Rear wall strength test device for driving cabs of commercial vehicles

A technology of strength test and cab, which is applied in the direction of measuring device, vehicle test, machine/structural component test, etc., can solve problems such as occupant injury, deformation of cab rear wall structure, squeeze occupant living space, etc., and achieve reliance Reduced resistance, accurate loading direction, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

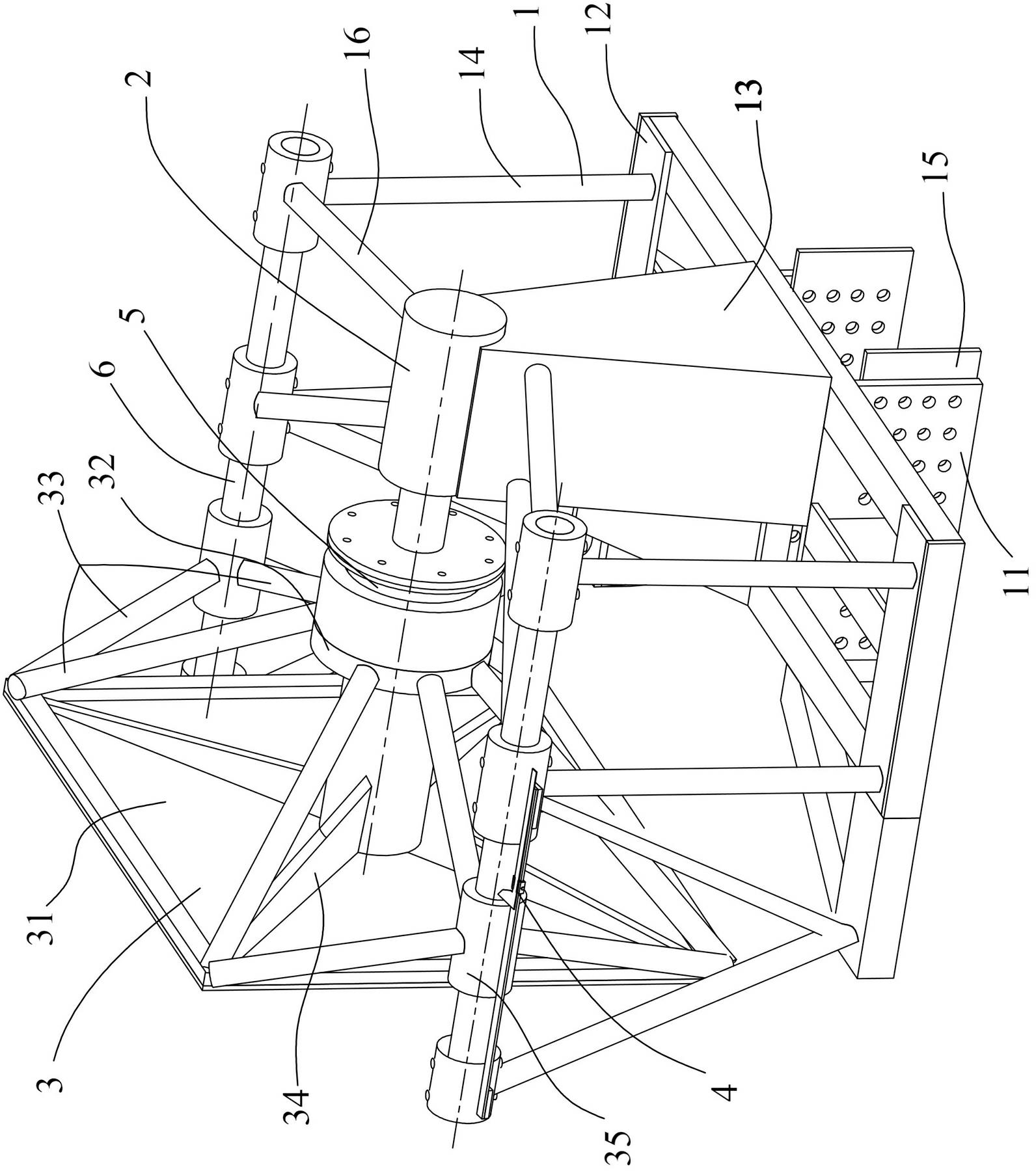

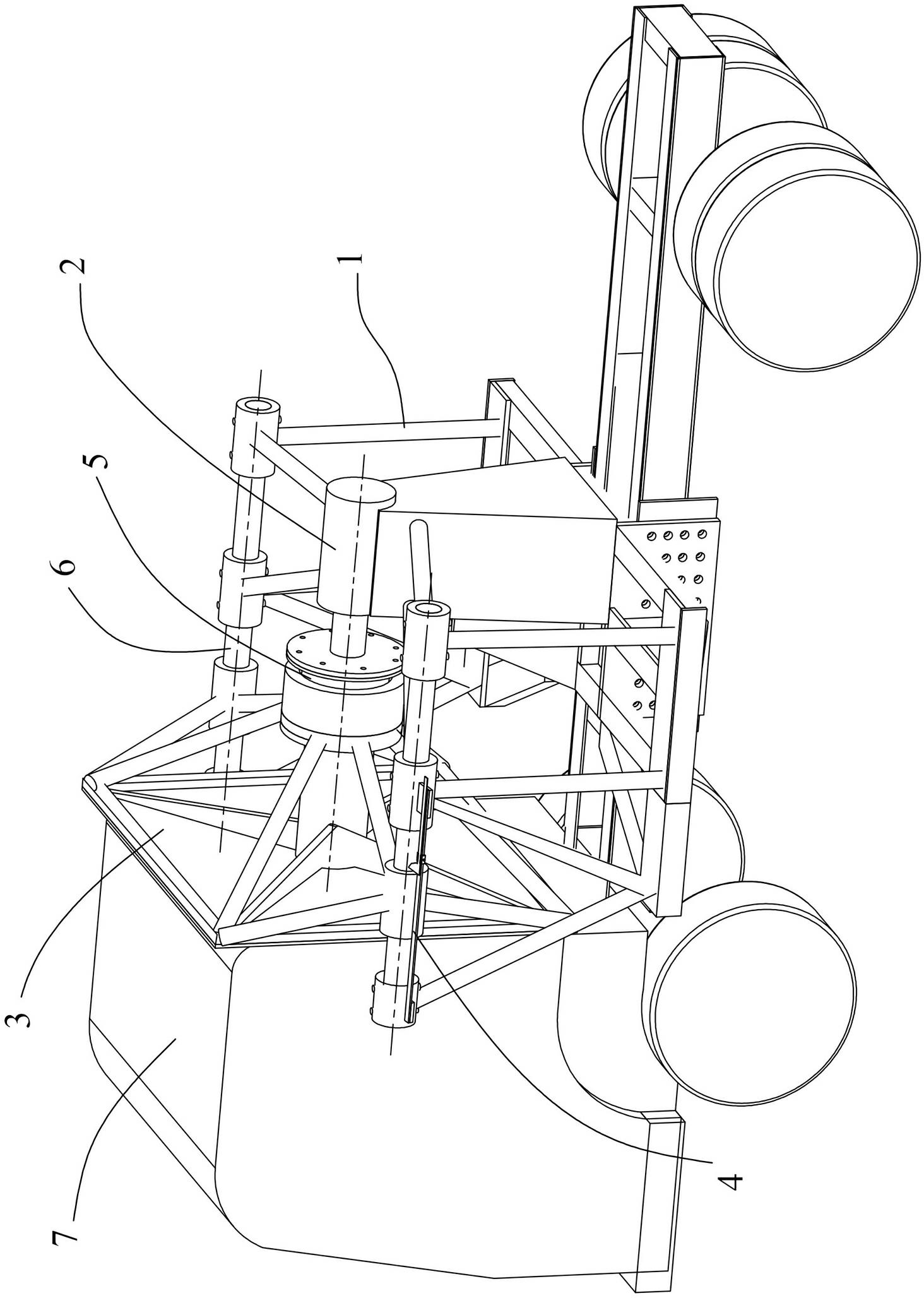

