High-strength and high-reliability-sealing radial friction welding method for steel pipe fitting

A technology of friction welding and steel pipes, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the difficult process of large-length stable clamping and high-speed rotation, and it is difficult to meet the high sealing requirements of high-pressure fluid steel pipes, and it is difficult to meet large Length steel pipe welding requirements and other issues to achieve the effect of saving process and process costs, avoid welding flash or weld burr, and ensure welding quality and welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Radial friction welding is carried out for 20 steel rings with an outer diameter of φ70mm and 35CrMoSi steel pipes with an outer diameter of φ60mm; a high-strength, high-reliability sealed radial friction welding method for steel pipes is characterized in that:

[0038] Include the following steps:

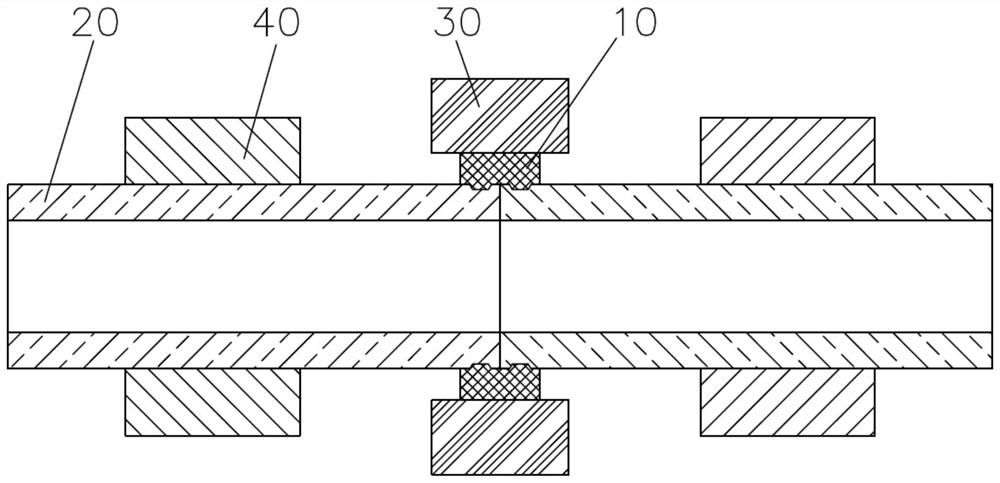

[0039] a. According to the structural dimensions of the steel pipe and the steel ring, select the appropriate steel ring rotating and pressurizing tooling 30 and the steel pipe fixing and clamping tooling 40;

