Patents

Literature

45results about How to "Reduce additional force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

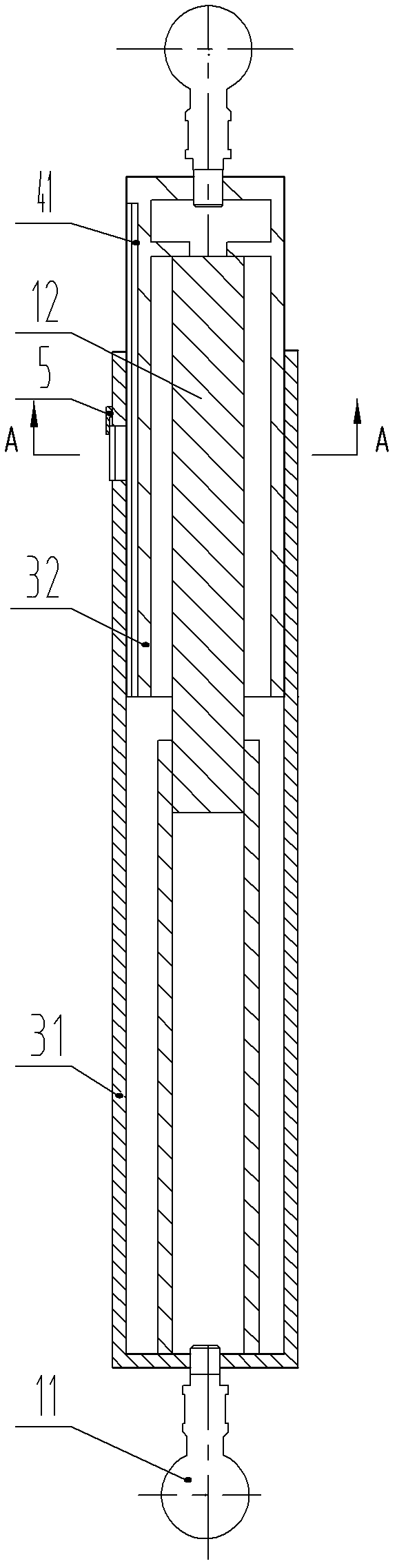

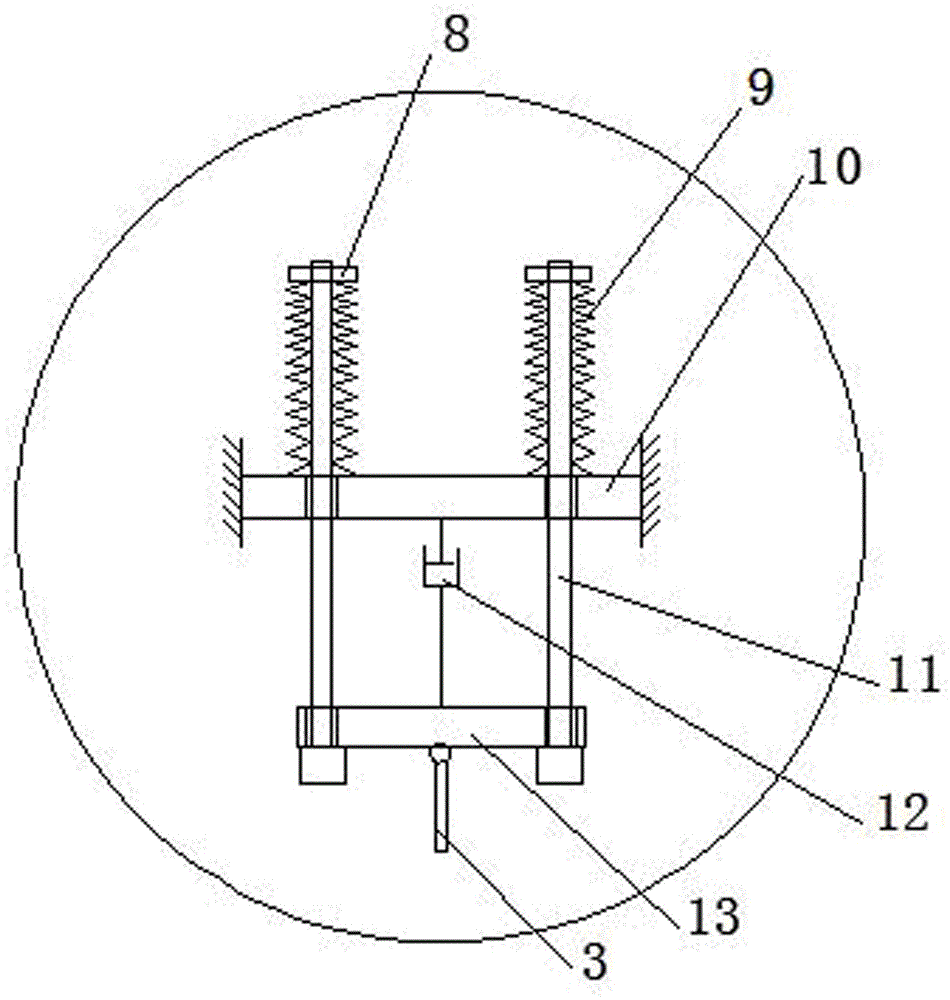

Spatial six-degree-of-freedom vibration measuring and damping vibration attenuating method

InactiveCN102628728AStrong impact resistanceSimple structureNon-rotating vibration suppressionVibration testingVibration controlMeasurement point

The invention discloses a spatial six-degree-of-freedom vibration measuring and damping vibration attenuating method. The method comprises the following steps of: 1) erecting six-displacement-sensor parallel measuring and damping vibration attenuating mechanism; 2) fixing a detected motion object and a fixed platform; 3) obtaining a motion variation rule by using an expansion variation displacement time of an expansion pull rod, and obtaining a vibration rule of the detected motion object by using a measurement algorithm with a positive solution; 4) obtaining a damping value of a six-degree-of-freedom controllable damper required by the vibration by using a damping vibration attenuating algorithm; and 5) adjusting the damping value of the six-degree-of-freedom controllable damper to a value obtained by the damping vibration attenuating algorithm. According to the invention, six-degree-of-freedom measurements of three vibration displacements and three vibration angles of the motion object at the same measurement point are achieved by using one set of mechanism; meanwhile, the vibration control of the motion object can be achieved; and the spatial six-degree-of-freedom vibration measuring and damping vibration attenuating method disclosed by the invention has the advantages of high accuracy, simple structure, good flexibility, strong adaptability, wide application range and the like.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS +1

