Preparation method and system of TOPCon solar cell silicon oxide layer

A technology for solar cells and silicon oxide layers, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of slow oxide layer film formation, bombardment damage to silicon wafer substrates, and slag removal, so as to avoid bombardment damage and equipment maintenance. High frequency, solve the effect of slow film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

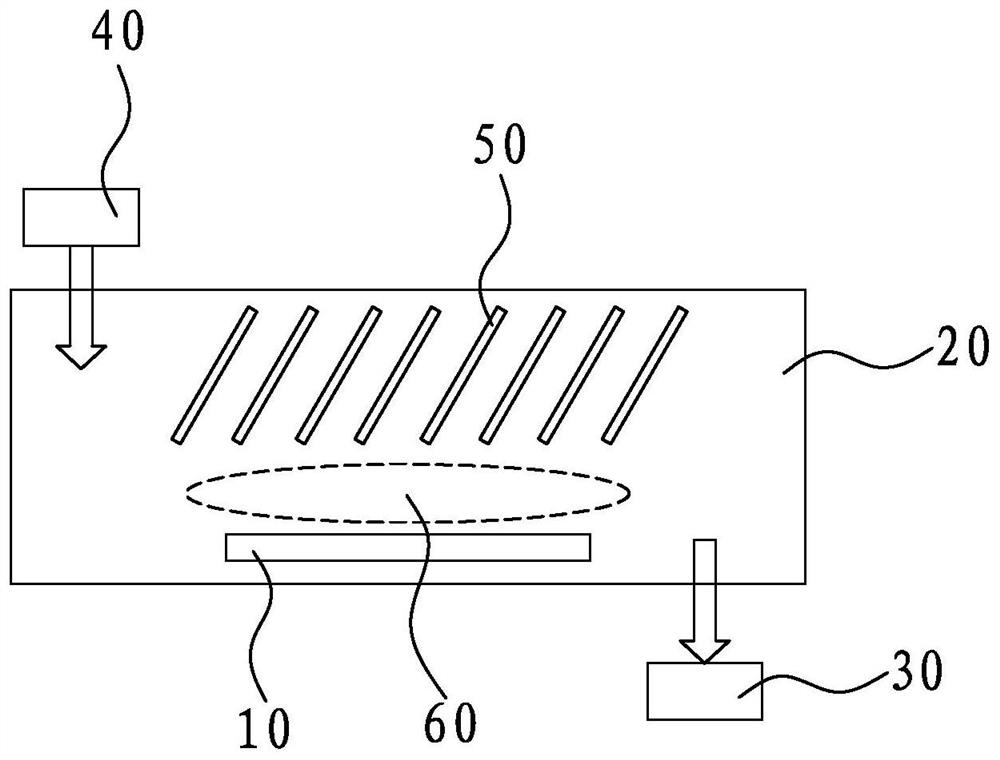

[0024] refer to figure 1 The preparation system of shown TOPCon solar cell silicon oxide layer, the invention provides a kind of preparation method of TOPCon solar cell silicon oxide layer, comprises the steps:

[0025] S1. First place the silicon wafer flat on the carrier plate 10 and transport the carrier plate 10 into the process chamber 20 through the horizontal conveying line; wherein, the carrier plate 10 with the silicon wafer placed on it passes through the process chamber 20 continuously to realize the dynamic growth of silicon oxide film , or pause in the process chamber 20 to achieve static growth of the silicon oxide film;

[0026] S2. After the silicon wafer enters the process chamber 20, the process chamber 20 is first evacuated by the vacuum device 30, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com