Temperature sensing fusing ejector pin type valve

A thimble type, fusing technology, applied in the direction of lifting valve, balance valve, valve device, etc., can solve the problems of explosion, unable to cut off the gas source in time, and cannot automatically stop, etc., to achieve improved stability, simple structure, and improved safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

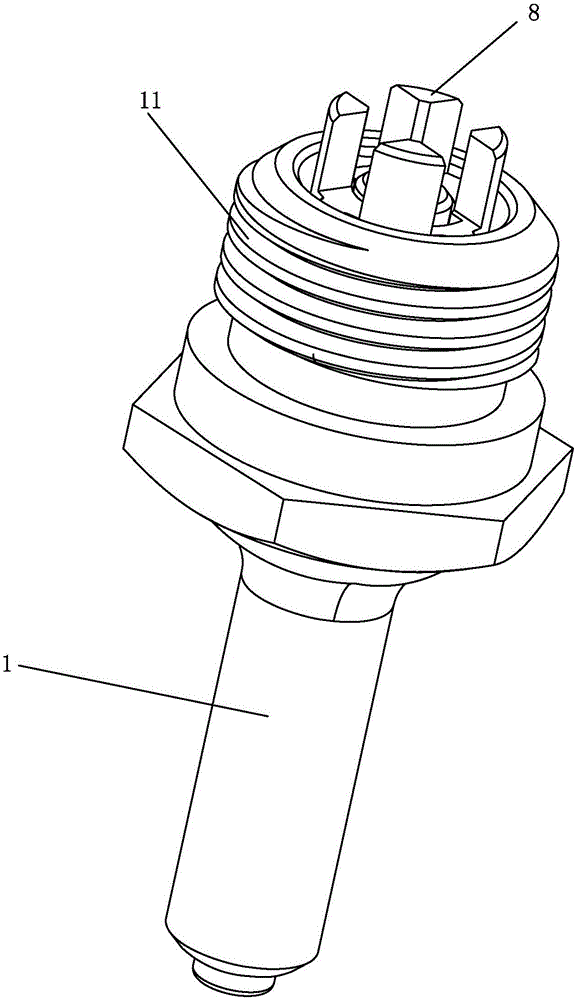

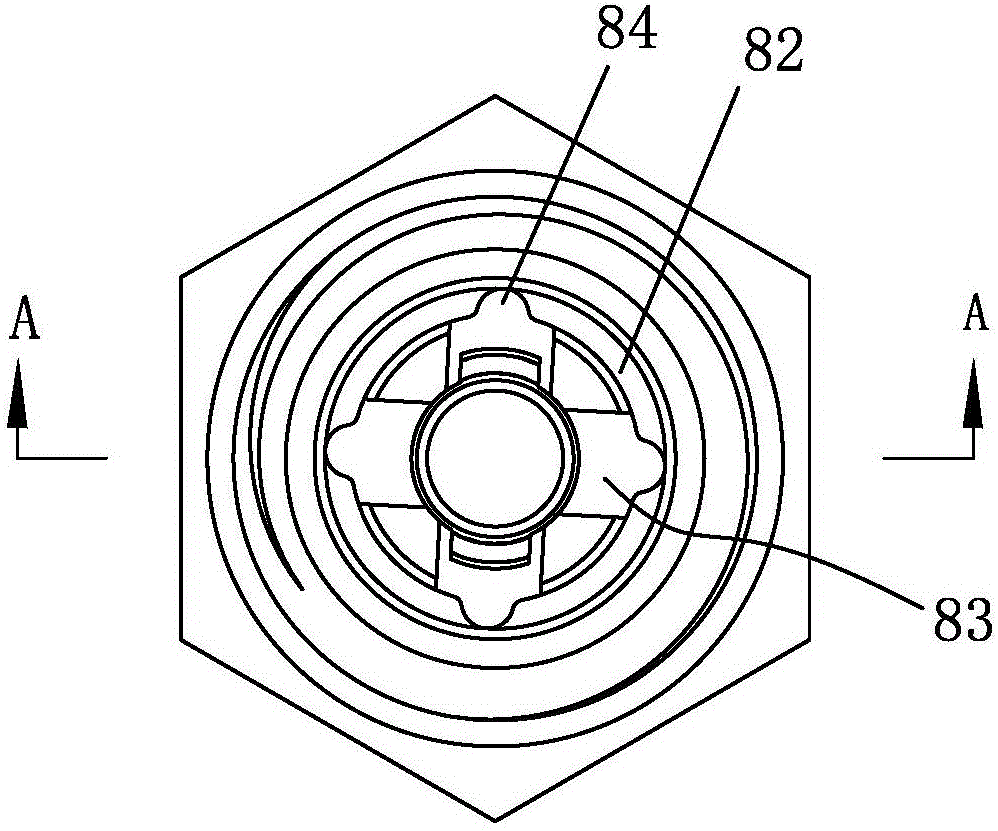

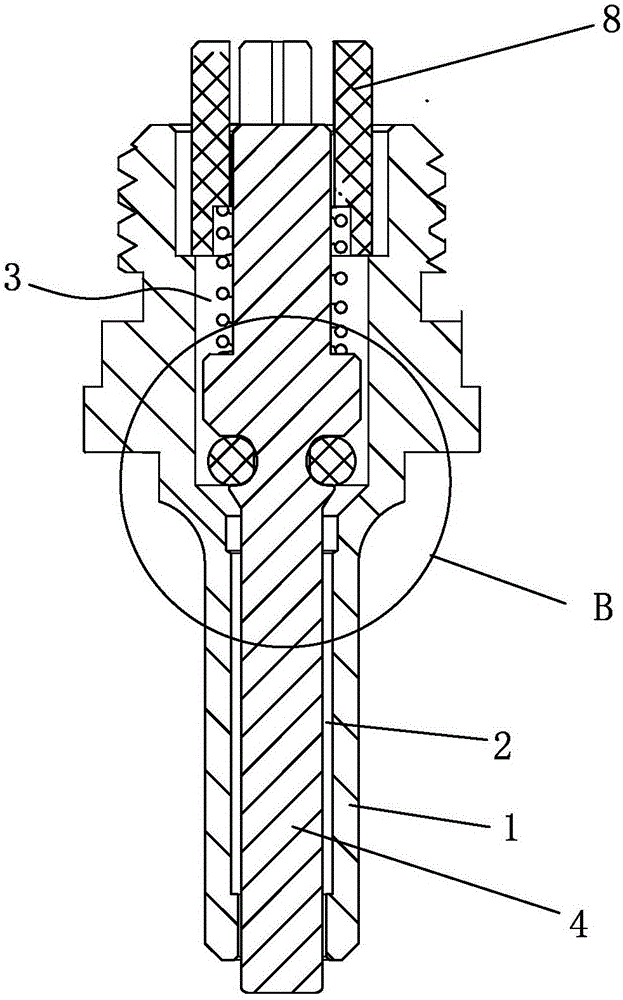

[0032] Such as Figure 1 to Figure 5 As shown, a thimble-type valve with temperature-sensitive fusing in this embodiment includes a valve body 1, and the valve body 1 is provided with an air inlet passage 2 for gas or liquid flow and a valve chamber 3 communicating with the air inlet passage 2, The valve body 1 is provided with a valve needle 4 that can slide in the intake passage 2 and is made of a low-melting point substance. The low-melting point substance has the characteristic that it begins to deform or melt when the temperature is higher than 100 ° C. The intake passage 2 There is a step hole 5 between the valve chamber 3, and the valve needle 4 is provided with a sealing step 6 that can cooperate with the step hole 5 in the intake passage 2 to close the intake passage 2. In this embodiment, the valve needle 4 adopts a low Made of high-density ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com