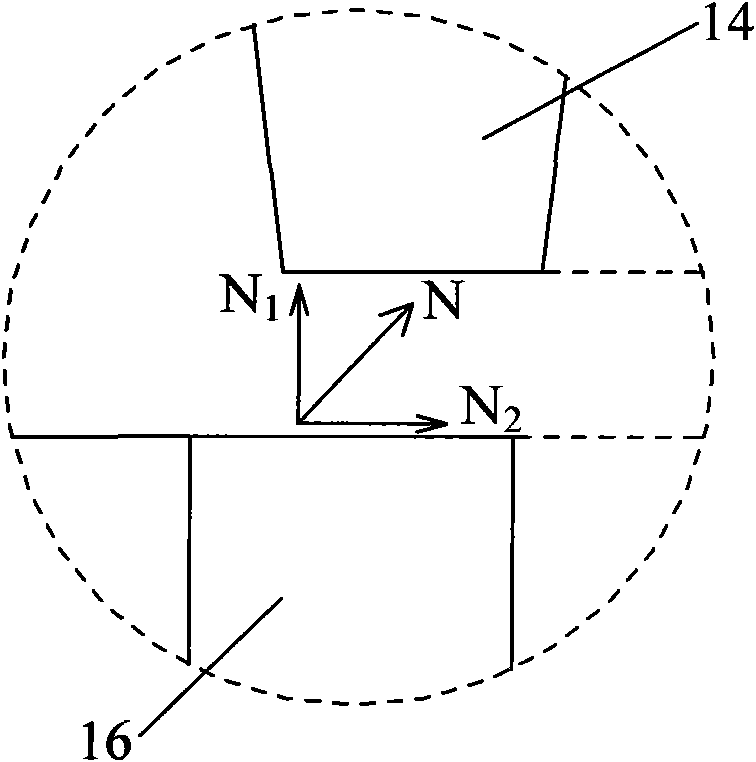

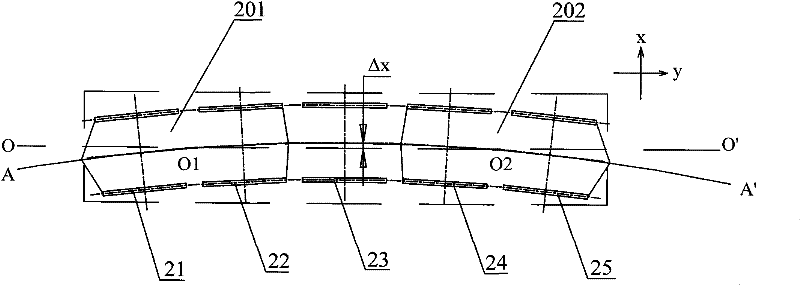

Magnetic levitation steering mechanism

ActiveCN102019938AImplement vertical scrolling linksLarge vertical forceBogie-underframe connectionsElectric propulsionBogieAir spring

The invention provides a magnetic levitation steering mechanism which is installed between a vehicle body and a steering frame of a magnetic levitation vehicle, and the steering mechanism is an arc movable sliding table, wherein the upper part of the sliding table is connected with the vehicle body, and the lower part of the sliding table is connected with the steering frame; the upper part and the lower part of the sliding table make relative movement with a circular arc movement trail. The introduction of the magnetic levitation steering mechanism realizes that a moving point of a steering module forming the steering frame makes arc movement around a relative rest point to drive the vehicle body and the steering frame to make circular arc relative movement together, so that the vehicle passes through a curve track smoothly, and the service life of an air spring and the steering frame is prolonged.

