Patents

Literature

100results about How to "Avoid runout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

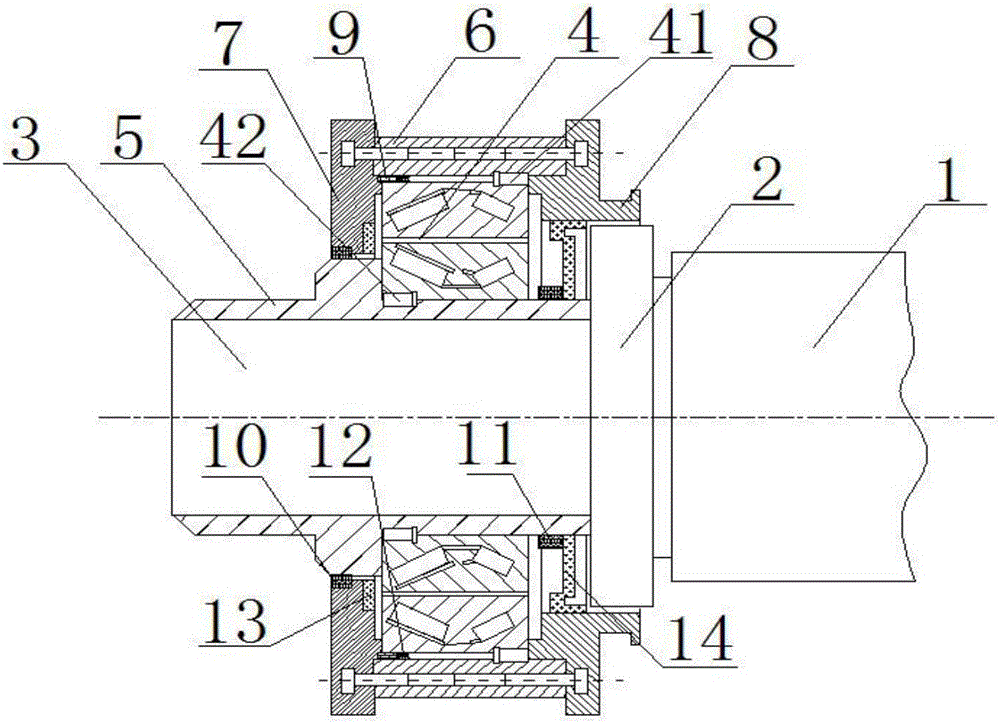

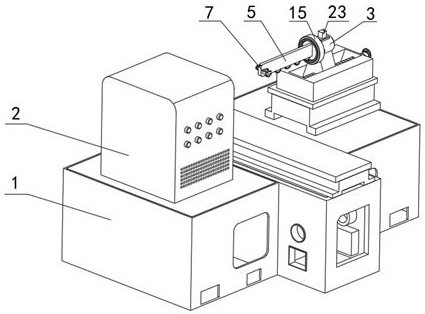

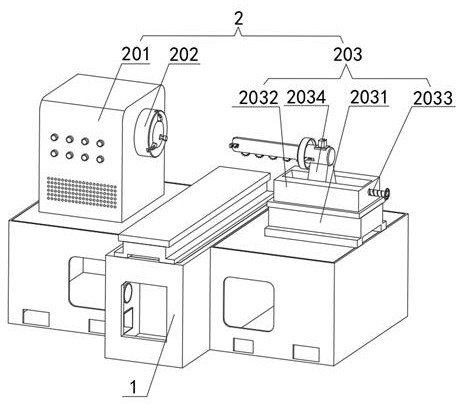

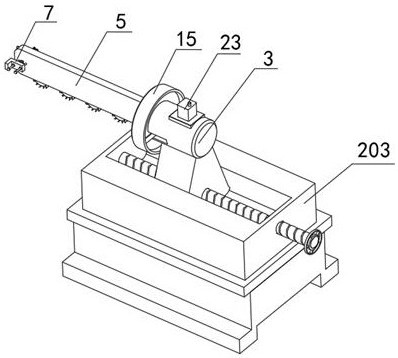

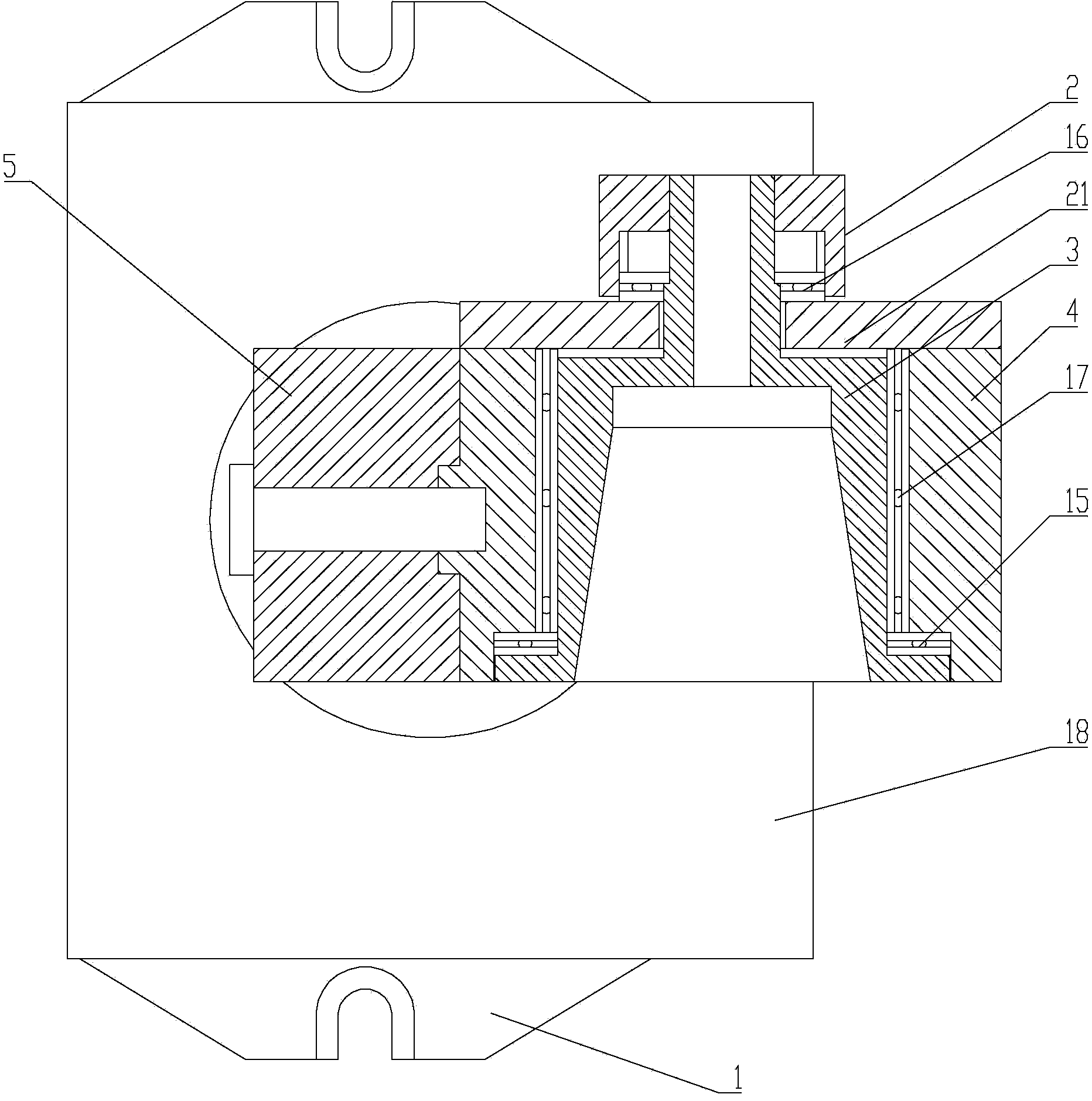

Measurement device and method for simulation air compressor in working state

ActiveCN108106515APrecise positioningAvoid runoutMechanical diameter measurementsImpellerMeasurement device

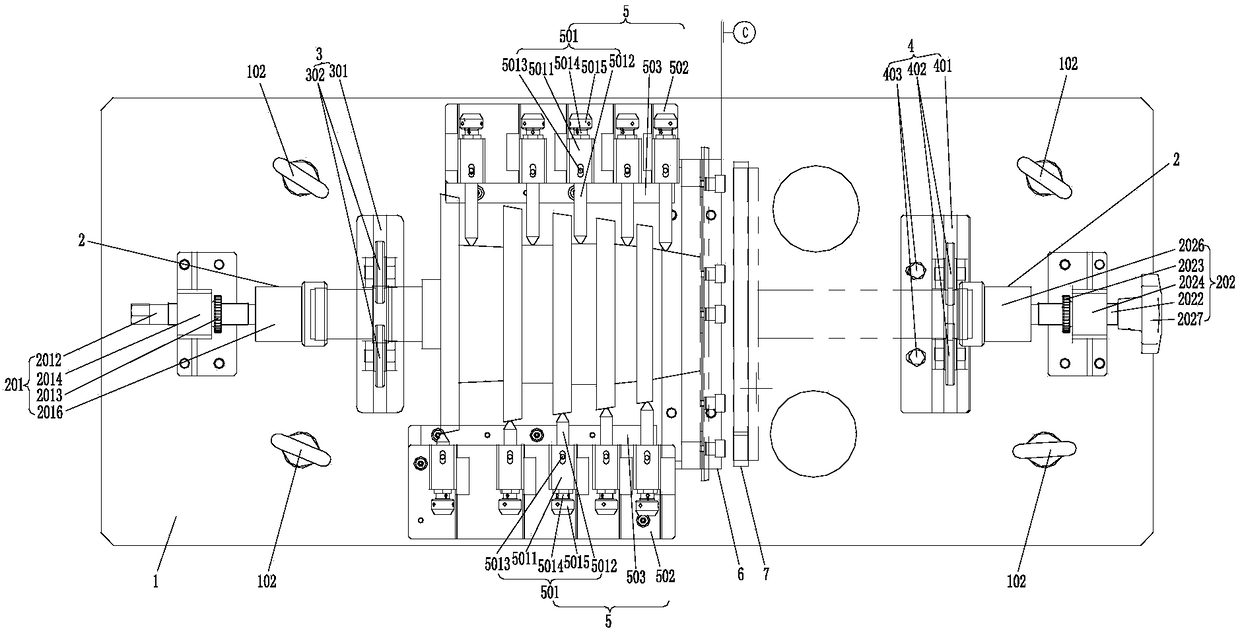

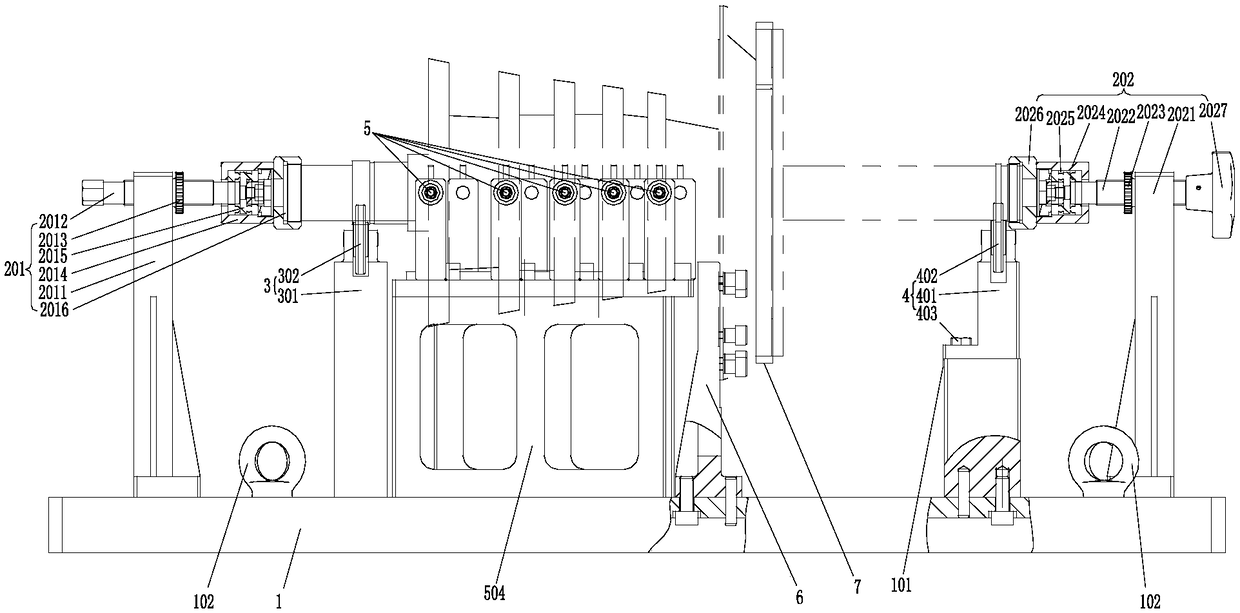

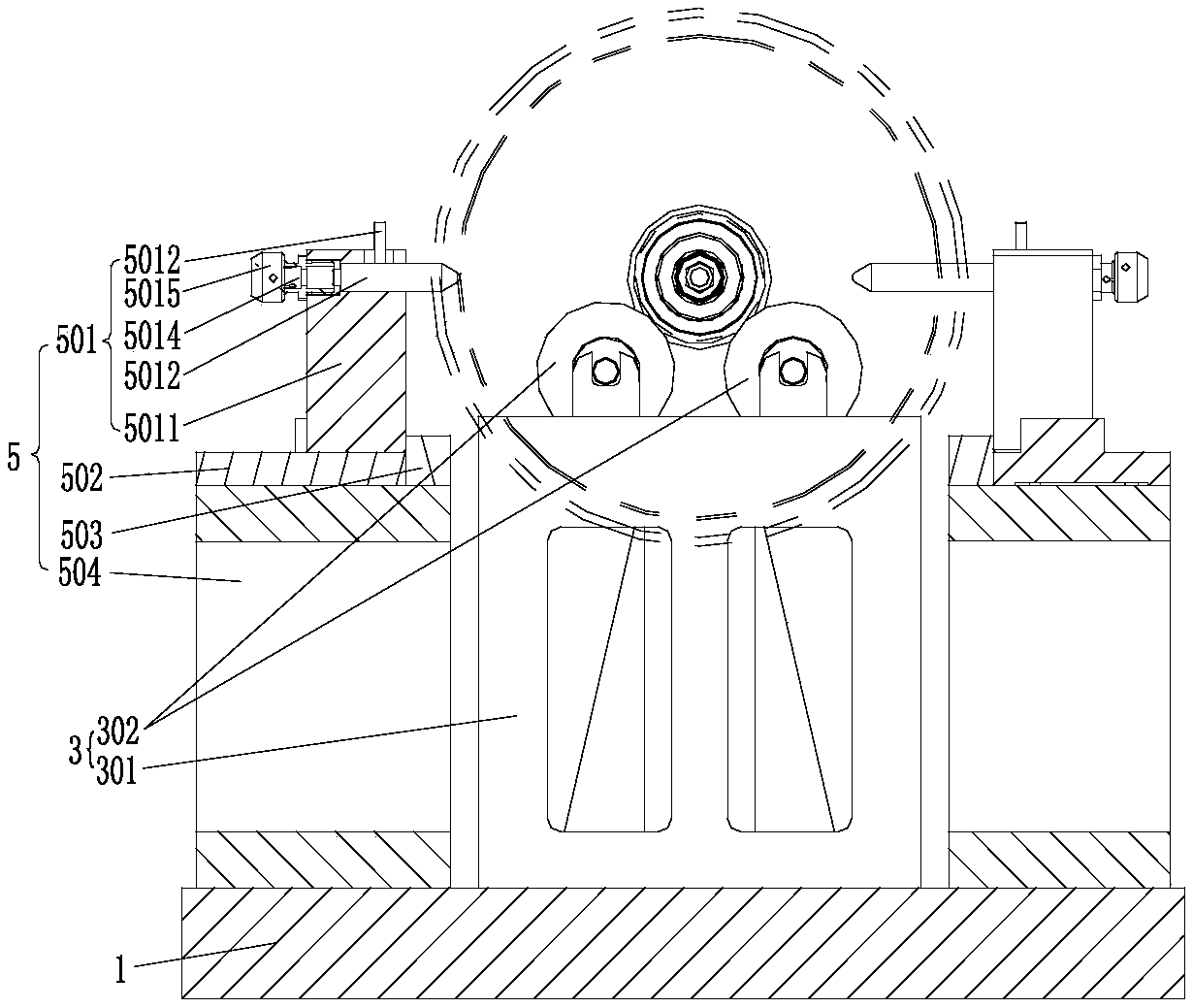

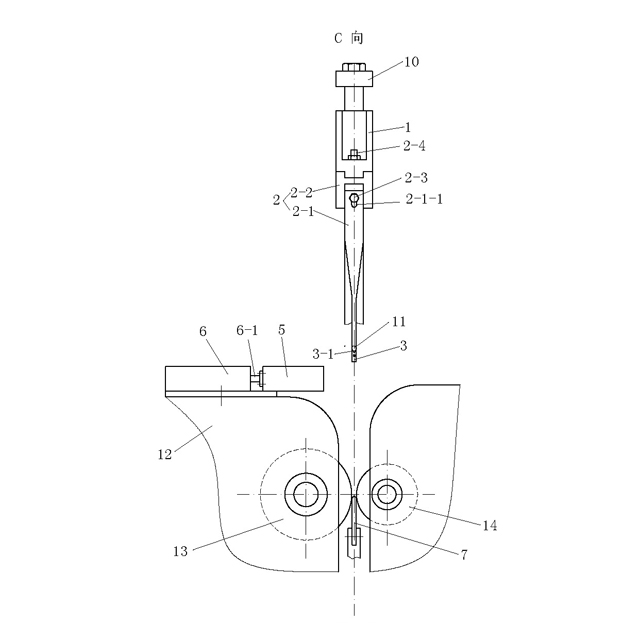

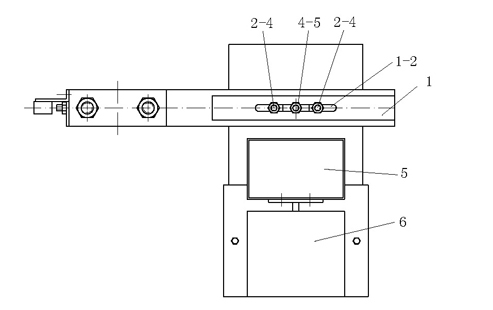

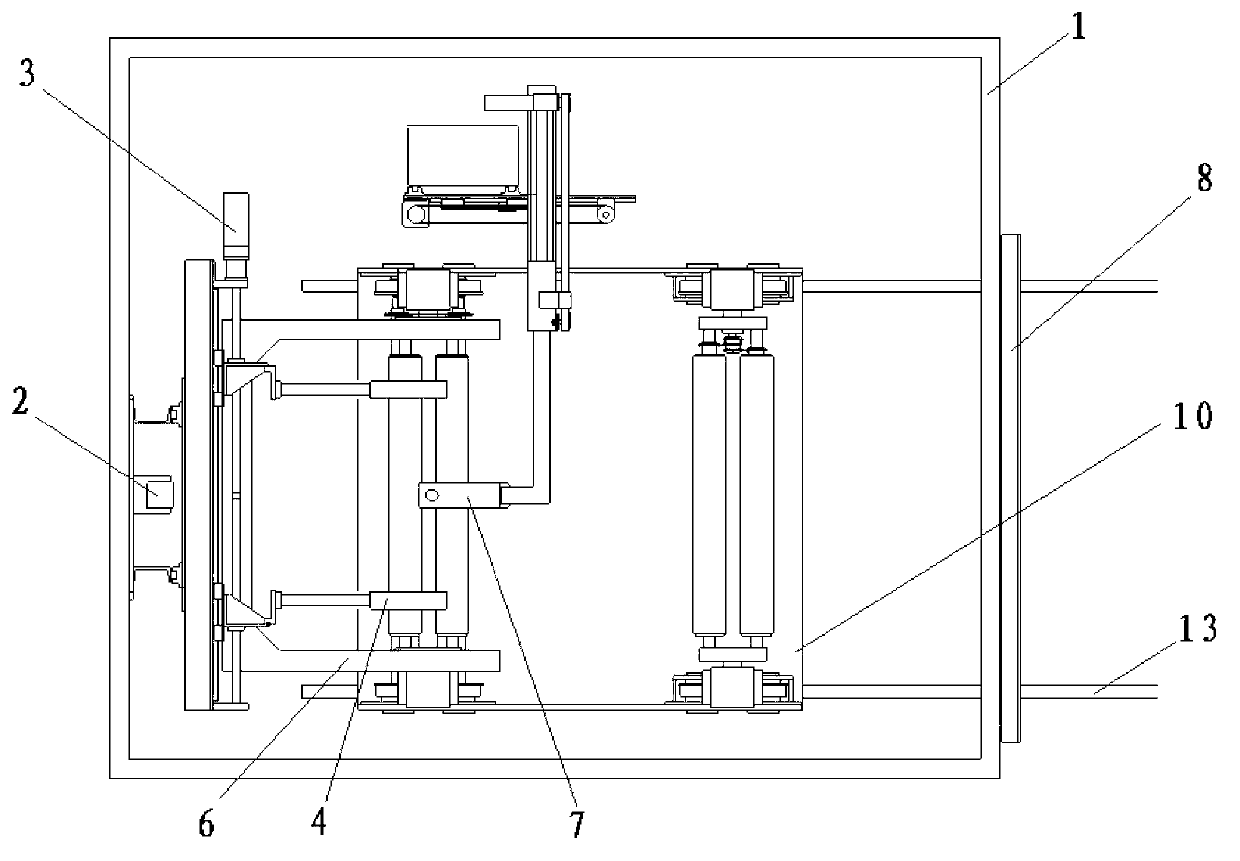

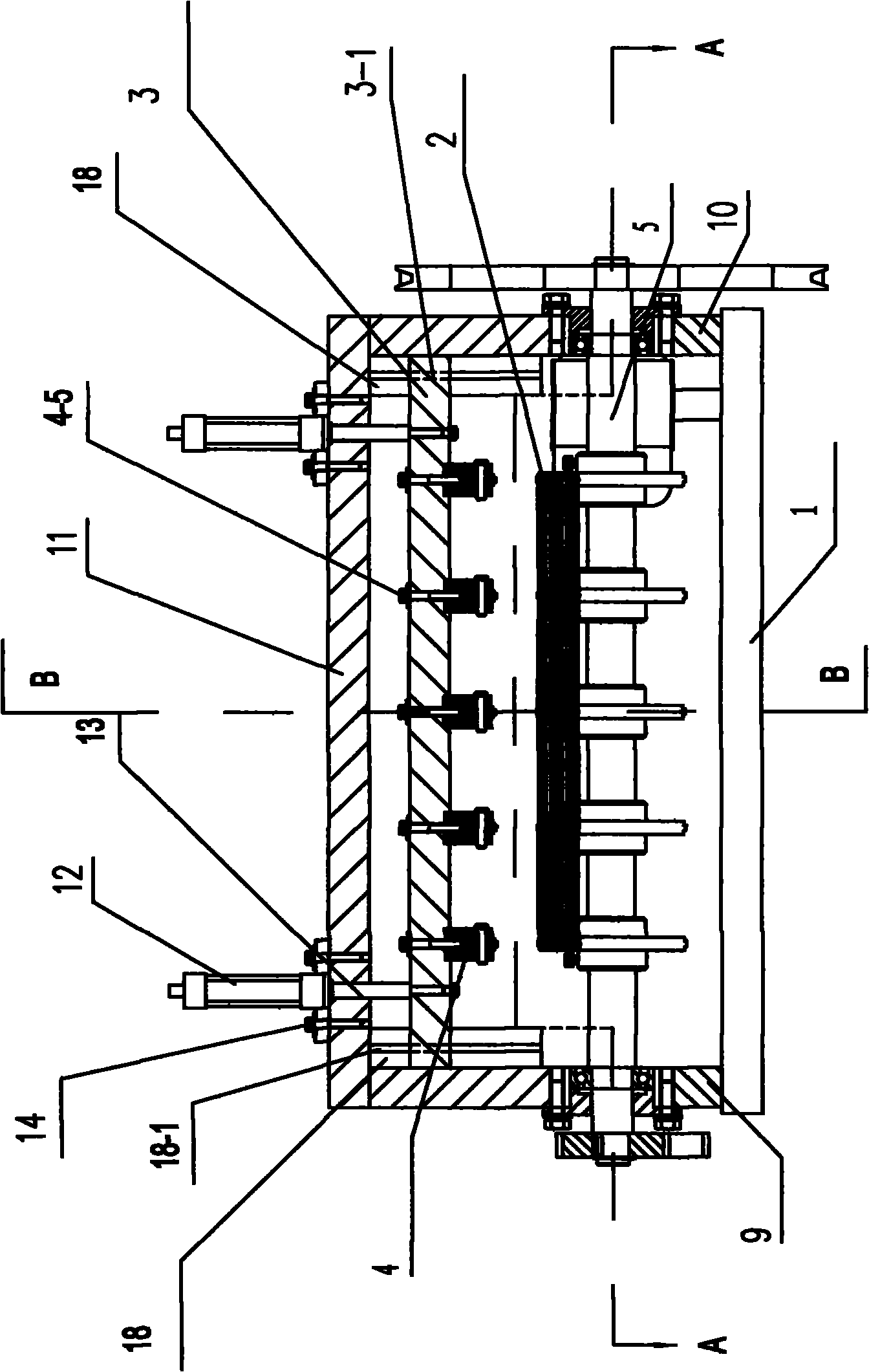

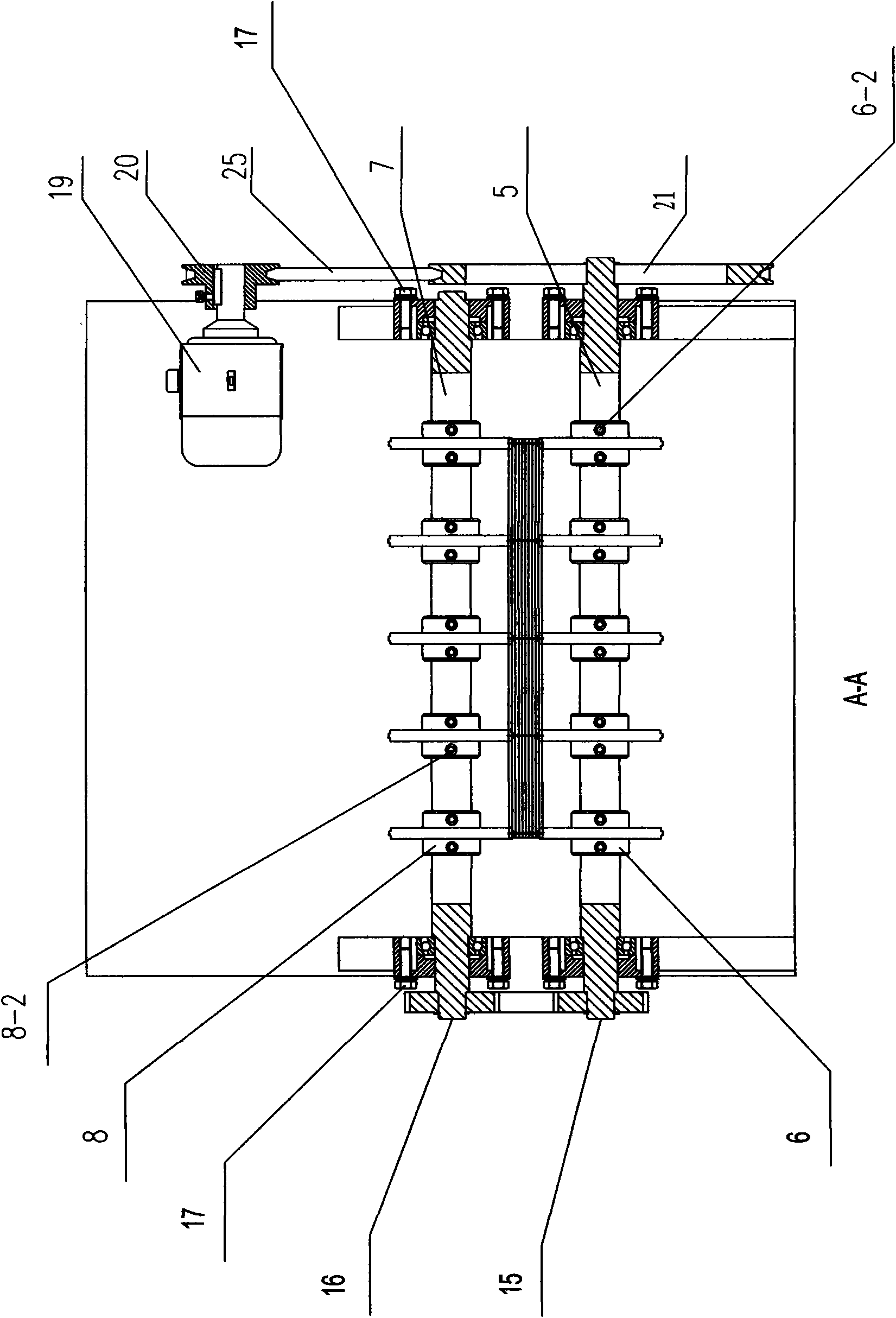

The invention discloses a measurement device and method for a simulation air compressor in a working state. The measurement device comprises a bottom plate, and the bottom plate is provided with an end part assembly module, a first bearing mechanism which is used for bearing a first end journal of an air compressor rotor assembly from the bottom of the air compressor rotor assembly, and a second bearing mechanism which is used for bearing a second end journal of the air compressor rotor assembly from the bottom of the air compressor rotor assembly, and carrying out the axial and / or radial finetuning and control of a bearing position. A measurement mechanism and a positioning plate are disposed between the first bearing mechanism and the second bearing mechanism, wherein the measurement mechanism is corresponding to centrifugal impellers of the air compressor rotor assembly and the parts between the adjacent centrifugal impellers and is used for measuring the jump values of blade tipsof the centrifugal impellers, the wheel hubs of the centrifugal impellers and an air compressor rotor shaft in a rotating process, and the positioning plate is attached to a reference surface of the air compressor rotor assembly so as to form a measurement reference of the measurement mechanism.

