Preparation and application methods of cellulose derivative-grafted polylactic acid

A technology of cellulose derivatives and grafted polylactic acid, which is applied in the field of medicine, can solve problems such as cumbersome preparation methods, safety issues, and long process routes, and achieve the effects of improving mechanical properties and saving time and technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

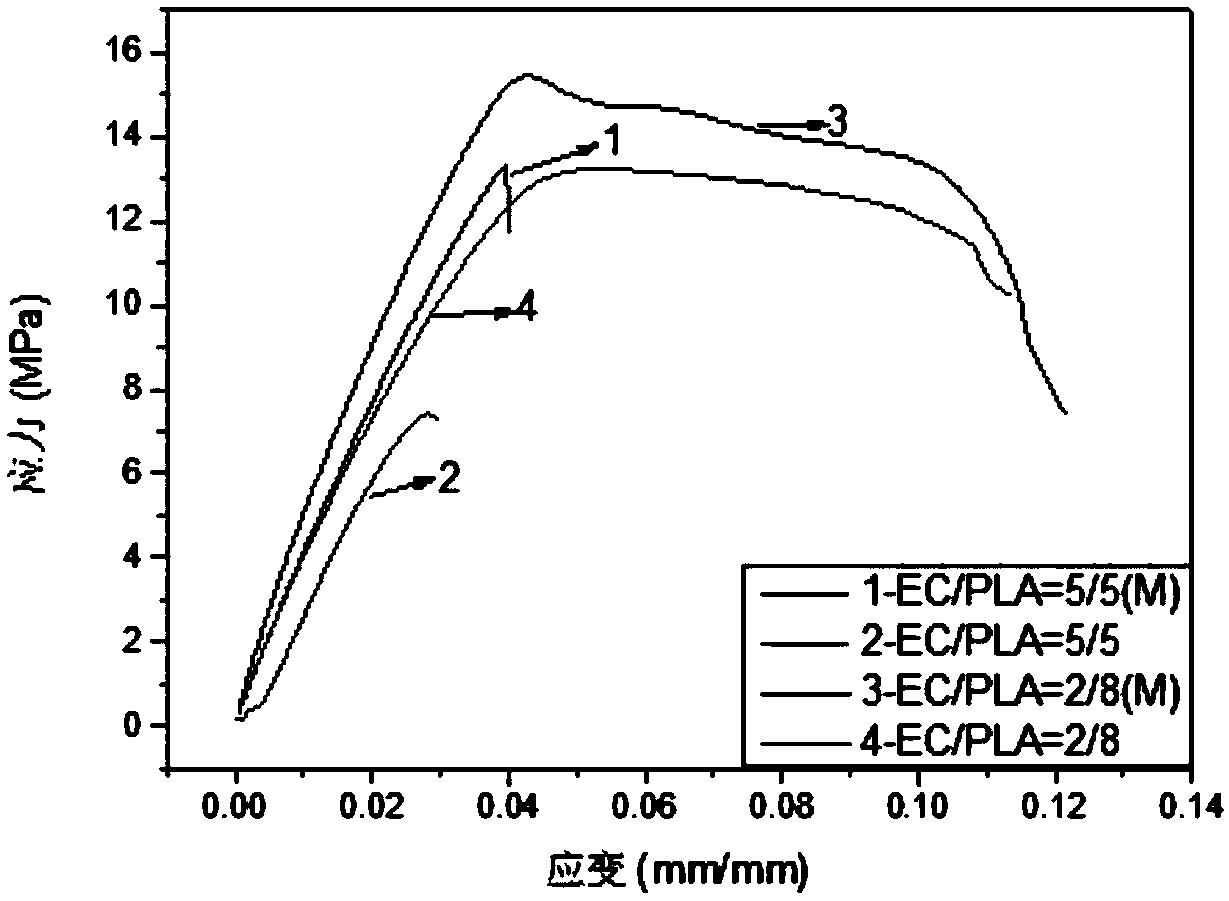

[0061] The method for preparing cellulose-grafted polylactic acid of the present invention is that the solvent is toluene, and when 20 liters of toluene is heated to a temperature of 60° C., 1000 grams of ethyl cellulose is added, and after stirring until the ethyl cellulose is completely dissolved, polylactic acid is added. 1000g (commercial polylactic acid produced by NatureWorks and Hisun), heated up to 100°C, stirred until the polylactic acid was completely dissolved, added 20g of stannous octoate as a catalyst, heated to toluene under reflux for 5 hours, and formed through the solution after reaction. The method of preparing a composite film is to prepare a composite film. Specifically, the solution is spread on a horizontally adjusted film by the casting film method, placed in a fume hood, and naturally air-dried at room temperature for 48 hours, and then dried in a vacuum oven for 24 hours (40°C) ), remove the membrane and store in a desiccator for later use. Measure it...

Embodiment 2

[0064] The method for preparing cellulose-grafted polylactic acid of the present invention is: when 10 liters of toluene is heated to a temperature of 60° C., 400 grams of ethyl cellulose is added, and the ratio of ethyl cellulose and PLA is 2 / 8. After the base cellulose is completely dissolved, add 1000 grams of polylactic acid, heat up to 100°C, stir until the polylactic acid is completely dissolved, add 8 grams of stannous octoate as a catalyst, heat to toluene under reflux for 5 hours, and form a film through the solution after the reaction To prepare a composite film, specifically spread the solution on a horizontally adjusted film tool by casting a film method, put it in a fume hood, let it dry naturally at room temperature for 48 hours, and then dry it in a vacuum oven for 24 hours (40°C). The lower membrane is placed in a desiccator for later use. Determine its tensile stress-strain curve (tested by CMT4104 electronic universal testing machine of Shenzhen Xinsansi Mate...

Embodiment 3

[0067] The method for preparing cellulose-grafted polylactic acid of the present invention is as follows: when heating 20 liters of xylene to a temperature of 60° C., add 1000 grams of ethyl cellulose, stir until the ethyl cellulose is completely dissolved, add 1000 grams of polylactic acid, Raise the temperature to 100°C, stir until the polylactic acid is completely dissolved, add 10 grams of stannous octoate as a catalyst, and heat to react for 5 hours under the reflux of toluene; after the reaction, a composite film is prepared by the method of solution film formation, specifically, the solution is cast into a film Lay it flat on a horizontally adjusted film tool, put it in a fume hood, and let it dry naturally at room temperature for 48 hours, and then dry it in a vacuum oven for 24 hours (40°C) to obtain a composite film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com