precleaning; 2, cleaning with a cleaning agent; 3, rinsing; 4, preparing of a demisting aqueous solution; 5, anti-mist treatment; and 6, air drying. Optical glass are subjected to cleaning and demisting via the above six steps, after cleaning, no residue or particle matter is left on the surfaces of lens; clean class is high; cleaning and demisting are combined, so that steps are avoided, fewer steps are needed, and technology is simplified, subsequent processing of optical glass is not influenced; practicability is high; and waste water generated in step 3 is recycled, is treated, and then is used for precleaning in step 1, so that water is recycled, and water resource is saved.

Owner:张进

Technique for preparing high-nitrogen vanadium-nitrogen alloy

ActiveCN105063398AReduce surface cracksImprove surface qualitySelf-propagating high-temperature synthesisContent distribution

The invention relates to a technique for preparing a high-nitrogen vanadium-nitrogen alloy, belonging to the technical field of metallurgy. The technique uses a self-propagating high-temperature synthesis process and comprises the following steps: by using coarse ammonium metavanadate as a raw material, mixing with a retardant, directly introducing hydrogen, and accelerating nitridation by using NH4<+> in NH4VO3 to implement nitriding at high temperature; and after the reaction is complete, cooling the high-nitrogen vanadium-nitrogen alloy in the graphite crucible by introducing nitrogen, taking out, and crushing into blocks. An exhaust valve is utilized to control synthesis pressure in the closed synthesis container so as to control the surface air cleft on the final product vanadium-nitrogen alloy; and thus, the product prepared by the combustion synthesis technique has high strength, is almost not crushed in the material transportation and use process, thereby lowering the attrition rate of the material. The synthetic product has the advantages of high compactness, high specific gravity (up to 6.5 g / cm<3>) and uniform nitrogen content distribution.

Owner:HUNAN ZHONGXIN NEW MATERIALS TECH

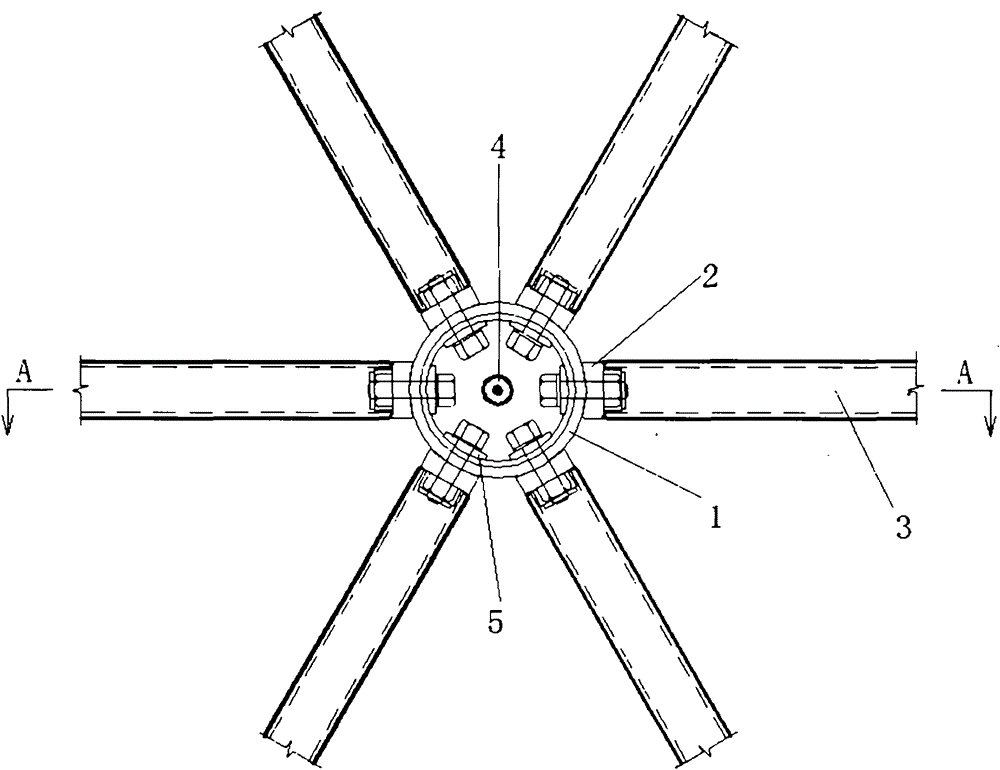

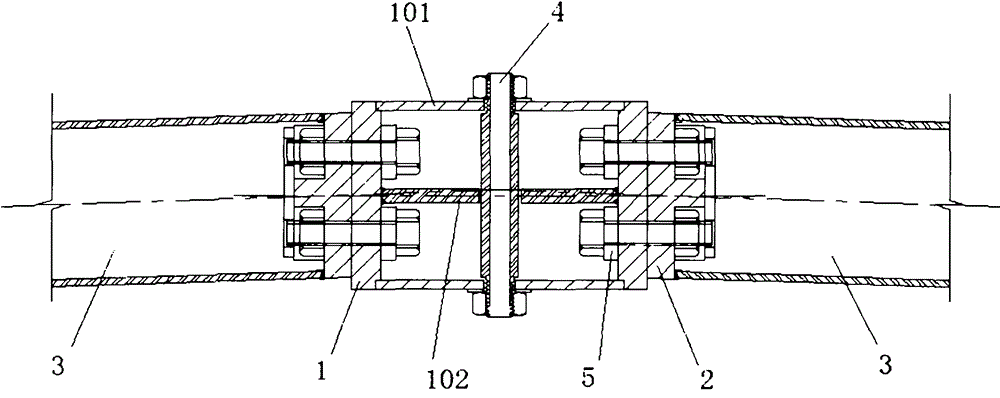

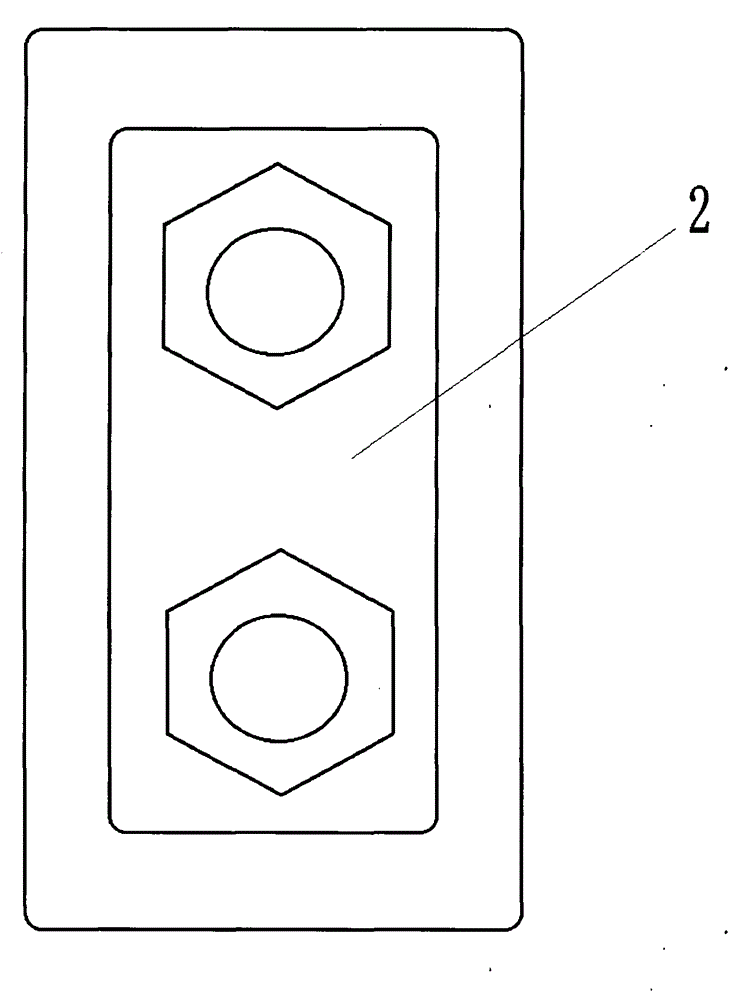

Joint drum structure for connecting steel structural part

InactiveCN104420543AThe structure is complex and beautifulSophisticated node structureBuilding constructionsBolt connectionThin-shell structure

The invention relates to a joint structure, in particular to a joint structure of a single-layer reticulated shell structure, more particularly, is a joint drum structure for connecting a steel structural part, and belongs to the technical field of roof building. A bolt drum joint structure of a rigid single-layer reticulated shell structure is characterized by comprising a bolt drum (1) and six hollow rod pieces (3), wherein the bolt drum (1) is of a hollow cylinder structure; detachable cover plates (101) are arranged on the two end surfaces of the bolt drum; six groups of bolt holes are uniformly distributed in the circumferential direction of the bolt drum (1); the angle of the tangent plane of each hollow rod piece (3) can be adjusted; each hollow rod piece (3) is welded and fixed with a sealing plate (2); a group of bolt holes are formed in each sealing plate (2); the six hollow rod pieces (3) are in bolted connection with the bolt drum (1) through the bolt holes after being welded and fixed with the sealing plates (2).