Owner:CRRC TANGSHAN CO LTD +2

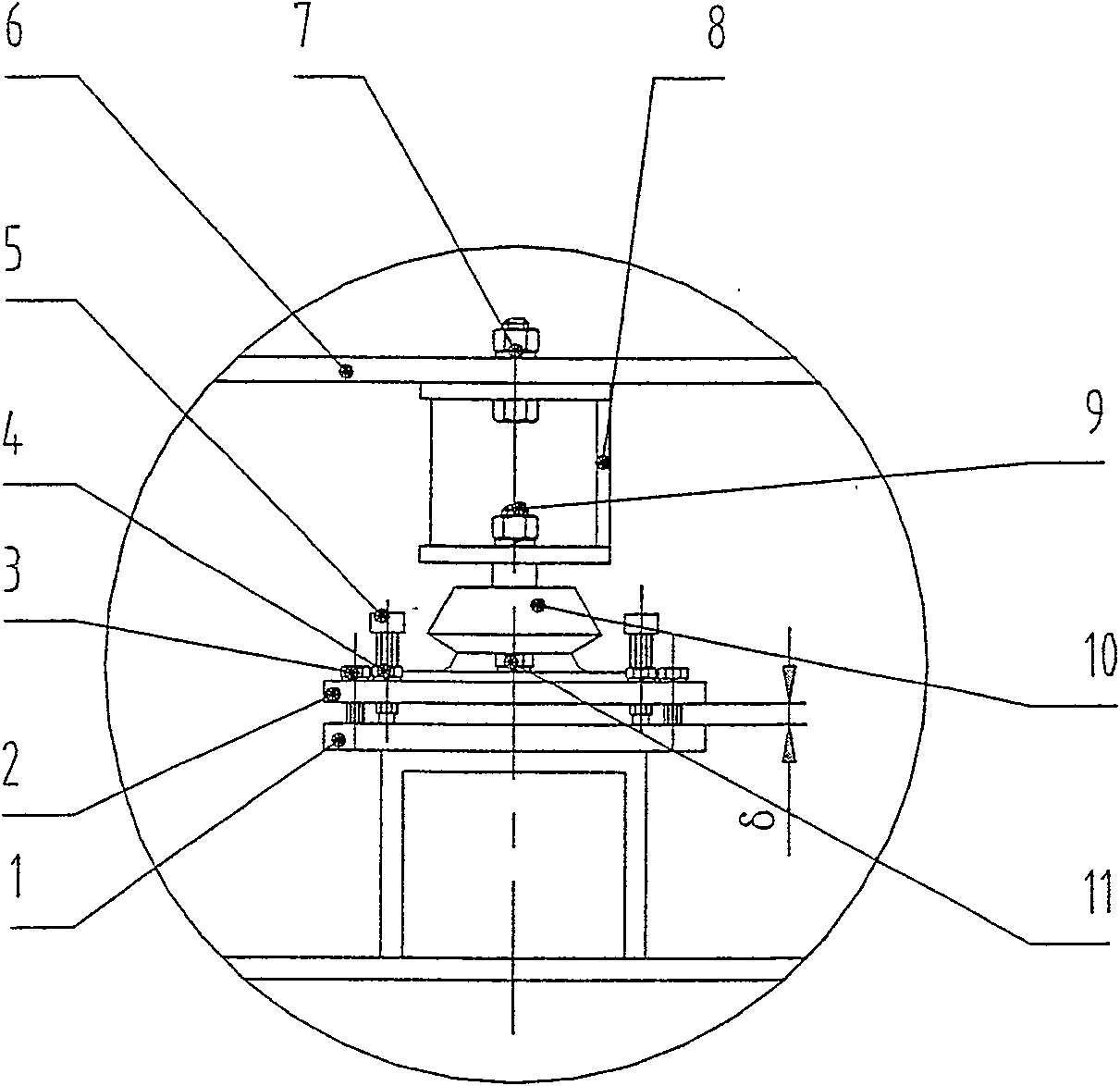

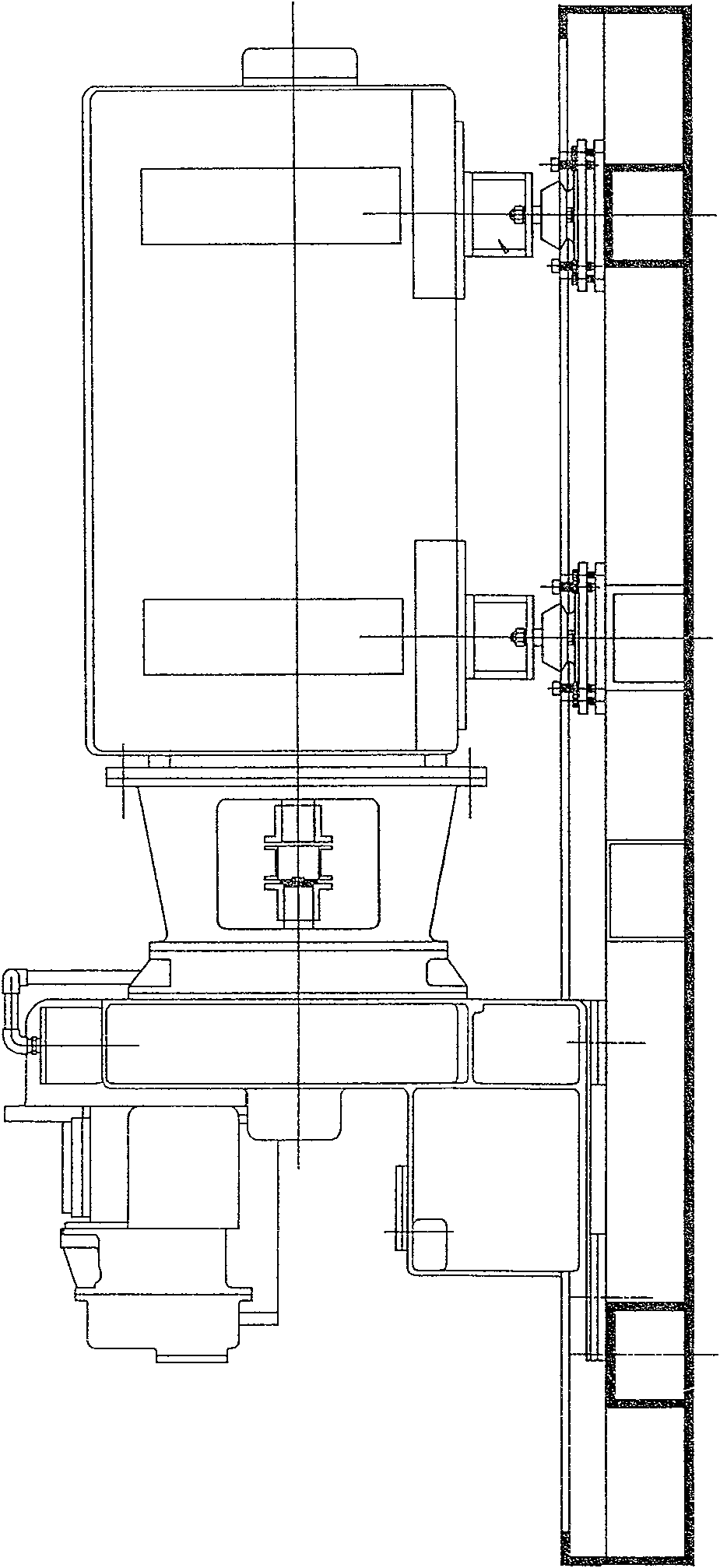

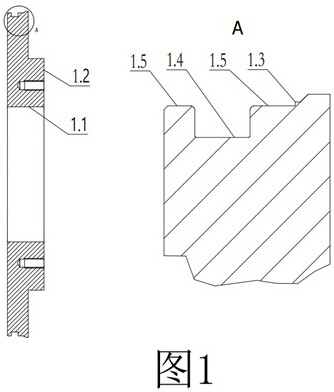

Adjustable elastic support structure

InactiveCN100555806CEliminate manufacturing errorsEliminate installation errorsSupports/enclosures/casingsCouplingEngineering

The invention relates to an adjustable elastic support structure, specifically for the support connection between rotary machines (screw compressors, motors, etc.) and machine bases, and belongs to the technical field of support devices. It mainly adopts the shock absorber to be connected with the bottom plate and the bracket respectively, the motor is connected with the bracket, the chassis is supported by the top screw, the nut locks the top screw, and the bottom plate and the chassis are connected by the connecting bolt. The invention has a simple, compact and reasonable structure; the elastic support can eliminate and reduce the transmission of motor vibration; the adjustable support can eliminate the manufacturing error and installation error of each component, so that each support point can obtain ideal support force and reduce additional vibration and noise ; It can reduce the additional bending moment on the connecting cylinder and the additional force of the connecting bolts, so as to ensure the smooth operation of the machine.