Owner:CHINA HANGFA SOUTH IND CO LTD

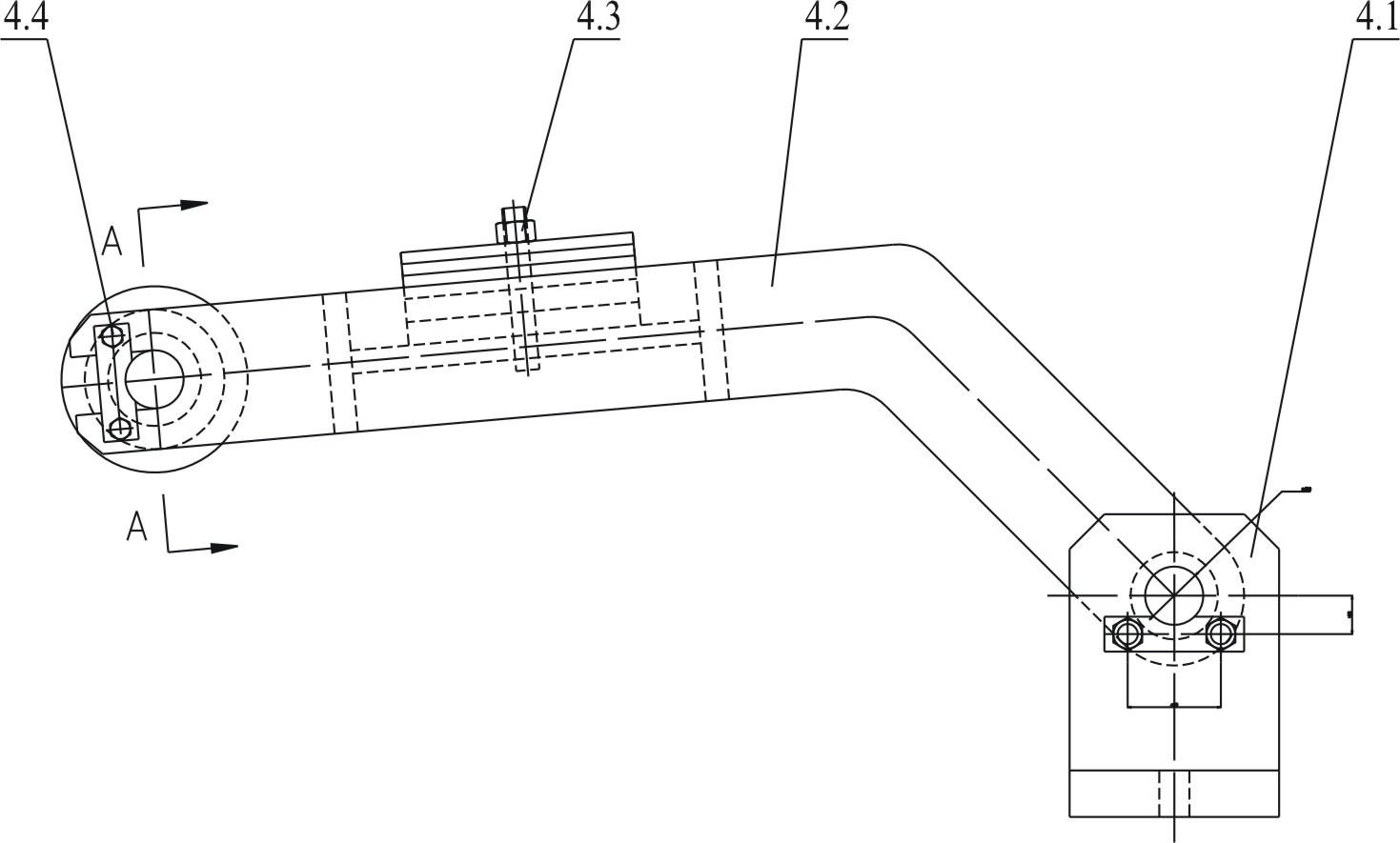

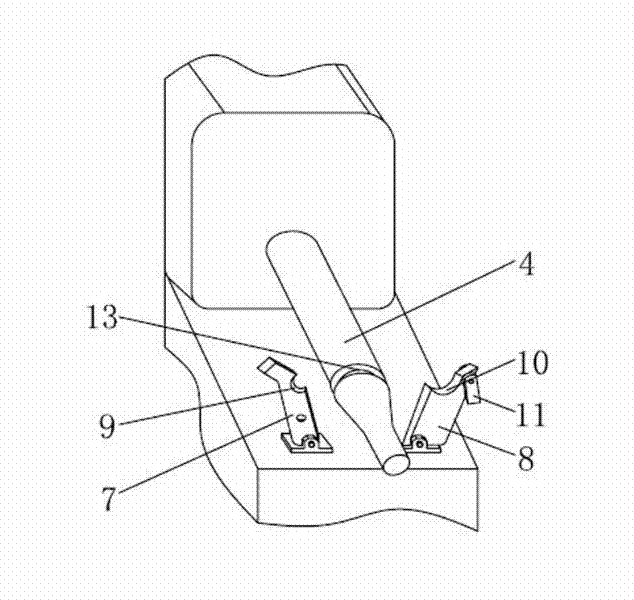

Mechanical arm device of centerless grinding machine

ActiveCN102069430AAvoid runoutRealize profilingProgramme-controlled manipulatorRevolution surface grinding machinesHydraulic cylinderRobotic arm

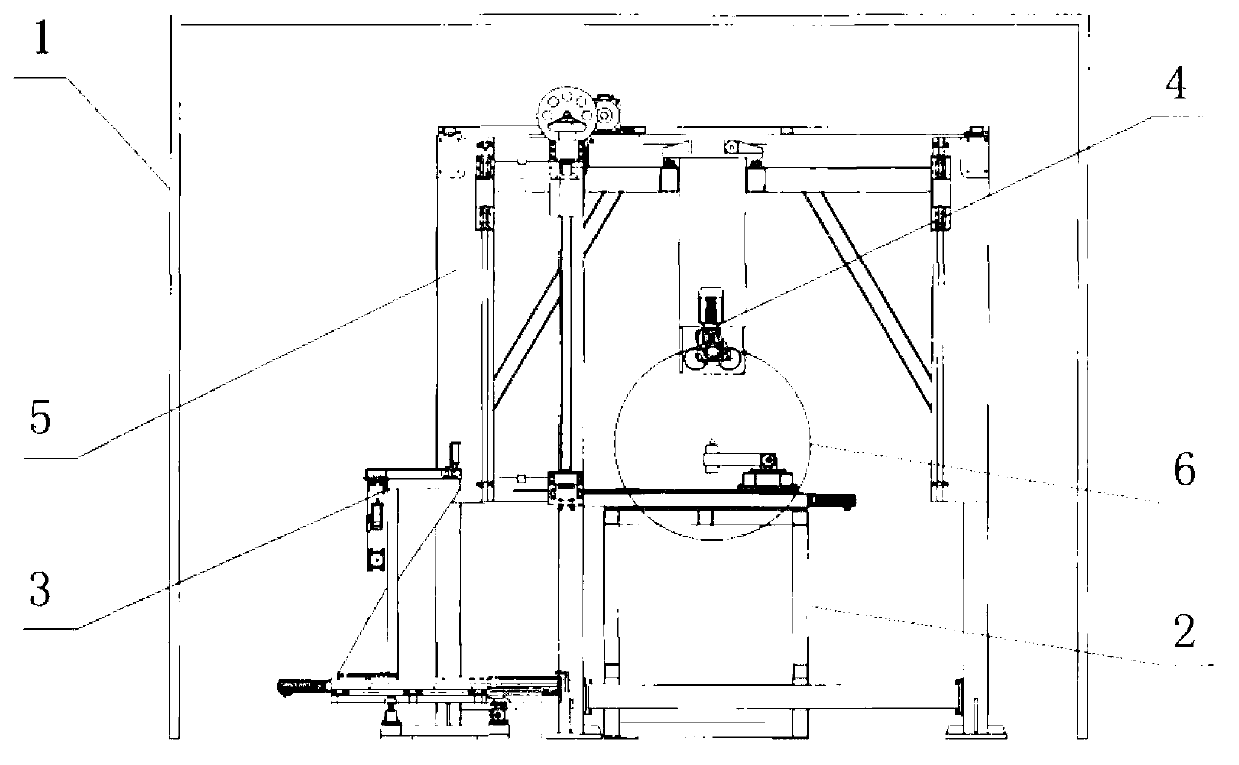

The invention discloses a mechanical arm device of a centerless grinding machine, which comprises a supporting plate, a bracket fixed on a main machine rack, a hydraulic cylinder fixed on the lower part of the bracket, a pair of guide pillars fixed on the upper part of the bracket and a lifting seat for driving the pair of guide pillars to slide by a piston rod of the hydraulic cylinder. A pair of mechanical arms for arranging work pieces on the supporting plate is arranged on the lifting seat. The thicknesses of the lower parts of the two mechanical arms are smaller than that of the work piece. An elastic pressure plate component is arranged between the two mechanical arms on the lifting seat. The device has a simple structure; and the pair of mechanical arms supports the two ends of each work piece to realize loading and unloading, and is driven by the hydraulic cylinder, so that the loading and unloading are more stable and accurate and entire-shaft profiling can be realized. The device solves the problem that the conventional centerless grinding machine cannot machine a combined slender shaft consisting of a plurality of concentric cylinders with different diameters, and compared with the conventional device utilizing ordinary external grinding, improves the machining accuracy and reduces the rejection rate.

Owner:常州市武滚轴承有限公司

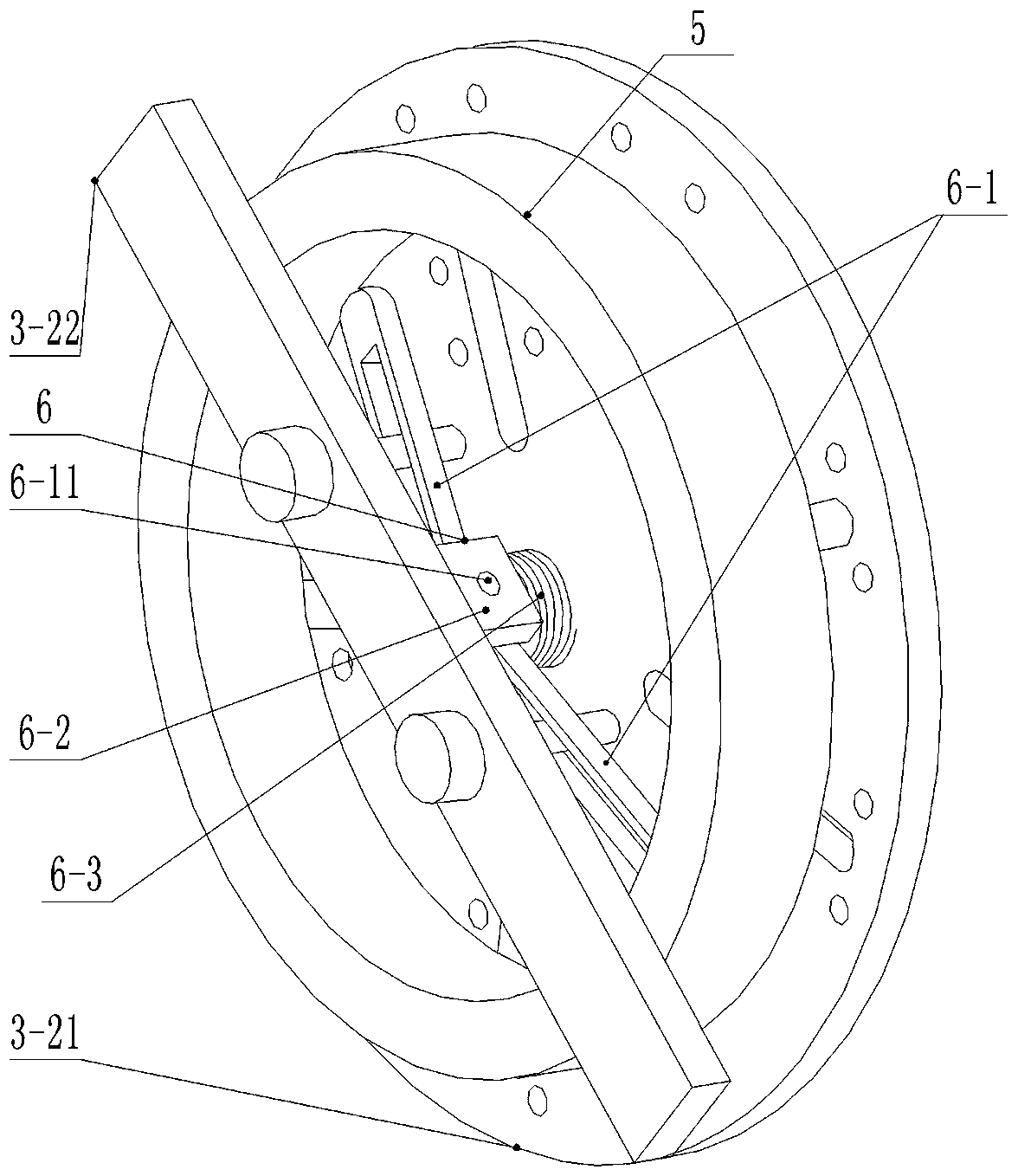

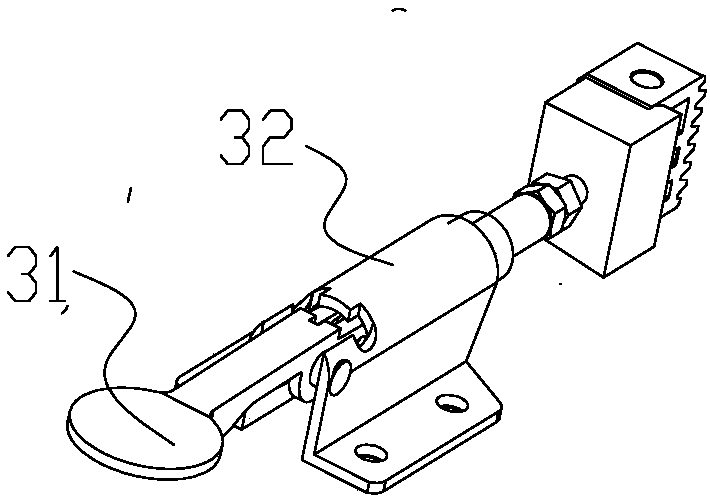

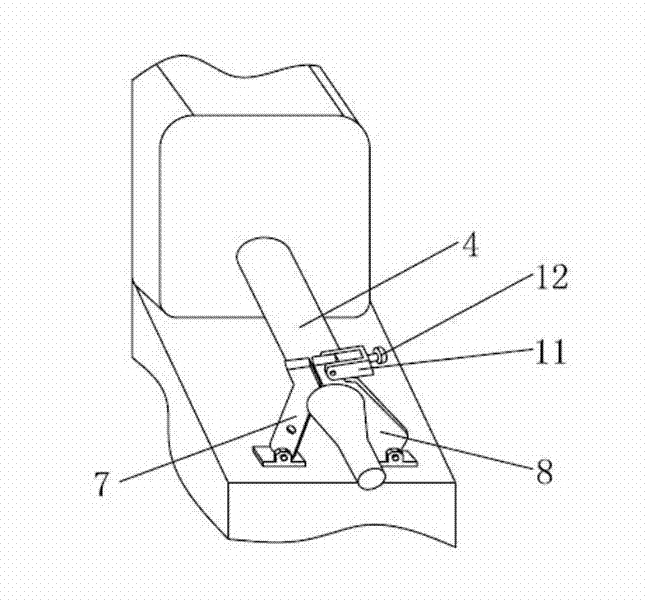

Tool for drilling inclined hole in circular plate-shaped part

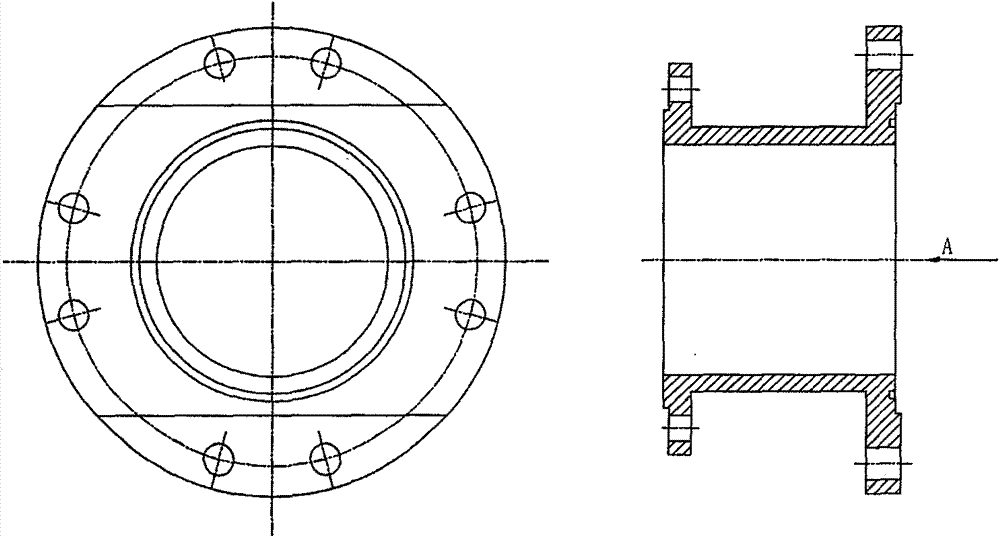

PendingCN109128891ARotation constraintsAvoid runoutDrilling/boring measurement devicesPositioning apparatusEngineeringOblique angle

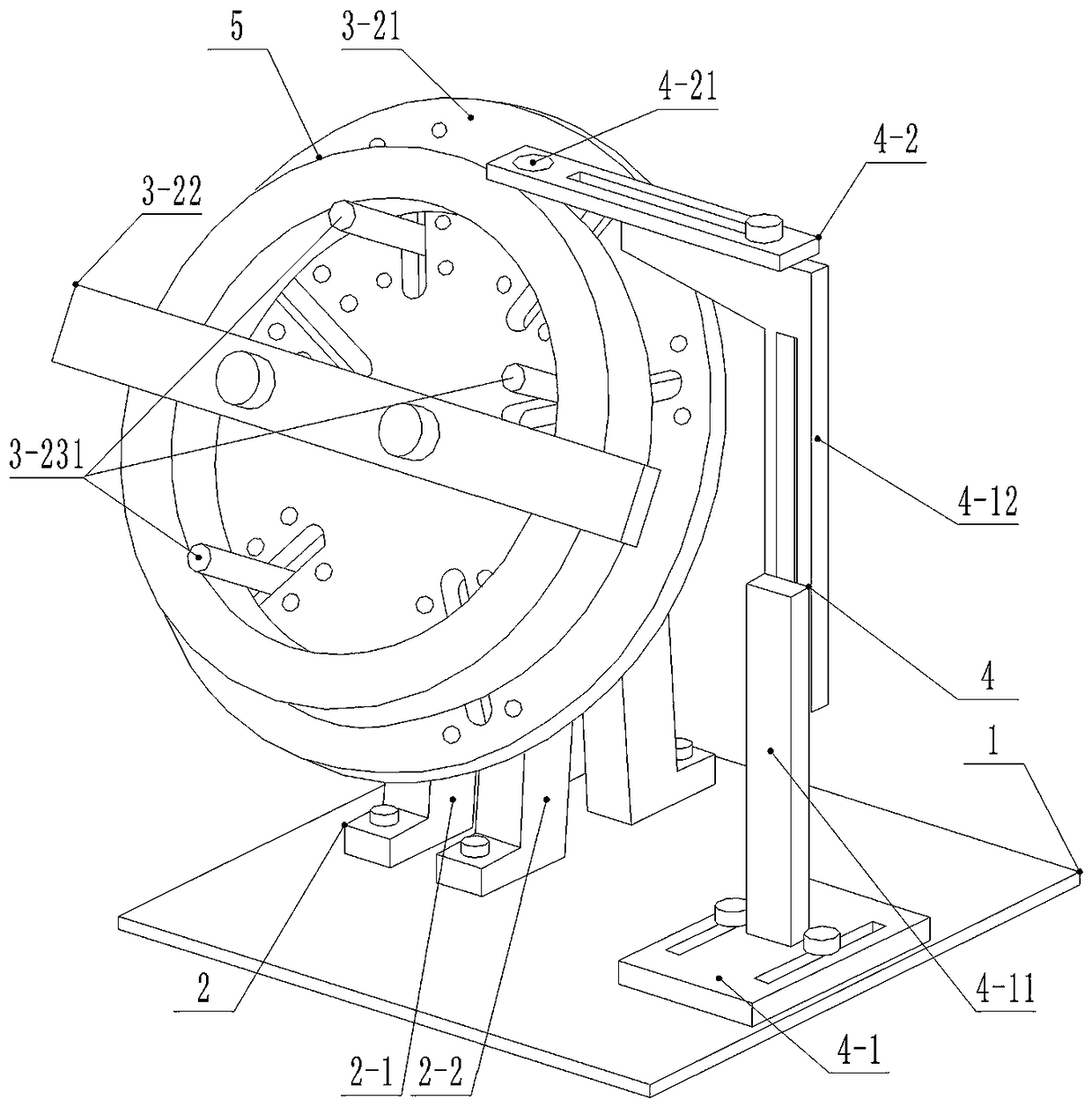

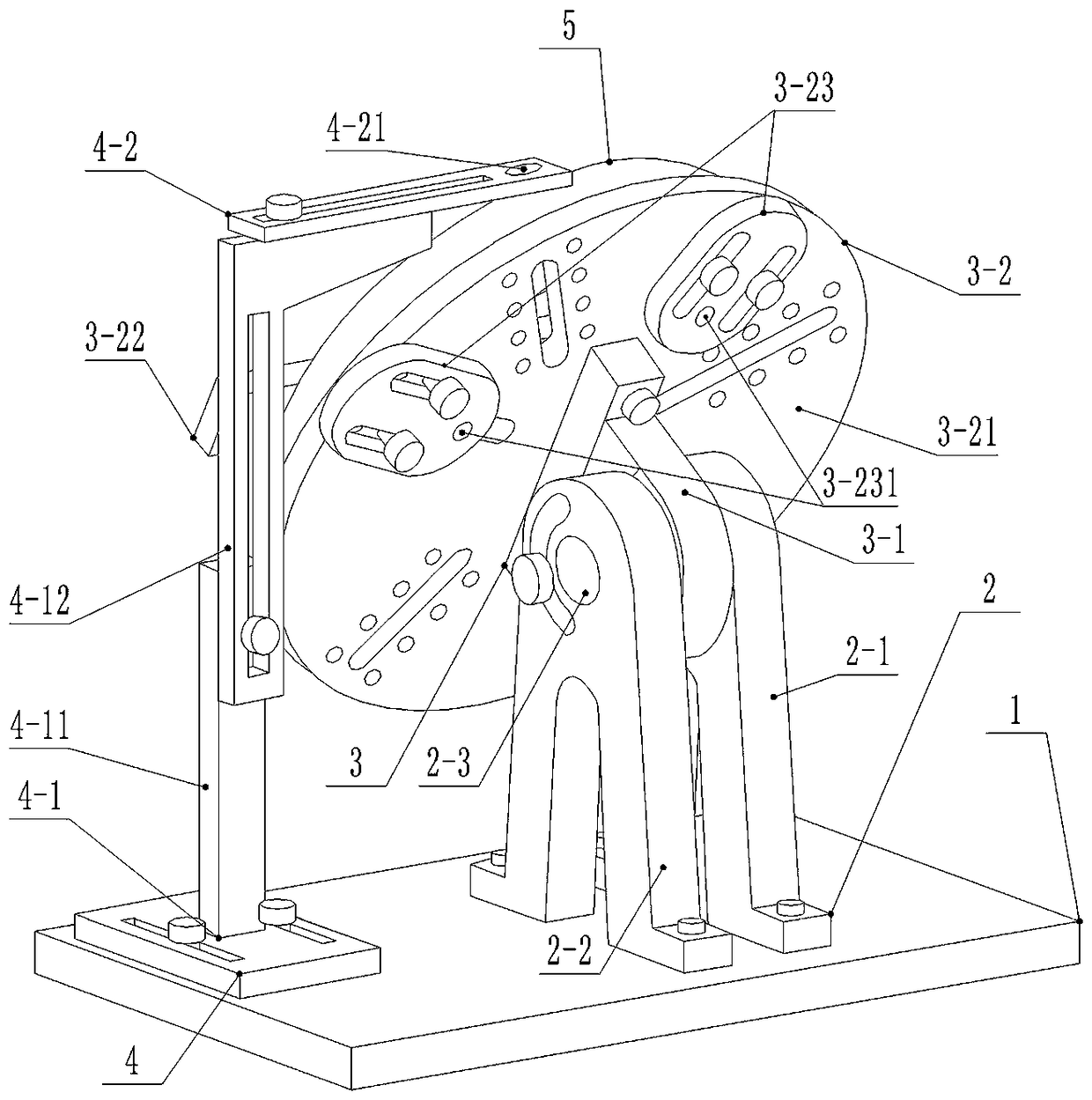

The invention belongs to the field of mechanical machining equipment, specifically relates to a tool for drilling an inclined hole in a circular plate-shaped part, and aims to solve the problems thatthe angle cannot be well controlled and clamping is not easy when the inclined hole is drilled in the side wall of the annular plate-shaped part. The tool comprises a workbench, a support base, a support plate and a drill sleeve guiding device. The support base is composed of a left support arm and a right support arm, a horizontal rotating shaft is connected to the top of the left support arm andthe top of the right support arm, and the support plate is inserted between the two support arms and is connected with a rotating shaft in a sleeve manner; the support plate comprises a bottom plate,a pressing plate and a positioning pin plate, the pressing plate is further provided with a two-force rod device, the support plate rotates around the horizontally-arranged rotating shaft to drive workpieces to pitch, and drilling at different oblique angles can be realized; the position of the positioning pin plate is changed so that the workpieces with different radii can be fixed, and radial runout of the workpieces during drilling can be prevented; the pressing plate restricts axial movement of the workpieces; the two-force bar device realizes restriction on rotation of the workpieces; and the drill sleeve guiding device can achieve accurate guiding of a drill bit for working.

Owner:GUILIN FUDA

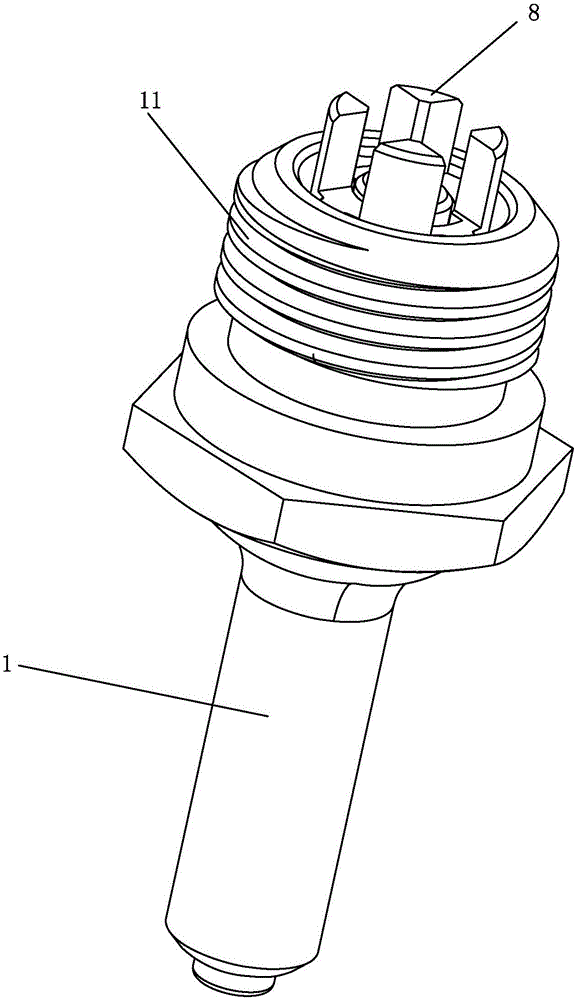

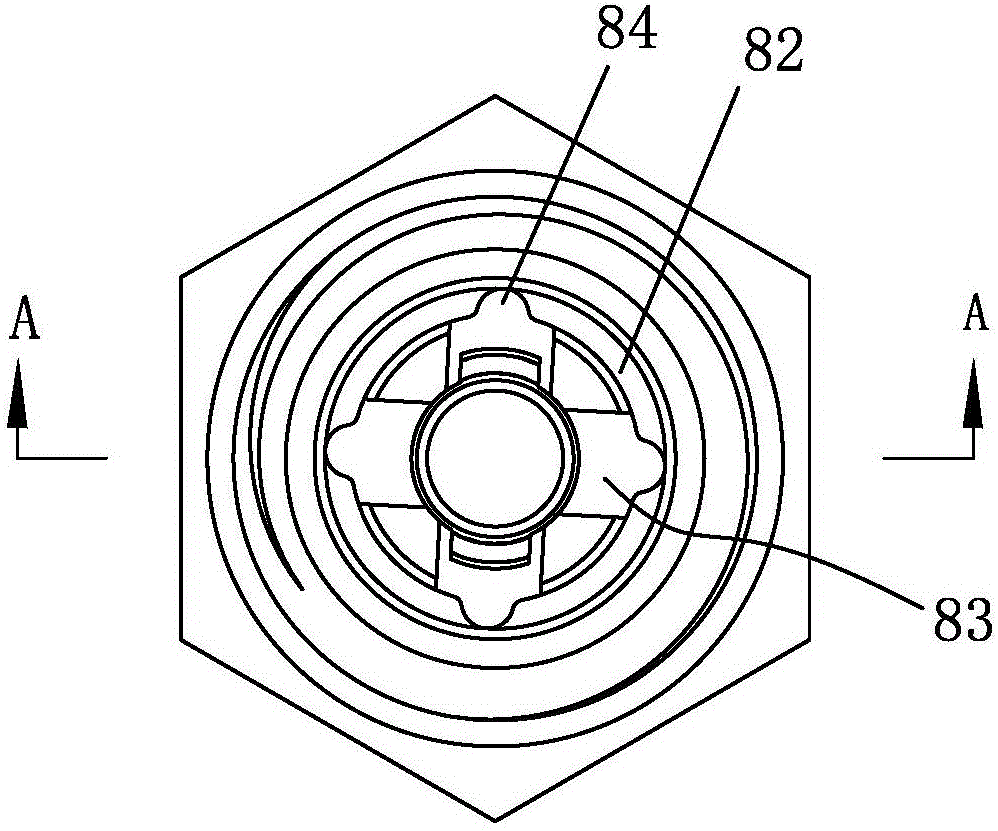

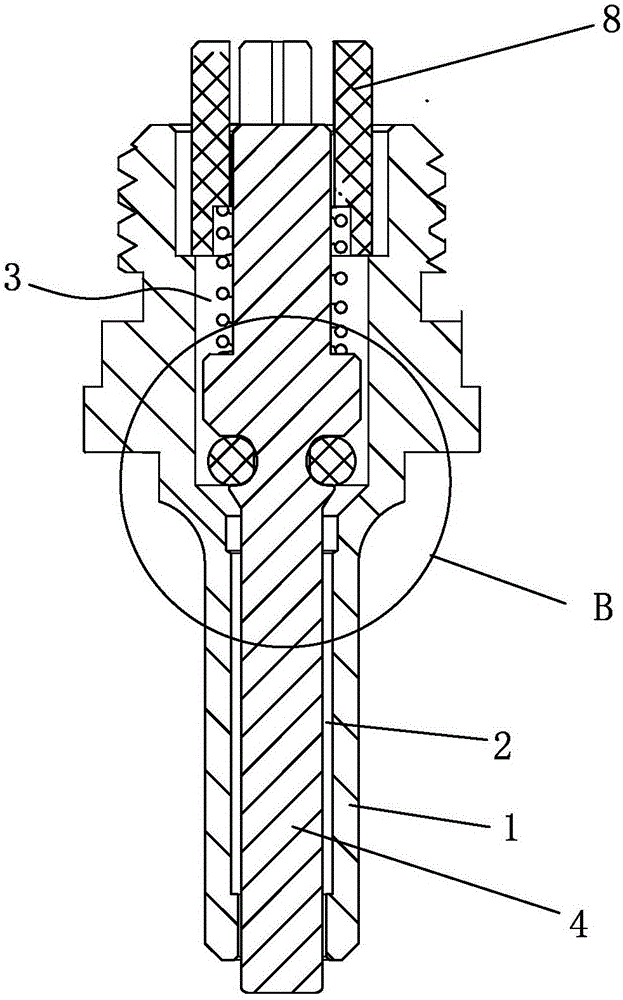

Temperature sensing fusing ejector pin type valve

InactiveCN106337956AImprove securitySimple structureOperating means/releasing devices for valvesEqualizing valvesInlet channelMechanical engineering

The invention discloses a temperature sensing fusing ejector pin type valve. The valve comprises a valve body. The valve body is internally provided with an air inlet channel, a valve cavity and a valve pin, wherein the air inlet channel allows air or liquid to flow and communicates with the valve cavity, and the valve pin can slide in the air inlet channel and is made from low-fusing-point matter; a stepped hole is formed between the air inlet channel and the valve cavity; and a sealing step capable of being matched with the stepped hole in the air inlet channel to close the air inlet channel is arranged on the valve pin. The valve pin is made from the low-fusing-point matter, after the valve pin is installed, when a fire occurs, the valve pin or a spring seat deforms in a temperature sensing fusing mode, a spring and the valve pin are shortened due to loss of support, the valve pin cannot normally eject open a valve core on an air source, the air source is cut off, and a bigger danger is avoided. The temperature sensing fusing ejector pin type valve is simple in structure, ingenious in design and obvious in effect, and improves the safety of the ejector pin type valve in fires.