Owner:上海岑晨钢结构网架有限公司

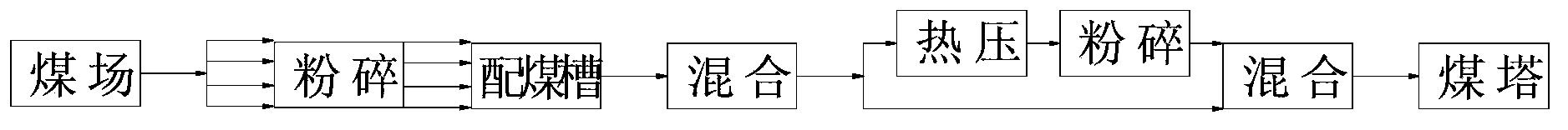

Production method of metallurgy coke

ActiveCN104073274AQuality improvementReduced responseSpecial form destructive distillationEngineeringCoke oven

The invention discloses a production method of metallurgy coke. The production method comprises a coal blending step and a coking step, and specifically comprises the following steps: mixing coals from a coal blending groove so as to obtain blended coal, transporting 10% to 40% of the mass of the blended coal into a hot-pressing device to carry out hot pressing so as to obtain hot-pressed blocks, crushing the hot-pressed blocks, blending the crushed blocks with the rest blend coal, and finally transporting the mixture into a coke oven to carry out coking; wherein the hot-pressing temperature is 300 to 650 DEG C, the hot-pressing pressure is 5-30 MPa, and the stay time under the hot-pressing operation is within 5 seconds. The technology operation method is simple and practical, effectively improves the coke quality on the basis that the ratio of the blended coal is not changed, reduces the reactivity of coke, increases the coke strength after the reactions, protects the high-quality coke, and reduces the coke production cost.