Owner:WUXI COMPRESSOR CO LTD

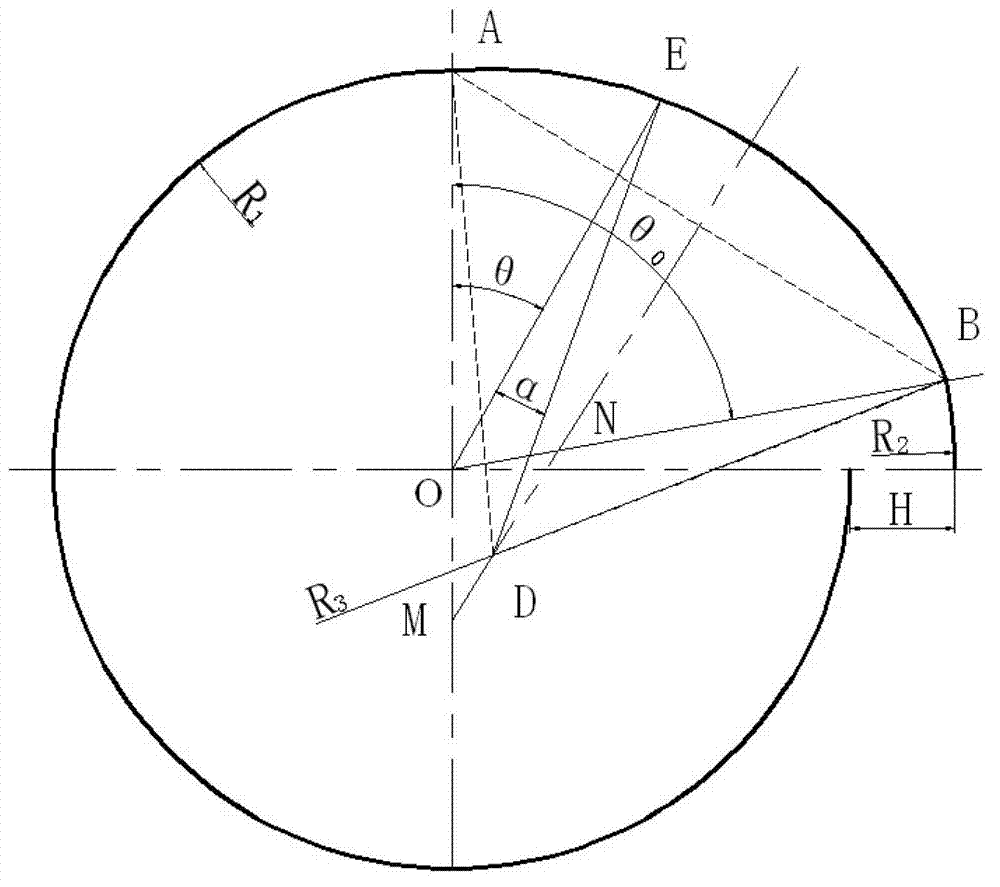

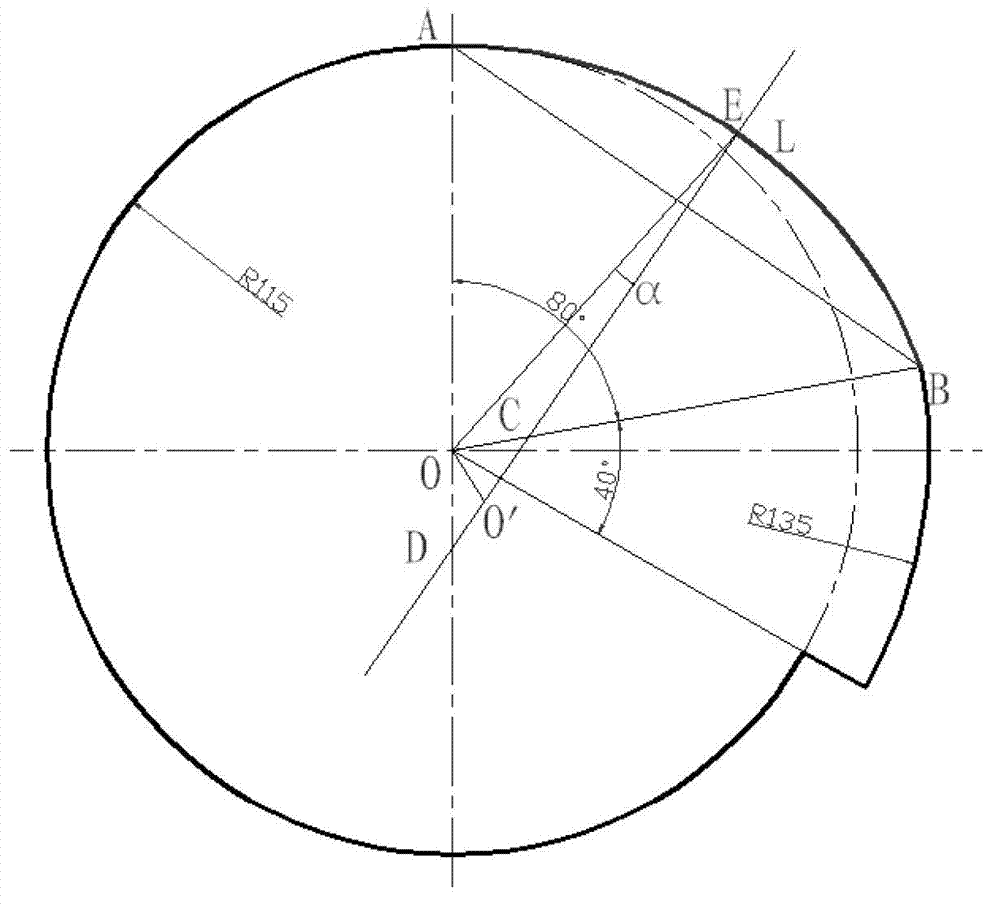

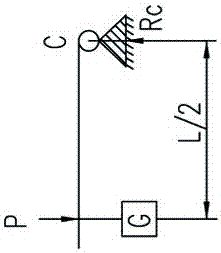

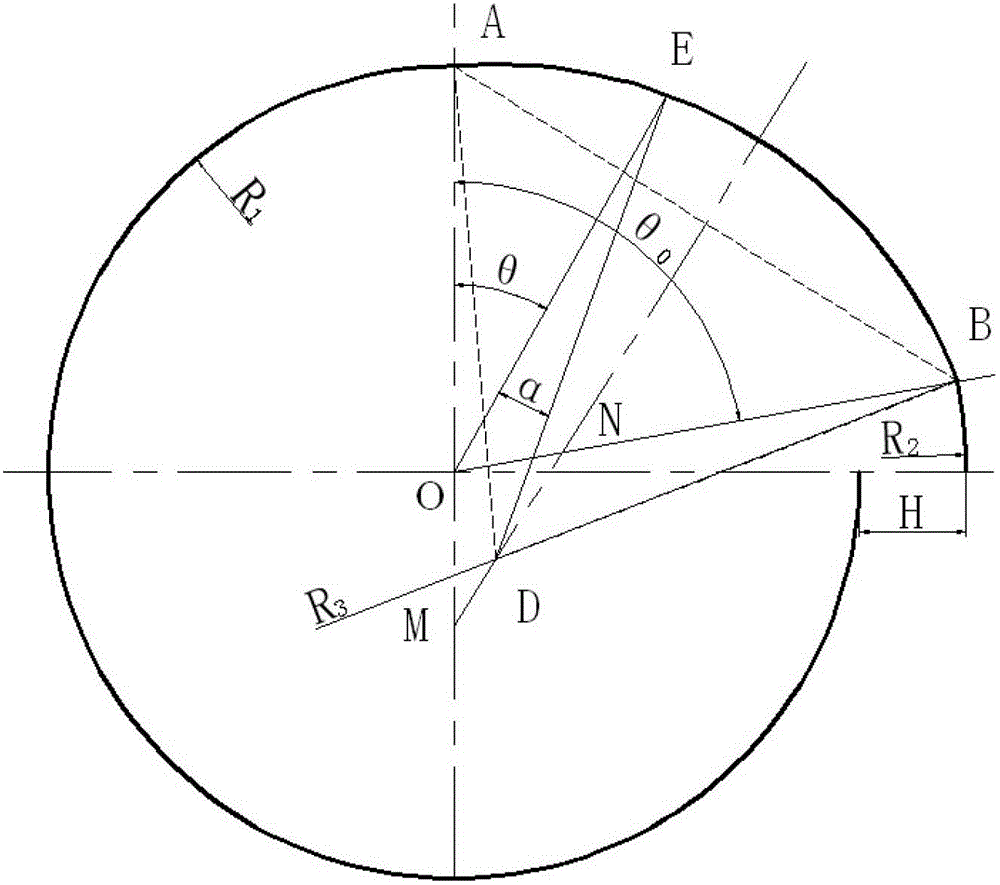

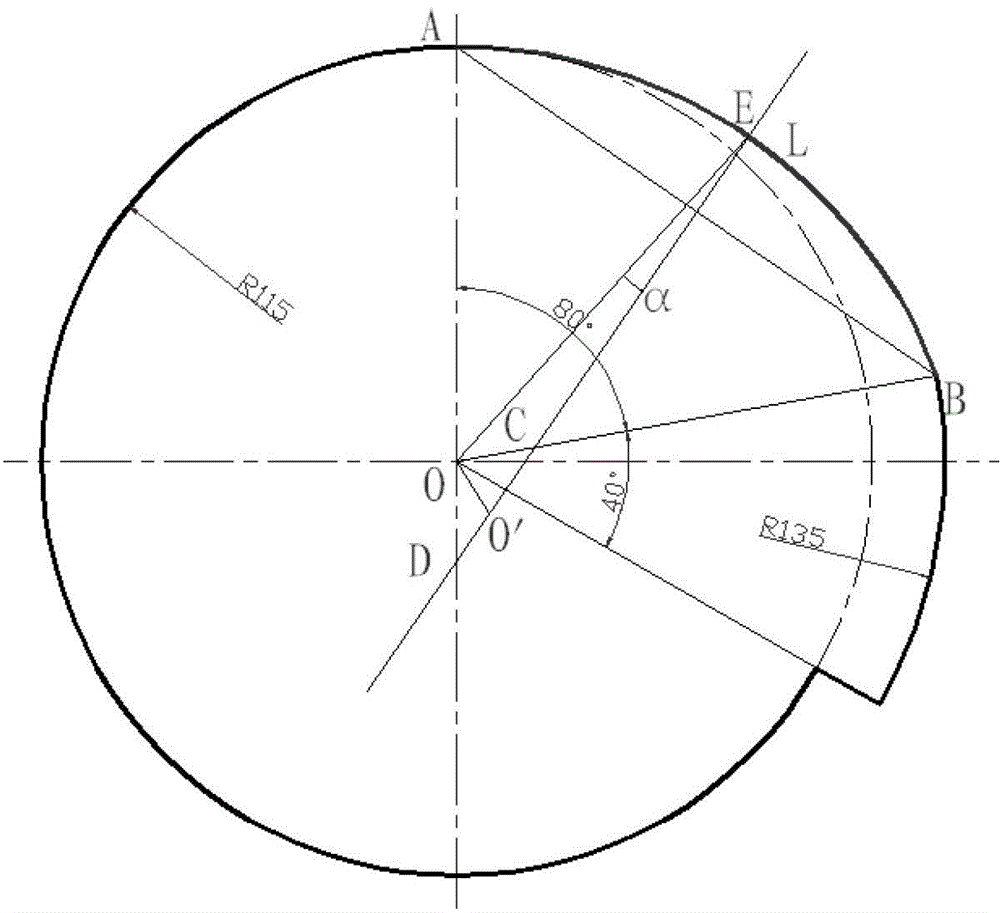

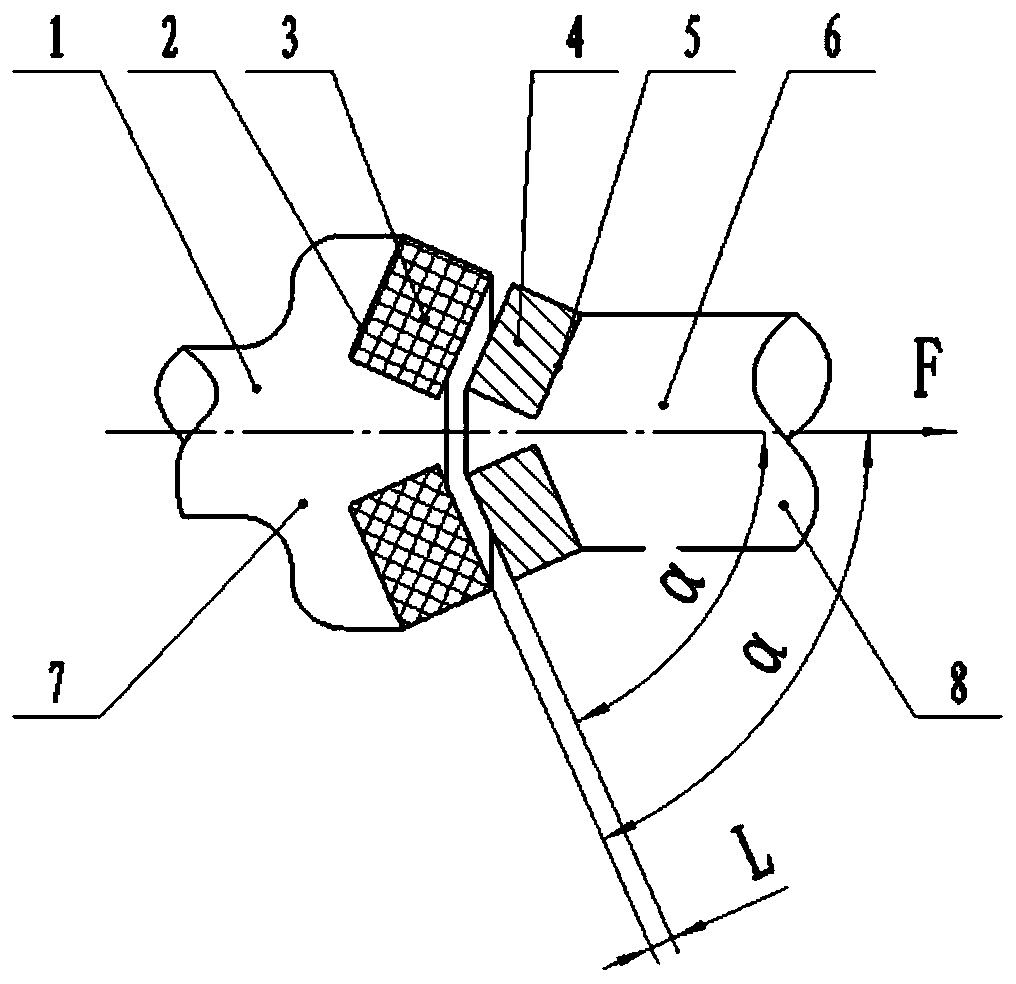

Variable pressure angle cam contour line design method applicable to sudden variable load

The invention discloses a variable pressure angle cam contour line design method applicable to sudden variable load. R1 refers to the radius of a base circle omicron, R2 refers to the farthest dwell arc radius, AB arc refers to a cam contour line with the radius of R3, and alpha refers to a theoretical working curve pressure angle. When the normal values R1 and R2 are given, a graph of relation between a lift range h and the pressure angle alpha can be determined under different R3 values. An optimal arc radius value R3 corresponding to the pressure angle alpha changed along with the lift range h under sudden variable