Owner:ENERCO GROUP

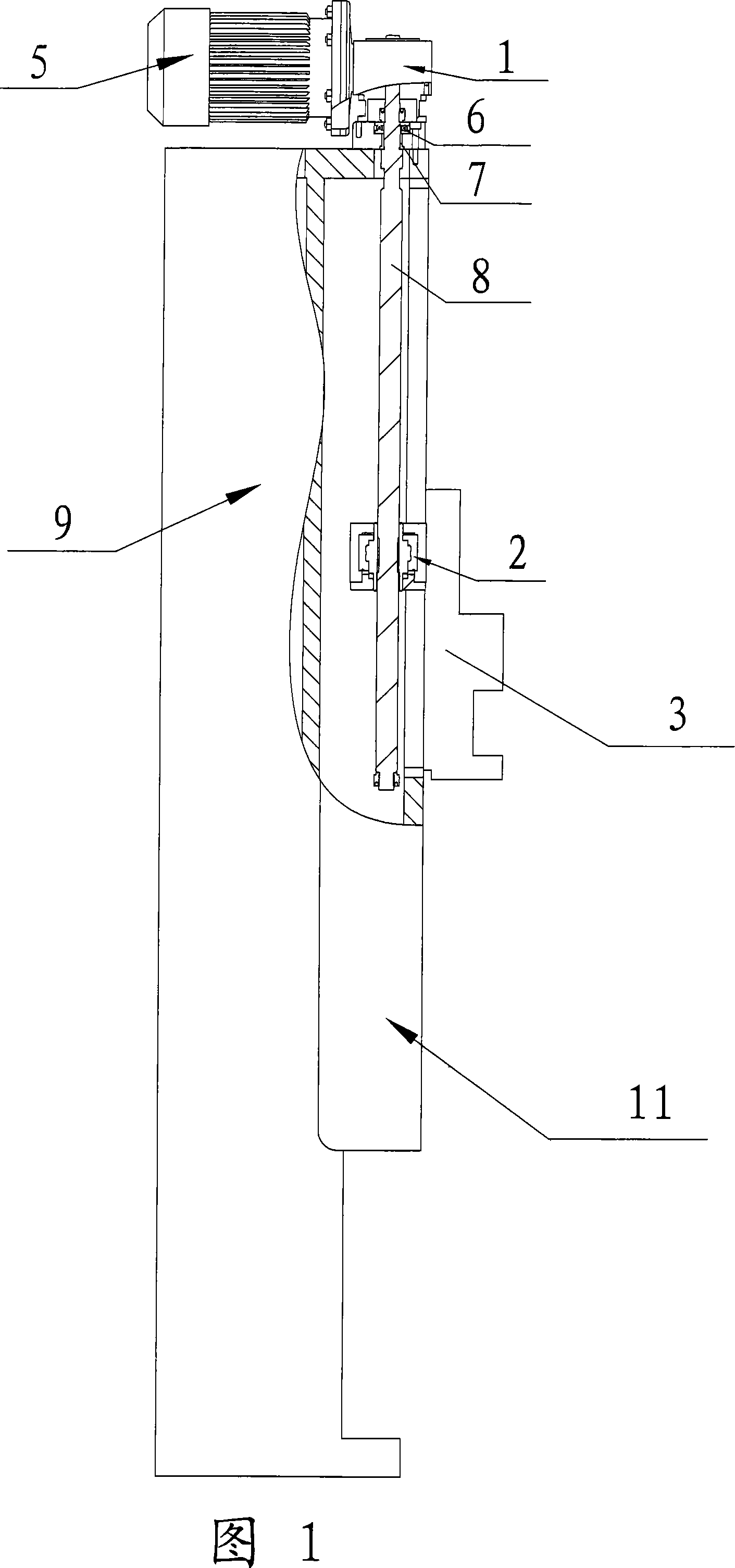

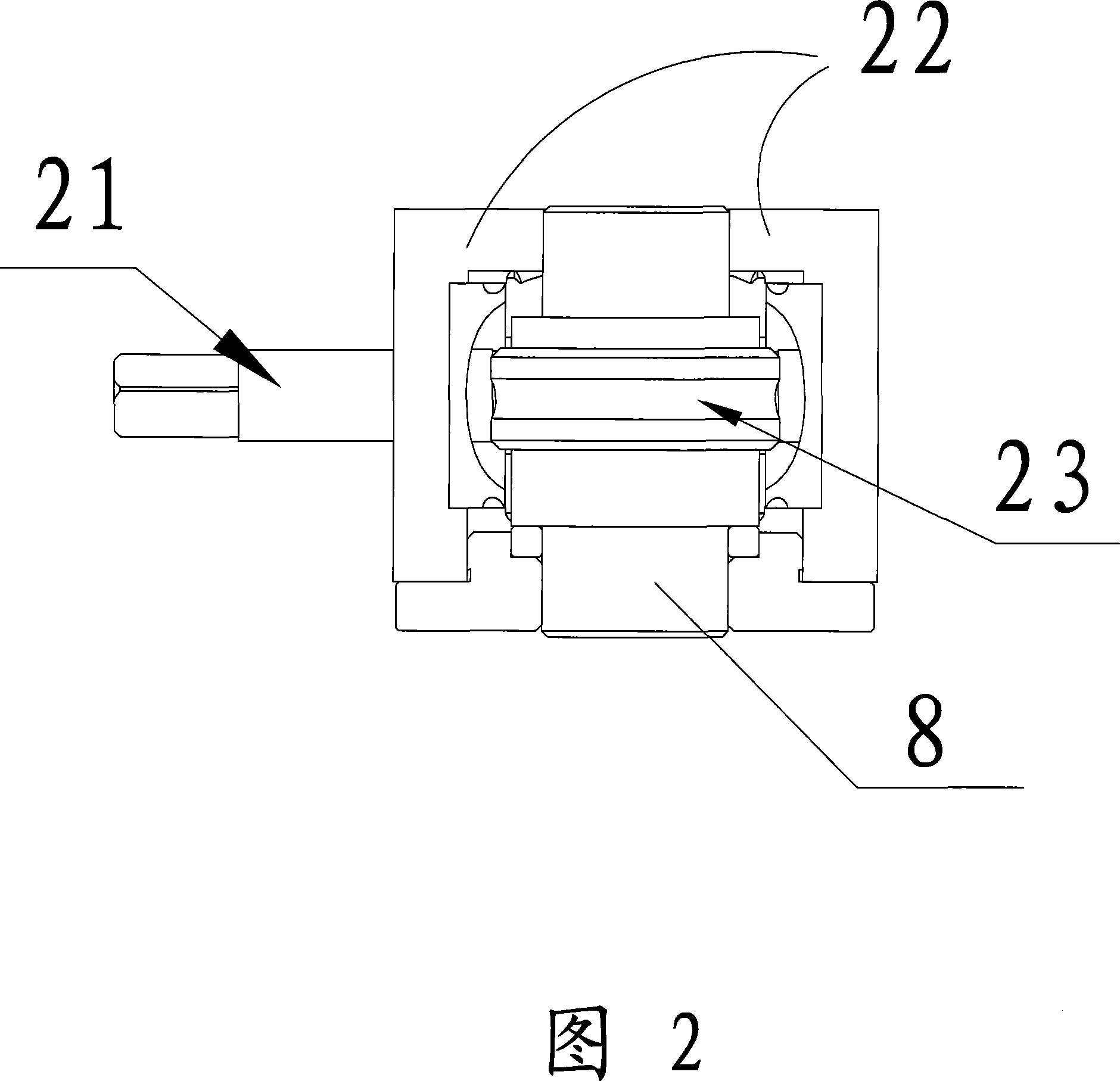

Outer circle grinding device for thin and long shaft workpiece

PendingCN108000256AReduce distortionEasy to feed axiallyGrinding carriagesRevolution surface grinding machinesGear wheelEngineering

An outer circle grinding device for a thin and long shaft workpiece comprises a head frame centre and a tail frame centre. The thin and long shaft workpiece is arranged between the head frame centre and the tail frame centre and arranged in a machine shell. A plurality of grinding mechanisms are arranged in the machine shell. Each grinding mechanism comprises a lead screw, wherein the two ends ofthe lead screw are arranged on a fixing base and a supporting base correspondingly, one end of the lead screw is connected with a hand wheel after stretching out of the fixing base, the lead screw isin screw joint with a nut, the nut is fixedly connected with a grinding wheel frame, the grinding wheel frame is fixedly connected with a sliding block, the sliding block is in sliding connection witha guide rail in the machine shell, the grinding wheel frame is further fixedly connected with a motor, an outer ring of a first bearing and an outer ring of a second bearing, the inner ring of the first bearing is connected with an output shaft of the motor, the output shaft is connected with a drive gear, the drive gear is engaged with a driven gear, and the driven gear is connected with a grinding wheel through a transmission rod. Grinding force of various grinding wheels to the thin and long shaft workpiece offset with one another, and the machining precision is improved; and a rolling guide rail is adopted for positioning, and the workpiece machining quality is guaranteed.

Owner:LUOYANG INST OF SCI & TECH

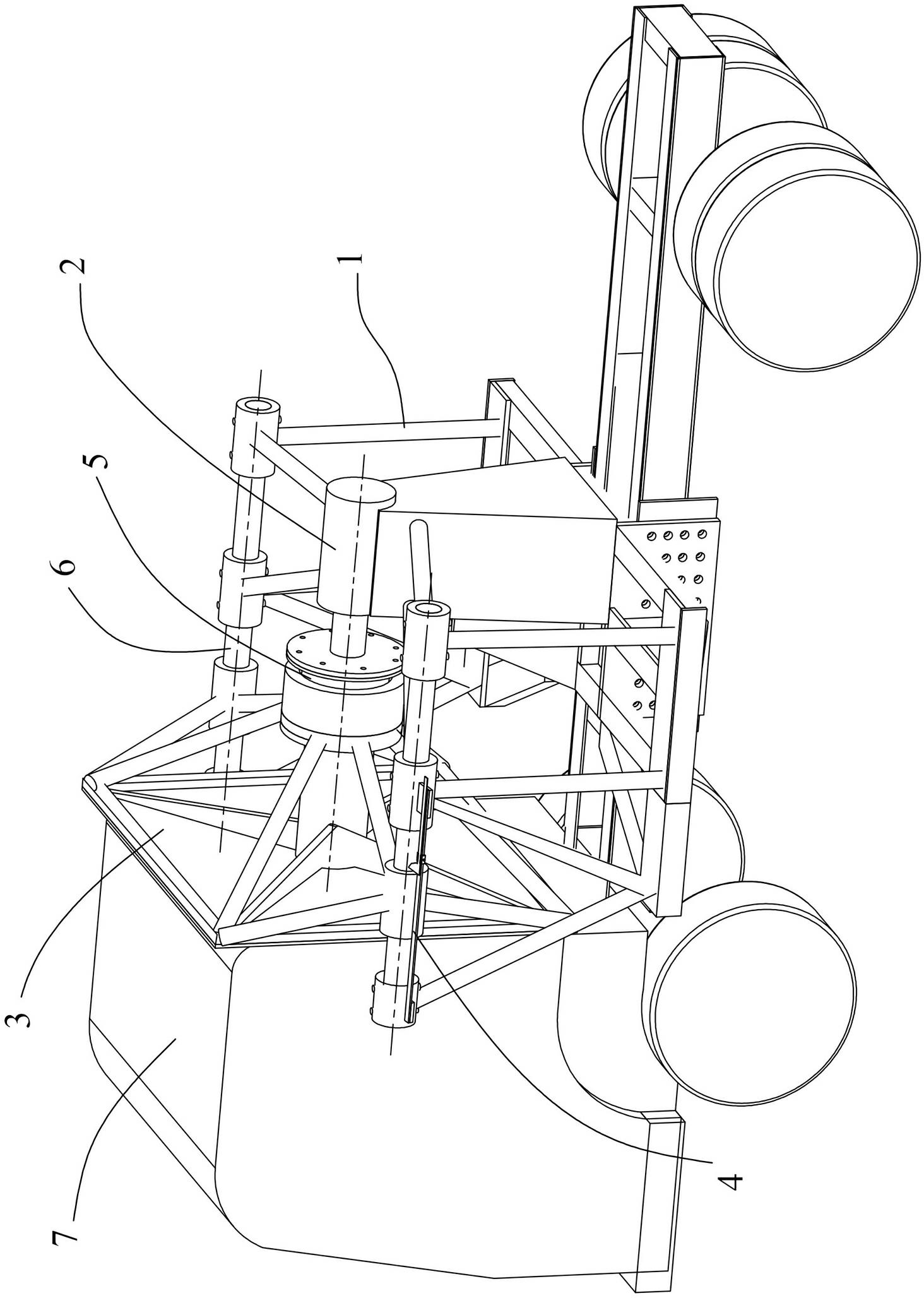

Rear wall strength test device for driving cabs of commercial vehicles

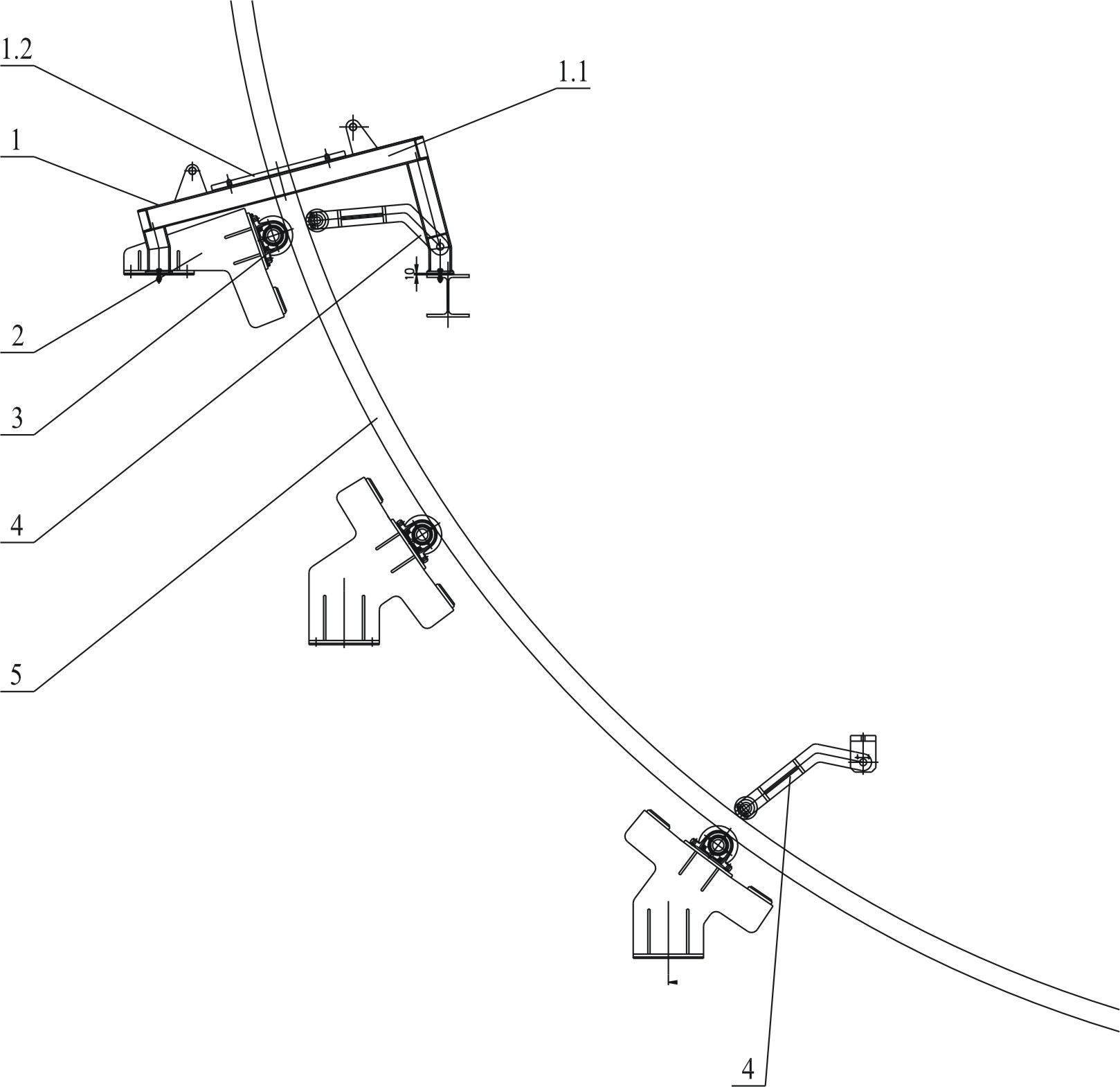

InactiveCN102620940AAccurate loading directionData test measurement is accurateVehicle testingCommercial vehicleEngineering

The invention discloses a rear wall strength test device for driving cabs of commercial vehicles, which comprises a mounting frame assembly, a flexible driving device, a rigid loading mechanism, a displacement measuring device and a force measuring device, wherein the mounting frame assembly is provided with a pair of guide rails arranged in parallel, the pair of guide rails is arranged along the longitudinal direction of the vehicle, the rigid loading mechanism is arranged on the pair of guide rails in a sliding mode, the flexible driving device is fixed on the mounting frame assembly, an output end of the flexible driving device is connected with the rigid loading mechanism through the force measuring device, and the displacement measuring device is arranged on the guide rails. The rear wall strength test device for driving cabs of commercial vehicles has the advantages that the structure is simple, the loading direction and the loading speed are stable, the data measurement is accurate, and test results can fully reflect the real condition of the real facts of the rear wall strength of driving cabs.

Owner:HUNAN UNIV

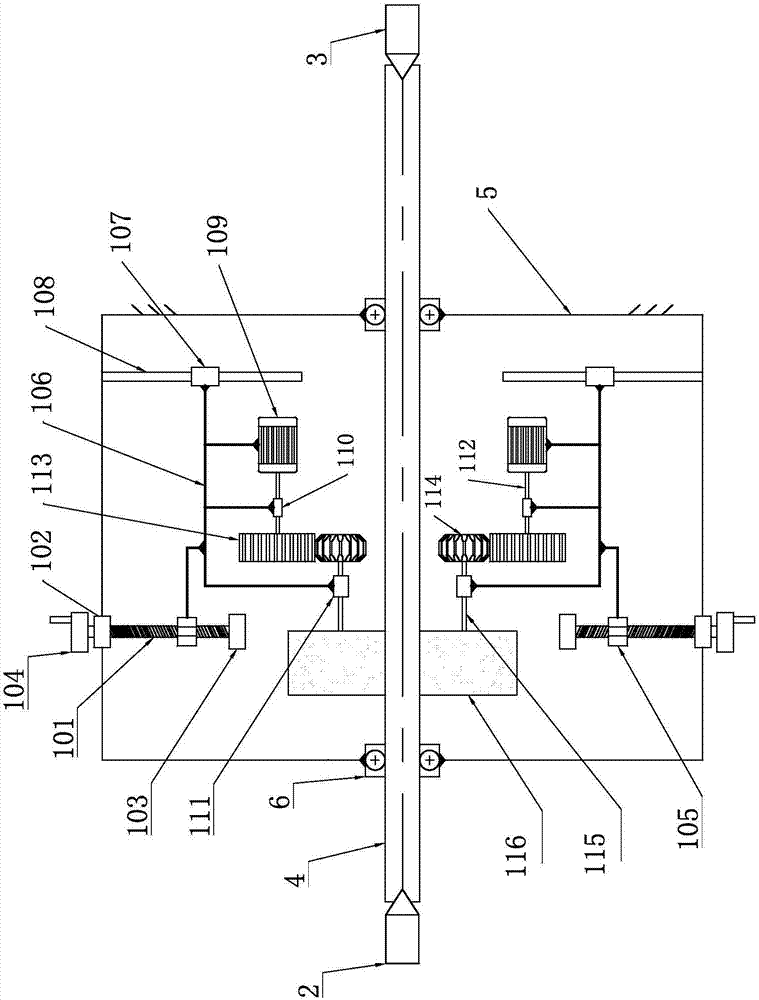

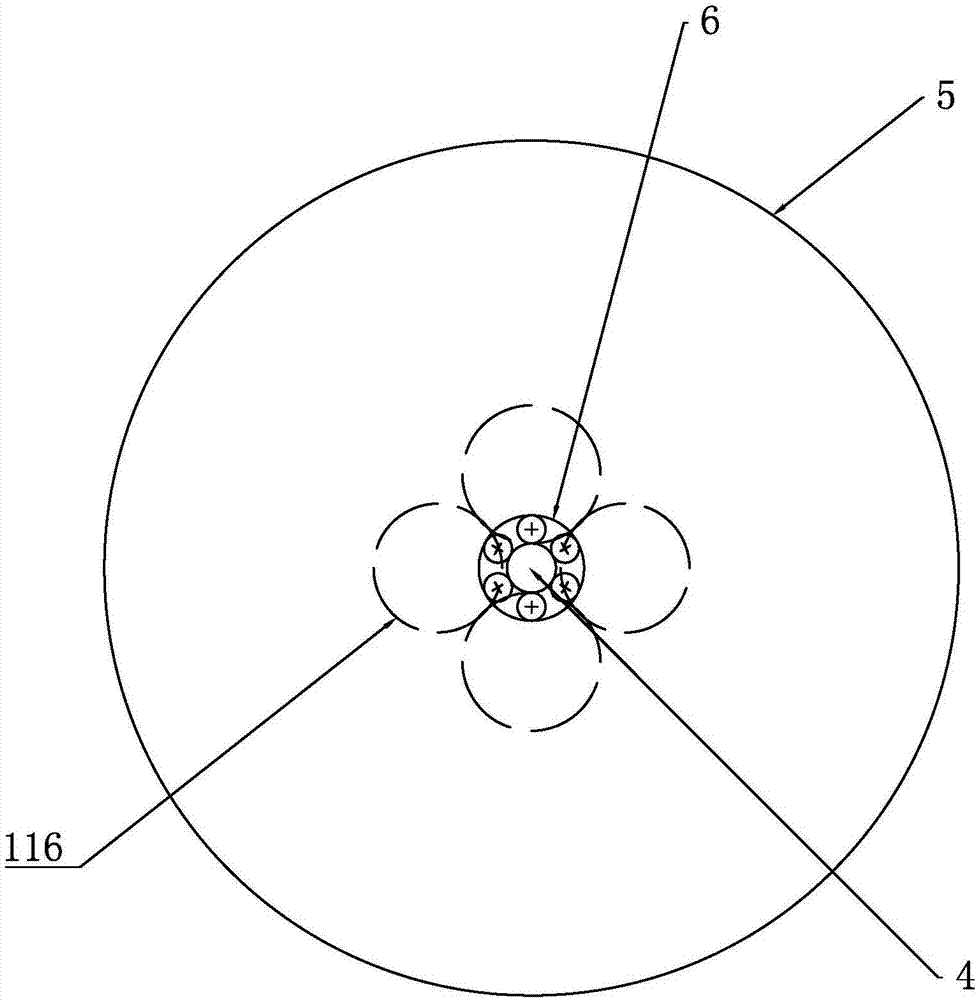

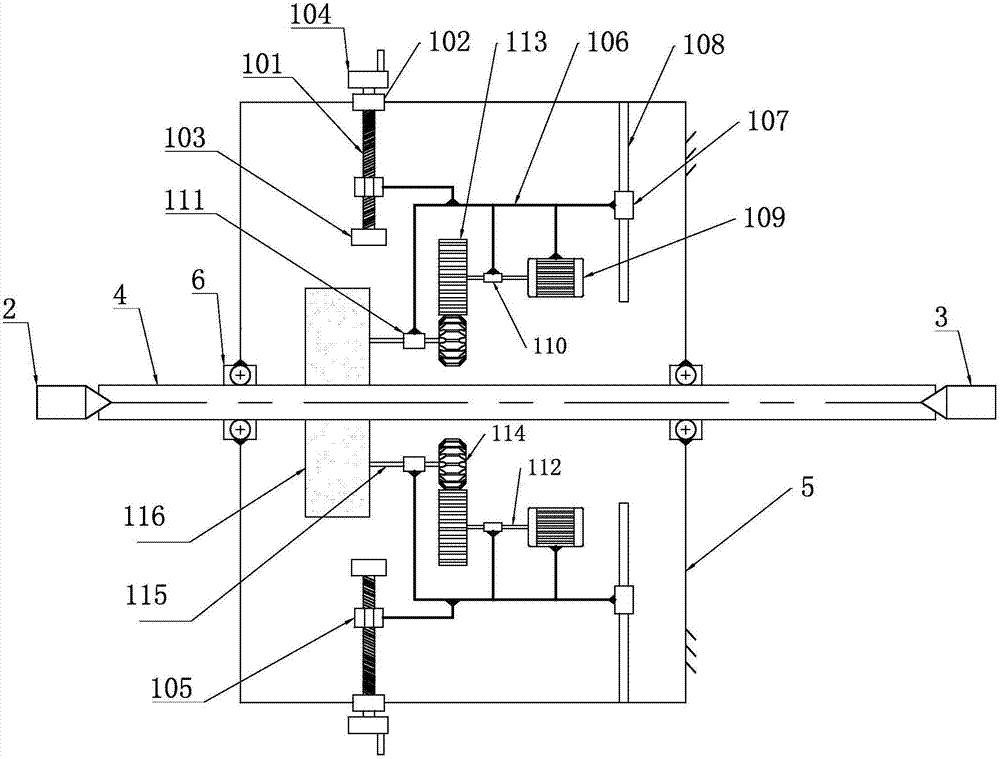

Double-worm and worm gear transmission mechanism used for machine tool

The present invention relates to a drive mechanism of twin-worm wheel applied in machine tool, comprising a secondary worm wheel reducer which can be slightly regulated and is arranged on a guide screw; the reducer includes a worm shaft, a worn wheel case, a worm wheel which is arranged in the worm wheel case and has inner screw thread; the inner screw thread engages with the guide screw, the worm shaft is vertical with the guide screw and the worm wheel case is fixedly connected with a sliding element which can be driven to slide along the vertical pole or the dragging board by the worm wheel case. The manual adjustment of the worm shaft on the secondary worm wheel reducer can drive the worm wheel on the secondary worm wheel reducer to move slowly along the guide screw, and the worn wheel case can impel the sliding element to slide along the vertical pole or the dragging board; thus, the position of the sliding element is slightly adjusted, thereby realizing the precise position effect.