Owner:ANGANG STEEL CO LTD

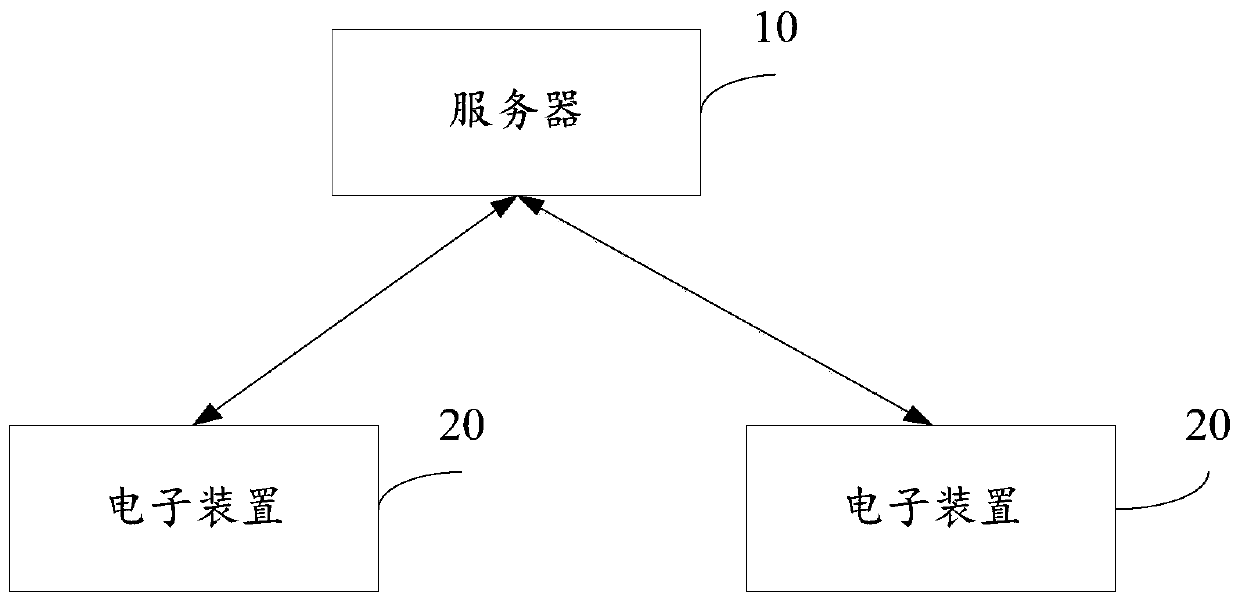

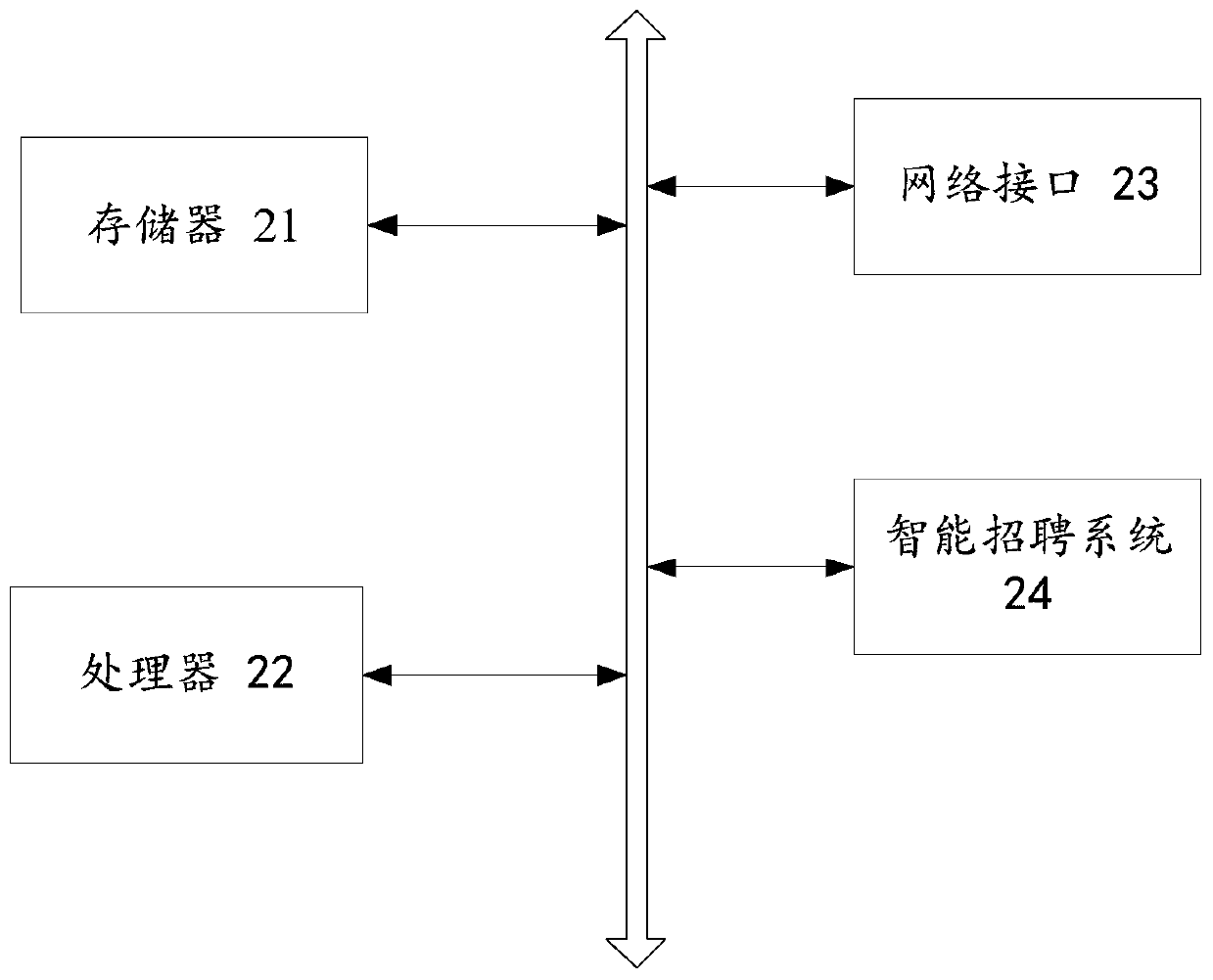

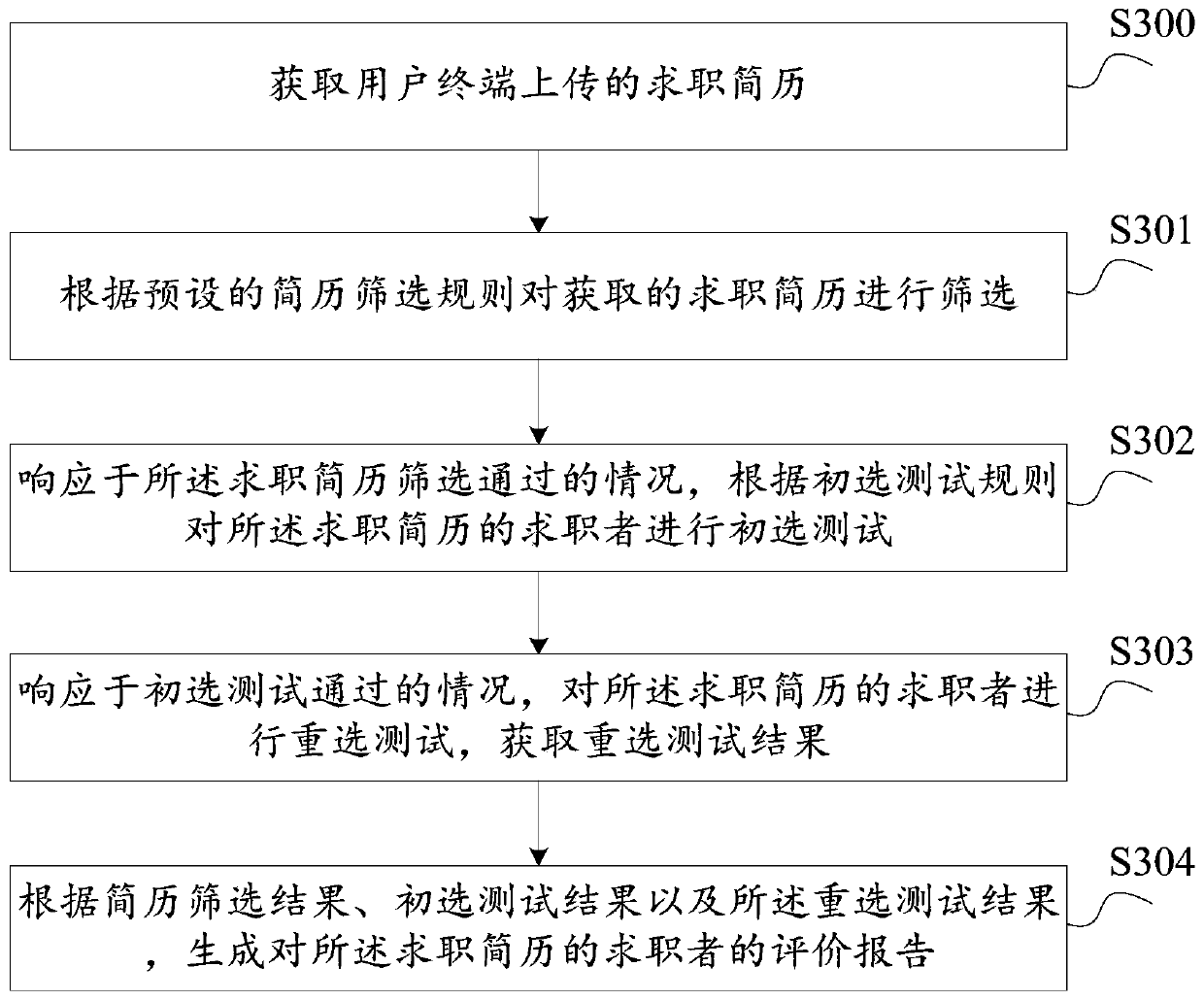

Occupational matching degree evaluation method, electronic device and computer equipment

PendingCN110135799AShorten the timeSaving processOffice automationResourcesComputer scienceScreening Result

The invention discloses an occupational matching degree evaluation method, an electronic device, computer equipment and a storage medium. The method comprises the following steps: obtaining a job resume; screening the obtained resumes to obtain resume screening results; in response to the condition that the resume screening result is passed, performing a primary selection test on the job seeker ofthe resume to obtain a primary selection test result; responding to the condition that the primary selection test result is passed, performing a reselection test on the job seeker of the job resume,and obtaining a reselection test result; and generating an evaluation report of the job seeker of the job resume according to the resume screening result, the primary selection test result and the reselection test result. According to the occupational matching degree evaluation method, the job seekers are automatically and gradually screened, the comprehensive evaluation report for the job seekersis generated, manual intervention is not needed in the period, the recruitment time and process are saved, the recruitment efficiency is improved, and the cost is reduced.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

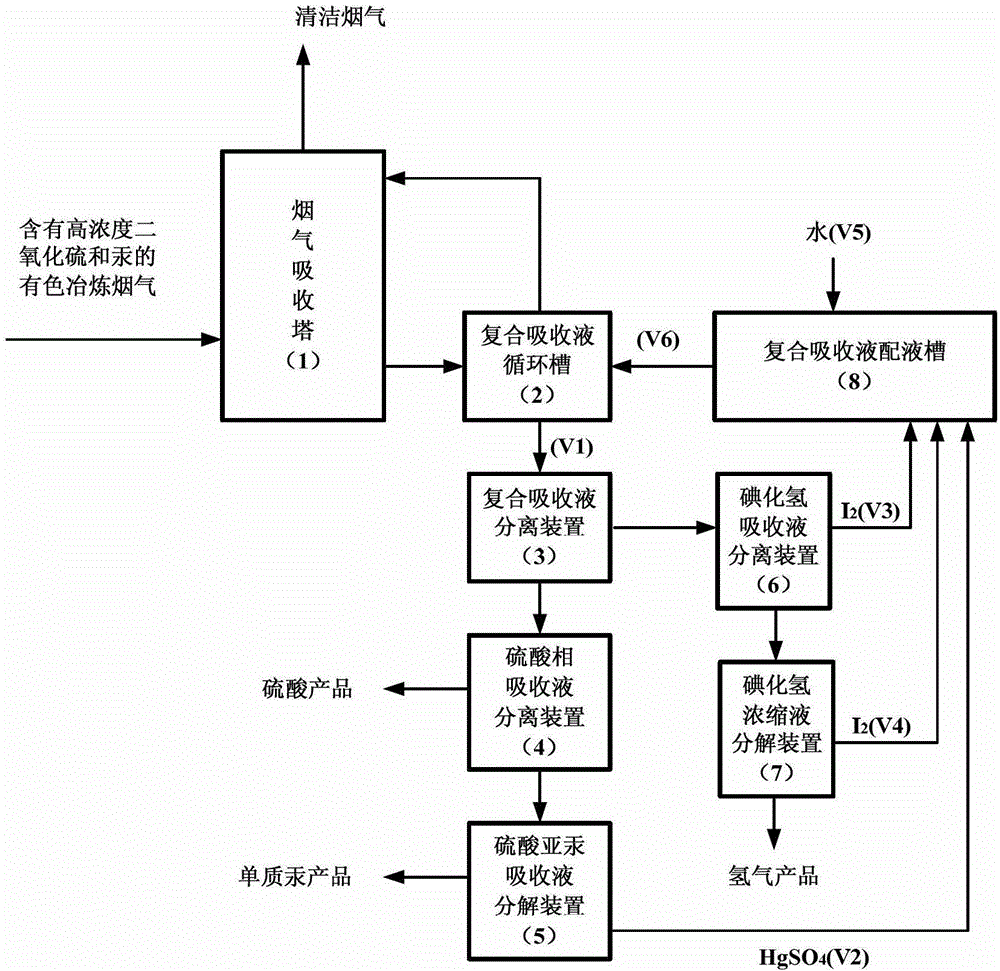

Method for purifying non ferrous metal smelting flue gas and realizing synchronized multiple resource utilization

ActiveCN103331094AGuaranteed emission standardsImprove absorption efficiencyDispersed particle separationHigh concentrationResource utilization

The invention relates to a method for purifying non ferrous metal smelting flue gas and realizing synchronized multiple resource utilization. The method is as below: using a composite absorption liquid comprising main components of mercury sulfate, sulfuric acid and iodine to carry out high efficiency absorption of sulfur dioxide and zero valent mercury in the non ferrous metal smelting; conversing sulfur dioxide into sulfuric acid through reaction with iodine, and conversing zero valent mercury into mercurous sulfate through reaction with mercury sulfate; and finally separating and decomposing the absorption liquid to recover generated sulfuric acid and zero, and simultaneously utilizing other methods to separate, purify and decompose the hydrogen iodide generated in the reaction process for hydrogen production. The method provided by the invention mainly carries out discharge control and recovery utilization of flue gas containing high-concentration sulfur dioxide and zero valent mercury in the non ferrous metal smelting industry, and realizes multiple resource.