load can be found through the graph. The variable pressure angle cam contour line design method applicable to sudden variable load has the advantages that the pressure angle is extremely small in an open stage of a main valve core during opening of a cam and matched with characteristics of loads, and additional force applied to a top rod can be decreased.

Owner:CENT SOUTH UNIV

Design method for crack control crack of overlong concrete frame structure

InactiveCN101942863AReduce additional forceReduce consumptionBuilding constructionsLower limitEngineering

The invention discloses a design method for crack control crack of an overlong concrete frame structure, concretely comprising the following steps of: determining the value of a comprehensive calculation temperature difference sigma delta t: determining the value of a season temperature difference delta t1 and determining the value of an equivalent temperature difference delta t2 of the contraction distortion of the concrete; calculating the additional elastoplasticity force of the concrete frame: introducing the elastoplasticity rigidity reduction coefficient beta' and determining the upper and lower limits of beta', calculating the elastoplasticity sideway movement resisting rigidity of an intermediate column of the frame, calculating the column top shearing force value of an intermediate column in the frame column line, and calculating the column top shearing force value Vn0 of an (n) column on the end part of the frame; and designing and rechecking the sections of the beam and column of the overlong frame: designing the section of the frame beam and rechecking the frame column. The design method has simple solving process and simple and clear design process, and cannot only save materials, but also can control the width of the crack in a maximal crack width limitate value, thereby bringing convenience to the design and the construction.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG +1