Owner:SUZHOU BAOMA NUMERICAL CONTROL EQUIP

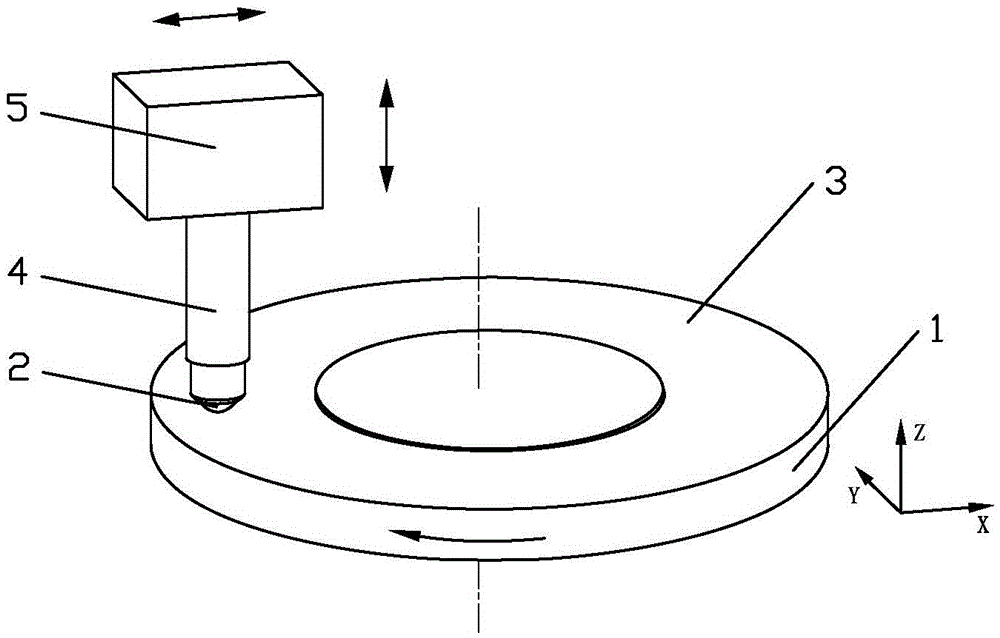

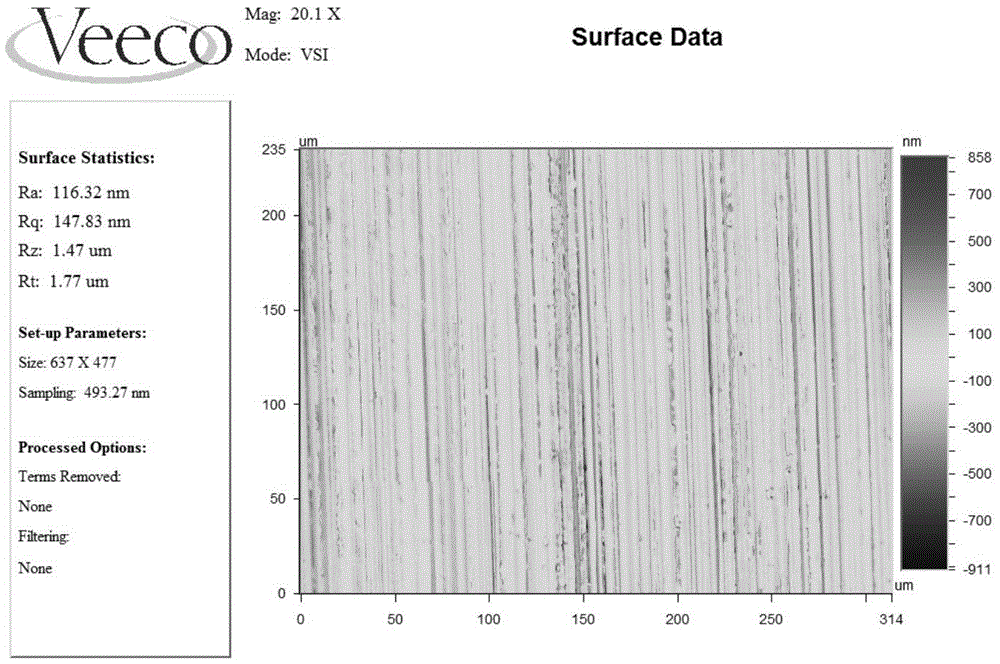

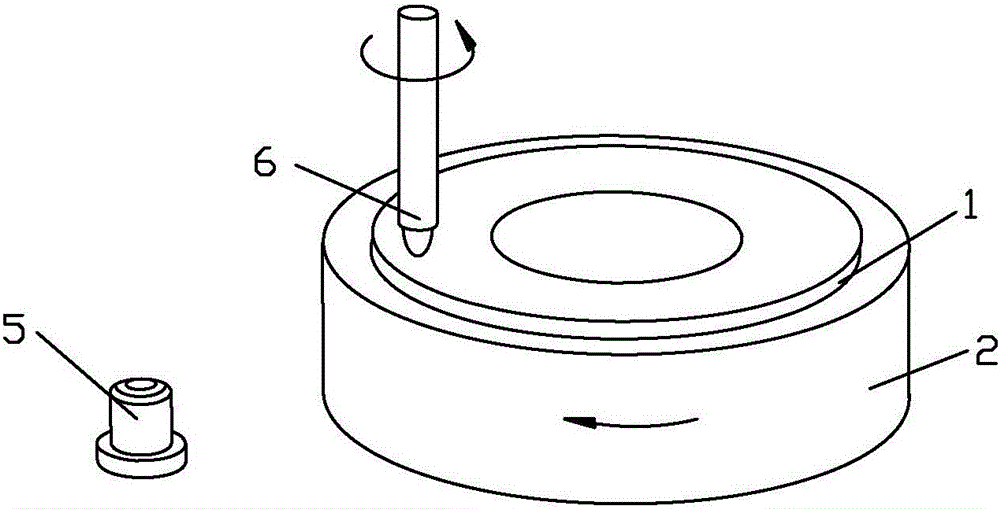

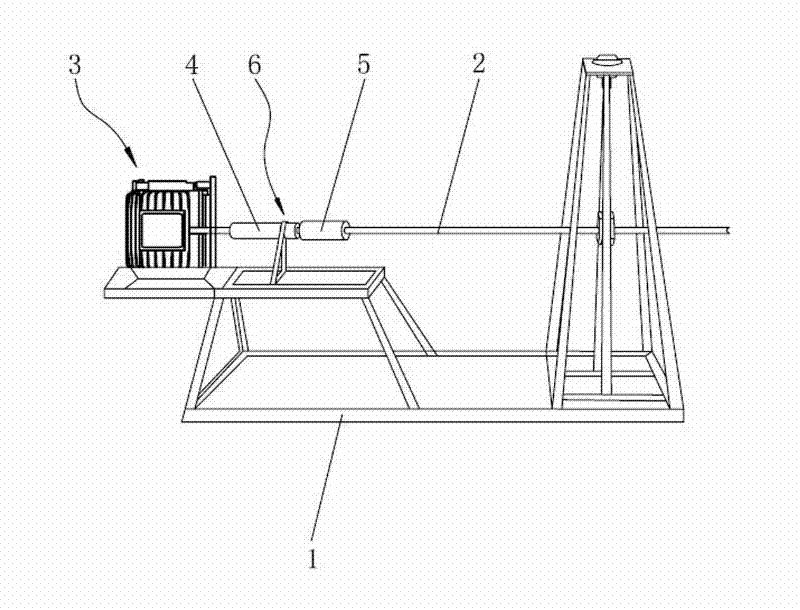

High-speed friction testing method for spherical grinding head prepared ferrous metal friction pair

ActiveCN105651635AImprove stabilityGuaranteed shape accuracy and relative position accuracyInvestigating abrasion/wear resistanceAcoustic emissionFriction test

The invention discloses a high-speed friction testing method for a spherical grinding head prepared ferrous metal friction pair, and belongs to the field of tribological testing and precision and ultraprecision machining. A ferrous metal friction disk is fixed to an electric spindle, and subjected to online dynamic balancing; then a spherical grinding head is adopted for finishing the friction disk, and the requirement of end face run-out and roughness needed for testing is met; then a friction tool is clamped on a clamp connected with a force feedback device, ball-disk tests, pin-disk tests and other friction tests are carried out, the friction disk rotates at the specified rotating speed, the friction tool and the friction disk are in contact, the pressure between the friction tool and the friction disk is fixed as a set testing value, testing is finished till the set time, and friction force, acoustic emission signals and other physical quantities are collected by a measuring system in the process. According to the high-speed friction testing method, high-speed friction testing can be achieved.

Owner:HUAQIAO UNIVERSITY

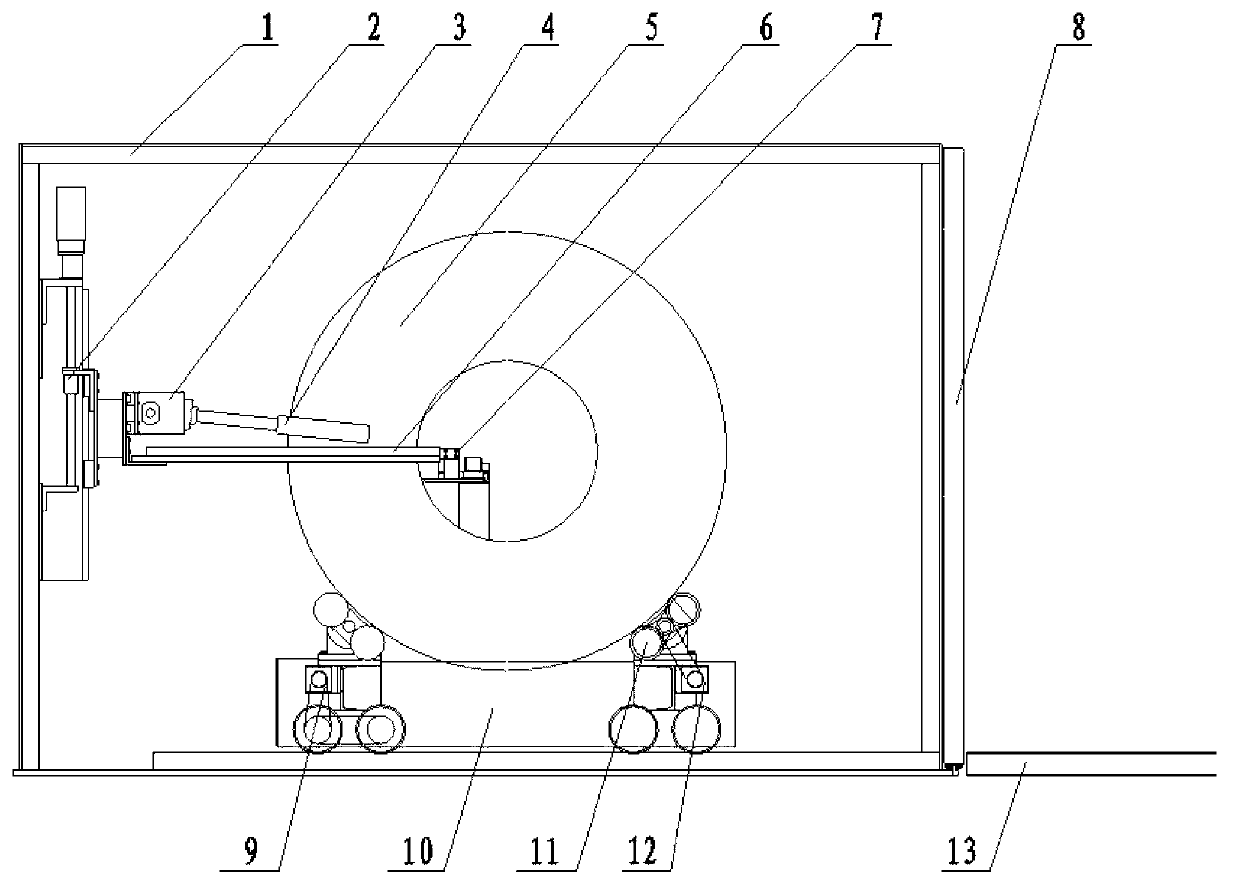

X-ray detection method and full-automatic detection equipment for engineering tires

ActiveCN103105404ASmooth rotationRadial stabilityMaterial analysis by transmitting radiationAutomatic test equipmentX-ray

The invention discloses an X-ray detection method and full-automatic detection equipment for engineering tires. The method comprises the step of detecting the interior of a tire to be detected in an X-ray protection chamber by virtue of a ray tube and an imaging sensor, and specifically comprises the following steps of: mounting the tire on a carrier vehicle on rails outside the ray protection chamber, and moving the vehicle to a preset position in the protection chamber and closing a protection door when the tire is mounted on the vehicle, wherein the tire bearing part of the vehicle is a tire rotating mechanism consisting of multiple rollers; and starting a tire centering mechanism and the tire rotating mechanism, rotating the tire on the rollers of the tire rotating mechanism, adjusting the tire to an accurate detection position through the centering mechanism, starting the imaging sensor and the X-ray tube to preset positions for detection, and displaying and storing detected images in a computer. The method has the advantages that the size of the X-ray protection chamber is reduced, and the construction cost is reduced; the tire rotates stably, and thus the imaging precision is improved; radial run-out caused by concave and convex parts of the excircle of the tire is prevented; and moreover, radiation during manual operation is eliminated.

Owner:辽宁仪表研究所有限责任公司

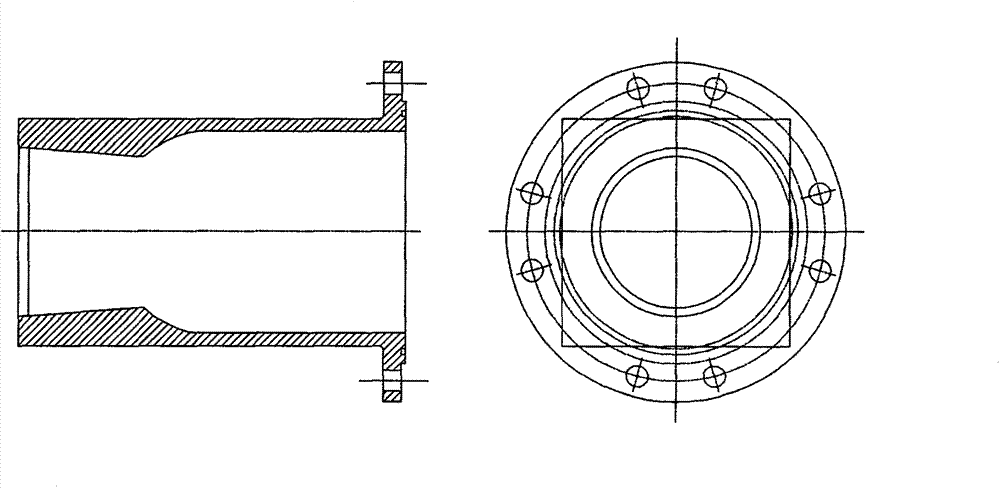

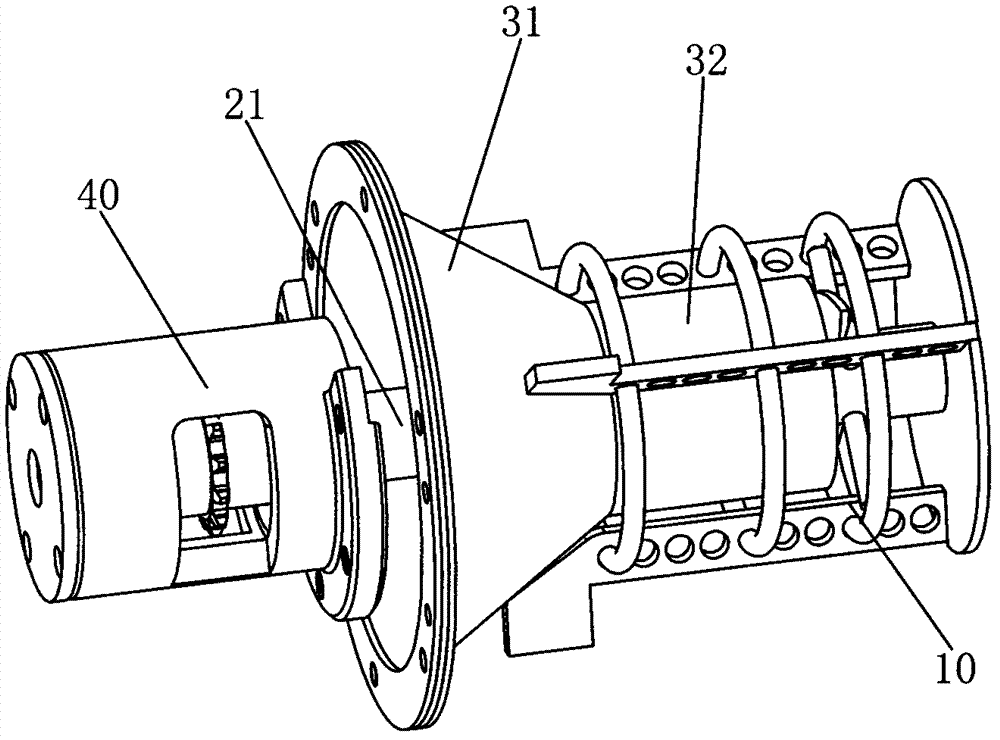

Pull-rod modularized guide vane type diagonal flow pump

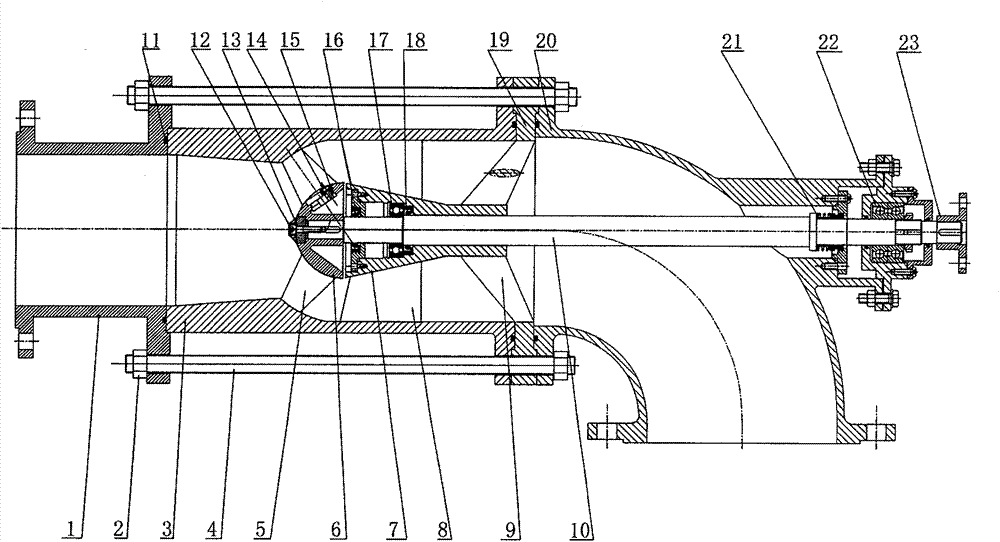

InactiveCN103321911AGuaranteed concentricityGuaranteed clearanceRotary non-positive displacement pumpsNon-positive displacement fluid enginesImpellerButt joint

The invention relates to a high-flow and low-lift water pump used in medium-and large-scale water conservancy projects, and discloses a pull-rod modularized guide vane type diagonal flow pump. The diagonal flow pump comprises parts of square outer barrel and inlet pipe connecting sections, square outer barrels, pull rods, impeller blades, blade hubs, guide vane hubs, guide vane blades, streamlined ribbed plates, a pump shaft, guide vane body flanges, hydrocones, screws, press plates, oil seals, bend pipe sections, rolling bearings, mechanical seals, couplers and the likeother parts. The diagonal flow pump is characterized in that impeller casings and guide vane body outer walls are integrated to form the outer barrels, a cross section of each outer barrel adopts an square outside and round inside shape, the left sides of the outer barrels can be directly clamped in the connecting sections for positioning, so that fast butt joint is achieved, and the left sides require no fastening part; and moreover, the right sides of the outer barrels are connected and fixed with the guide vane body flanges and flanges on the left sides of the bend pipe sections through the pull rods and the nuts. Pull-rod connection is adopted, the guide vane bodies are connected with the outer barrels and the bend pipe sections, therefore, compared with a traditional diagonal flow pump, the pull-rod modularized guide vane type diagonal flow pump is more convenient to dismount and mount, facilitates maintenance and detection, and can be used for observing cavitation bubbles produced due to internal cavitation of the diagonal flow pump.

Owner:JIANGSU UNIV

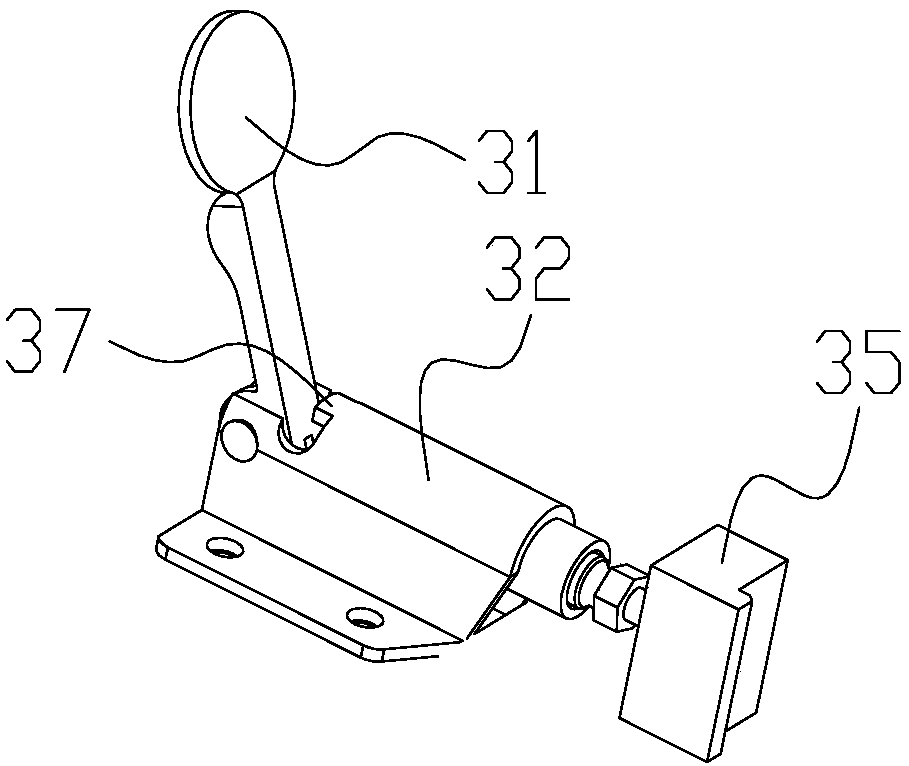

Positioning mechanism for machining pipes

The invention discloses a positioning mechanism for machining pipes. A circular-hole positioning groove is formed in the plate face of one side of a circular-plate base, and a through hole communicated with the positioning groove is also formed in the base; an output shaft of a motor runs through the through holes to be detachably connected with an installing shell sleeve, and the installing shellsleeve is contained in the positioning groove; one axial end of a to-be-machined pipe is detachably fixed on the installing shell sleeve; multiple sliding grooves are formed in the plate face of thepositioning groove formed in the base, and are radially distributed with the positioning groove as a base point at equal intervals, one ends of limiting shafts in the axial direction extend into the sliding grooves, the limiting shafts are driven by a driving mechanism to slidingly move in the extending directions of the sliding grooves, rollers sleeve the limiting shafts, the inner walls of the rollers are in rolling connection with the outer walls of the limiting shafts, and the outer walls of the rollers are in frictional contact with the outer wall of the to-be-machined pipe. According tothe positioning mechanism for the machining pipes, it can be avoided that the to-be-machined pipe conducts radial run-out in the rotating process.

