Apparatus and method for utilizing exhaust gas from an electric

A technology of facilities and electric power, applied in the field of equipment and methods for utilizing waste gas from power multiple conversion facilities, capable of solving problems such as cost separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

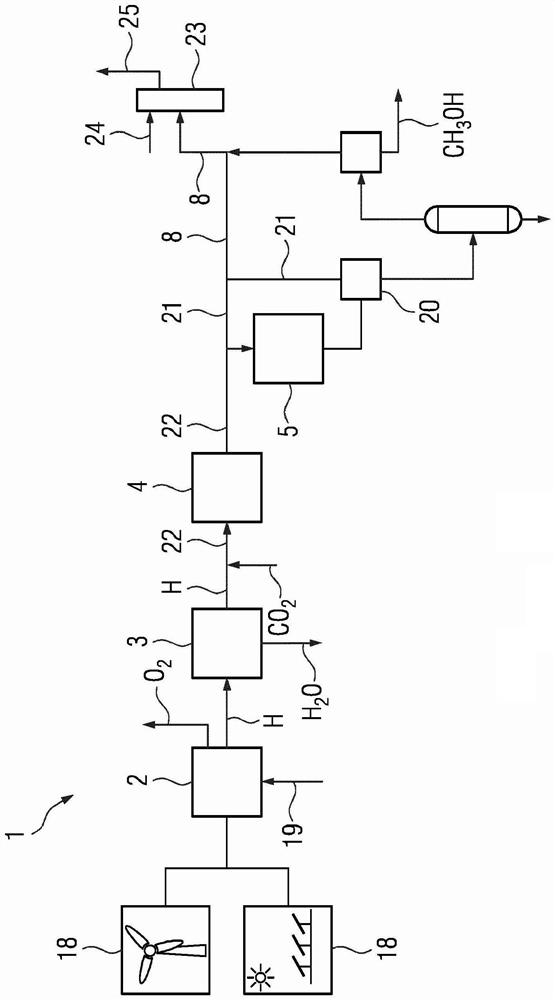

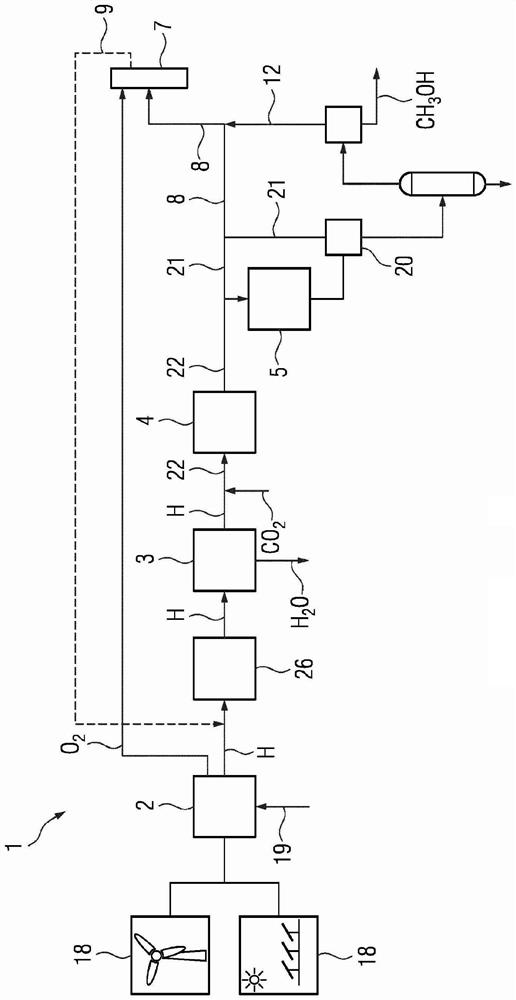

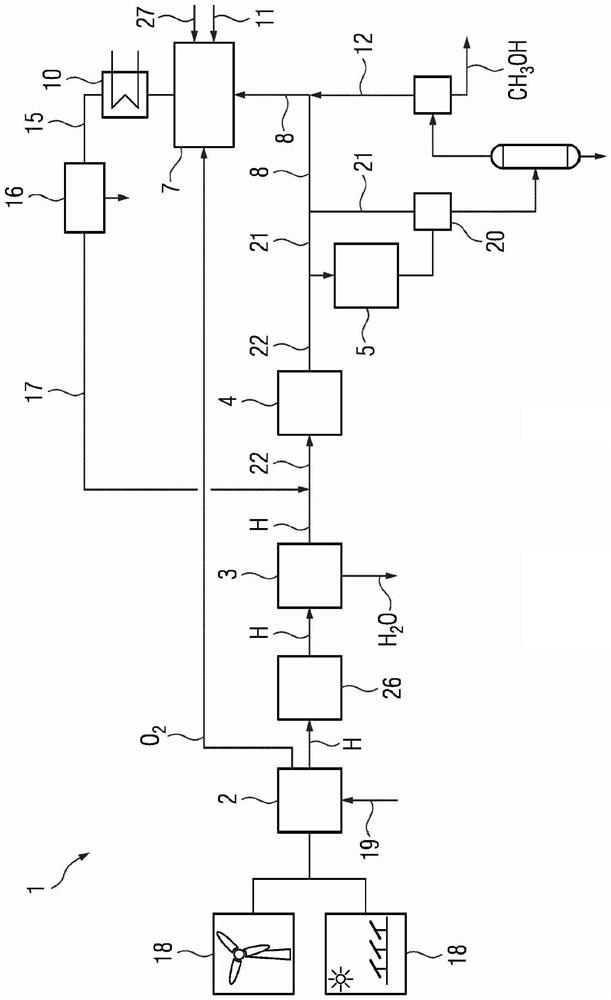

[0035] figure 1 A power multi-conversion facility 1 according to the prior art is shown. The power multi-conversion facility basically consists of an electrolyzer 2, a facility 3 for processing hydrogen, a compressor 4 and a chemical reactor 5 for methanol synthesis.

[0036] The electrolyzer 2 is fed with renewable electrical energy 18, eg from a wind or photovoltaic installation. Furthermore, the electrolyzer 2 is fed with water 19 . Hydrogen H is produced in the electrolyzer 2 and oxygen O 2 . Oxygen O 2 is released into the atmosphere, while the hydrogen H 2 It is directed to the facility 3 for processing for drying. Extraction and export of hydrogen H from facility 3 for processing hydrogen 2 . Hydrogen H dried in facility 3 2 Derived from the facility 3 and combined with carbon dioxide CO 2 Mixed, the carbon dioxide is delivered externally to the power multi-conversion facility.

[0037] Hydrogen H 2 / Carbon dioxide CO2 mixture is also known as synthesis ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com