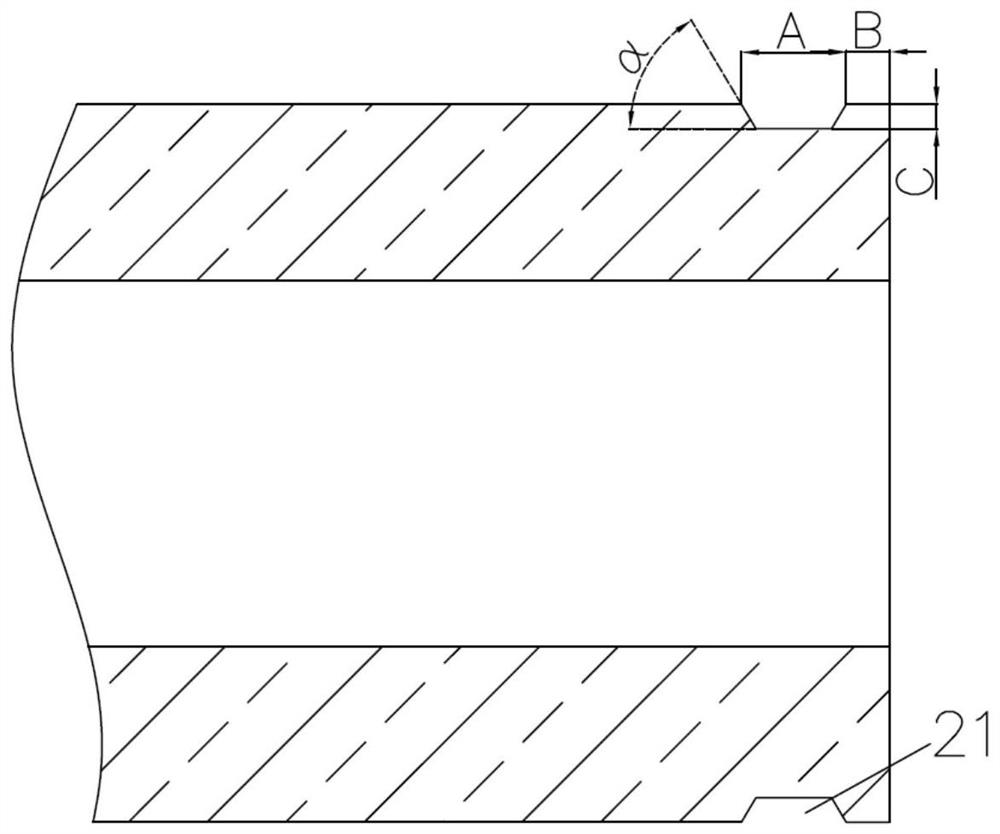

[0040] b. Carry out machining on the steel ring to be welded and the steel pipe to be welded to be welded, and process the steel ring welding blank 10 and the steel pipe welding blank 20. The specific processing dimensions of the steel ring welding blank 10 are: width 15mm, outer diameter φ70mm, inner diameter φ62mm , the specific processing size of the steel pipe welding blank 20 is φ60mm×7mm×5000mm; the tensile strength of the steel ring material to be welded is no...

Embodiment 2

[0048] Radial friction welding is carried out for 20 steel rings with an outer diameter of φ150mm and 35CrMoSi steel pipes with an outer diameter of φ130mm; a high-strength, high-reliability sealed radial friction welding method for steel pipes is characterized in that:

[0049] Include the following steps:

[0050] a. According to the structural dimensions of the steel pipe and the steel ring, select the appropriate steel ring rotating and pressurizing tooling 30 and the steel pipe fixing and clamping tooling 40;

[0051] b. The steel ring to be welded and the steel pipe to be welded are machined to process the steel ring welding blank 10 and the steel pipe welding blank 20. The specific processing dimensions of the steel ring welding blank 10 are: width 35mm, outer diameter φ150mm, inner diameter φ132mm , the specific processing size of steel pipe welding blank 20 is φ130mm×10mm×5000mm; the tensile strength of the steel ring material to be welded is not greater than 600MPa, ...

Embodiment 3

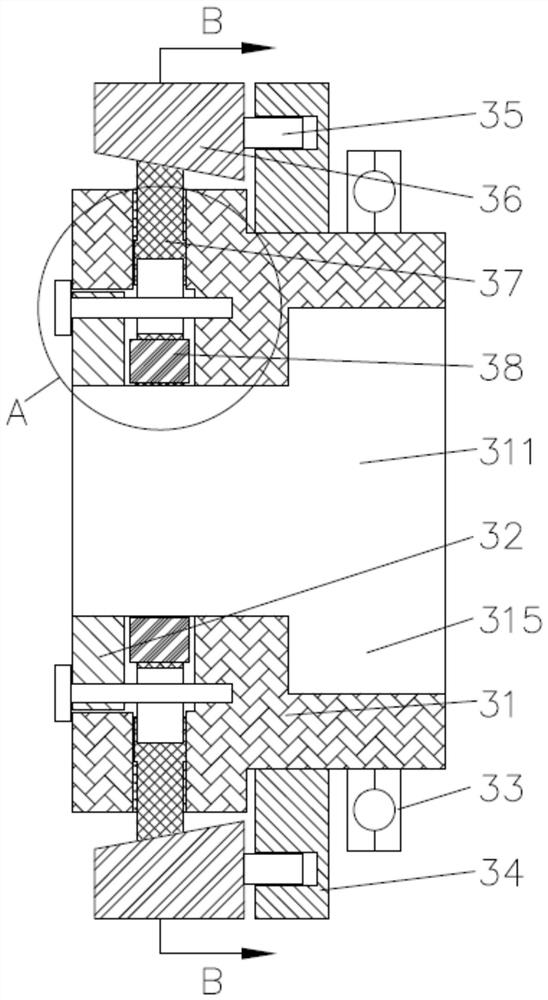

[0059] The rotary pressing tool 30 includes a tool body 31, a mounting plate 32, a ball bearing 33, an annular positioning plate 34, a telescopic rod 35, a reversing fixture 36, a radial ejector rod 37 and a clamping claw 38; the tool body 31 is a round sleeve structure and its cross-section is a stepped structure, the middle part of the tooling body 31 is provided with a through-type shaft hole 311; The central axis is collinear, and the mounting disc 32 is an annular disc; the other end of the tooling body 31 is provided with a positioning groove 315 for setting the fixed clamping tooling 40; one end of the tooling body 31 near the positioning groove 315 is fixedly sleeved with a ball bearing 33, It is used to connect with external equipment so as to fix and install the entire tool body 31. The outer wall of the tool body 31 on the side of the ball bearing 33 close to the installation groove 312 is fixedly sleeved with an annular positioning disc 34. The annular positioning d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com