Owner:LUZHOU YUANCHENG ENG MACHINERY CO LTD

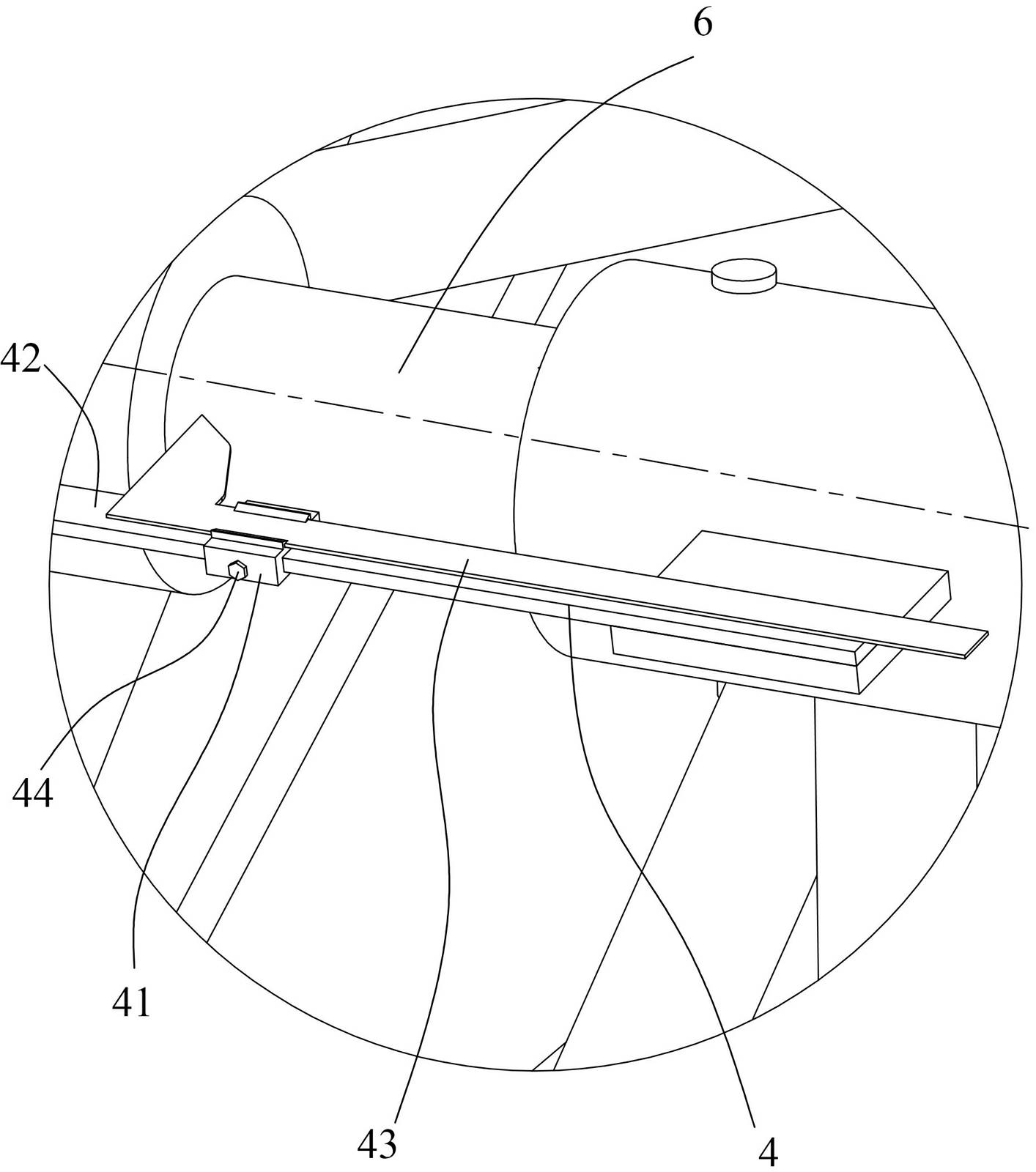

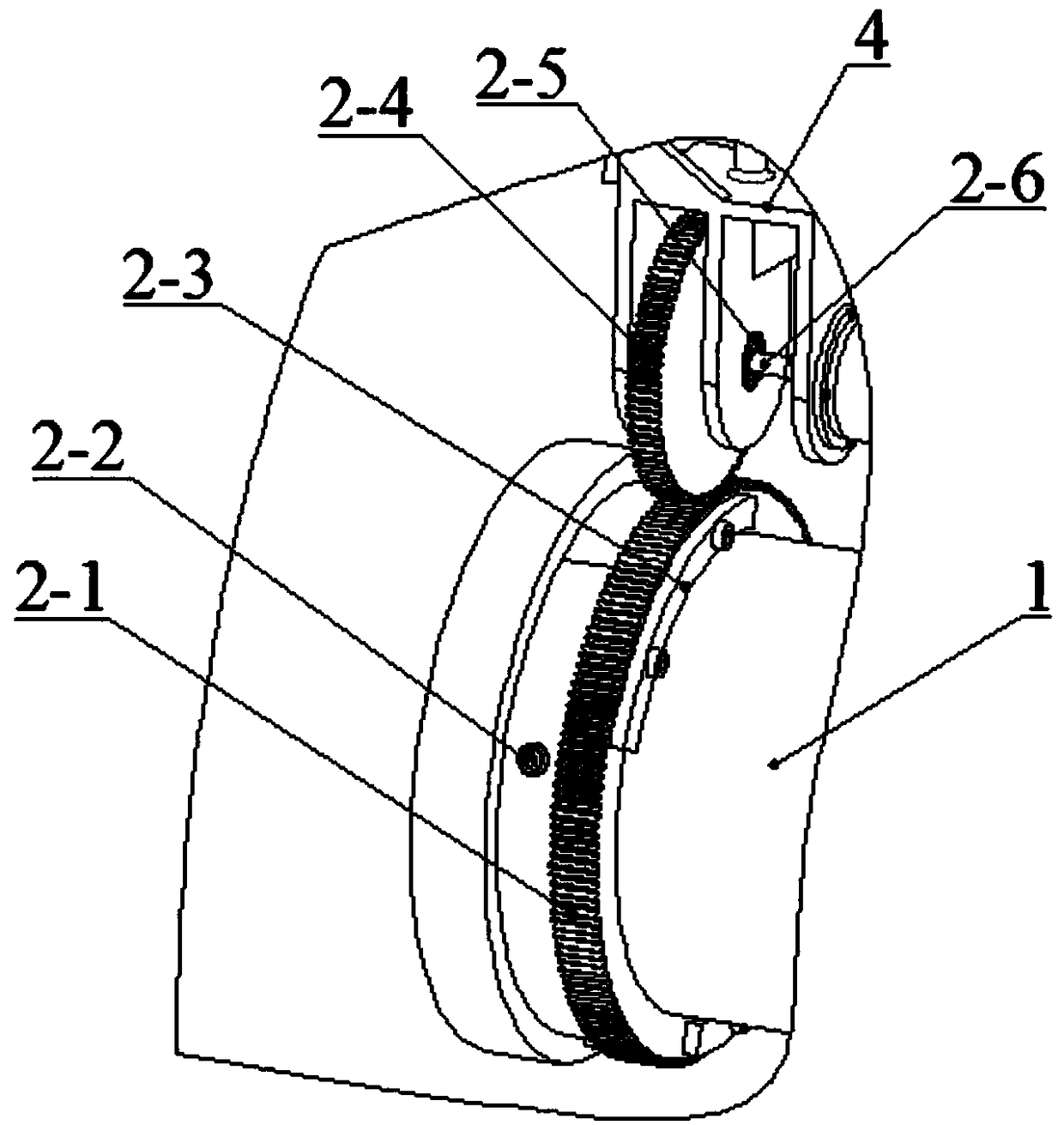

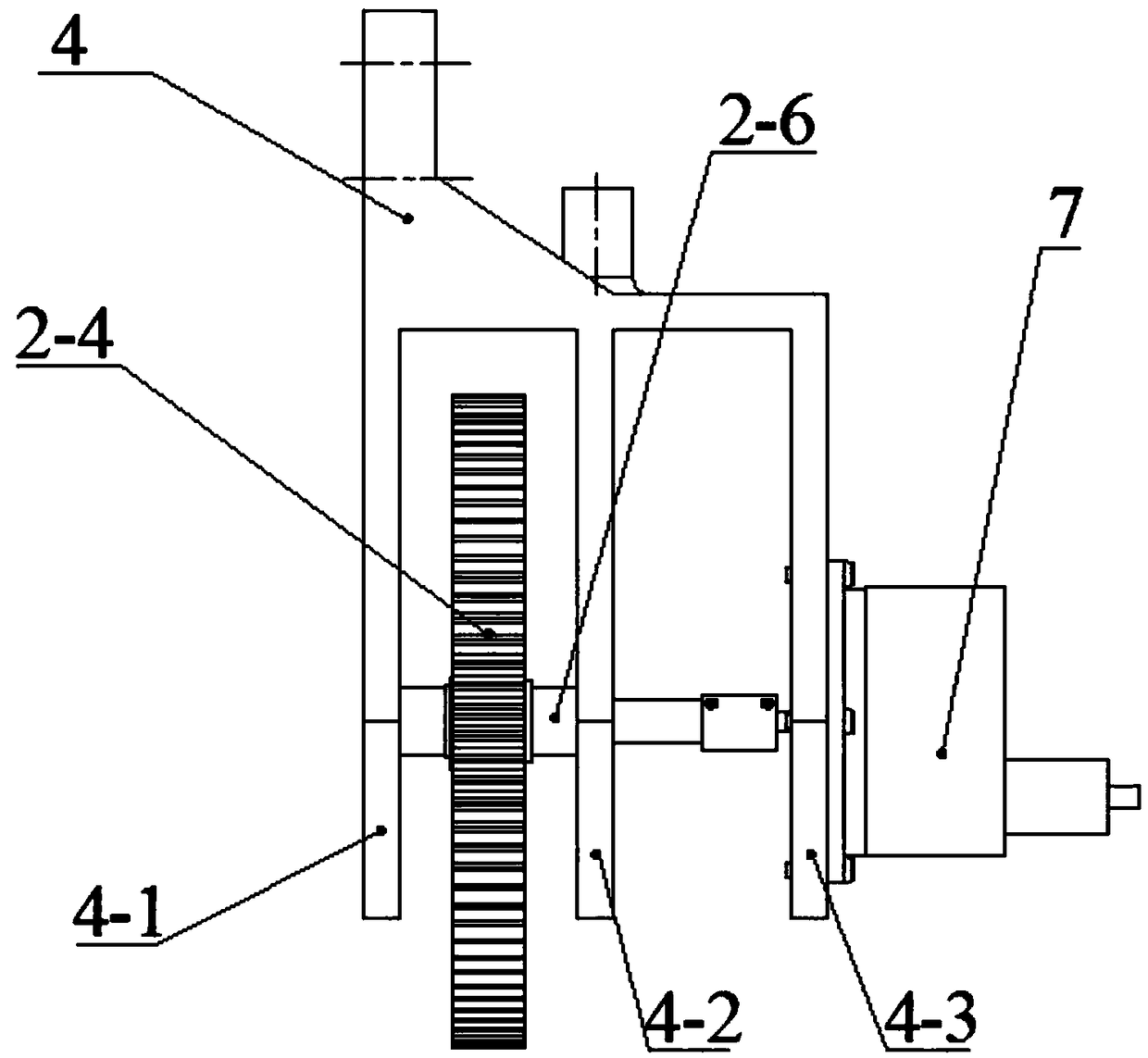

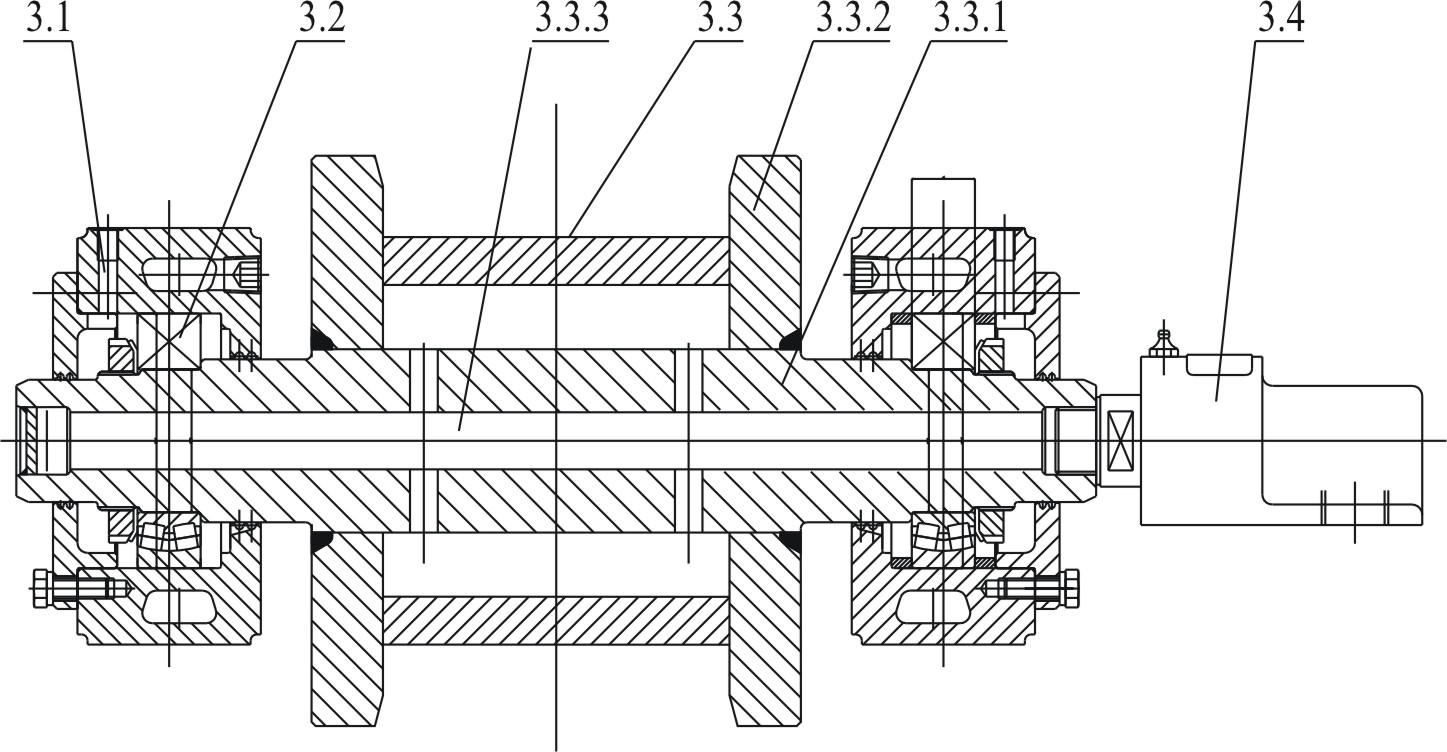

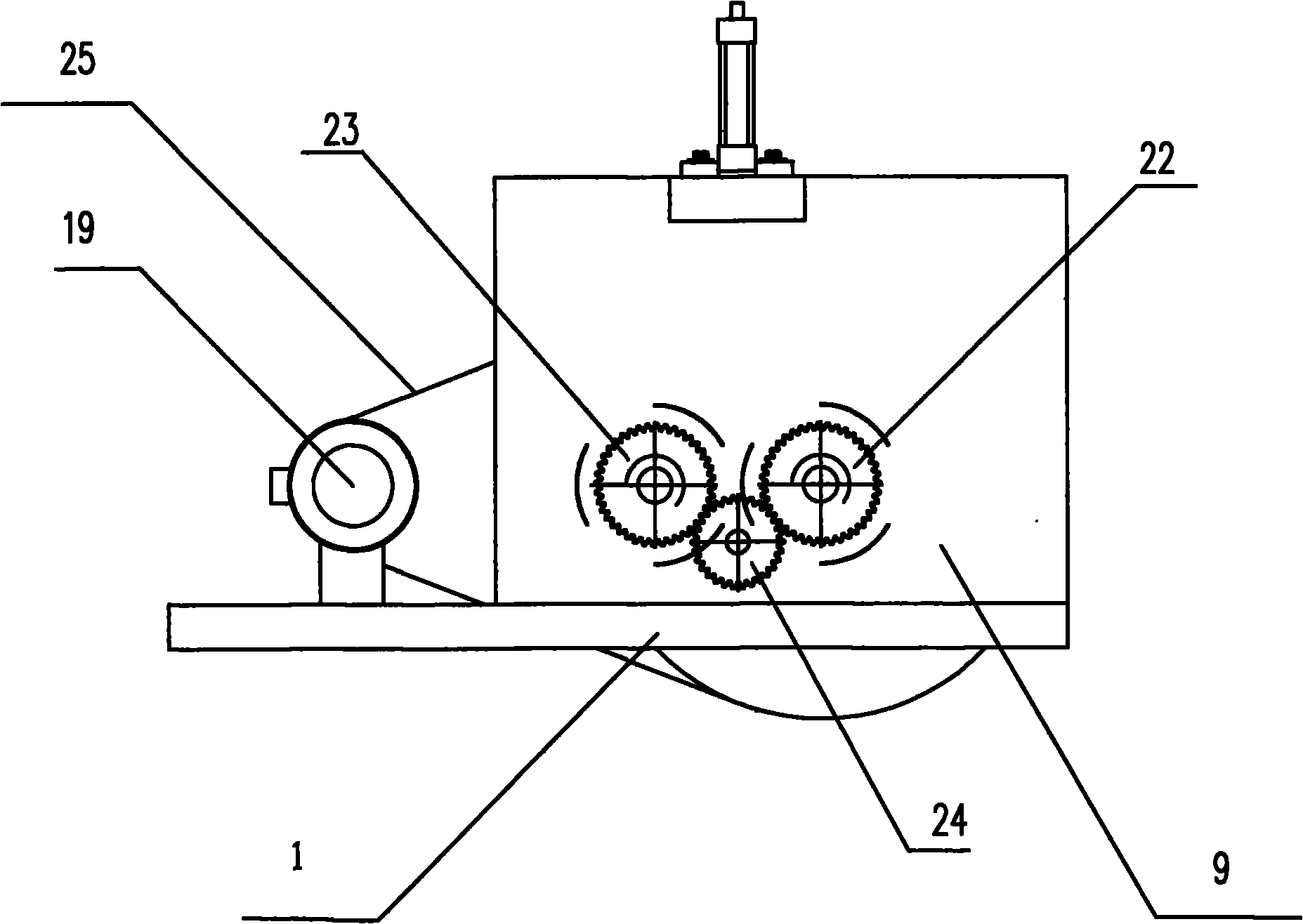

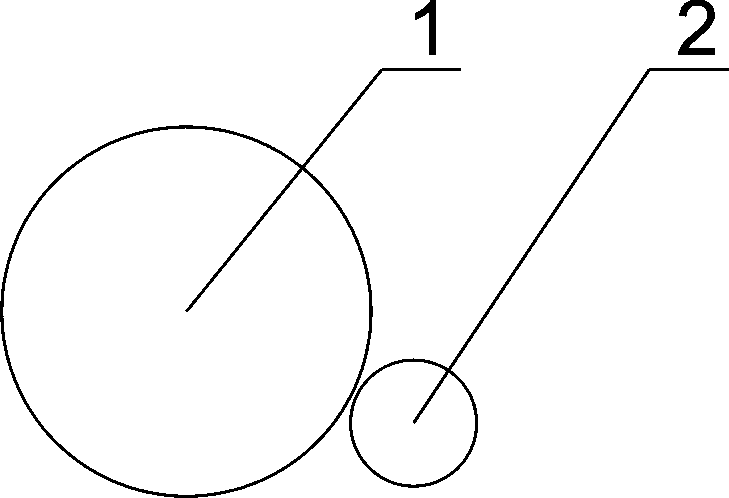

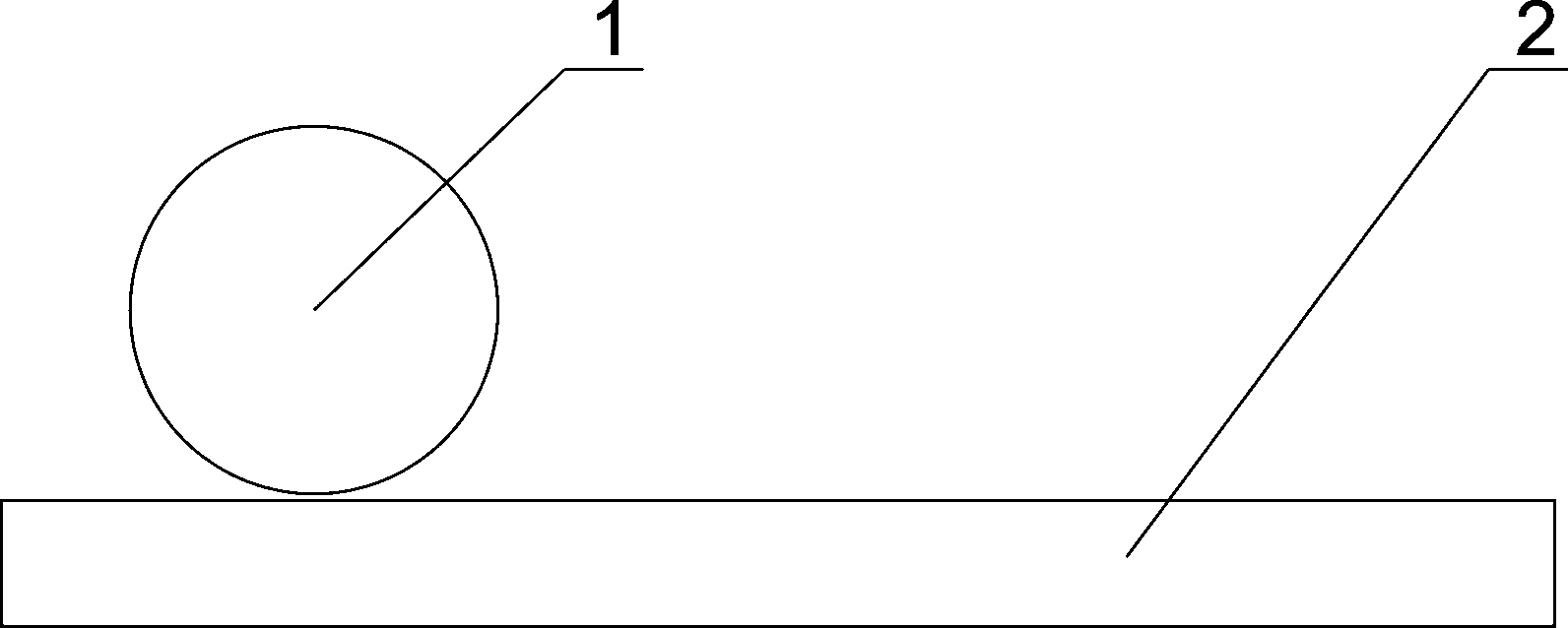

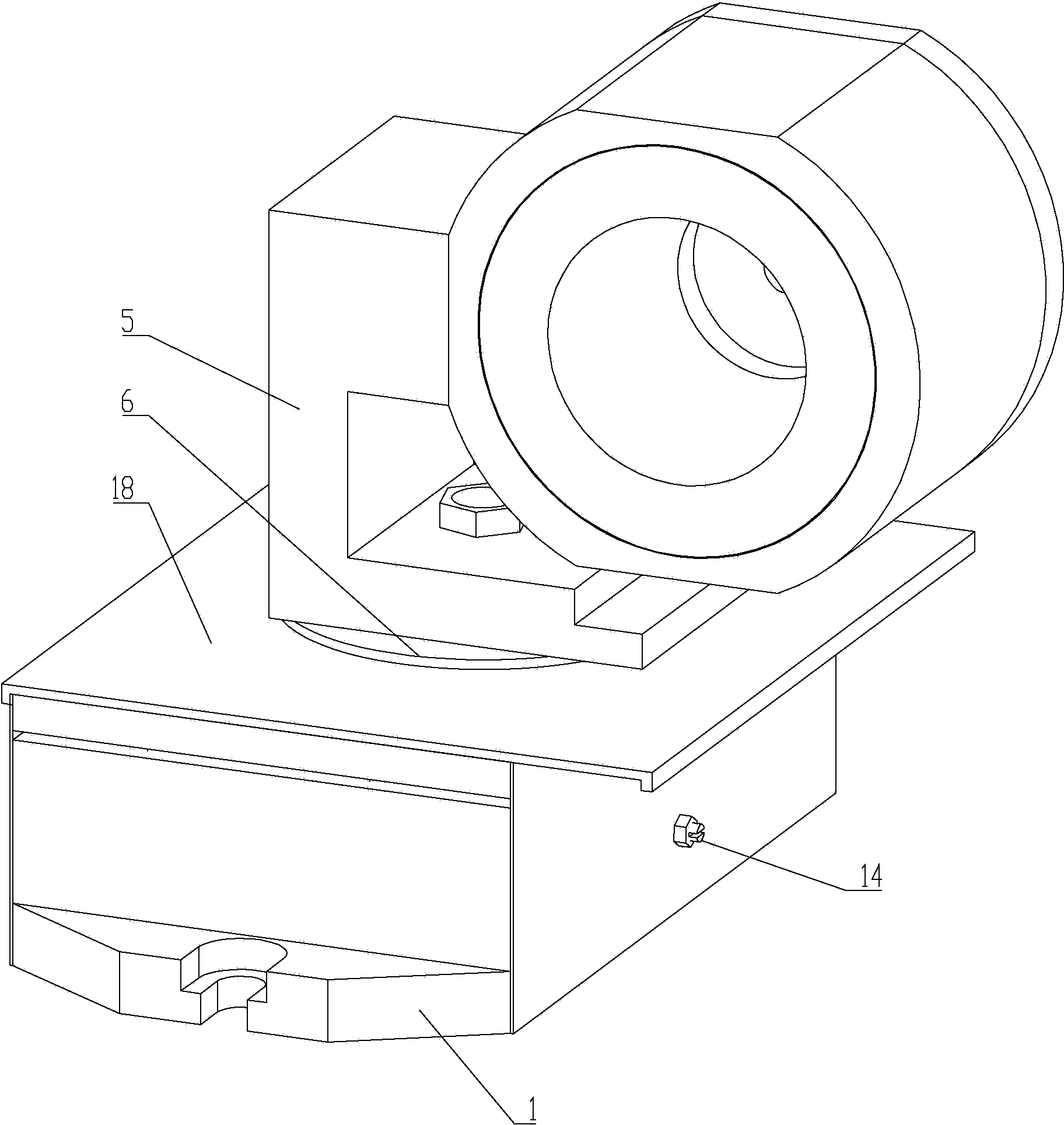

Speed detector for large diameter rotating shaft without protruding end

InactiveCN108226559AAdjustable center distanceAvoid runoutSpeed/acceleration/shock instrument detailsHydraulic motorControl theory

The invention discloses a speed detector for a large diameter rotating shaft without a protruding end. The speed detector comprises a rotational speed extractor, a movable bracket, a buffer device, afixed bracket and a rotary encoder, wherein the rotational speed extractor mainly comprises a pair of gear mechanisms; the rotational speed is extracted by gear mesh; the rotary encoder is arranged onan output shaft; one end of the rotational speed extractor is arranged on a to-be-detected rotating shaft and the other end of the to-be-detected rotating shaft is arranged on the movable bracket; the fixed bracket is arranged on a hydraulic motor base; and the buffer device is arranged between the movable bracket and the fixed bracket. According to the speed detector for the large diameter rotating shaft without the protruding end, disclosed by the invention, the rotational speed measurement can be carried out without disassembling or reforming the rotating shaft; and the speed detector hasthe advantages of accurate speed measurement, convenience in installation and low transformation cost.

Owner:CHINA UNIV OF MINING & TECH

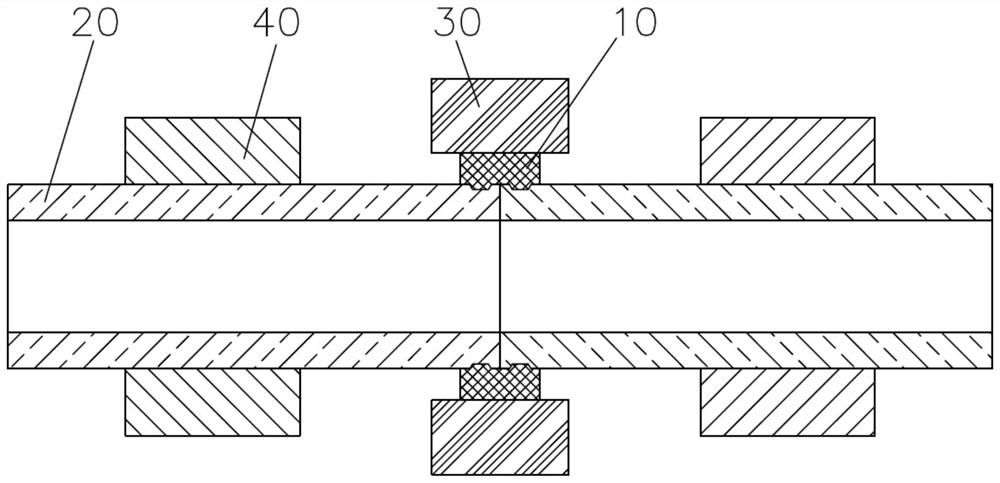

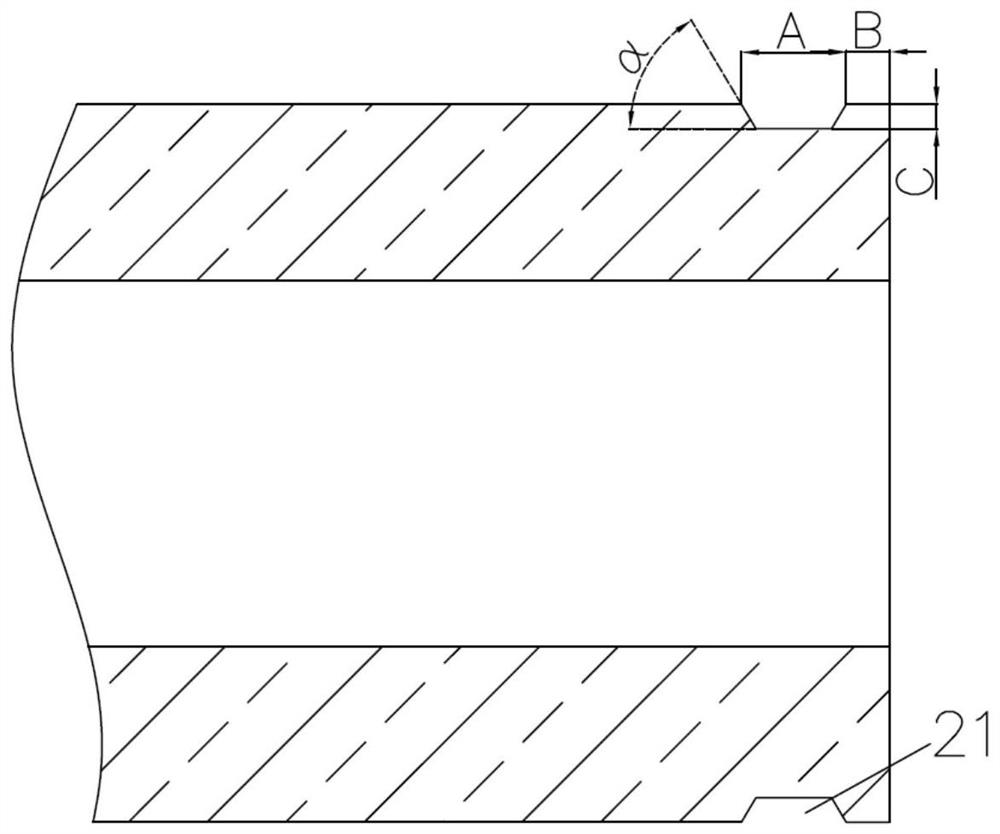

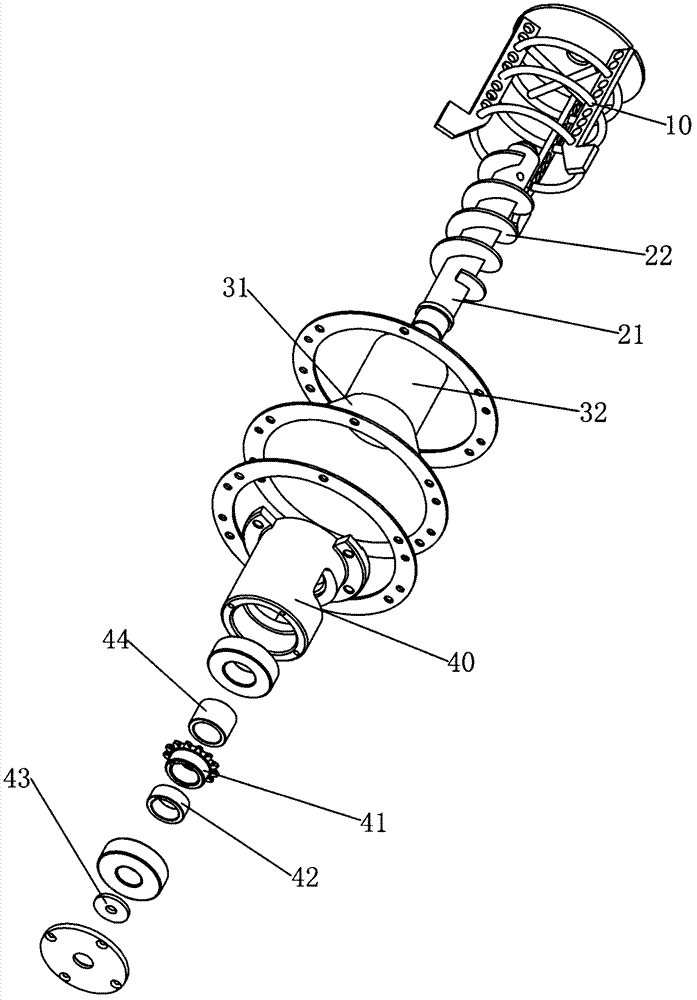

High-strength and high-reliability-sealing radial friction welding method for steel pipe fitting

ActiveCN113770507AAchieve Radial Friction WeldingImprove coaxialityNon-electric welding apparatusFriction weldingPipe fitting

The invention provides a high-strength and high-reliability-sealing radial friction welding method for a steel pipe fitting. According to the method, a clamping mode that a rotary pressurizing tool (30) clamps a steel ring welding blank (10) and fixed clamping tools (40) clamp two steel pipe welding blanks (20) respectively is adopted, and the radial friction welding mode that the steel pipe welding blanks (20) at the two ends do not rotate, the steel ring welding blank (10) rotates and pressurizes, and annular grooves (21) are formed in the welding positions of the steel pipe welding blanks (20) at the two ends is adopted; radial friction welding of a large-length steel pipe is achieved, high coaxiality of the welded steel pipe is guaranteed, meanwhile, radial run-out caused by self-rotation of the large-length steel pipe is effectively avoided, welding flashes or weld beading and the like in the pipe are avoided, the welding quality is guaranteed, the annular grooves (21) form a double-spigot locking structure, and the welding strength and the high-reliability-sealing performance of a weldment are ensured.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

