Production method of metallurgy coke

A production method and technology of metallurgical coke, applied in coke ovens, special forms of dry distillation, petroleum industry, etc., can solve the problems of reliability impact, increased transportation costs, increased coking time, etc., to achieve easy industrial production, save equipment and processes, The effect of increasing the total output of coke oven

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

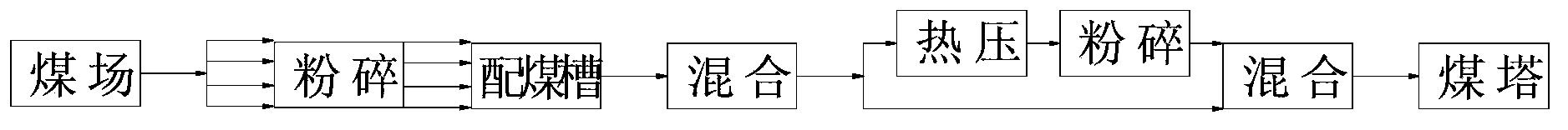

Method used

Image

Examples

Embodiment 1

[0026] Proportion of mixed coal: 10% gas coal, 1 / 3 coking coal 25%, fat coal 25%, coking coal 30%, lean coal 10%, the proportion of hot briquette in furnace coal is 40%, particle size 3 ;Stay under the pressure of the hot pressing operation for 5 seconds; The diameter of the hot briquette is 30mm, and the height is 10mm; The reactivity of coke is 21.36%. Compared with the coke obtained by using the same coking process without pretreatment, the reactivity of coke is reduced by 8.75 percentage points; Compared with coke obtained by hot briquetting and using the same coking process, the strength of coke after reaction increases by 11.69 percentage points.

Embodiment 2

[0028] Mixed coal ratio: gas coal 5%, 1 / 3 coking coal 25%, fat coal 30%, coking coal 30%, lean coal 10%, the proportion of hot briquetting coal in the furnace is 10%, particle size 3 ;Stay under the pressure of the hot pressing operation for 5 seconds; the diameter of the hot briquette is 40mm, and the height is 30mm; the hot briquette is mixed with the blended coal and loaded into a top-loading coke oven for coking. The reactivity of the coke is 23.91%. Compared with the coke obtained by using the same coking process without pretreatment, the reactivity of the coke is reduced by 5.65 percentage points; Compared with coke obtained by hot briquetting and using the same coking process, the strength of coke after reaction increases by 3.96 percentage points.

Embodiment 3

[0030] Mixed coal ratio: gas coal 10%, 1 / 3 coking coal 25%, fat coal 25%, coking coal 30%, lean coal 10%, the proportion of hot briquetting coal in the furnace is 20%, particle size 3 ;Stay under the pressure of the hot pressing operation for 5 seconds; The diameter of the hot briquette is 30mm, and the height is 10mm; The reactivity of coke is 23.94%. Compared with the coke obtained by using the same coking process without adding pretreatment, the reactivity of coke is reduced by 6.35 percentage points; Compared with coke obtained by hot briquetting and using the same coking process, the strength of coke after reaction increases by 8.29 percentage points.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com