Owner:SHANGHAI JIAO TONG UNIV

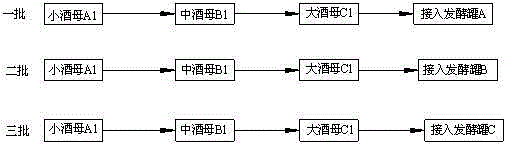

Enlarged culture method for distiller yeast in alcohol production

The invention provides an enlarged culture method for a distiller yeast in alcohol production, belonging to the technical field of ethanol production. The enlarged culture method comprises the following steps of inoculating a distiller yeast cultured to be matured in a Carlsberg flask into a small distiller yeast tank, introducing sterile air or stirring by using a machine, inoculating the distiller yeast into a middle distiller yeast tank to culture after the distiller yeast in the small distiller yeast tank is cultured to be matured, and inoculating the distiller yeast into a large distiller yeast tank to culture after the distiller yeast in the middle distiller yeast tank is cultured to be matured; and dividing 4 / 5 of the matured distiller yeast for inoculation in a fermentation tank and replenishing a fresh distiller yeast saccharification liquor into 1 / 5 of the rest matured distiller yeast to further culture after the distiller yeast in the large distiller yeast tank is cultured to be matured, and further dividing after the distiller yeast is cultured to be matured, repeating the operation in such a way for n (n>=1) times, and respectively inoculating the matured distiller yeasts divided from the large distiller yeast tank into different fermentation tanks. By using the enlarged culture method for the distiller yeast in alcohol production, resources can be saved, the cost can be reduced, the method is simpler in operation, labor and time can be saved, the quality of the distiller yeast is stable, and the benefit of an ethanol plant is greatly increased.

Owner:HENAN TIANGUAN GRP

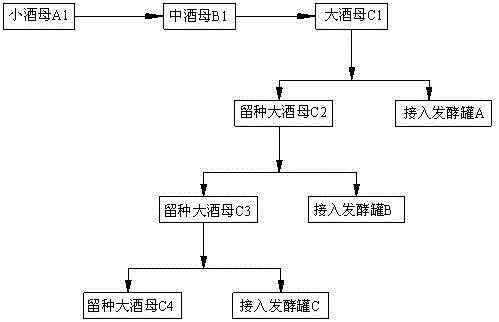

Preparation and application methods of cellulose derivative-grafted polylactic acid

The invention relates to preparation and application methods of a cellulose derivative-grafted polylactic acid. The preparation method of the cellulose derivative-grafted polylactic acid comprises thefollowing steps of dissolving cellulose derivatives into solvent, then completely stirring and dissolving in polylactic acid; adding in catalysts and increasing the temperature for reaction; performing vacuum drying to obtain the cellulose derivative-grafted polylactic acid. The prepared cellulose derivative-grafted polylactic acid is applied to fully biodegradable films to improve two-phase interface compatibility, mechanical performance and transparency of a polylactic acid-cellulose composite film. According to the preparation method the cellulose derivative-grafted polylactic acid, the applied polylactic acid is commercial polylactic acid and reacts with the cellulose derivative through transesterification to prepare the cellulose derivative-grafted polylactic acid, which can serve asan interfacial solubilizer for polylactic acid / cellulose composite materials to improve the mechanical performance of the polylactic acid / cellulose composite materials. The preparation method of thecellulose derivative-grafted polylactic acid avoids the problems of high reaction requirements and expensive catalysts of ring-opening polymerization of high-purity lactide monomers and is easy to industrialize.

Owner:HUBEI GUANCHENG BIODEGRADABLE PLASTIC PRODS

High-strength and high-reliability-sealing radial friction welding method for steel pipe fitting

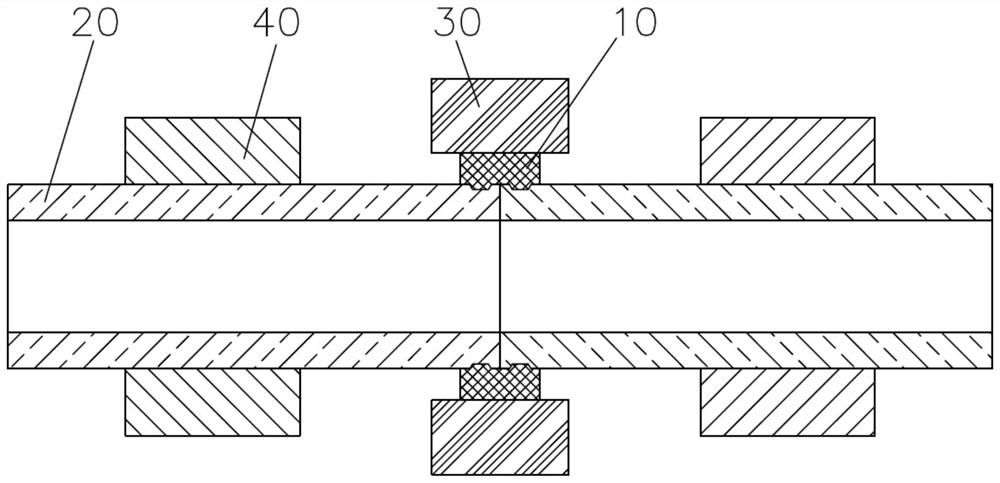

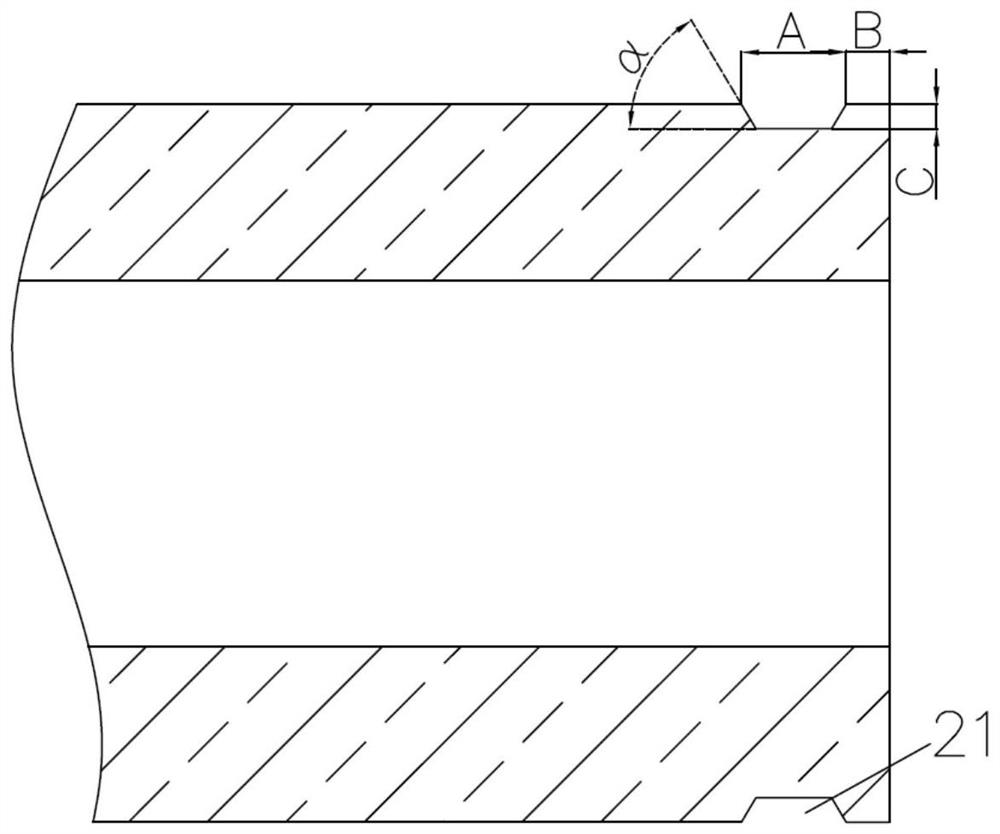

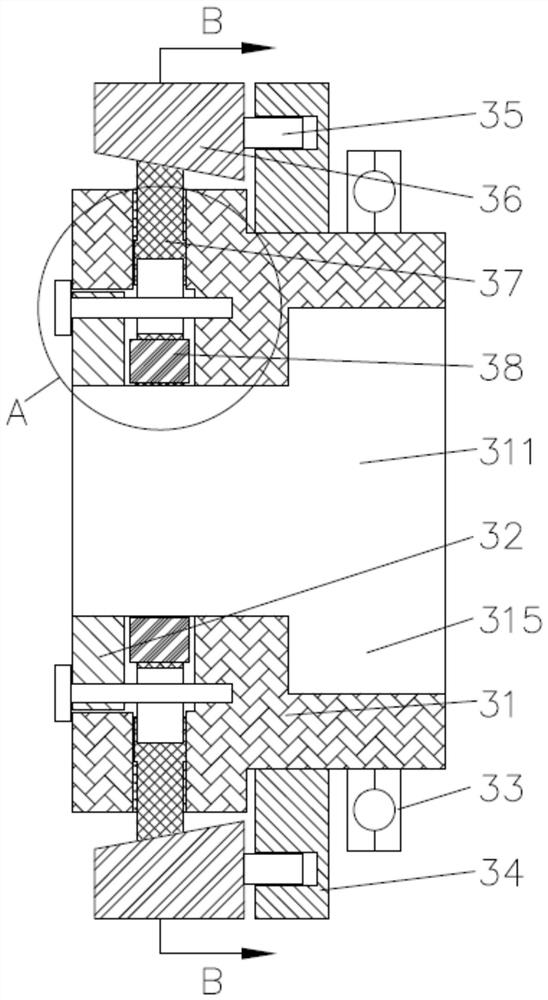

ActiveCN113770507AAchieve Radial Friction WeldingImprove coaxialityNon-electric welding apparatusFriction weldingPipe fitting