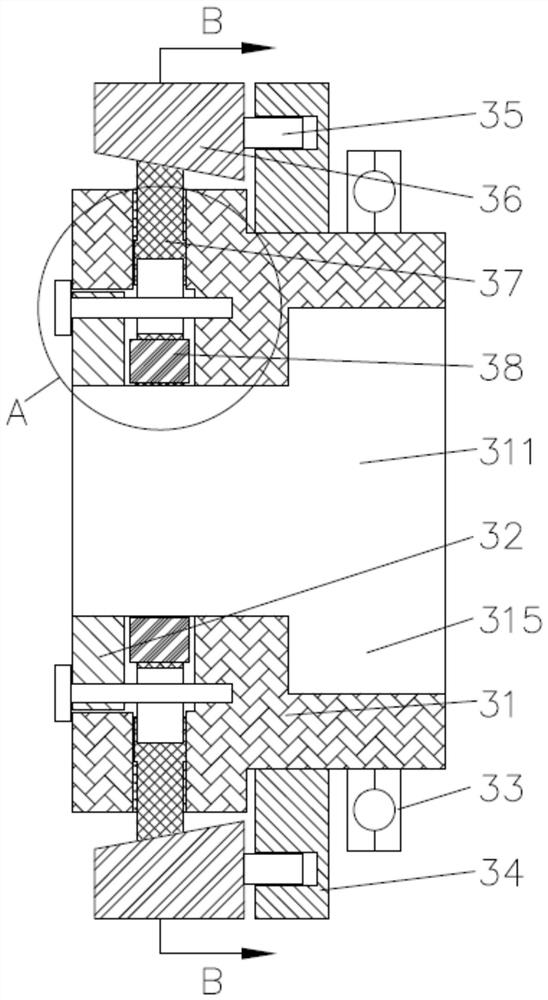

Guide section device for billet continuous casting machine

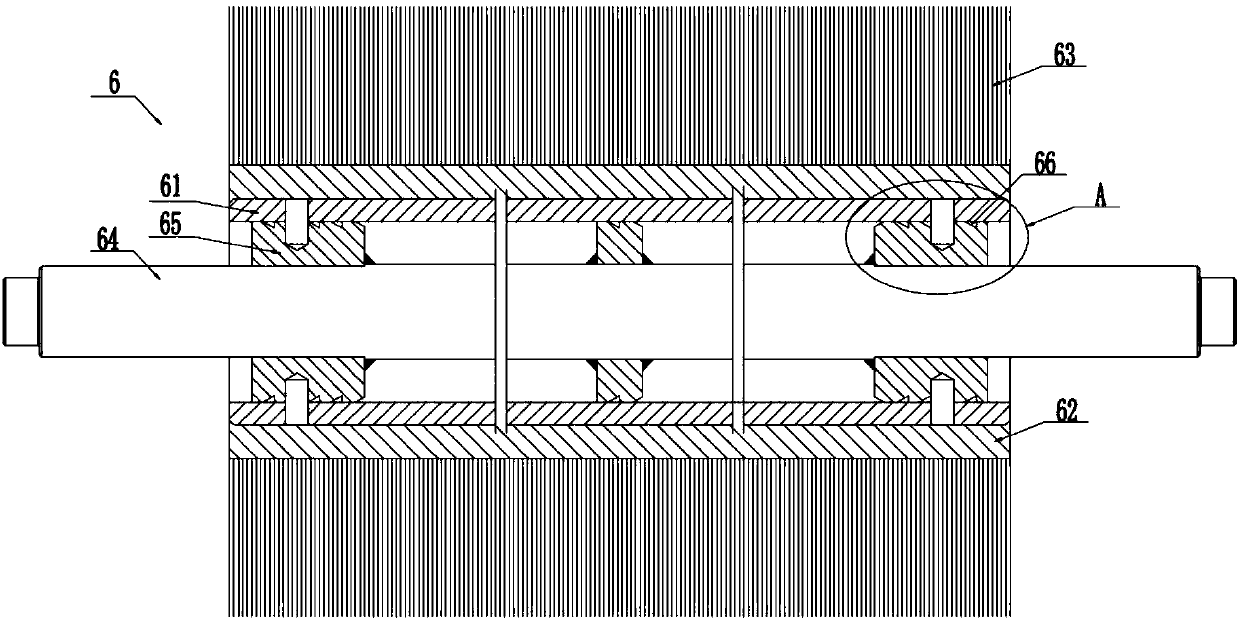

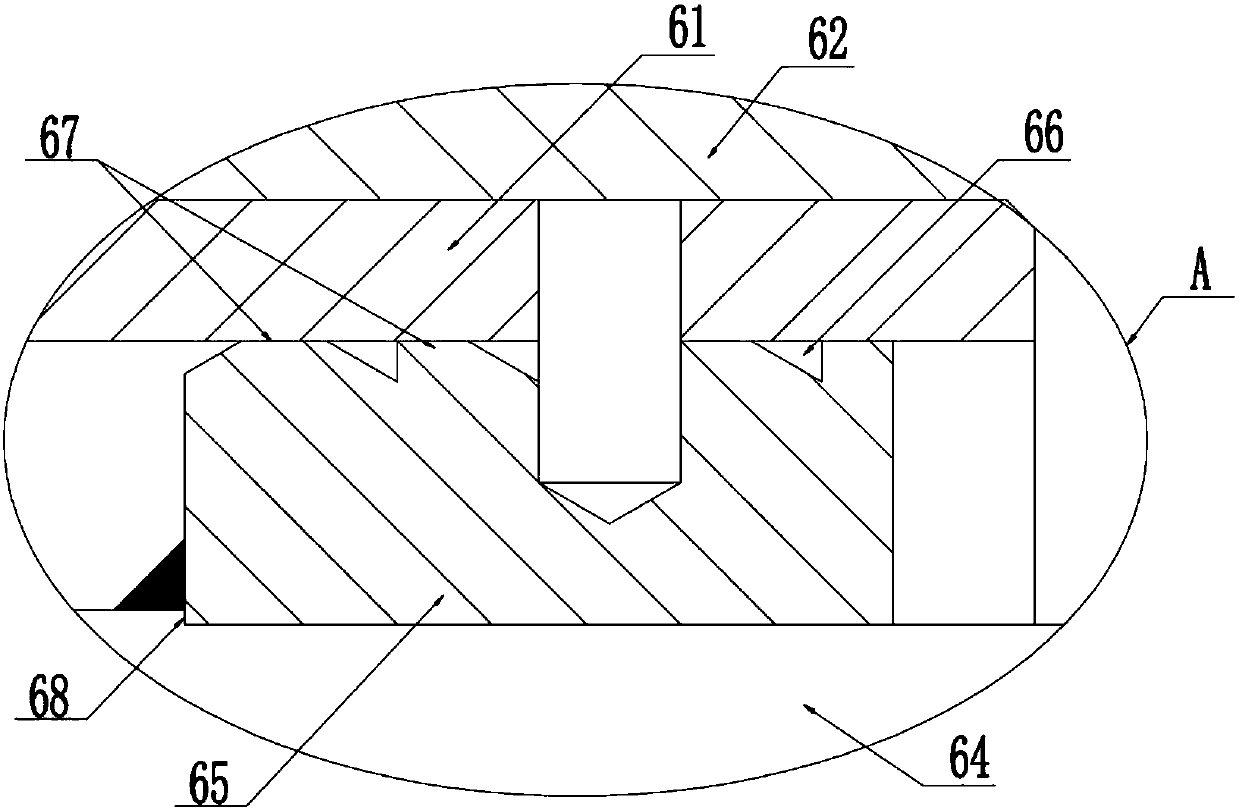

The invention discloses a guide section device for a billet continuous casting machine, relates to a billet continuous casting machine system and aims to solve the problems of short service life, complex assembly and disassembly and the like of a guide roller in the conventional guide section device for the billet continuous casting machine. The guide section device for the billet continuous casting machine comprises a guide roller base and a guide roller. The guide roller base is fixed on a structural platform. The guide roller is arranged on the guide roller base. The guide section device for the billet continuous casting machine is characterized in that: the guide roller comprises a water-cooled bearing support, a roller bearing, a roller and a rotary joint; the roller is arranged on the water-cooled bearing support by the roller bearing; a water cooling passage is formed in the roller; the rotary joint is arranged at one end of the roller and is communicated with the water cooling passage. In the device of the invention, the guide roller has a water cooling structure and long service life and is convenient to assemble, disassemble and maintain so as to improve the continuous working time of the whole continuous casting machine.

Owner:WISDRI ENG & RES INC LTD

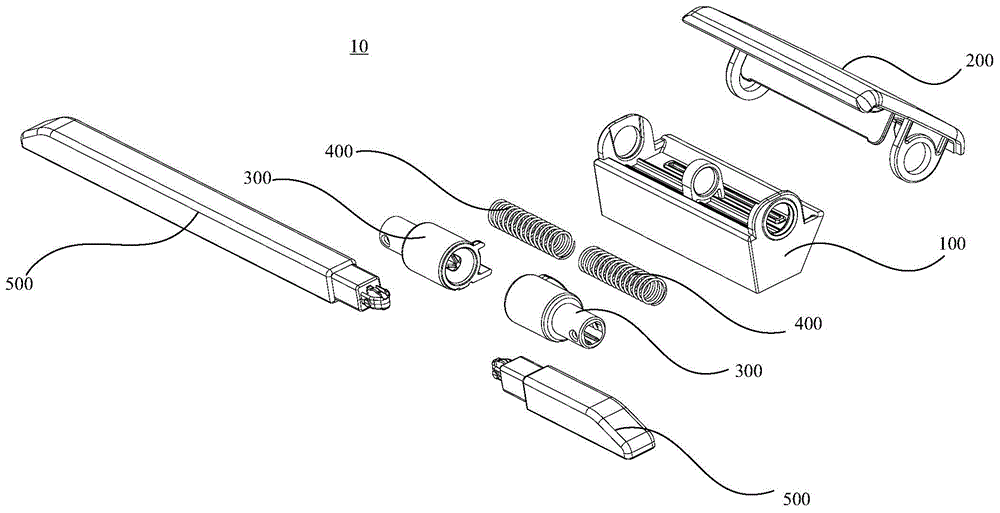

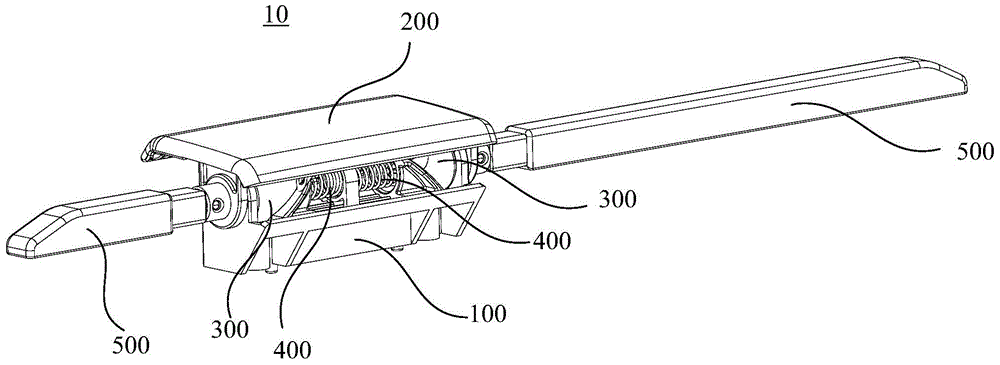

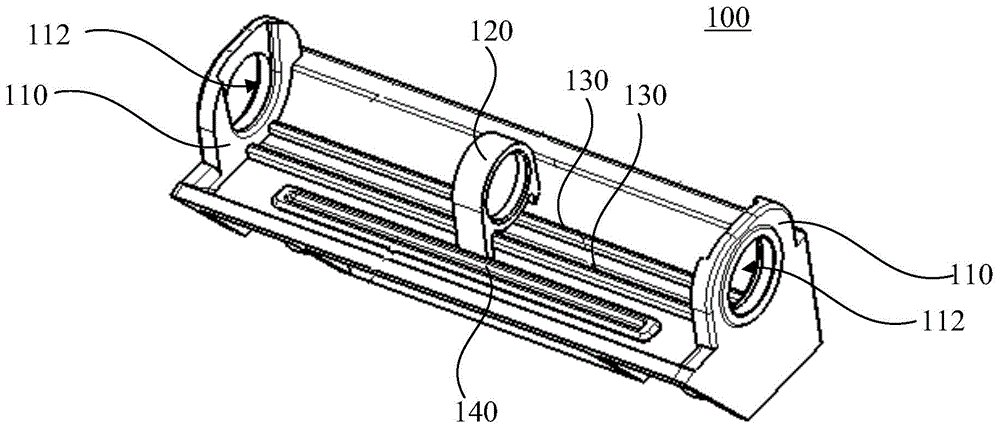

Double-hook locking device of storage box

InactiveCN103556895APrevent abnormal openingControl Assembly ClearanceWing fastenersEngineeringWrench

The invention discloses a double-hook locking device of a storage box for locking the storage box. The double-hook locking device comprises a support main body, an operation wrench, two driving arms, two reset springs and two locking hooks, wherein the inner surface of the operation wrench protrudes to form two contacts; the driving arms comprise driving arm bodies and driving arm shaft necks which are integrally formed, the outer surfaces of the driving arm bodies can form guiding inclined surfaces in the extruding manner, and the contacts can slide on the guiding inclined surfaces; when the storage box is in a locking state, end parts of the two locking hooks are clamped into lock catch holes in the side wall of the storage box, the two locking hooks are additionally provided with a turnover hinge of an outer cover plate of the storage box, and thus a four-point locking position is formed; the locking force distribution is uniform, and an assembling clearance and surface difference among the storage box and a periphery part are effectively controlled. Compared with the traditional mono-lock hook design, the double-hook locking device of the storage box can effectively avoid abnormal opening of the storage box, secondary harm to a passenger is avoided. The double-hook locking device of the storage box provided by the invention has the advantages that the structure is simple and compact, the space usage is small, and the service life is long.

Owner:SHENZHEN ZHIHENG PLASTIC

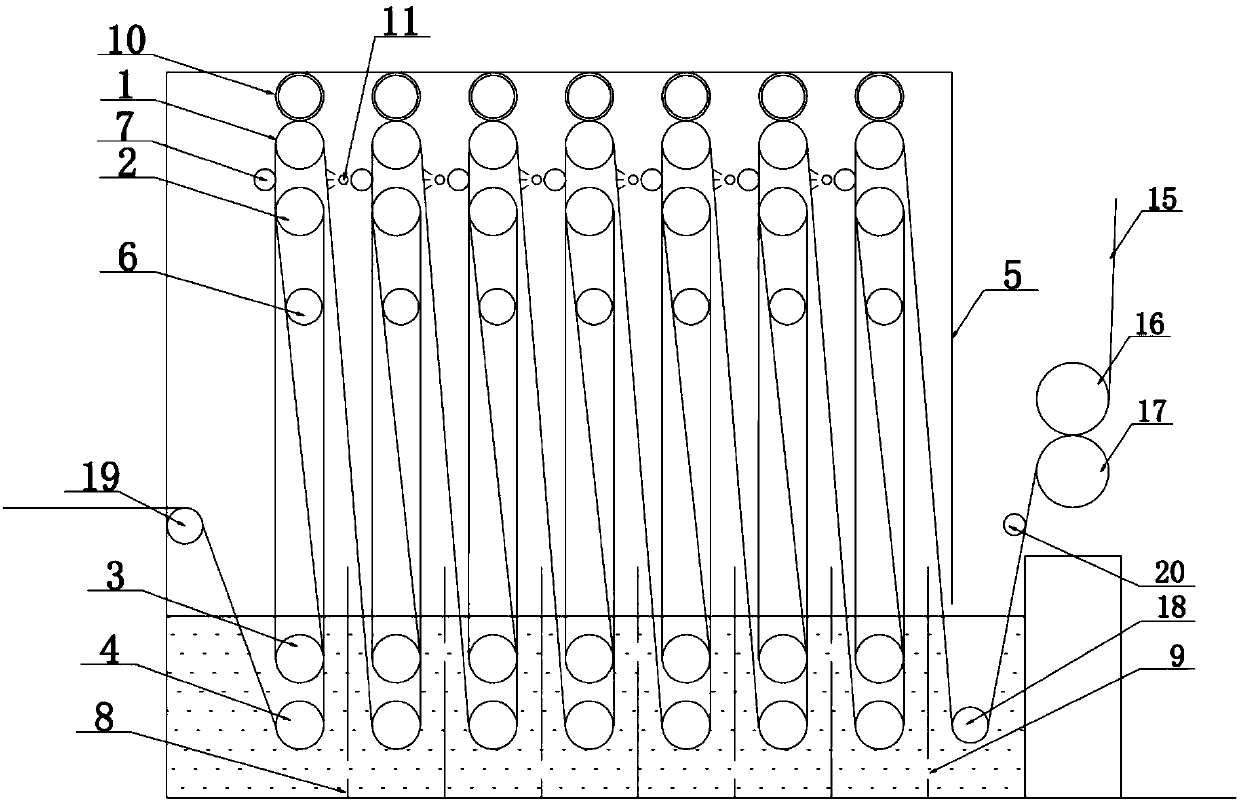

Vertical efficient water washer

PendingCN107558045AEasy to cleanImprove washing effectMechanical cleaningPressure cleaningEngineeringStructural engineering

The invention discloses a vertical efficient water washer which comprises a rectangular box. At least two groups of fabric guide components are arranged in the rectangular box, the fabric guide components comprise first fabric guide rollers, second fabric guide rollers, third fabric guide rollers and fourth fabric guide rollers, a fur brush roller is arranged between each second fabric guide roller and the corresponding third fabric guide roller, a beating and expanding roller is arranged between each first fabric guide roller and the corresponding second fabric guide roller, the diameters ofthe second fabric guide rollers and the third fabric guide rollers are larger than that of the first fabric guide rollers and the second fabric guide rollers, partition plates are arranged among the fabric guide components on the lower portion of the rectangular box, and circulation openings are formed in the partition plates. According to the water washer, fabric surfaces are rubbed, fabrics arebeat, washed and combed, washing effects of the fabrics are further improved, a water washer box is compact in box structure and divided into a plurality of washing spaces, the fabric storage quantityof the water washer is improved, and the washing effects of the fabrics are improved.

Owner:SHANDONG GUANGTAI ENVIRONMENTAL TECH CO LTD

Three-directional roll riveting equipment of through-flow fan blade

The invention discloses three-directional roll riveting equipment of a through-flow fan blade, and belongs to the technical field of the roll riveting equipment of the through-flow fan blade. The three-directional roll riveting equipment comprises a base, a roll riveting system, a fixing and driving system, a guiding system and a conduction system, wherein the roll riveting system comprises a roller row; the roller row is arranged parallel to the base and comprises an upper roller row, a lower front roller row and a lower rear roller row; the upper roller row is arranged over a machined blade wheel and is provided with an upper roll riveting hob set of which a hob edge is vertically downward; the lower front roller row and the lower rear roller row are symmetrically arranged at two sides of a vertical plane on which a center line of the machined blade wheel is positioned and are provided with a lower front roll riveting hob set and a lower rear roll riveting hob set of which hob edges are obliquely upward respectively; and the upper roll riveting hob set, the lower front roll riveting hob set and the lower rear roll riveting hob set form a three-directional roll riveting structure. During machining, the blade wheel is uniformly stressed in three directions so as to ensure that machining pressure is always aligned with the center, the coaxial heights of central discs of the blade wheel are consistent, and the blade wheel is prevented from performing circular runout.

Owner:宁波市天超通风设备有限公司

Bearing system on paper transferring roller of printing machine

The invention provides a bearing system on a paper transferring roller of a printing machine. The bearing system comprises the paper transferring roller, a cylinder bearer arranged on the end face of the paper transferring roller, a journal arranged on the extension side of the cylinder bearer and a rolling bearing arranged on the journal in a sleeving mode, wherein the rolling bearing is installed in sealed space composed of a shaft sleeve, an upper end cover, a left end cover and a right end cover, and a dust ring, a check ring and a seal ring are installed in the sealed space. The rolling bearing comprises an inner rolling bearing ring and an outer rolling bearing ring, the outer rolling bearing ring is provided with first bolt holes, the rolling bearing is fixed to the upper end cover through the first bolt holes, and the inner rolling bearing ring is provided with second bolt holes and is fixed to the shaft sleeve through the second bolt holes. The bearing system has the beneficial effects that the structure is reasonable, the rotation accuracy is high, the radial clearance is small, and the usage rate of the bearing can be increased.

Owner:TIANJIN ZEYANG PRINTING

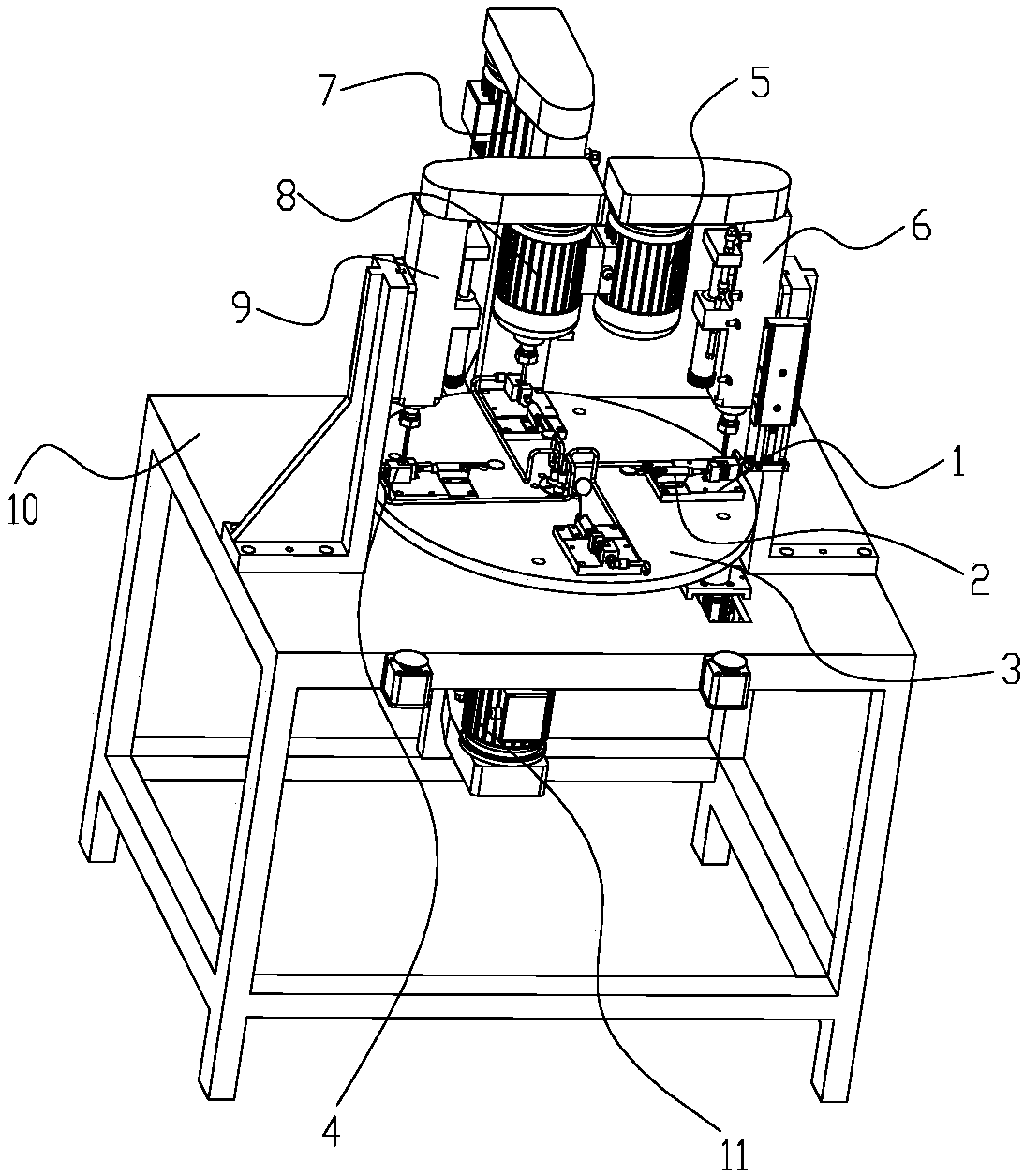

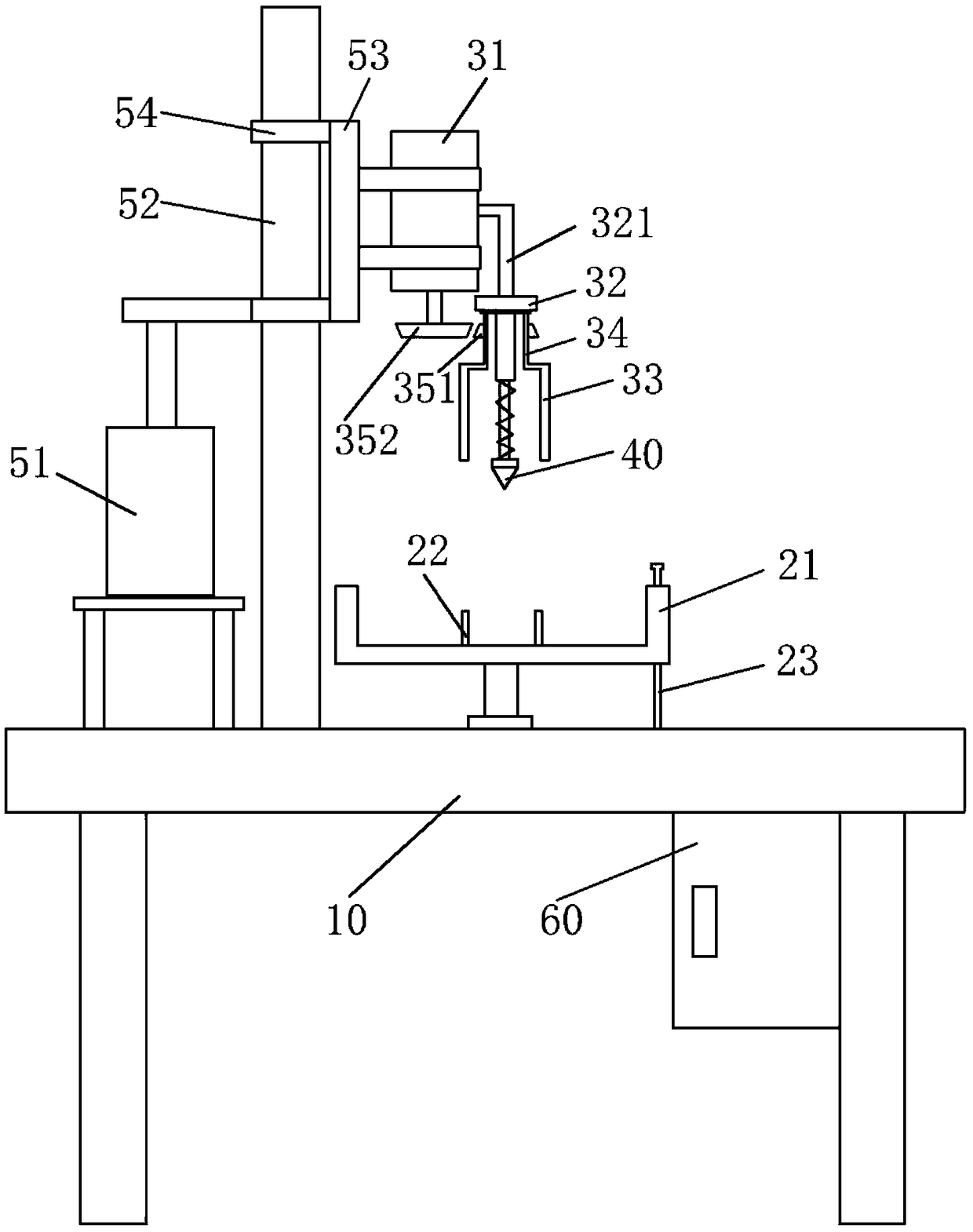

Machining equipment for wire harness fixing block

InactiveCN107553139AAchieve drilling effectRealize the effect of chamferingOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention provides machining equipment for a wire harness fixing block. The machining equipment comprises a work platform capable of rotating by itself, four stations, a drilling mechanism, a reaming mechanism and a first chamfering mechanism. The four stations are fixed to the work platform, the included angle between every two adjacent stations is 90 degrees, and a clamping mechanism used for clamping and fixing the wire harness fixing block is fixed to each station. The drilling mechanism is fixed to the position over the first station and used for drilling the wire harness fixing block. The reaming mechanism is fixed to the position over the second station and used for reaming the wire harness fixing block. The first chamfering mechanism is fixed to the position over the third station and used for chamfering the wire harness fixing block. The equipment is simple in structure and low in cost.