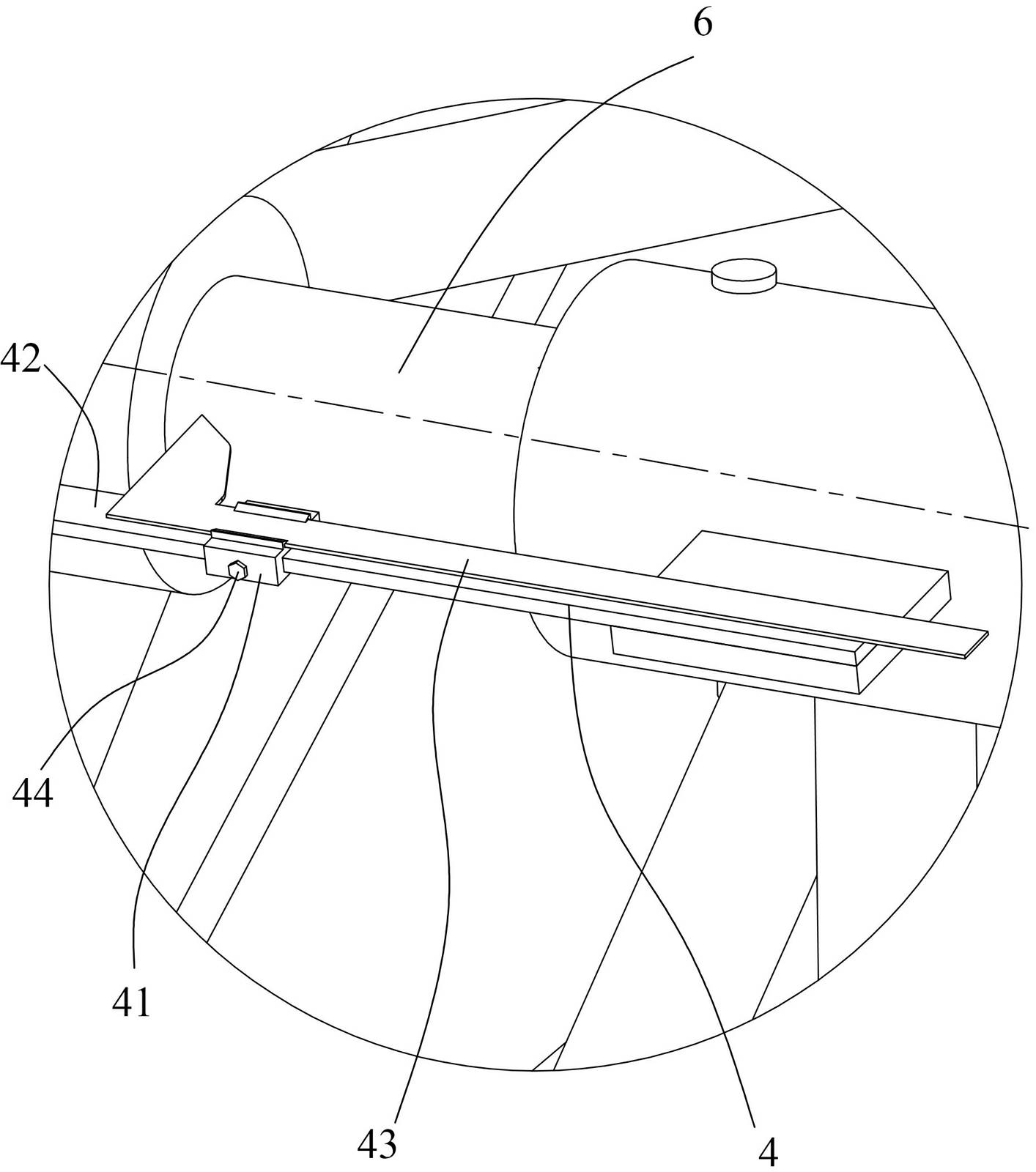

[0027] Figure 1 to Figure 4 It shows an embodiment of a test device for the rear wall strength of a commercial vehicle cab of the present invention, the test device includes a mounting bracket assembly 1, a telescopic drive device 2, a rigid loading mechanism 3, a displacement measuring device 4 and a force measuring device 5, The mounting bracket assembly 1 is provided with a pair of guide rails 6 arranged in parallel. The pair of guide rails 6 are arranged along the longitudinal direction of the vehicle. The rigid loading mechanism 3 is slid on the pair of guide rails 6. When loading, the guide rails 6 are used to guide the loading direction to ensure the loading direction. Accurate and stable, the telescopic driving device 2 is fixed on the mounting bracket assembly 1, which can maintain a stable loading speed and create favorable conditions for improving the simulation degree of the crash test. The output end of the telescopic driving device 2 is connected with the rigid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com