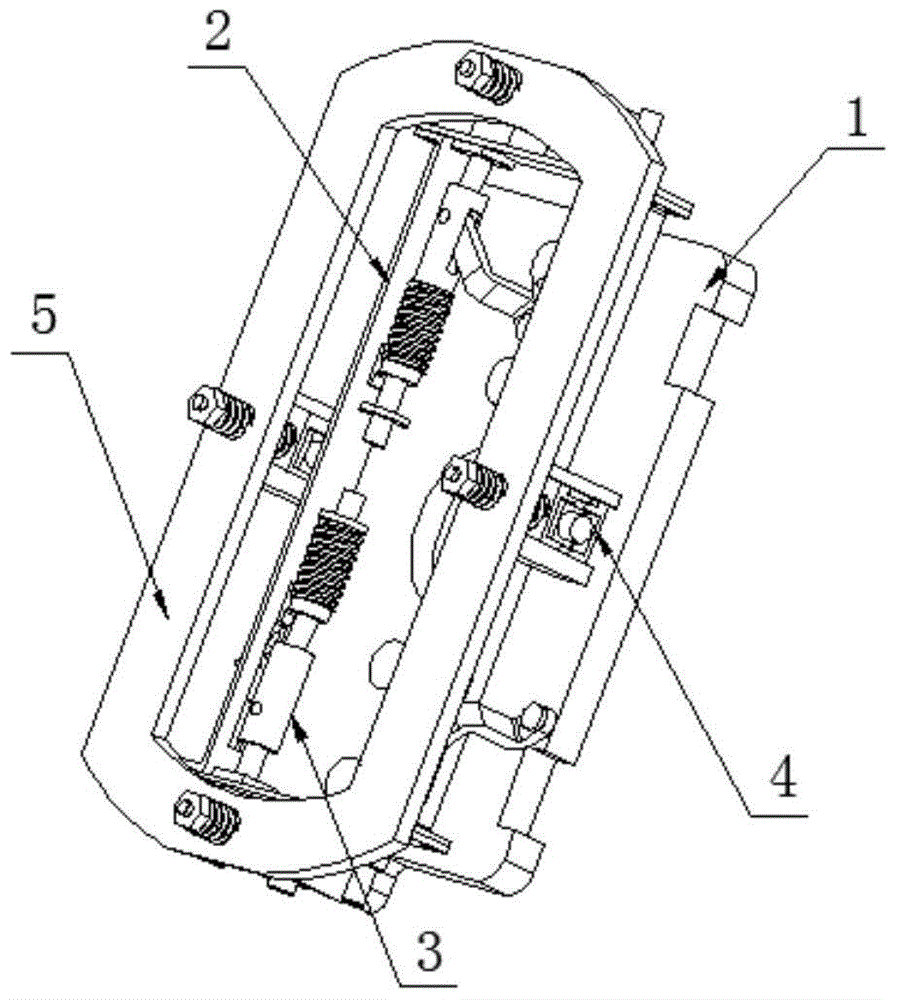

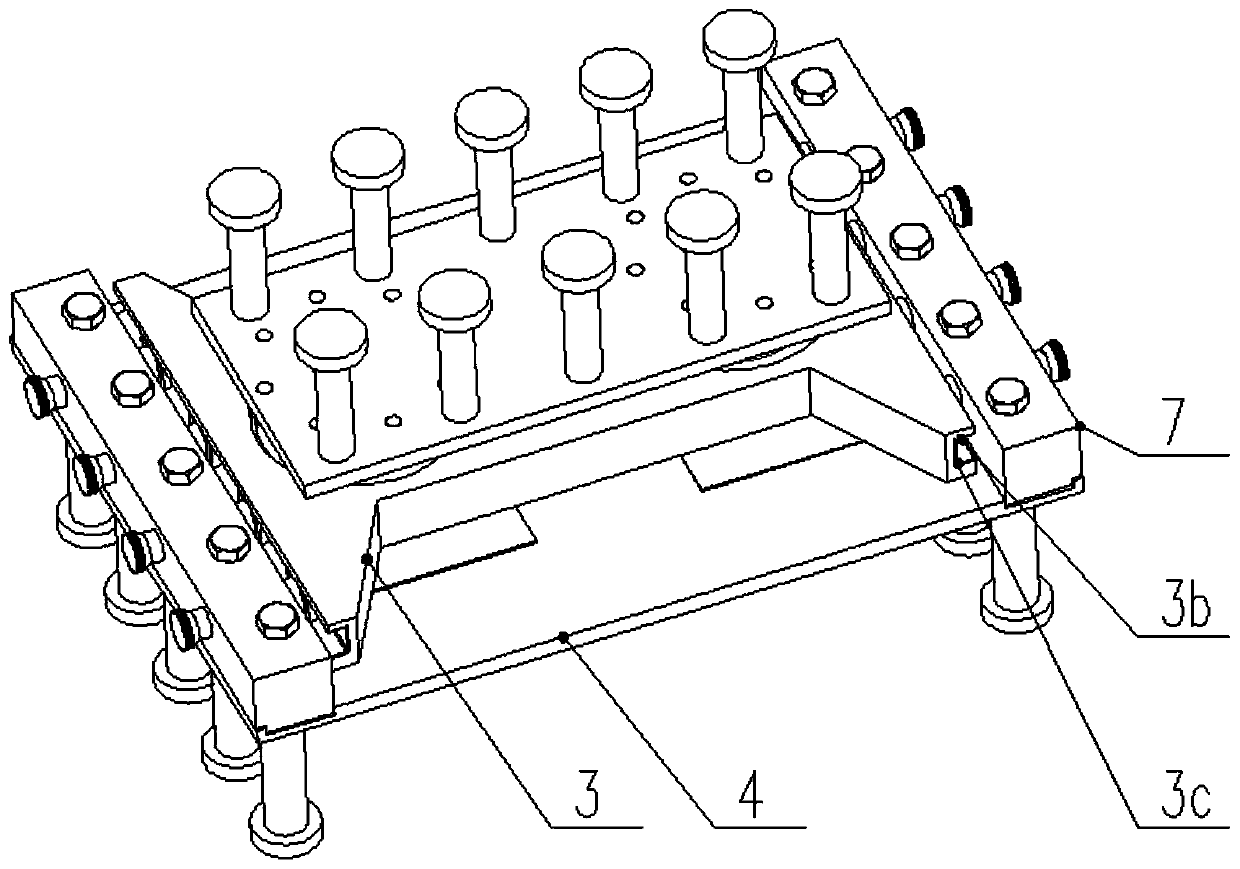

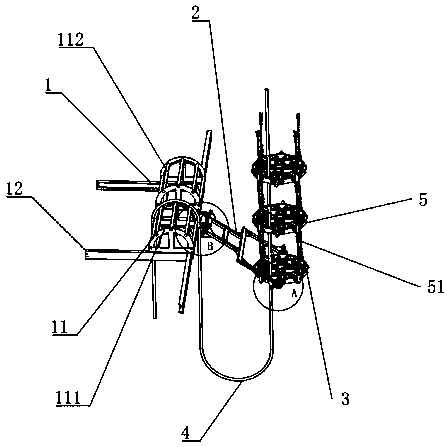

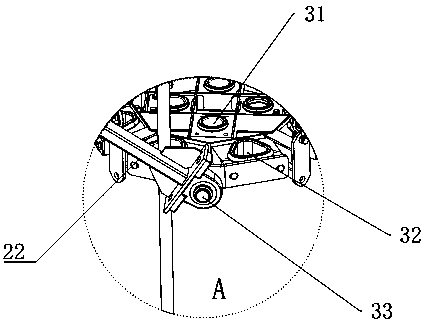

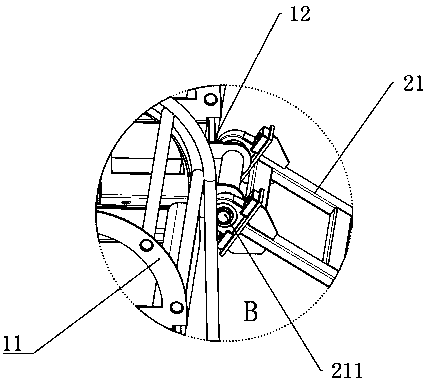

Space docking error compensation mechanism

InactiveCN105953666ASimple structureReduce weightSelf-propelled projectilesMulti degree of freedomRocket

The invention relates to the technical field of carrier rocket ground refueling devices, and particularly discloses a space docking error compensation mechanism. The space docking error compensation mechanism includes an integrated connector panel, a frame structure, four connection rod devices, four multi-degree of freedom joint devices and a reference panel; the four connection rod devices are symmetrically distributed in the inner part of the frame structure; the integrated connector panel is connected to the frame structure through the four connection rod devices; and the frame structure is connected to the reference panel through the four multi-degree of freedom joint devices. According to the technical scheme, the execution mechanism is flexibly connected the integrated connector panel, damage to the connector structures and a rocket structure due to position and angle errors existing between the reference panel and a movable door panel can be avoided during docking, moving, and falling of the connector system.