Owner:JIANGYIN JIANGSHI AUTO PARTS

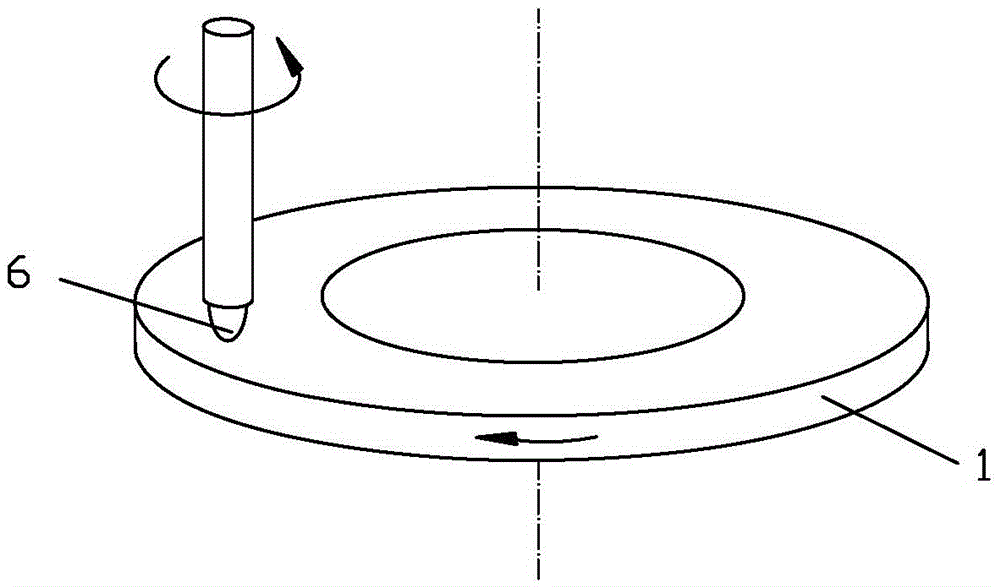

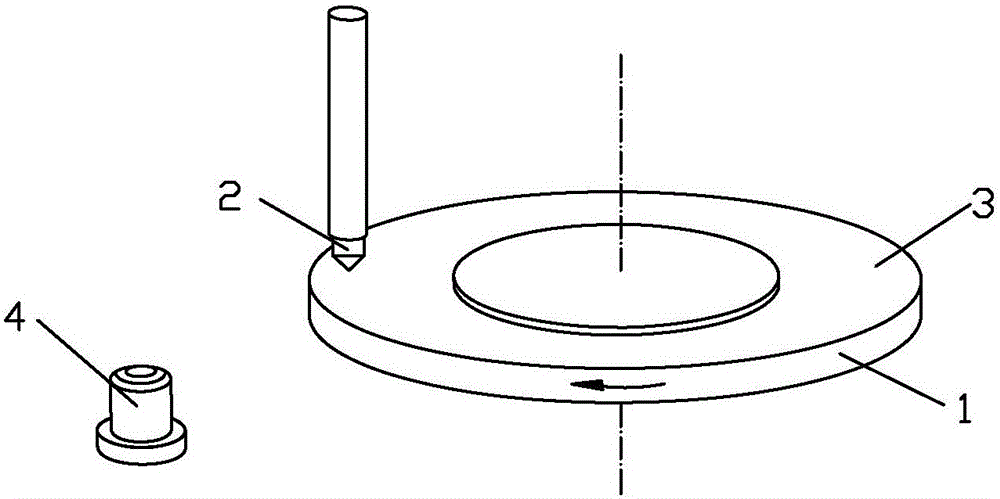

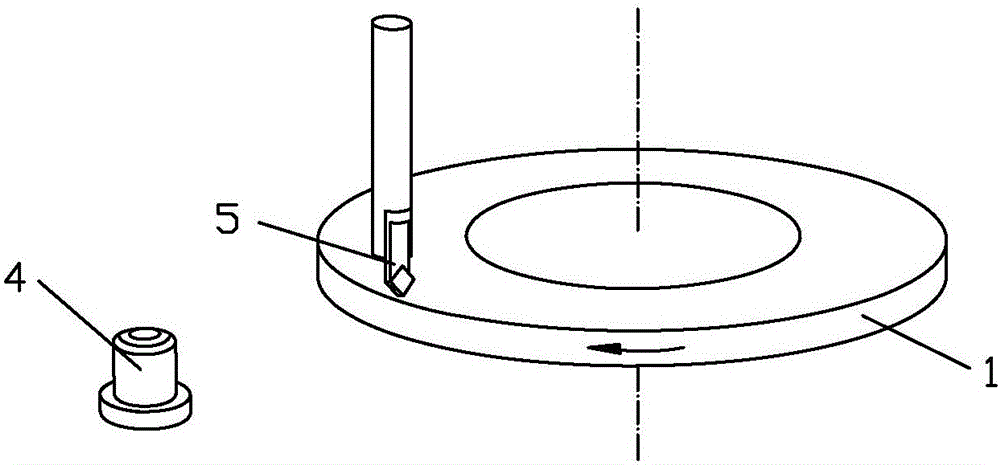

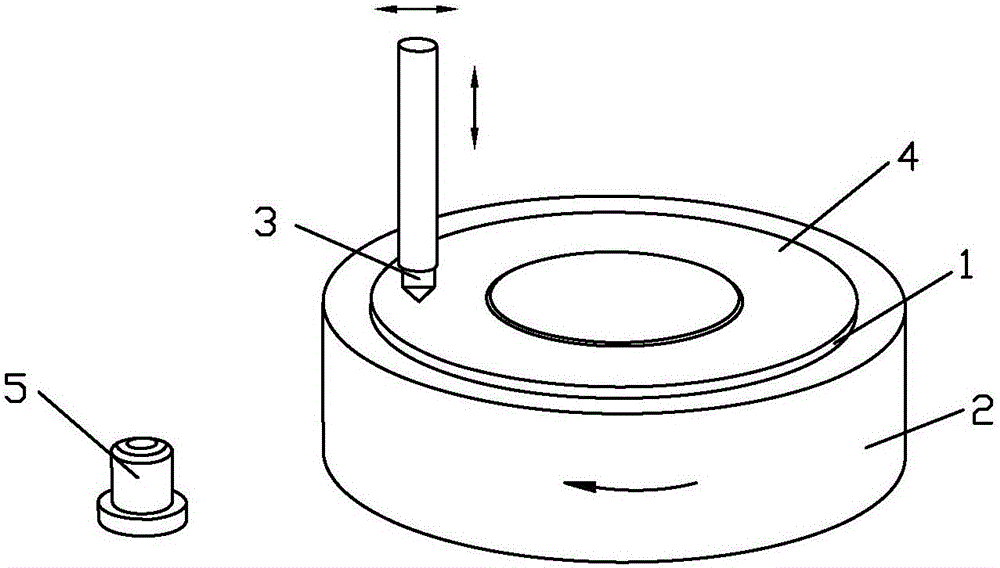

Method for machining optical fiber stress rod

ActiveCN103878649AAvoid runoutHigh surface finishRevolution surface grinding machinesSurface finishGrinding wheel

The invention discloses a method for machining an optical fiber stress rod. The method includes the steps of making the optical fiber stress rod with a conventional method, and grinding the optical fiber stress rod. The method is characterized in that in the step of grinding the optical fiber stress rod, a grinding wheel of a grinding device is arranged to be perpendicular to the optical fiber stress rod, and the grinding wheel and the optical fiber stress rod oppositely move in the axial direction of the optical fiber stress rod while the grinding wheel and the optical fiber stress rod rotate respectively around shafts. Compared with the prior art, the method has the advantages that the grinding wheel of the grinding device is perpendicular to the optical fiber stress rod, in the grinding process, the direction of the friction force borne by the optical fiber stress rod is changed from the radial direction in the existing mode to the axial direction, radial jumping generated in the grinding process of the optical fiber stress rod is accordingly avoided, the machining accuracy is improved, and the smooth degree of the surface of the grinded optical fiber stress rod is remarkably improved compared with the existing mode; existing line contact between the grinding wheel and the optical fiber stress rod is changed into surface contact, and therefore the polishing effect is improved.

Owner:武汉长盈通光电技术股份有限公司

Spiral feeding device for solder splash

InactiveCN103090680AScientific and reasonable designSimple structureCharge manipulationFailure rateEngineering

A spiral feeding device for solder splash is characterized in that the feeding device includes a solder splash separator, the solder splash separator is provided with a feeding shaft, the feeding shaft is provided with spiral pieces, and one end of the feeding shaft is disposed on a bearing support through a bearing. The spiral feeding device for solder splash has the advantages of scientific and reasonable design, simple structure, low failure rate, high stability, safe and energy conservation and easy operation, thereby ensuring feeding efficiency and evenly feeding of solder splash recycling machine without blocking materials.

Owner:欧阳儒友

Combined machine tool for manufacturing hollow shaft

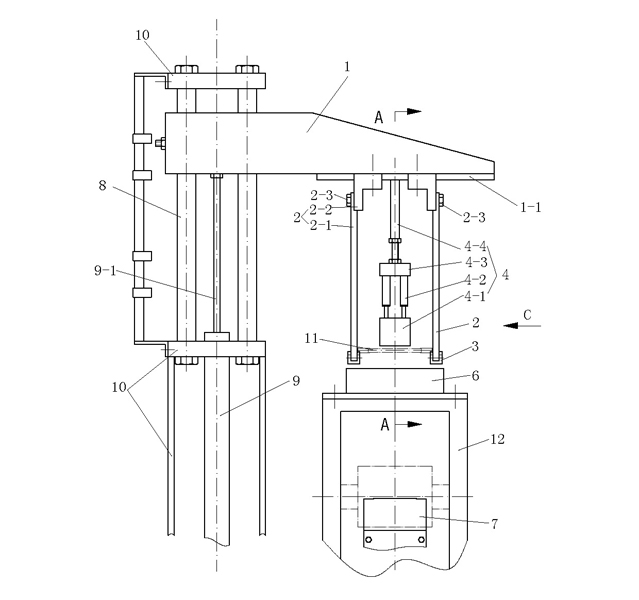

ActiveCN113635059AAvoid shakingAvoid runoutOther manufacturing equipments/toolsMaintainance and safety accessoriesStructural engineeringMachine

The invention belongs to the technical field of combined machine tools, and discloses a combined machine tool for manufacturing a hollow shaft. The combined machine tool comprises a rack, wherein a cutting mechanism is arranged on the top face of the rack, a connecting block is arranged at the right end of the top face of the rack, a fixing plate is fixedly mounted on the left side face of the connecting block, a lengthening plate is fixedly mounted in the middle of the fixing plate, and a first positioning shaft and a second positioning shaft are fixedly mounted on the front side face and the rear side face of the lengthening plate respectively. According to the combined machine tool, a connecting wire harness is powered off through a control box, then an electromagnet loses magnetism, and at the moment, a first push-out spring and a second push-out spring which are in a compressed state can push a cutting knife and a movable frame to make contact with a raw material respectively under the action of elastic force; and during cutting, a roller and the cutting knife position the space, in the hollow shaft, of the lengthening plate, so that shaking of the lengthening plate is avoided, radial run-out caused by shaking of the lengthening plate during cutting can be avoided, and the machining precision of the device is improved.

Owner:南通南飞精密钣金有限公司

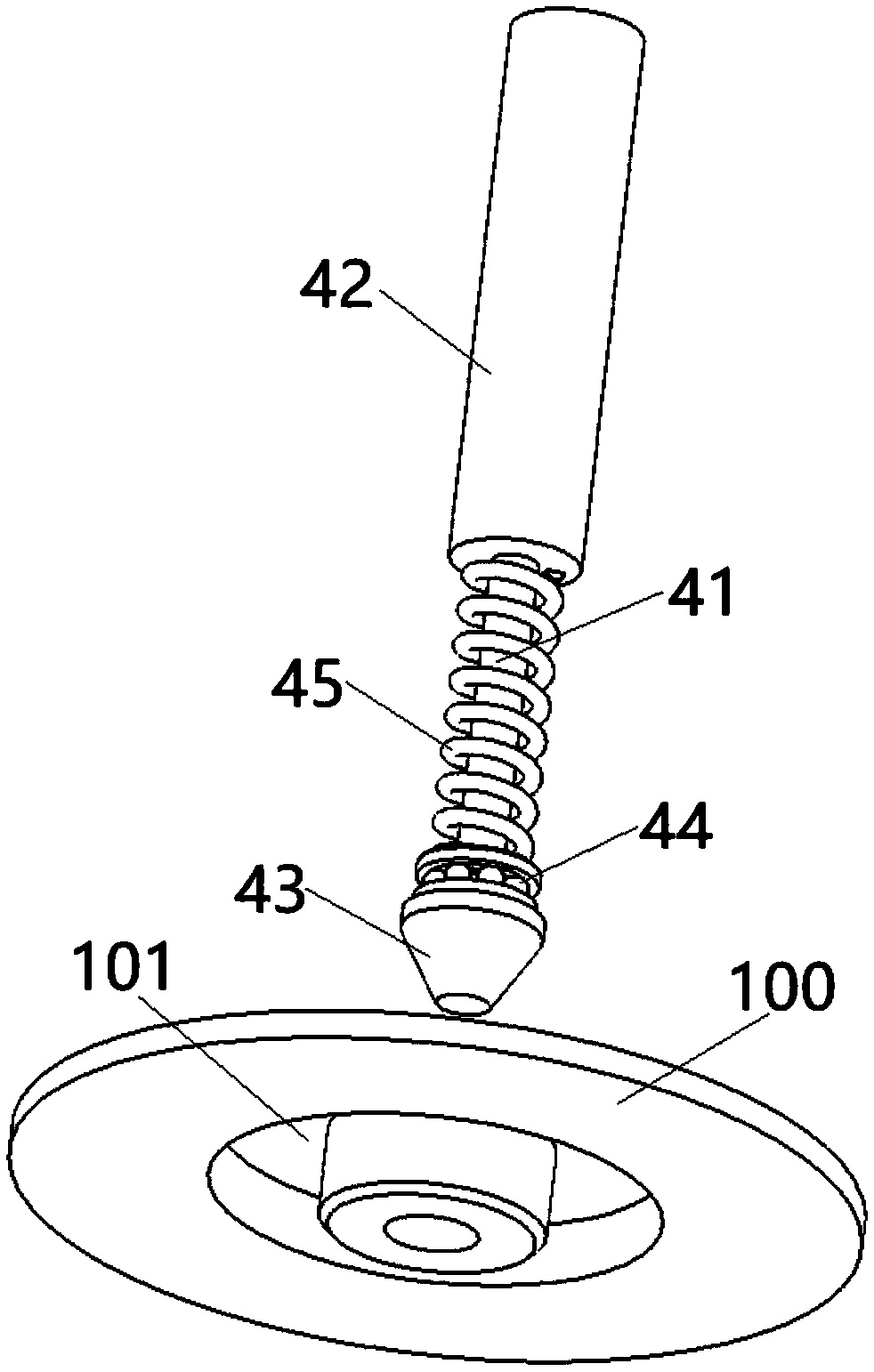

Polishing device of lamp holder

InactiveCN108637825AAvoid Horizontal OffsetAvoid runoutEdge grinding machinesGrinding carriagesMotor driveEngineering

The invention discloses a polishing device of a lamp holder. The polishing device comprises a working table, a polishing mechanism and an object mechanism. The object mechanism comprises an object rotating disc. Locating protrusions are arranged in the object rotating disc. The polishing mechanism comprises an end plate, a polishing barrel, a locating assembly and a polishing motor capable of ascending and descending. The end plate is connected with the polishing motor. The polishing motor drives the polishing barrel to rotate through a rotating pipe. A locating pipe sleeve is arranged in thepolishing barrel in a penetrating manner, and the top of the locating pipe is connected with the end plate. A locating rod stretches into the locating pipe sleeve and is sleeved with a locating spring. The two ends of the locating spring are connected with the locating pipe sleeve and the outer ring of a locating bearing. The locating bearing is arranged at the bottom of the locating rod in a sleeving manner, and the inner ring of the locating bearing is fixedly connected with the locating rod. The top of a locating head is fixedly connected with the inner ring of the locating bearing. According to the polishing device, effective polishing work can be carried out on the outer ring of the lamp holder, the labor intensity of workers is greatly reduced, the polishing efficiency is improved, and the polishing quality of the lamp holder is guaranteed.

Owner:嘉兴爱劳科斯智能照明有限公司

Tooth shape grinding clamp

ActiveCN103722457AReduce procurement costsImprove processing efficiencyMilling cuttersGrinding work supportsEngineeringMachine tool

The invention discloses a tooth shape grinding clamp. The tooth shape grinding clamp comprises a base, a rotating shaft mechanism, a support assembly and a horizontal movement mechanism, wherein the base is used for being fixedly connected with a machine tool workbench, the rotating shaft mechanism is used for positioning, clamping and rotating a workpiece, the support assembly is used for controlling the installation direction of the workpiece, the horizontal movement is used for automatically adjusting the position of the support assembly in a profiling mode, the horizontal movement is installed on the base, the support assembly is arranged on the horizontal movement, and the rotating shaft mechanism is fixed on the support assembly. By means of the tooth shape grinding clamp, cutter grinding of a working tooth shape is achieved through the axial movement of a machine tool platform top and the radial movement of a clamp support, and feeding of separated teeth and a spiral line of the workpiece is achieved through the rotation of a rotating shaft. The tooth shape grinding clamp expands the range of machining of an ordinal tool grinding machine cutter, reduces the procurement cost of equipment and improves the machining efficiency.

Owner:重庆工具厂有限责任公司

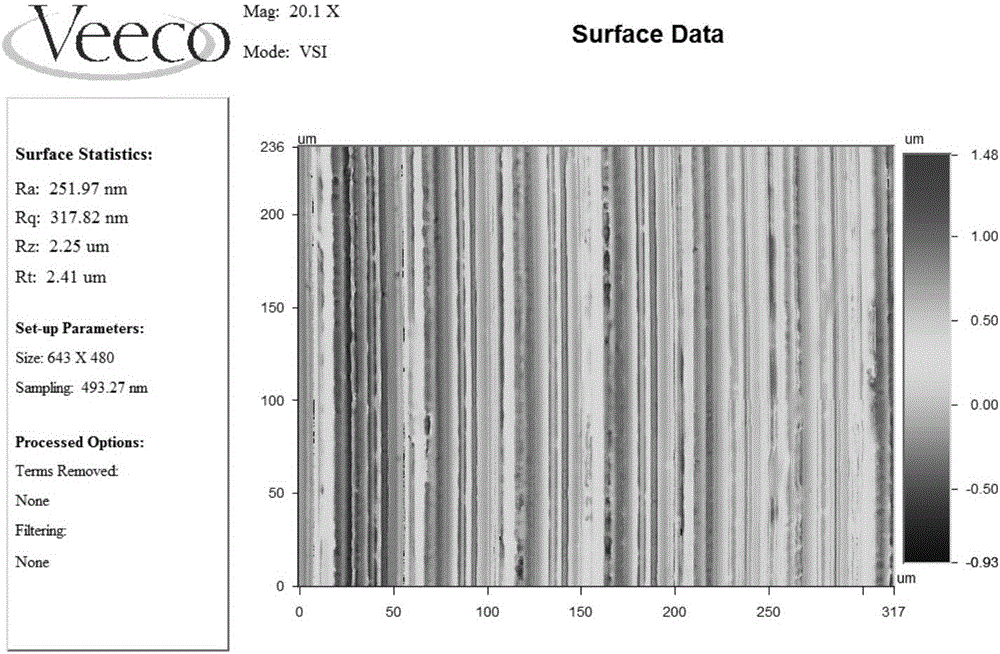

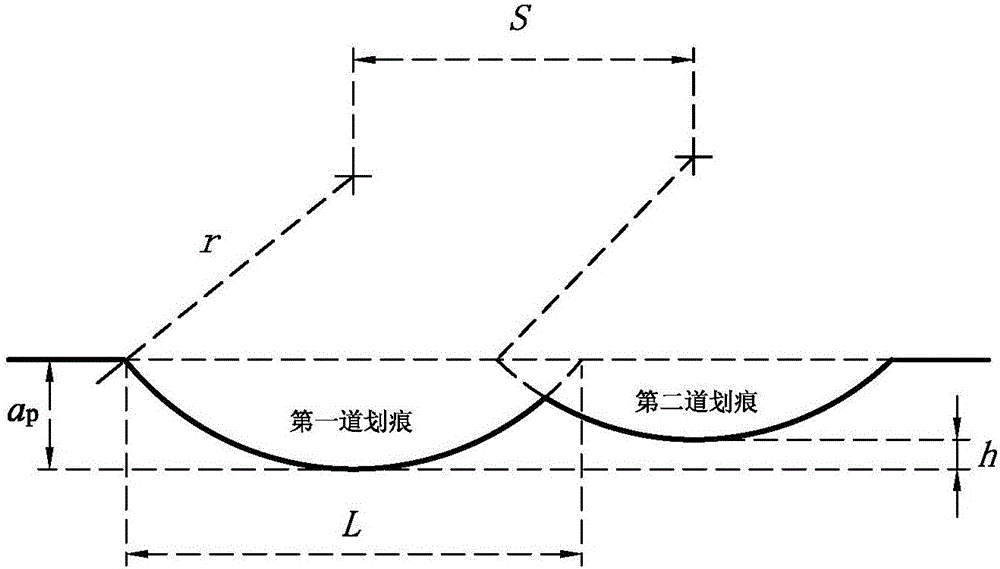

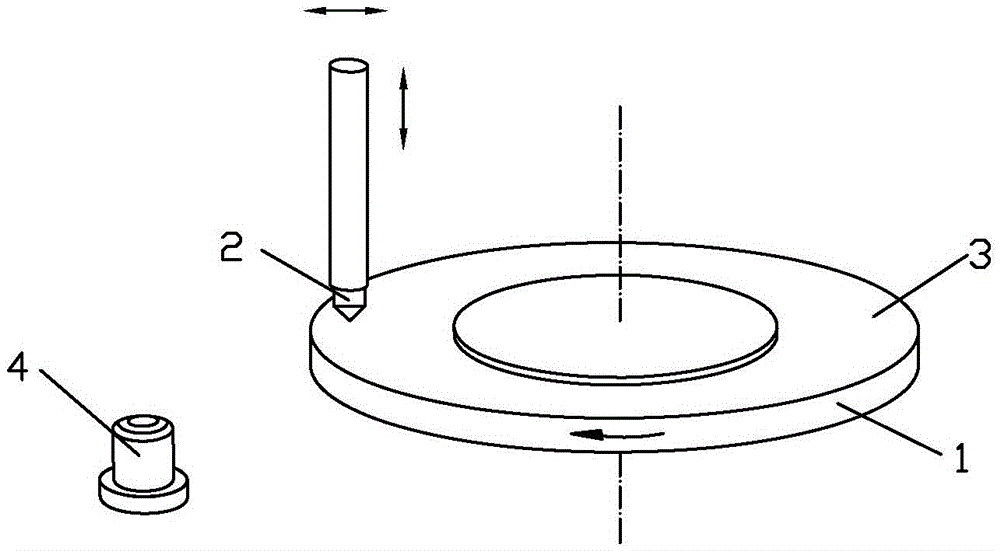

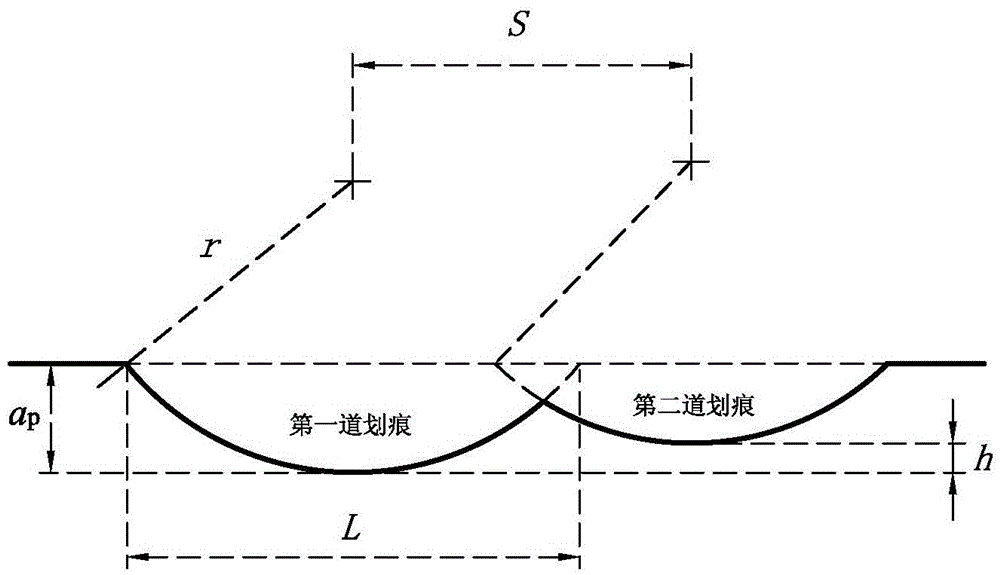

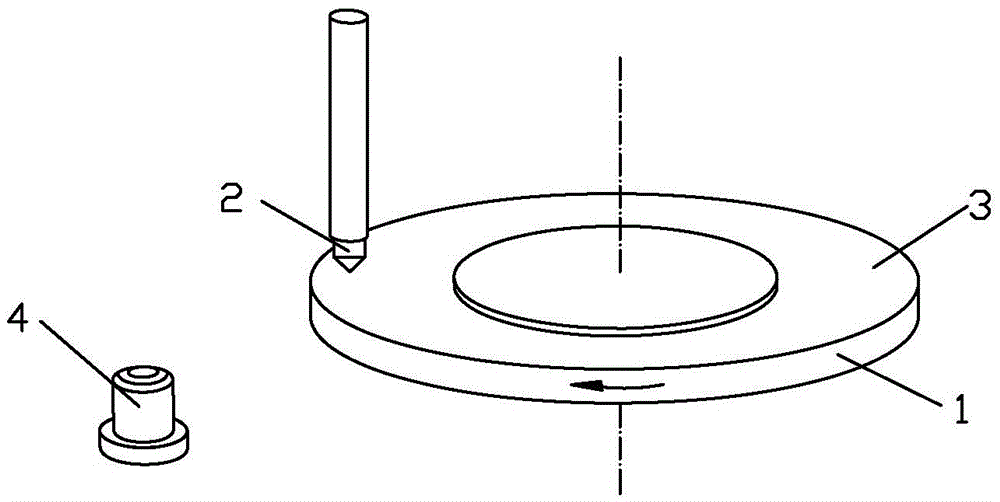

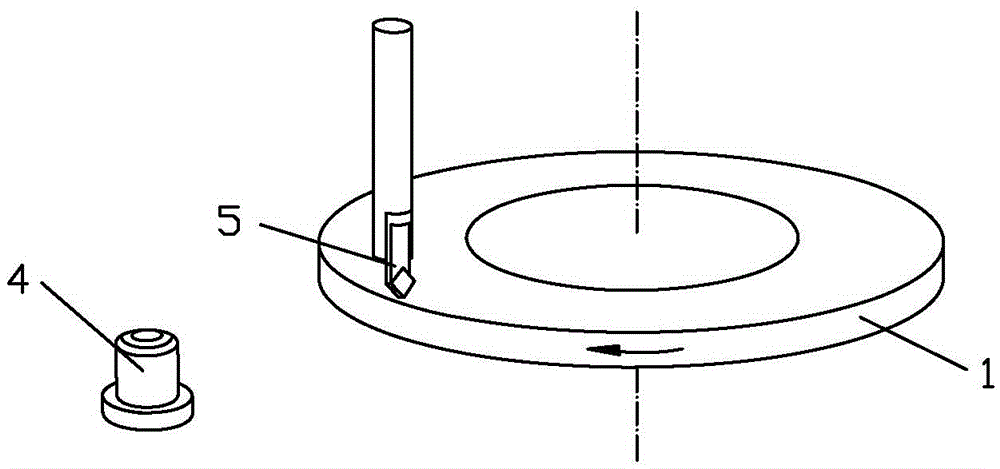

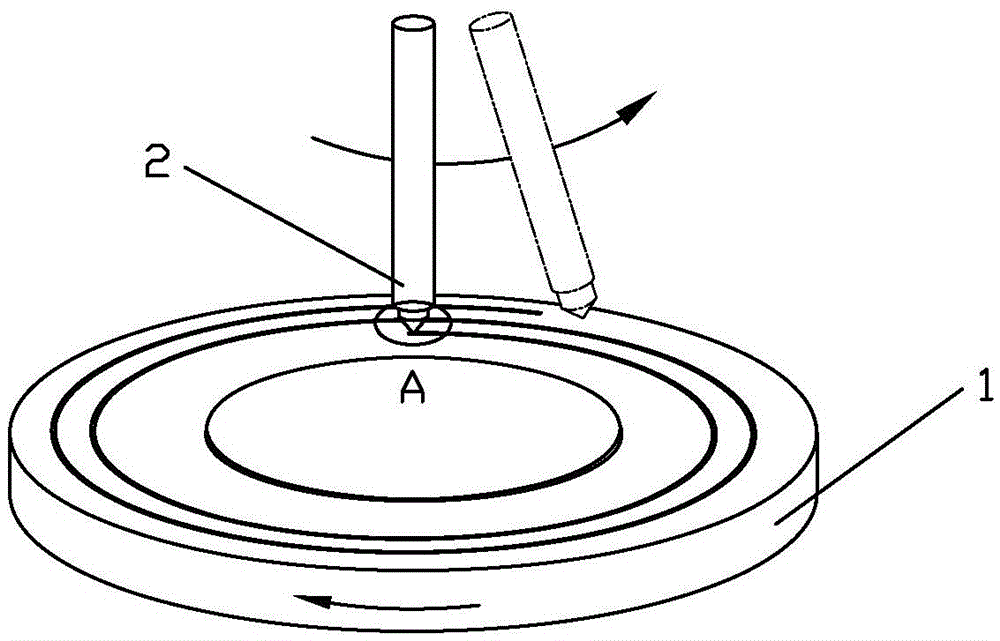

Single abrasive particle continuous scratching test method for CBN tool pre-maintenance ferrous metal test piece

ActiveCN105717031AHigh shape accuracyHigh surface finishIndividual particle analysisMaterial removalAcoustic emission

The invention discloses a single abrasive particle continuous scratching test method for a CBN tool pre-maintenance ferrous metal test piece, and belongs to the field of material performance testing in machining and precision and ultra-precision machining.The ferrous metal test piece is fixed to an electric main shaft, and online dynamic balance is conducted on the test piece; a CBN tool is used for conducting plate repairing on the test piece to meet the requirements for end face run-out and roughness needed for testing; a tool head with the top end fixedly connected with a single abrasive particle is replaced, and tool setting is conducted in the replacing process; finally, scratching testing is conducted, the test piece rotates at an appointed rotating speed, the tool head undercuts to the appointed cutting depth and conducts radial feeding, spiral scratches are formed on the end face of the test piece, and scratching force, acoustic emission signals and physical quantity are acquired by a measuring system in the process.By means of the method, it can be guaranteed that the abrasive particle and the test piece make stable contact on a long scratching distance, high-speed and high-precision scratching is achieved, and related test results can be used in studies of material removal mechanism in the frictional abrasion process and abrasion machining.