The invention provides a high-strength and high-reliability-sealing radial friction welding method for a steel pipe fitting. According to the method, a clamping mode that a rotary pressurizing tool (30) clamps a steel ring welding blank (10) and fixed clamping tools (40) clamp two steel pipe welding blanks (20) respectively is adopted, and the radial friction welding mode that the steel pipe welding blanks (20) at the two ends do not rotate, the steel ring welding blank (10) rotates and pressurizes, and annular grooves (21) are formed in the welding positions of the steel pipe welding blanks (20) at the two ends is adopted; radial friction welding of a large-length steel pipe is achieved, high coaxiality of the welded steel pipe is guaranteed, meanwhile, radial run-out caused by self-rotation of the large-length steel pipe is effectively avoided, welding flashes or weld beading and the like in the pipe are avoided, the welding quality is guaranteed, the annular grooves (21) form a double-spigot locking structure, and the welding strength and the high-reliability-sealing performance of a weldment are ensured.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

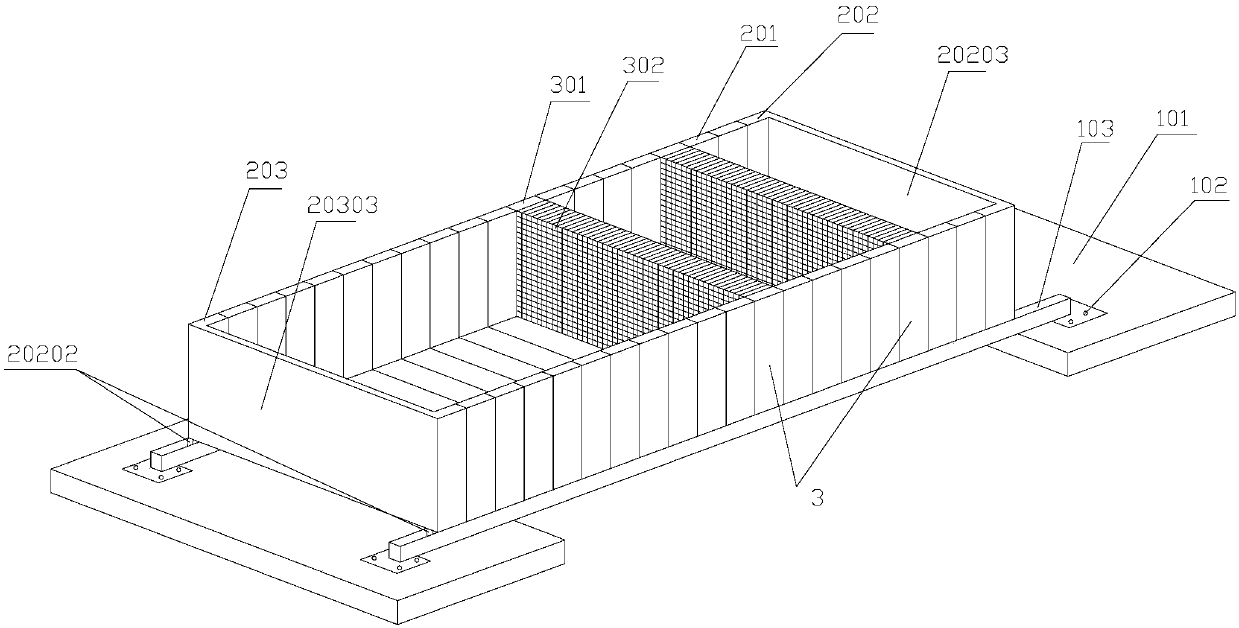

Rock fabrication device and method for simulating three-dimensional morphology of multi-structure surface

ActiveCN109100192ASaving processSave cyclePreparing sample for investigationThree dimensional morphologyPetrology

The invention relates to a rock fabrication device and method for simulating three-dimensional morphology of a multi-structure surface, and belongs to the technical field of engineering. The rock fabrication device comprises a bottom disk, a rock die rack and a structural surface die rack, wherein the structural surface die rack is inserted into a middle part of the rock die rack, and the rock dierack and the structural surface die rack are connected with the bottom disk in a sliding way. The rock fabrication method has the characteristics of short fabrication period and high efficiency, thefabricated rock is good in quality, and the defects such as non-uniform density are difficult to generate; and moreover, the device has characteristics of powerful function, low cost and practicability, is easy to maintain and simple and convenient to operate, and actual application is facilitated.

