Method for eliminating shallow trench isolation induced dark current of CMOS image sensor

An image sensor and shallow groove technology, applied in the direction of circuits, electrical components, electric solid devices, etc., can solve problems such as surface damage, easy release of electrons, and increased surface area of grooves, so as to avoid dark current, reduce dark current, Effect of suppressing dark current increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

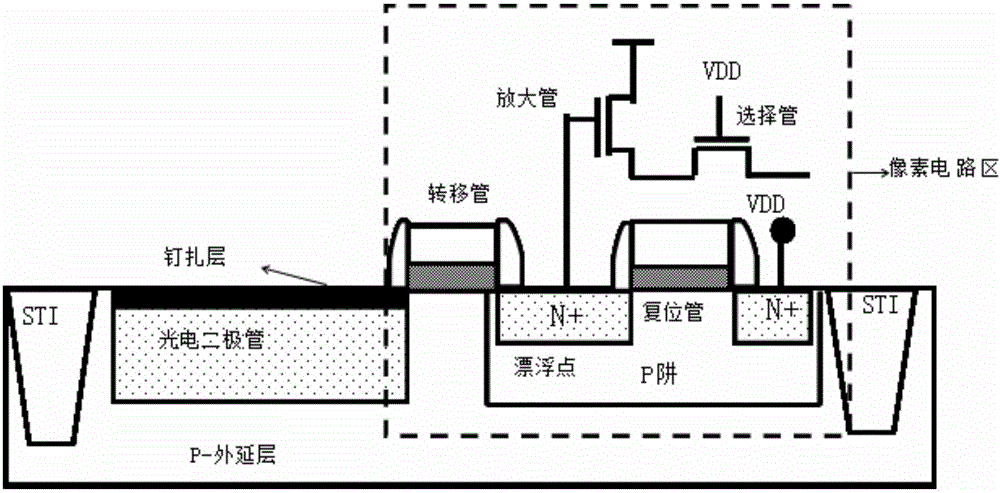

[0023] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

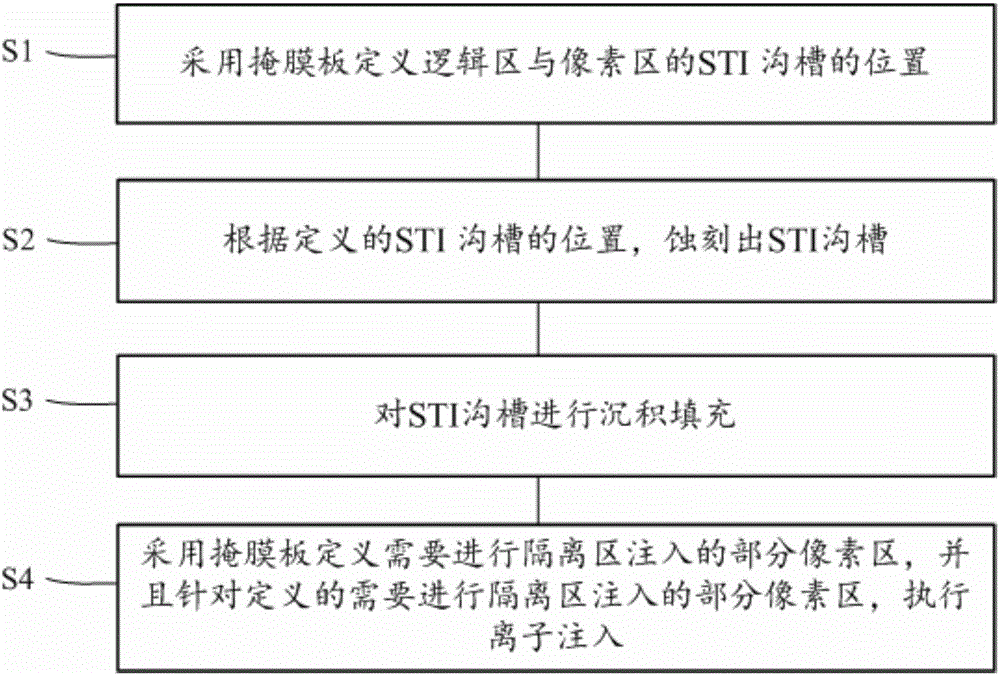

[0024] Before explaining the principle of the present invention in detail, the original two active region cycle process steps are briefly described. Specifically, the original two active region cycle process steps are as follows:

[0025] Firstly, a mask plate is used to define the position of the thicker STI groove (herein referred to as the first STI groove);

[0026] Subsequently, etching an initial first depth of the first STI trench;

[0027] Thereafter, the positions of all STI grooves are defined by using a mask;

[0028] Thereafter, etching is performed on all the STI trenches, wherein the second STI trench except the first STI trench among all the STI trenches has a second depth, and the depth of the first STI trench is equal to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com