Owner:HUAQIAO UNIVERSITY

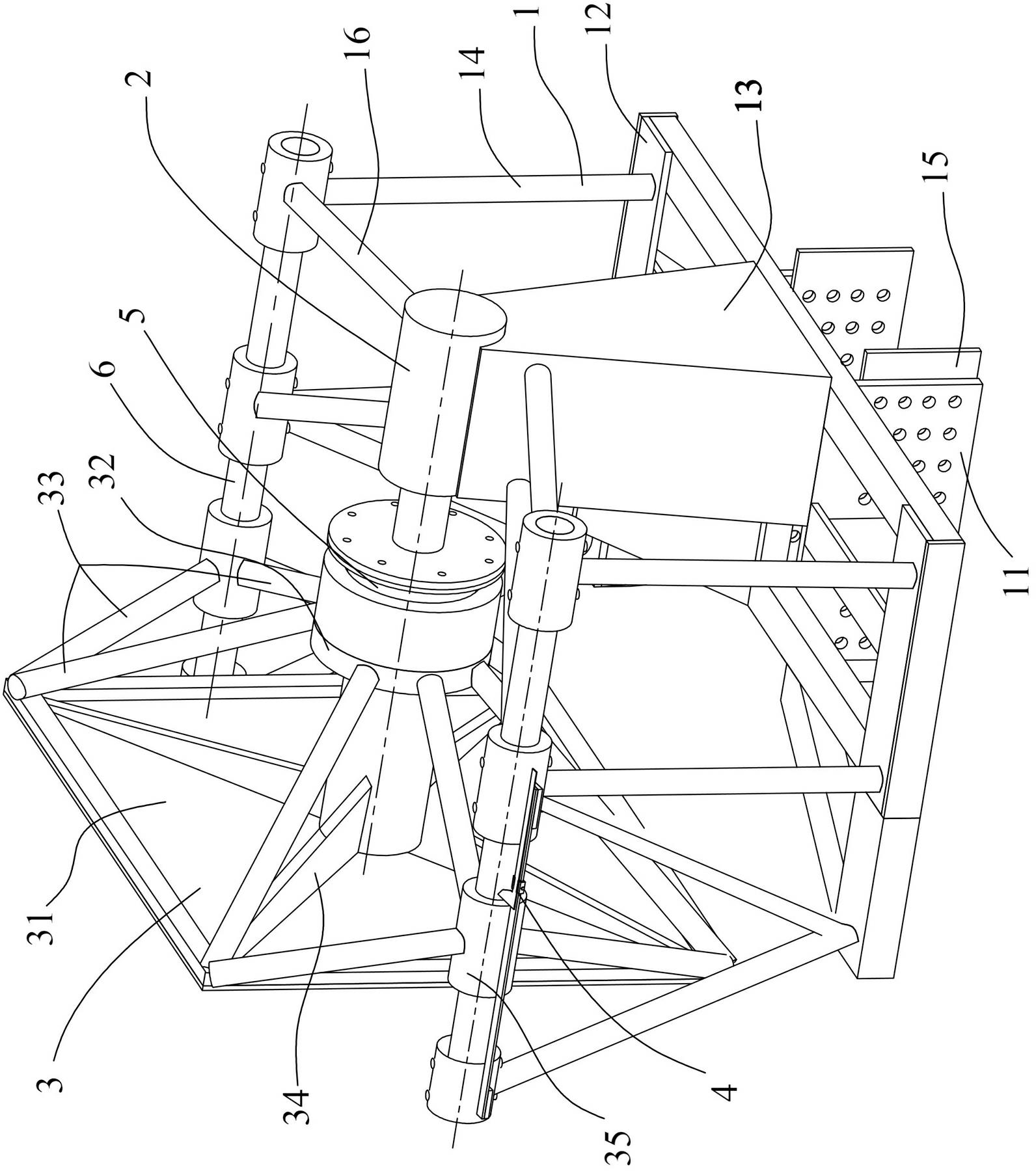

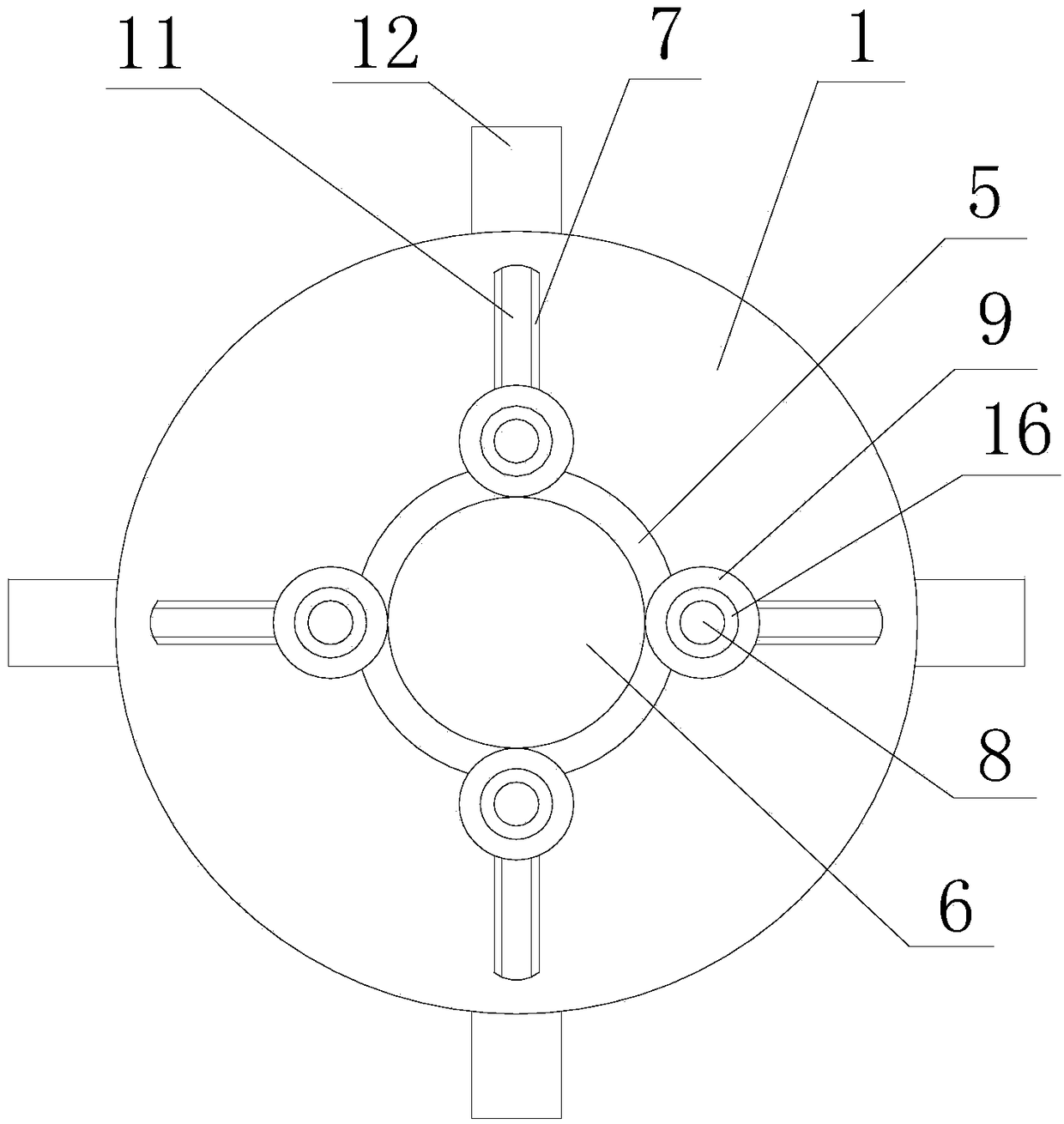

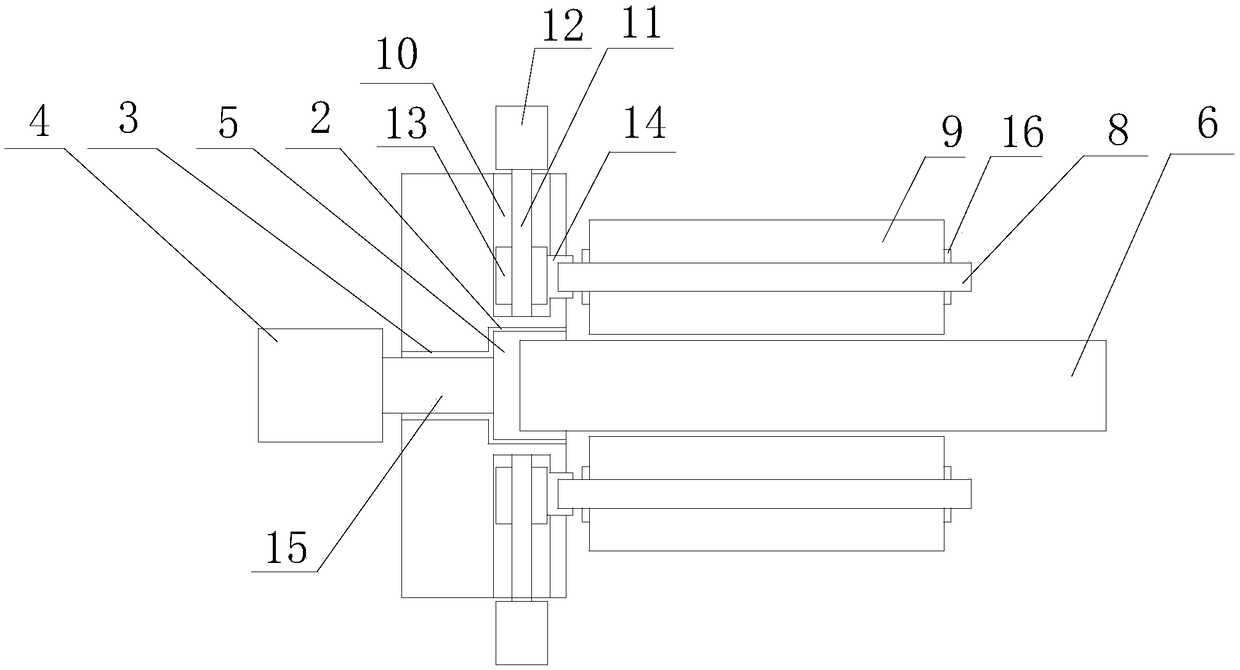

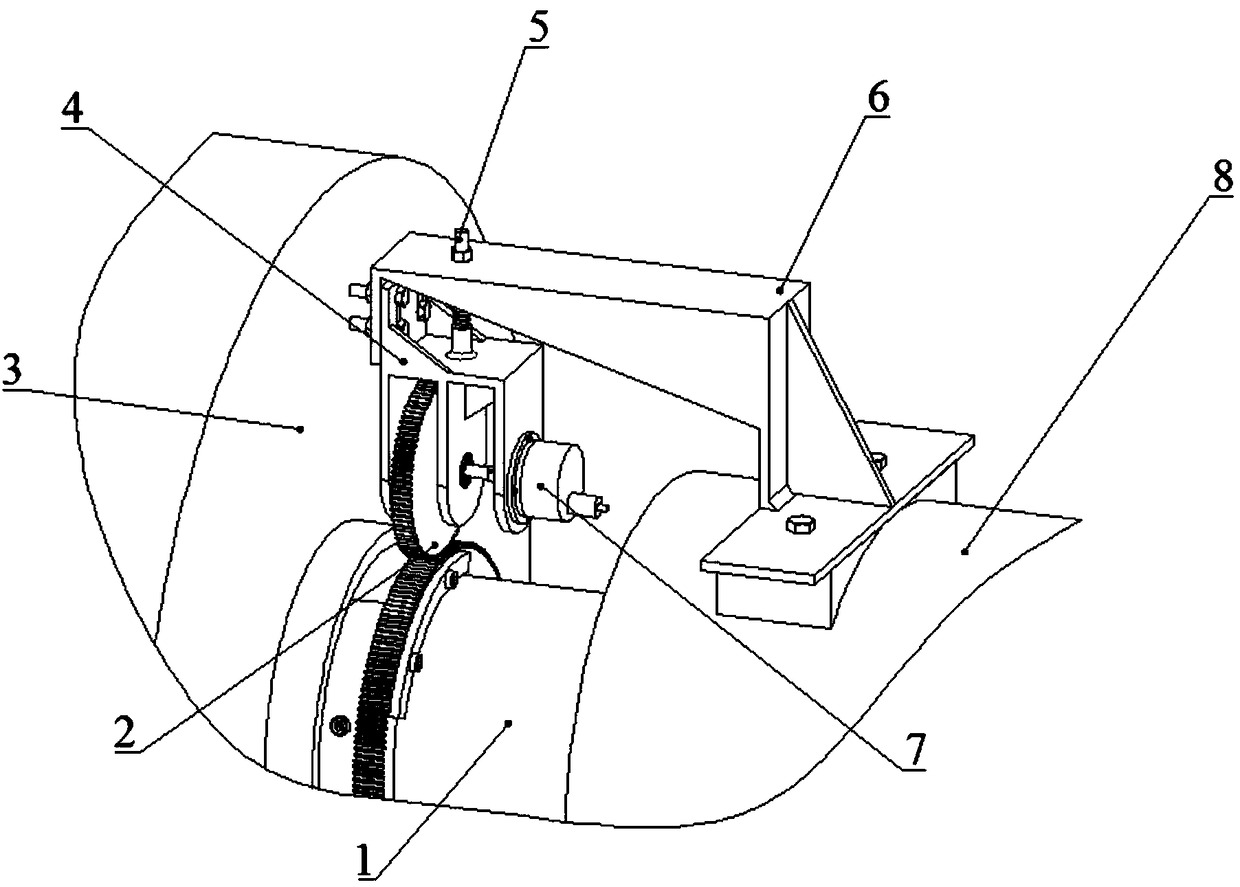

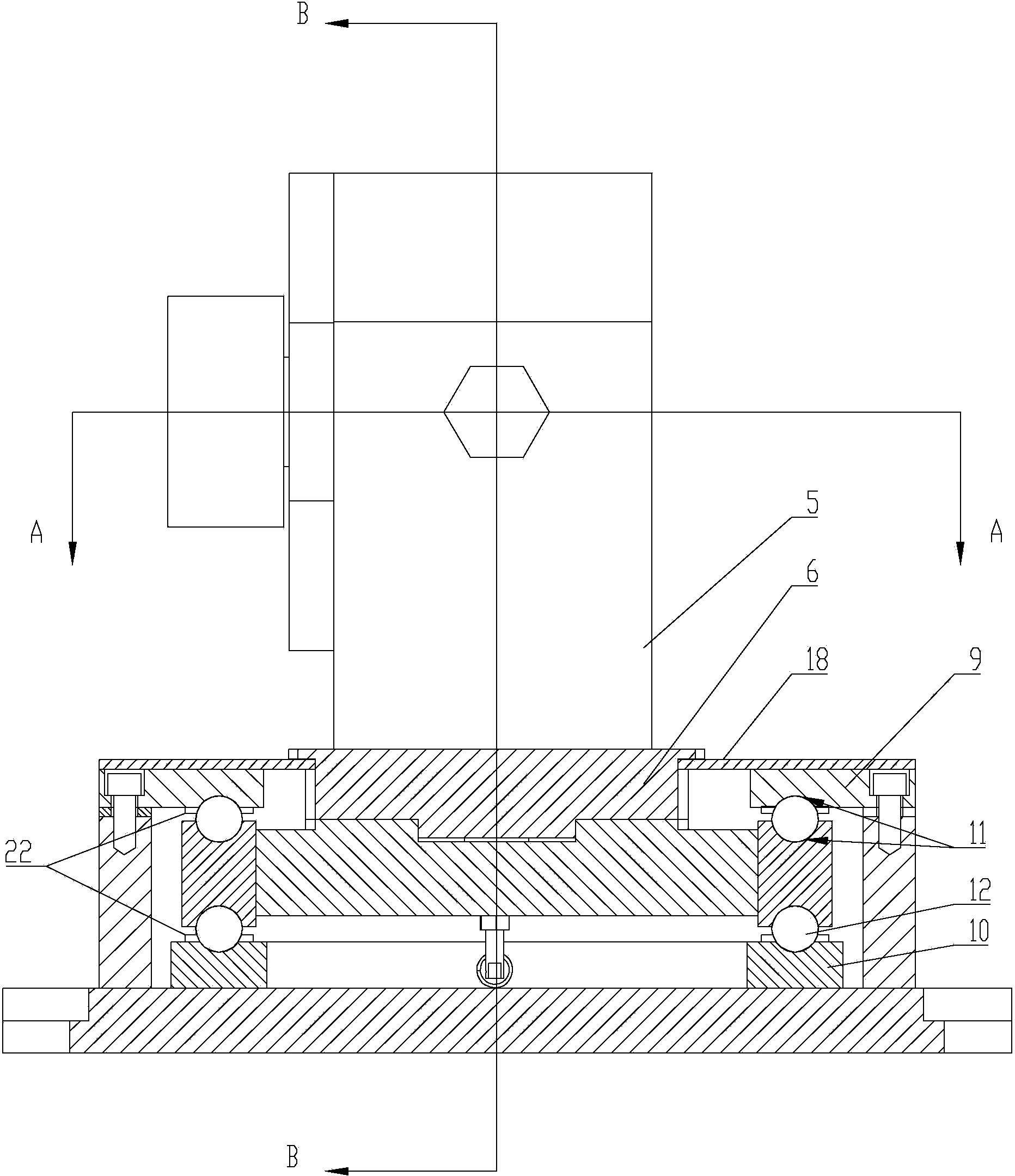

Test system for vertical compression power generation module

PendingCN113419106ARealize lifting functionSmooth liftPiezoelectric/electrostriction/magnetostriction machinesCurrent/voltage measurementSystem pressureElectric machinery

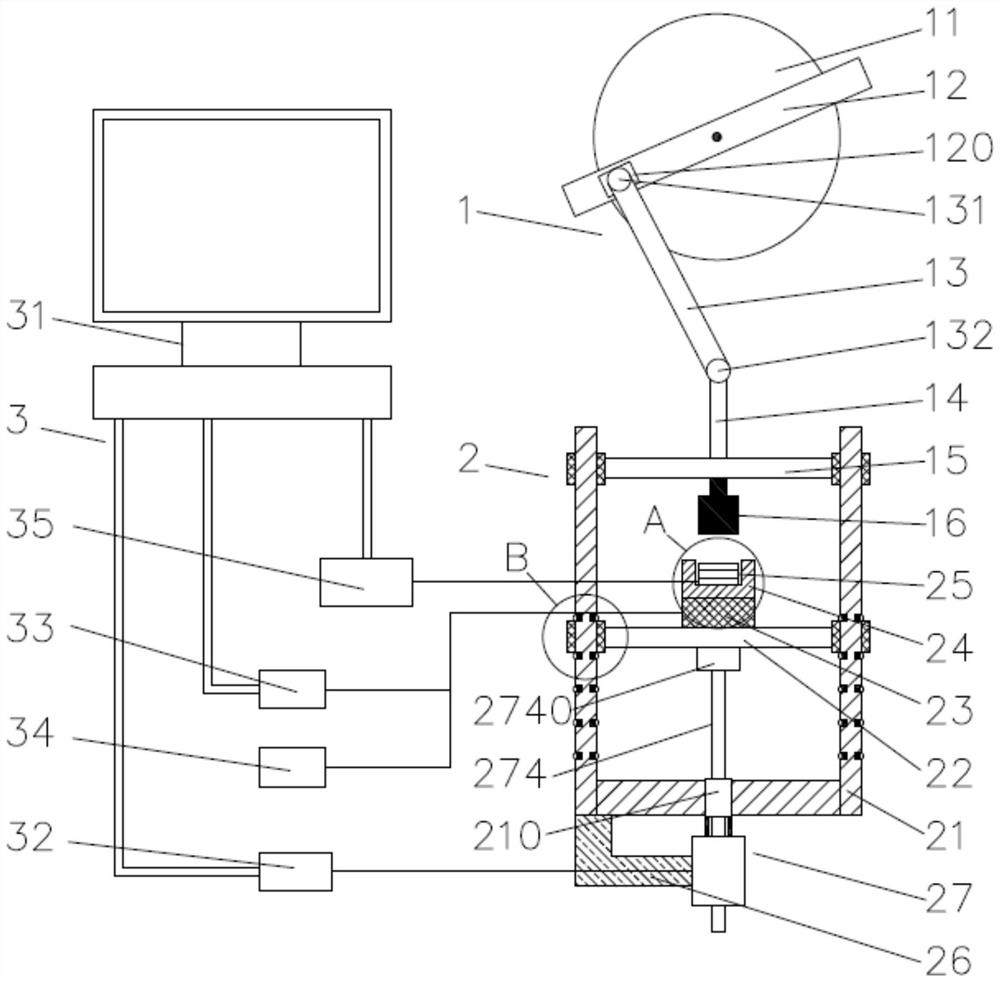

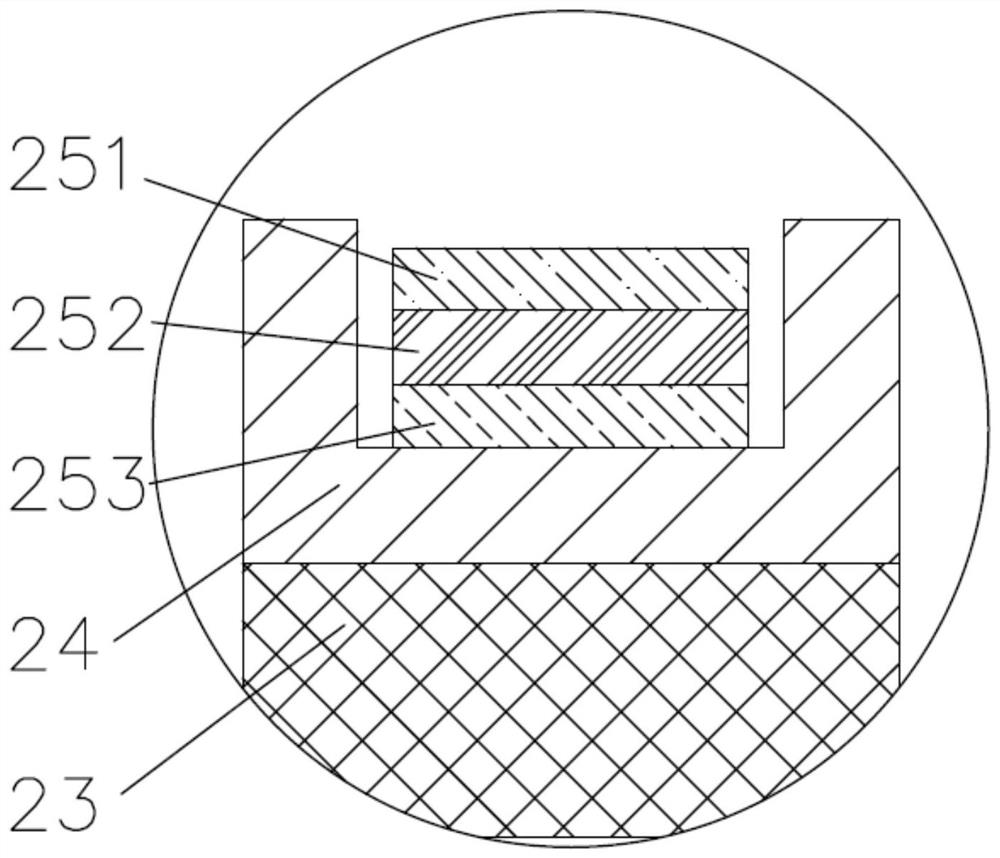

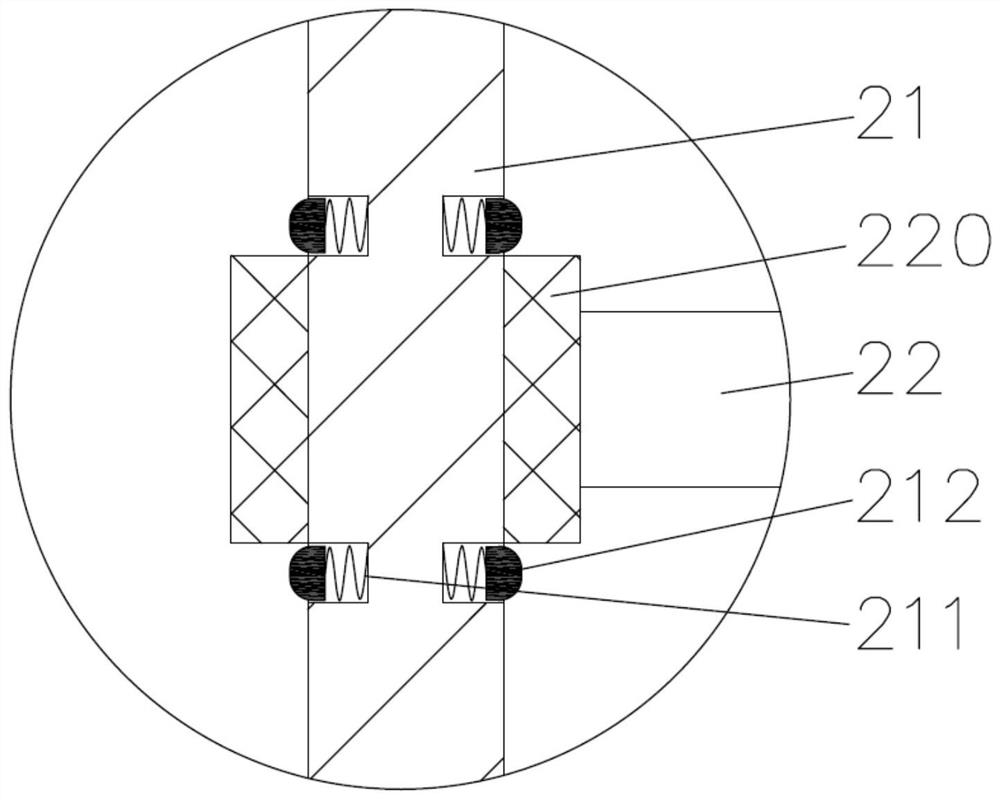

The invention provides a test system for a vertical compression power generation module. The test system comprises a reciprocating stamping assembly (1), a lifting test assembly (2) and monitoring equipment (3), the lifting test assembly (2) is arranged at the lower end of the reciprocating stamping assembly (1); the reciprocating stamping assembly (1) comprises a rotating disc (11), a fixing rod (12), a first connecting rod (13), a second connecting rod (14), a first sliding plate (15) and an impact hammer (16). The lifting testing assembly (2) comprises a supporting frame (21), a second sliding plate (22), a pressure sensor (23), a module container (24), a pressure testing module (25), an L-shaped connecting rod (26) and a lead screw motor (27). The system is controllable in pressure intensity, good in repeatability, capable of accurately measuring the pressure power generation module under the conditions of low frequency and high pressure value, and wide in measurement range; and meanwhile, the system can measure values of current, voltage and pressure changing along with time in real time, and analysis of the performance of the pressure power generation assembly is facilitated.

Owner:CHONGQING UNIV OF ARTS & SCI

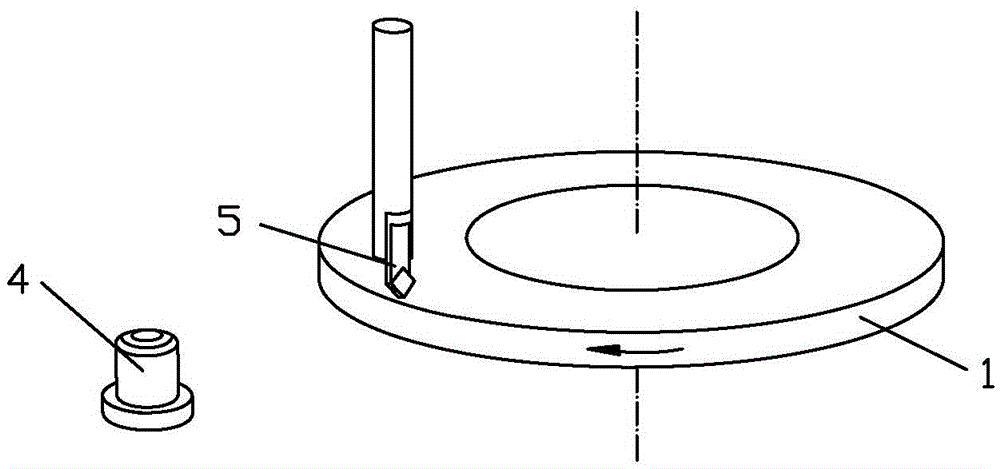

Single-grain continuous scratching interference behavioral testing method for spherical grinding head pre-maintenance rigid and brittle test piece

ActiveCN105738281AHigh control precisionAccurate and stable collectionUsing mechanical meansMaterial analysisElectricityHigh-speed grinding

The invention discloses a single-grain continuous scratching interference behavior testing method for a spherical grinding head pre-maintenance rigid and brittle test piece, and belongs to the field of material performance testing and precision and ultra-precision machining in machining.The method comprises the steps that the rigid and brittle test piece is fixed to an electric spindle, and online movable balance is performed on the test piece; then, a spherical grinding head is adopted for performing disc maintenance on the test piece, and the requirement for testing needed end face run-out and roughness is met; then, a reloading top end is fixedly connected with a tool head for single grains, and tool setting is performed in the displacement process; finally, scratching testing is performed, the test piece rotates at the designated rotating speed, a tool head performs radial feed with the designated cutting depth, interference spiral scratches are performed on the end face of the test piece, and a measuring system collects scratching force, acoustic emission signals and other physical quantity in the process.According to the single-grain continuous scratching interference behavior testing method, interference behaviors among the grains in the high-speed grinding process can be simulated, and the related testing result can be used for intensive study of a grinding mechanism and optimization of grinding parameters.

Owner:HUAQIAO UNIVERSITY

Transmission shaft spacing mechanism for wire rewinding machine

The invention relates to a transmission shaft spacing mechanism for a wire rewinding machine. The wire rewinding machine comprises a frame, a rotating shaft which is arranged on the frame and used for assembling a wire coil, and a drive part which is arranged on the frame and used for driving the rotating shaft to rotate, wherein the drive part drives the rotating shaft to drive the wire coil to rotate, and is connected with a transmission shaft; the transmission shaft is connected with the rotating shaft through a coupler; the frame is provided with a spacing mechanism for spacing the transmission shaft; the spacing mechanism comprises a first spacing block and a second spacing block; a first notch part is formed on the first spacing block; a second notch part is formed on the second spacing block; the first notch part and the second notch part are oppositely arranged; and when the first spacing block is matched with the second spacing block, the transmission shaft simultaneously passes through the first notch part and the second notch part. By utilizing the transmission shaft spacing mechanism, the rotating range of the transmission shaft is limited through the spacing part, and the radial runout of the transmission shaft in the turning process can be effectively avoided.

Owner:江苏省电力公司太仓市供电公司 +3

Testing method of continuous scratching interference behavior of single abrasive grain of black metal test piece pre-repaired by CBN tool

ActiveCN105538154AHigh control precisionAccurate and stable collectionGrinding feed controlGrinding machinesElectricityDynamic balance

The invention discloses a testing method of a continuous scratching interference behavior of a single abrasive grain of a black metal test piece pre-repaired by a CBN tool and belongs to the fields of material performance testing and precise and ultra-precise machining during machining. Due to the fact that the black metal test piece is fixed to an electric main shaft and subjected to online dynamic balance; then the CBN tool is adopted for repairing a disk of the test piece, and the requirements for end face bouncing and roughness required for testing are met; a tool bit with the top end fixedly connected with the single abrasive grain is installed through replacement, and tool setting is performed in the replacement process; finally, a scratching test is started, the test piece rotates at an assigned speed, the tool bit performs radial feeding at assigned cutting depth, interference spiral scratches are formed on the end face of the test piece, and a measurement system acquires scratching force, an acoustic emission signal and other physical quantity in the process. The method can simulate the interference behavior between abrasive grains in the high-speed grinding process. A relevant testing result can be used for deep research of a grinding mechanism and optimization of grinding parameters.

Owner:HUAQIAO UNIVERSITY

Single-abrasive-particle scratching quick stop testing method for CBN cutter pre-repaired ferrous metal test piece

ActiveCN105606531AUnderstand deformationAchieve "freezeUsing mechanical meansMaterial analysisDynamic balanceMachined surface

The invention discloses a single-abrasive-particle scratching quick stop testing method for a CBN cutter pre-repaired ferrous metal test piece, belonging to the fields of material performance test in machining and precision and ultraprecision machining. According to the single-abrasive-particle scratching quick stop testing method, the ferrous metal test piece is fixed and is subjected to online dynamic balance; the CBN cutter is utilized for repairing the ferrous metal test piece, so as to meet end surface jumping and roughness requirements required by the test; the test piece rotates at an assigned speed, a tool head with the top end fixedly connected with single abrasive particles is radially fed at an assigned cutting depth to form spiral scratches in the end surface of the test piece, and the tool head and the test piece are instantly separated in the scratching process to realize the 'freezing' of a contact state between the abrasive particle and the test piece in the scratching process of the single abrasive particle; by virtue of three-dimensional topographical measurement and microscopic observation, related mechanisms of material deformation, formation of the machined surface, boundary friction and the like in the process for removing materials by virtue of the abrasive particle can be well known, thereby providing measures to the deep research on material removal mechanisms in the abrasive particle machining process, such as grinding.

Owner:HUAQIAO UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com