Owner:CHINA WATER NORTHEASTERN INVESTIGATION DESIGN & RES

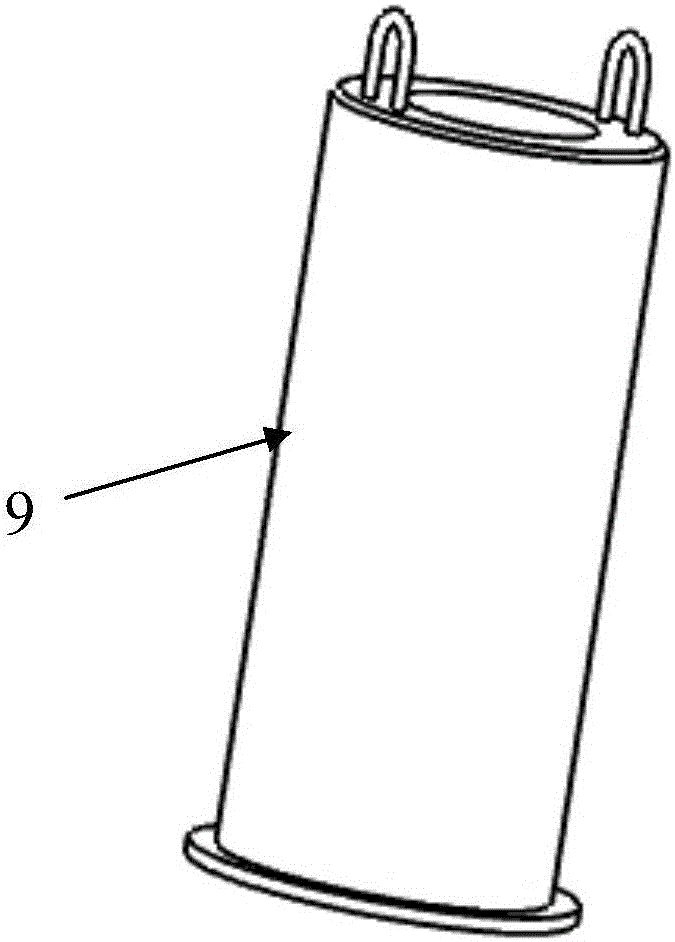

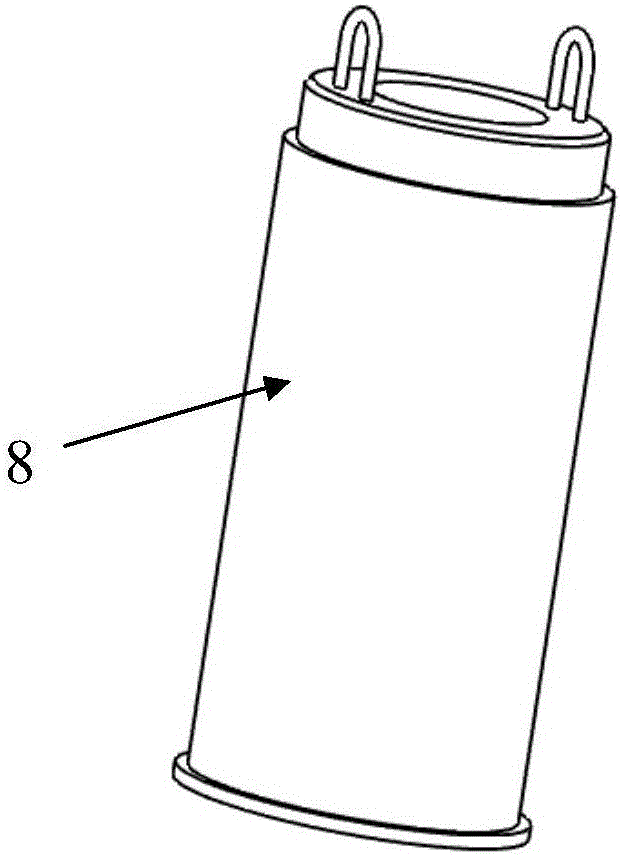

Electrolytic copper positive plate demoulding device

An electrolytic copper positive plate demoulding device is simple in structure and convenient to operate. For solving the technical problem, the electrolytic copper positive plate demoulding device comprises a mould and a jacking device which is arranged on the bottom face of the mould, wherein the jacking device is driven through hydraulic pressure. The bottom face of the mould is provided with a groove which is matched with the bottom portion of the jacking device so that when the jacking device and the bottom face of the mould are jointed, and metal liquid which is poured on a positive plate cannot leak. Compared with the prior art, the jacking device is adopted to enable primary demoulding pried from the side face to be changed into demoulding from acting surface of the positive plate, and when the positive plate is cooled to an appropriate temperature, the jacking device enables the positive plate to be separated from the mould. Under the effect of a transportation mechanism, transportation is conducted, process and time are saved, the structure is simple, and operation is simple and convenient.

Owner:重庆寿丰科技有限公司

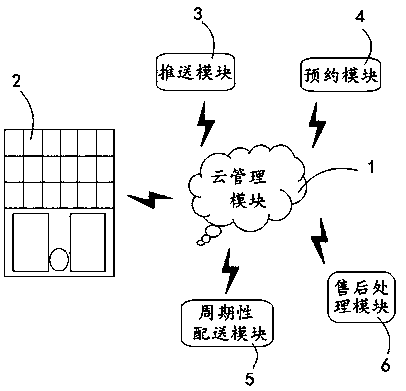

Community retail management system based on Internet of Things

InactiveCN108629654AMeet purchase needsConvenient shopping in the communityBuying/selling/leasing transactionsStructure of Management InformationThe Internet

The invention provides a community retail management system based on the Internet of Things, which comprises a cloud management module, a cabinet body with a controller, a pushing module, a reservation locking module, a periodic distribution module and a post-sales processing module. A commodity recognition mechanism and a commodity recovery mechanism with a recovery channel are arranged on the cabinet body. A cloud management module stores user data, and a pushing module is used for pushing the demand to the user and the recent information and help information of the conventional purchasing commodity according to the user data. The reservation locking module is used for sending the information of the booking commodity to the cloud management module, and the periodical distribution moduleis used for feeding information of regularly distributed commodities to the cloud management module according to the shopping period selected by the user, and the after-sales processing module is usedfor obtaining a matching result of the content of the user data according to the identification result of the commodity identification mechanism and the content of the user data, the recovery channelof the commodity recycling mechanism is selectively opened, and after-sales processing data are stored. The system framework has the advantages that the structure is simple, the cost is low, the efficiency is high, the goods returning and replacing are rapid and convenient.

Owner:蒋文华

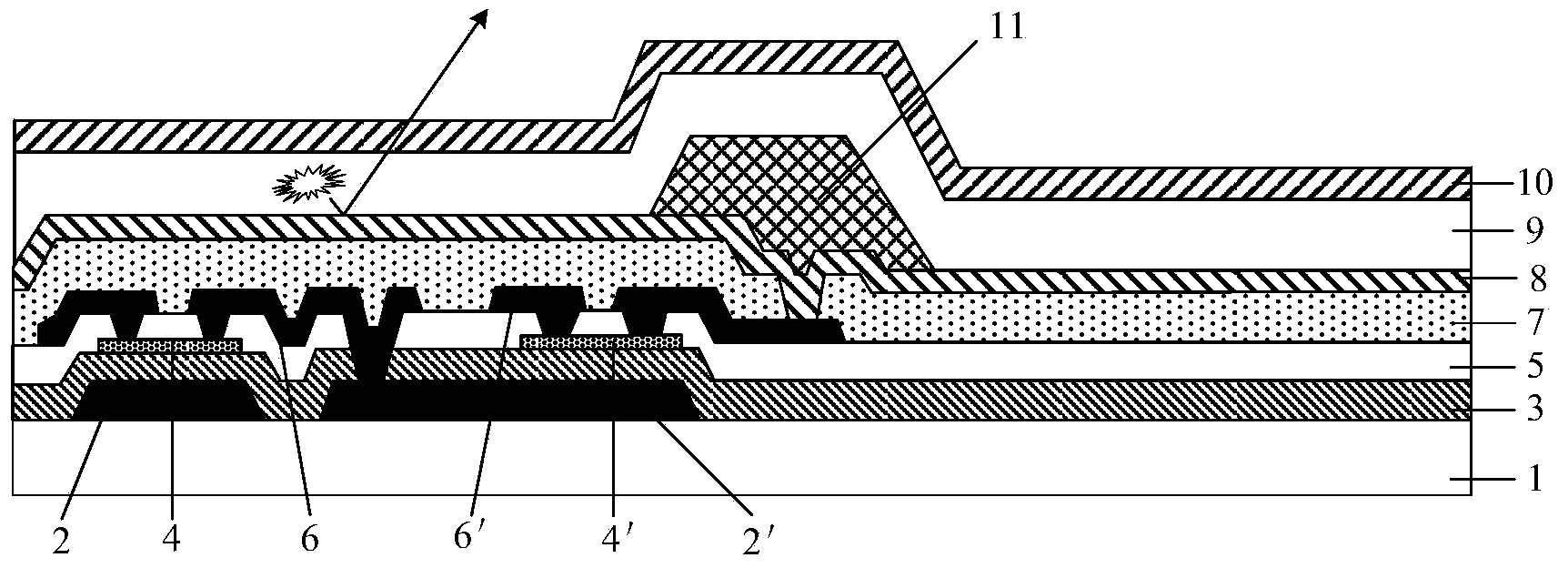

Array substrate, manufacturing method thereof and display device

ActiveCN103647028AReduce the number of masksSaving processSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses an array substrate manufacturing method. The array substrate manufacturing method comprises the steps of: forming a pattern including a data line, a source electrode and a drain electrode on a substrate; forming a pattern including an active layer; forming a pattern insulating a grid insulating layer and exposing a region of the drain electrode, which is connected with a to-be-formed anode; forming a pattern including a grid line, a grid electrode and the anode; forming a pattern including a pixel definition layer, an organic material layer and a transparent cathode. The invention also discloses an array substrate and a display device. The array substrate manufacturing method reduces number of times of mask, and therefore saves manufacturing technological process and manufacturing cost.

Owner:BOE TECH GRP CO LTD

Preparation method of glazing-free white porcelain

The invention relates to a preparation method of porcelain and provides a preparation method of glazing-free white porcelain. By adopting the preparation method, a glazing step after firing is omitted, product production period is shortened, and production cost is lowered especially; flatness and brightness of the surface of a porcelain product prepared by the method are maintained, and appearance of the product still has transparent and clean sense similar to that after being glazed. The glazing-free white porcelain comprises, by weight, 50-55 parts of kaolin, 38-42 parts of alkalifeldspar, 3-5 parts of quartz and 1-2 parts of talc powder. The preparation method includes steps: treating above raw materials to form a clay blank; heating and firing the clay blank from room temperature by means of staged linear temperature rising, wherein a temperature rise curve of each stage is y=kxPxt, y refers to temperature DEG C, P refers to power of a kiln, t refers to time min, and value of a coefficient k is greater than or equal to 0 and less than or equal to 1.

