High-speed friction testing method for spherical grinding head prepared ferrous metal friction pair

A spherical grinding head, ferrous metal technology, applied in the direction of testing wear resistance, etc., can solve problems such as difficulty in meeting high-speed friction test requirements, affecting test accuracy and accuracy, and changing the geometric shape of grinding tools, achieving high-speed friction testing, The effect of ensuring relative motion accuracy and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

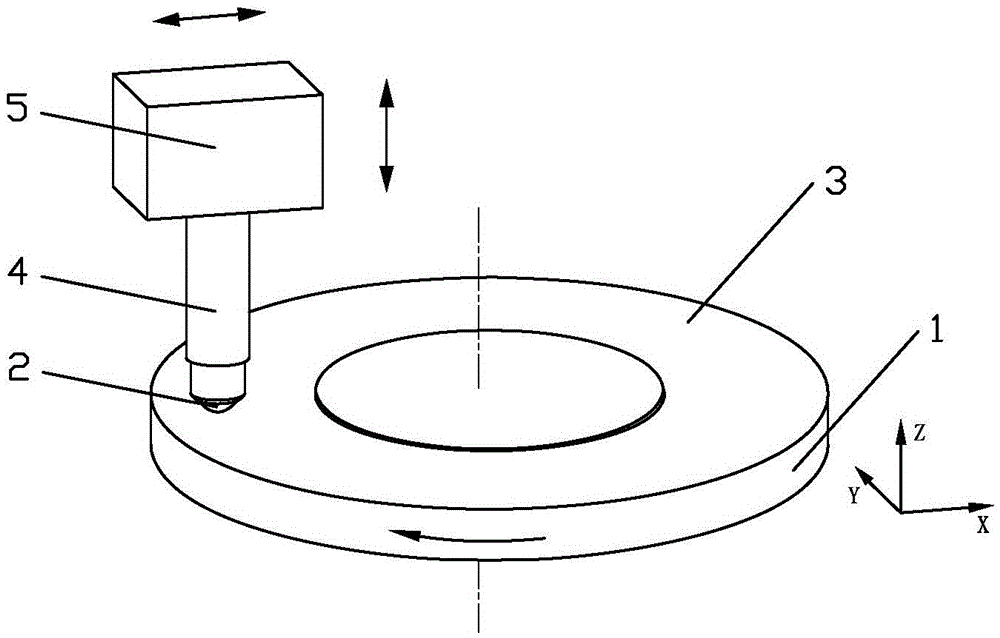

[0034] A high-speed friction test method for pre-repairing ferrous metal friction pairs with a spherical grinding head, the device used includes:

[0035] For machine tools, the disc-shaped ferrous metal friction disc 1 is mounted on the electric spindle of the machine tool, and the friction disc 1 can be rotated by the electric spindle;

[0036] A dynamic balancer, used for online dynamic balancing of the friction disc 1;