Owner:德化东华陶瓷有限公司

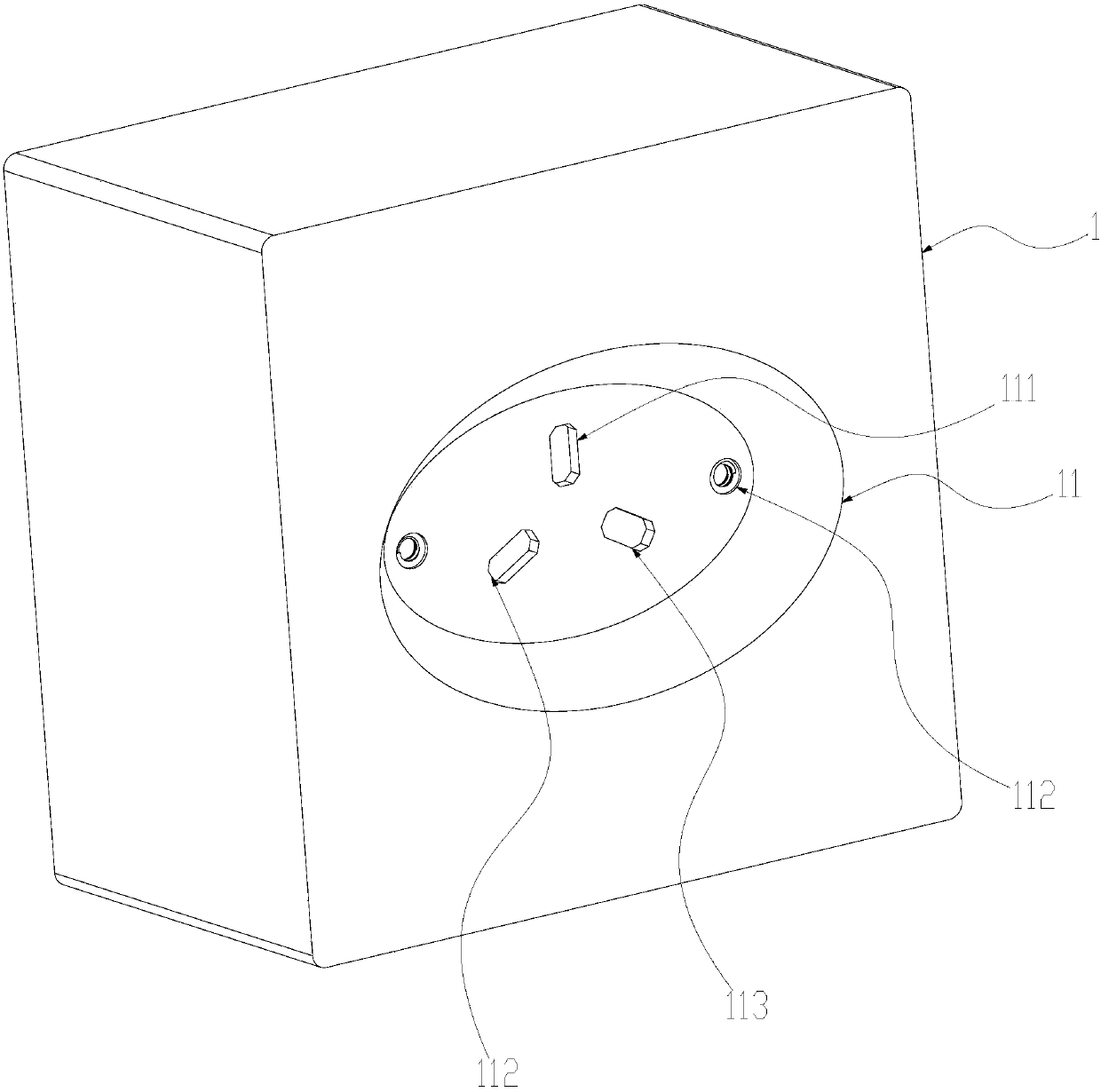

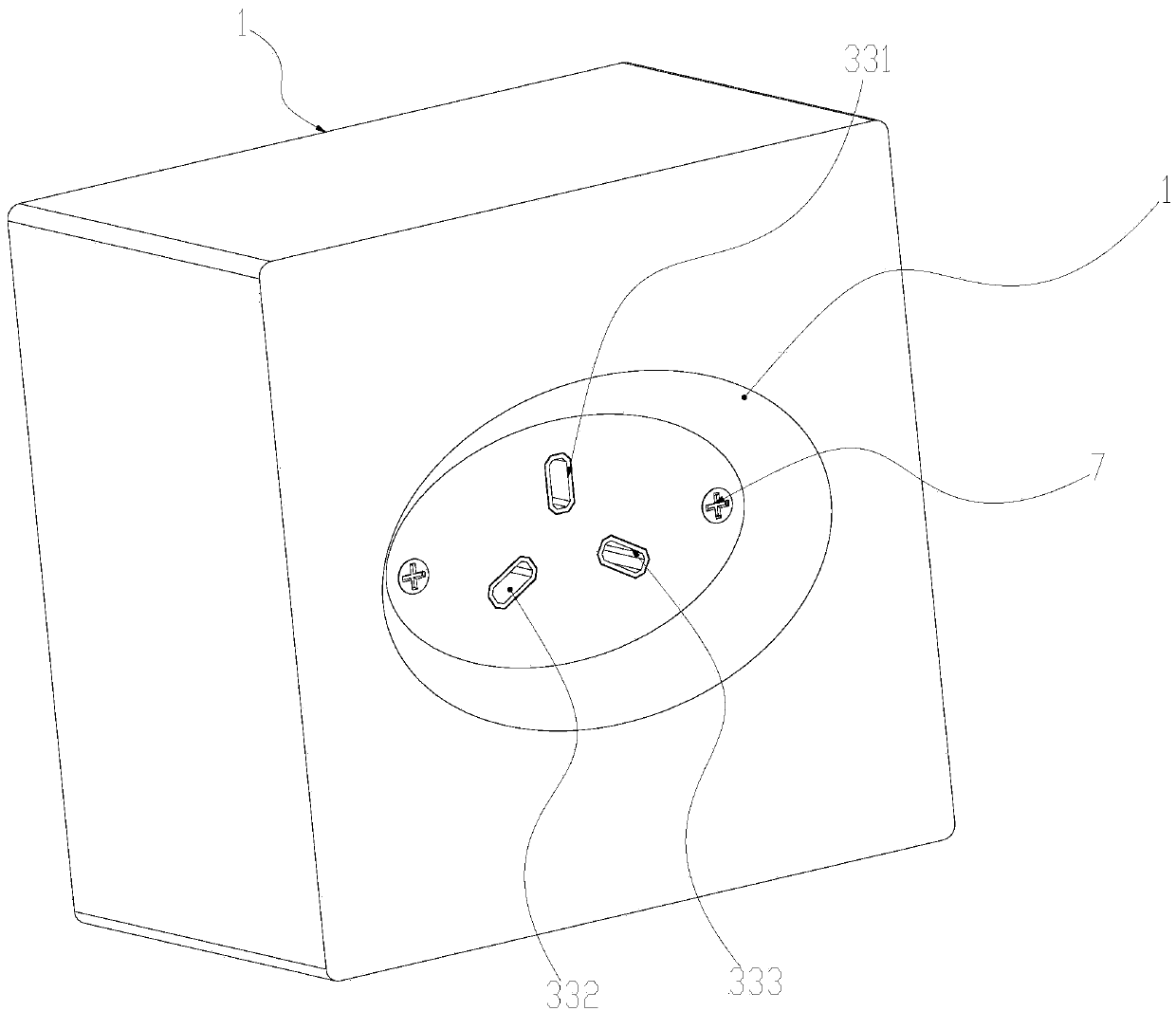

Waterproof touch socket

ActiveCN109524838AFast, effective and labor-saving plugging and unpluggingStagnant water flowCouplings bases/casesTwo-part coupling devicesInsulation layerFlange

The invention relates to a socket, in particular to a waterproof touch socket comprising a socket body, a plug and a mounting shell. The socket body is fixed in the mounting shell. A mounting slot isformed in the outer side of the mounting shell; and a ground wire mounting hole, a fire wire mounting hole and a zero wire mounting hole are respectively formed in the mounting slot. The plug includesa hand-held portion, a ground wire contact head, a live wire contact head and a zero wire contact head; the ground wire contact head, the live wire contact head and the zero wire contact head are coated with insulating layers; annular flanges are arranged at exposed part ends, close to the ground wire contact head, the live wire contact head and the zero wire contact head, of the insulation layers; and the annular flanges, a live wire contact slot, a zero wire contact slot, and a ground wire contact slot are in close contact to realize a good sealing effect. According to the invention, the buckle structure is used for replacing the magnetic suction structure to save the cost and procedures; and the effective waterproof design is obtained.

Owner:温州市鹿城区渊龙电器科技有限公司

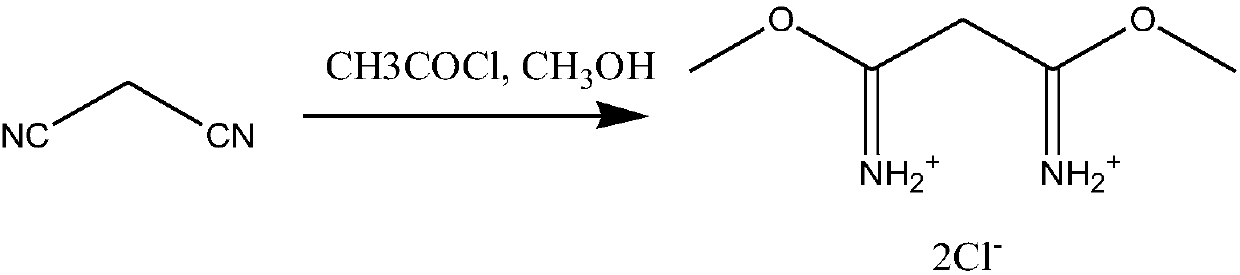

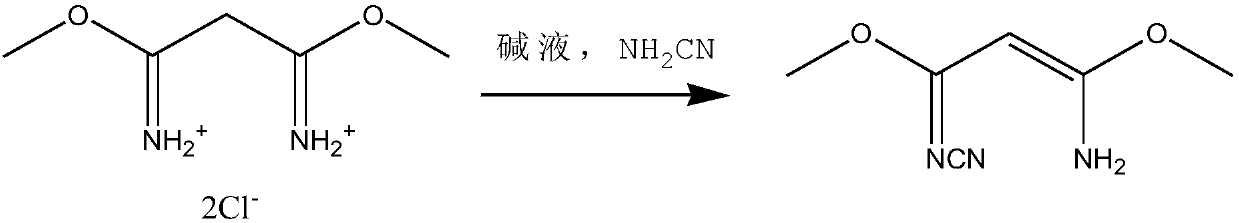

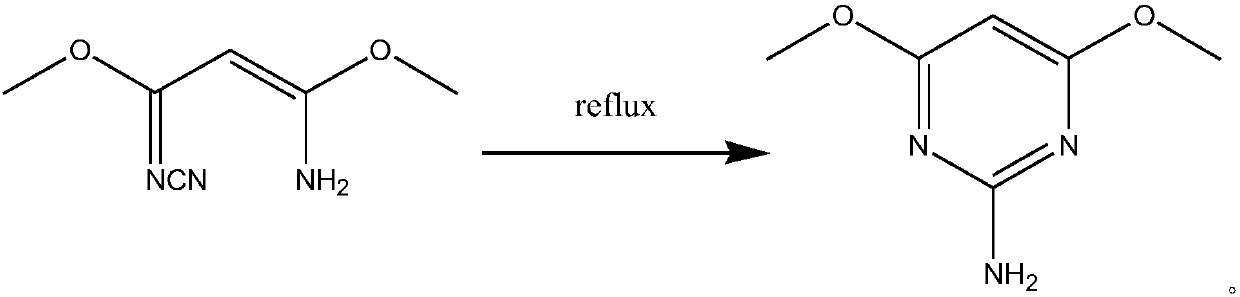

2-amino-4,6-dimethoxypyrimidine synthesis method

The invention provides a 2-amino-4,6-dimethoxypyrimidine synthesis method, which belongs to the technical field of organic synthesis. The invention provides a synthetic route which takes malononitrile, methanol, acetyl chloride, hydrogen cyanamide and alkali liquor as raw materials; the method comprises the following steps of dropwise adding the acetyl chloride to a system of the malononitrile andthe methanol, directly obtaining 1,3-dimethylpropanediamidine dihydrochloride, then reacting with the alkali liquor and the hydrogen cyanamide to obtain 3-amino-3-methoxy-N-cyano-2-propylamidine andfurther performing closed-loop rearrangement to obtain 2-amino-4,6-dimethoxypyrimidine. The synthesis method provided by the invention saves the cumbersome synthesis technology and equipment of the 1,3-dimethylpropanediamidine dihydrochloride, and comprises the steps of adding the acetyl chloride into the malononitrile and the methanol to directly obtain the 1,3-dimethylpropanediamidine dihydrochloride. The synthetic route of the 1,3-dimethylpropanediamidine dihydrochloride in the invention has extremely low moisture control, stable product quality and high yield.

Owner:YINGKOU YINGXIN CHEM TECH CO LTD

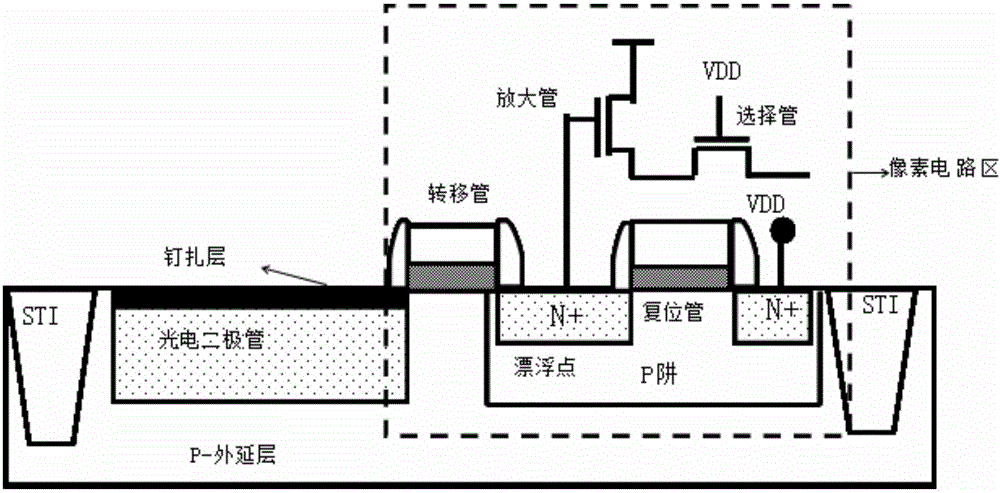

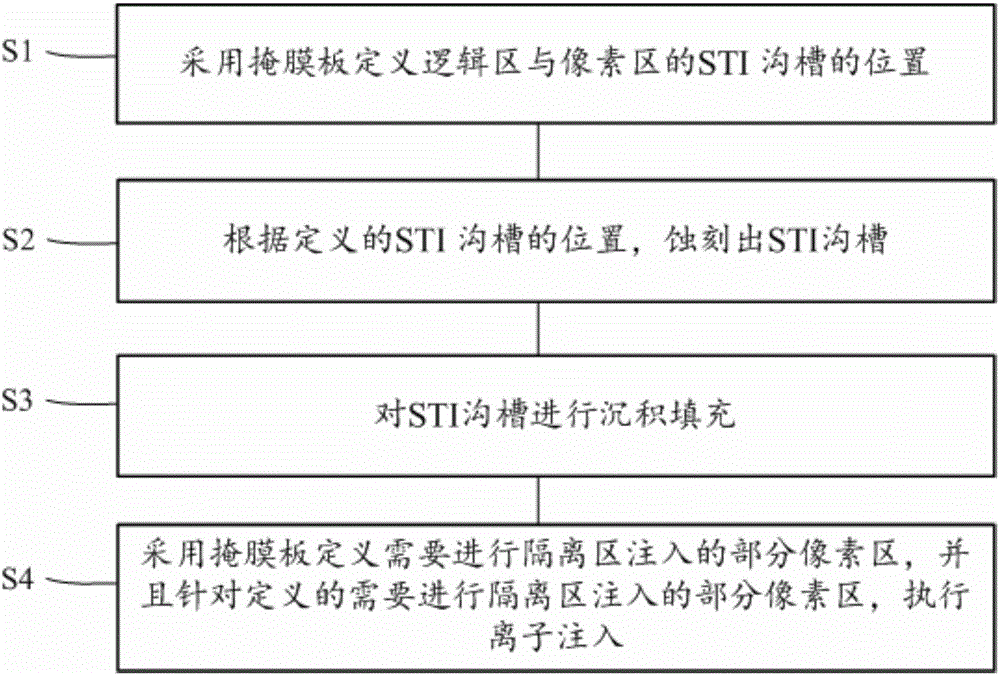

Method for eliminating shallow trench isolation induced dark current of CMOS image sensor

InactiveCN105870004AAvoid bombardment damageAvoid height differenceSolid-state devicesSemiconductor/solid-state device manufacturingCMOSEngineering

The invention provides a method for eliminating shallow trench isolation induced dark current of a CMOS image sensor. The method comprises the step of step 1: defining positions of STI trenches of a logic region and a pixel region through mask plates; step 2: etching the STI trenches according to the defined positions of the STI trenches; step 3: carrying out disposition and filling on the STI trenches; and step 4: defining a part of pixel regions which need to be subjected to isolation region injection by adopting the mask plates, and carrying out ion implantation for the part of the defined pixel regions which need to be subjected to isolation region injection.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com