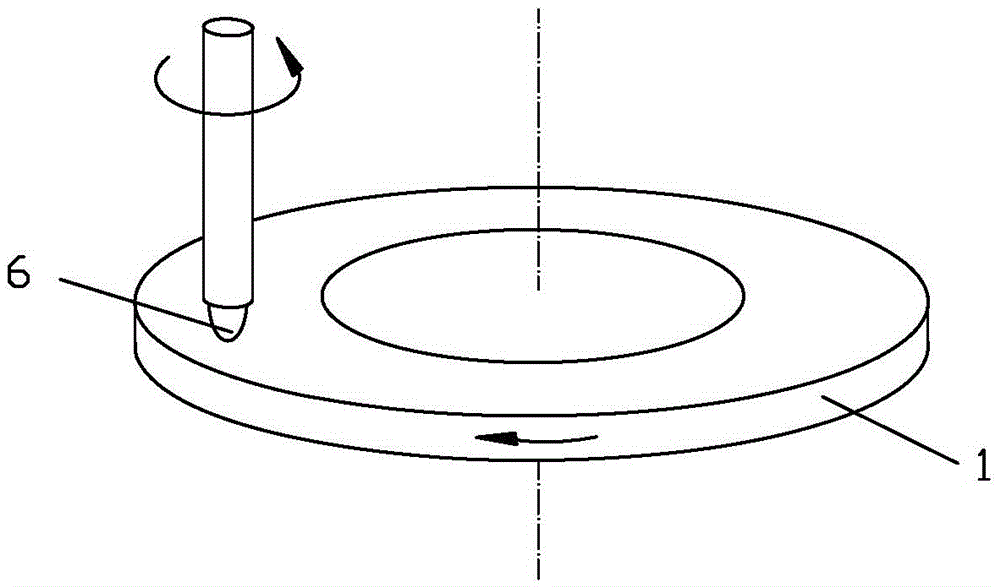

[0037] The spherical grinding head 6 is used to repair the end surface of the friction disc 1; the spherical grinding head 6 is detachably attached to the bracket, and is movably attached to the machine tool through the bracket; the axis of the spherical grinding head 6 is parallel to the friction disc 1 axis of rotation;

[0038] The grinding tool is a friction ball or a friction pin, which is clamped on the fixture 4 connected with the force feedback device 5; the fixture 4 is detachably attached to the bracket, and is movably attached to the machine to...

Embodiment 2

[0050] 1) Fix the disc-shaped friction disc of 45 gear steel 42CrMoV (HRC50) with a diameter of 300mm on the electric spindle of the machine tool with a magnetic chuck or mechanical fixture, and the friction disc can be rotated by the electric spindle; Perform online dynamic balance to reduce the vibration of the friction disc during high-speed rotation, so as to ensure stable contact between the grinding tool and the friction disc during the scratching process;

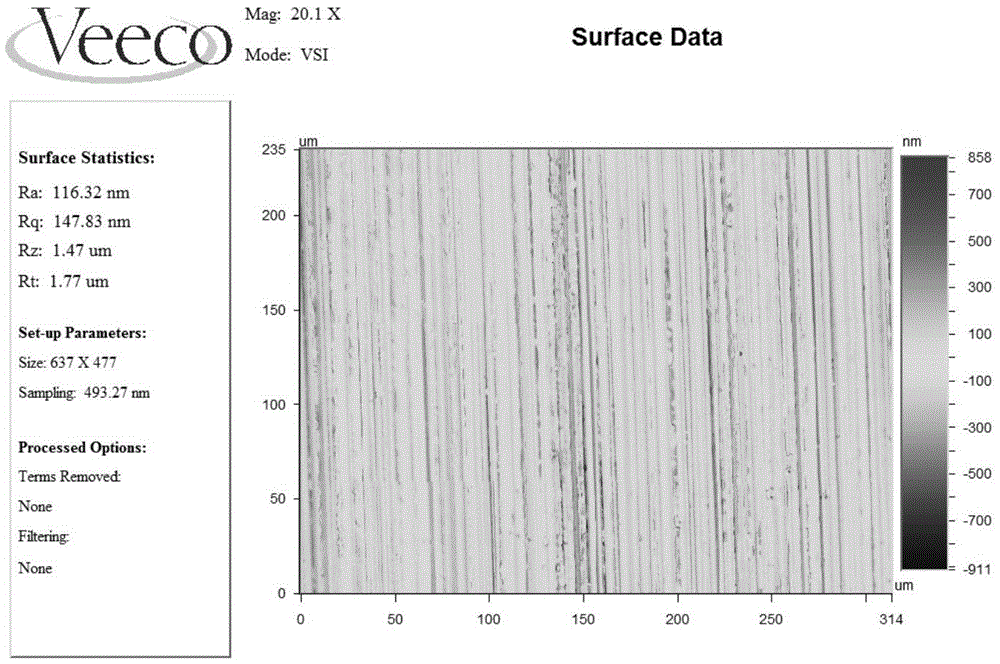

[0051] 2) Use a spherical grinding head to repair the friction disc, first rough machining, and then finish machining, so as to form a circular ring on the surface of the friction disc with the runout of the end face better than IT1 grade and the average surface roughness Ra better than 10nm Repair the disc area to reduce the runout of the end face of the friction disc, improve the surface quality, and further ensure the stable contact between the grinding tool and the friction disc during the scratching process. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average roughness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Surface average roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com