Owner:赵纯

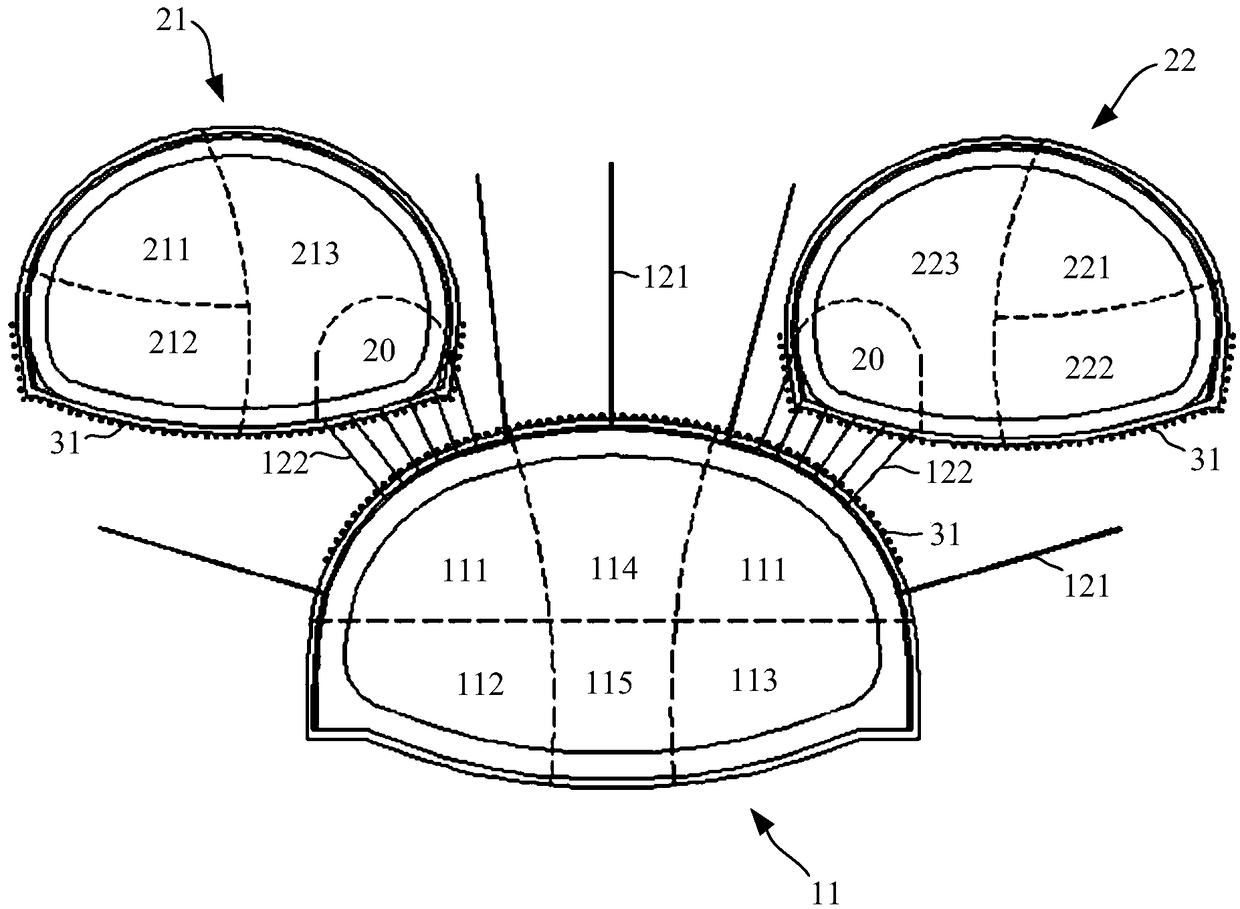

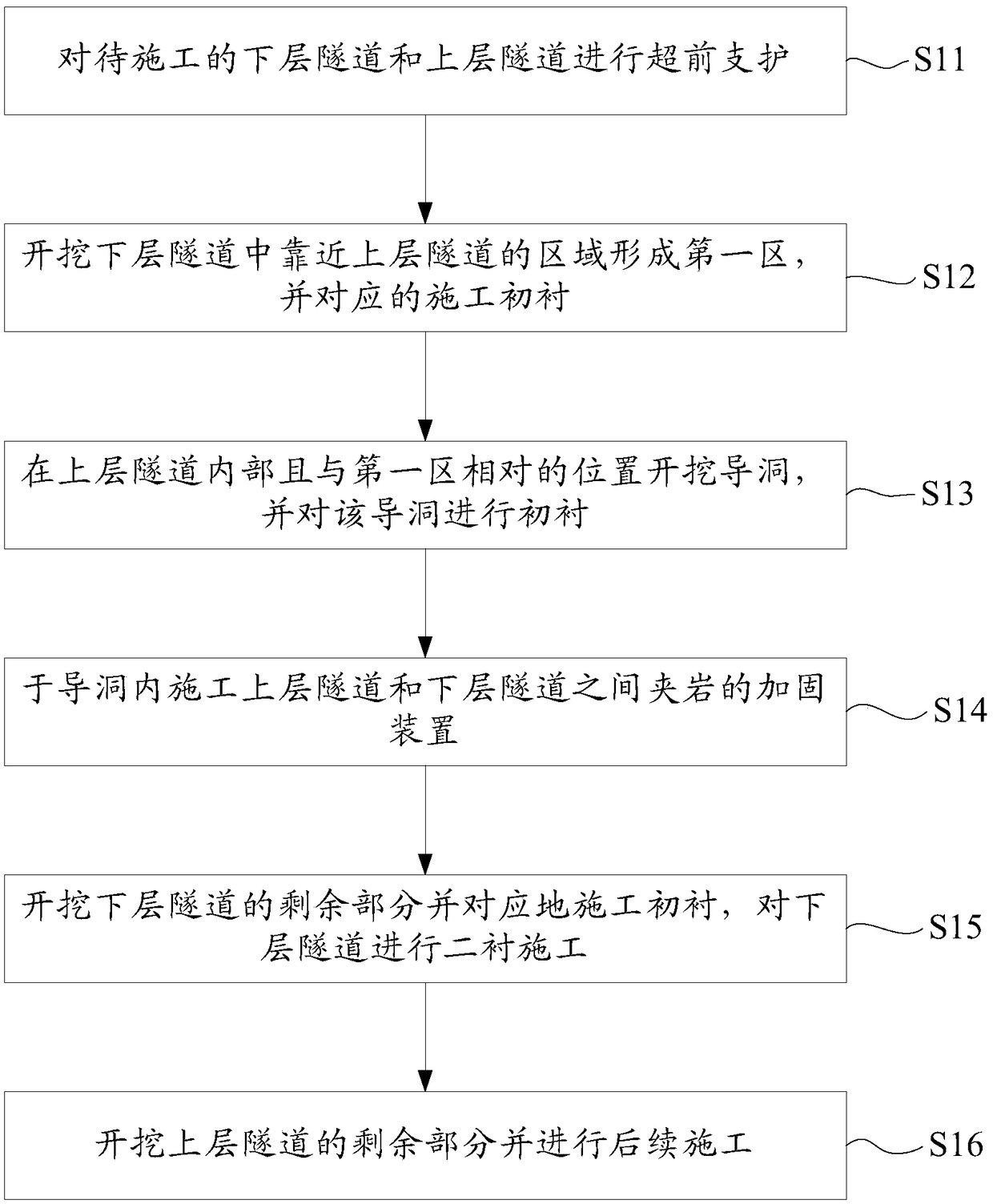

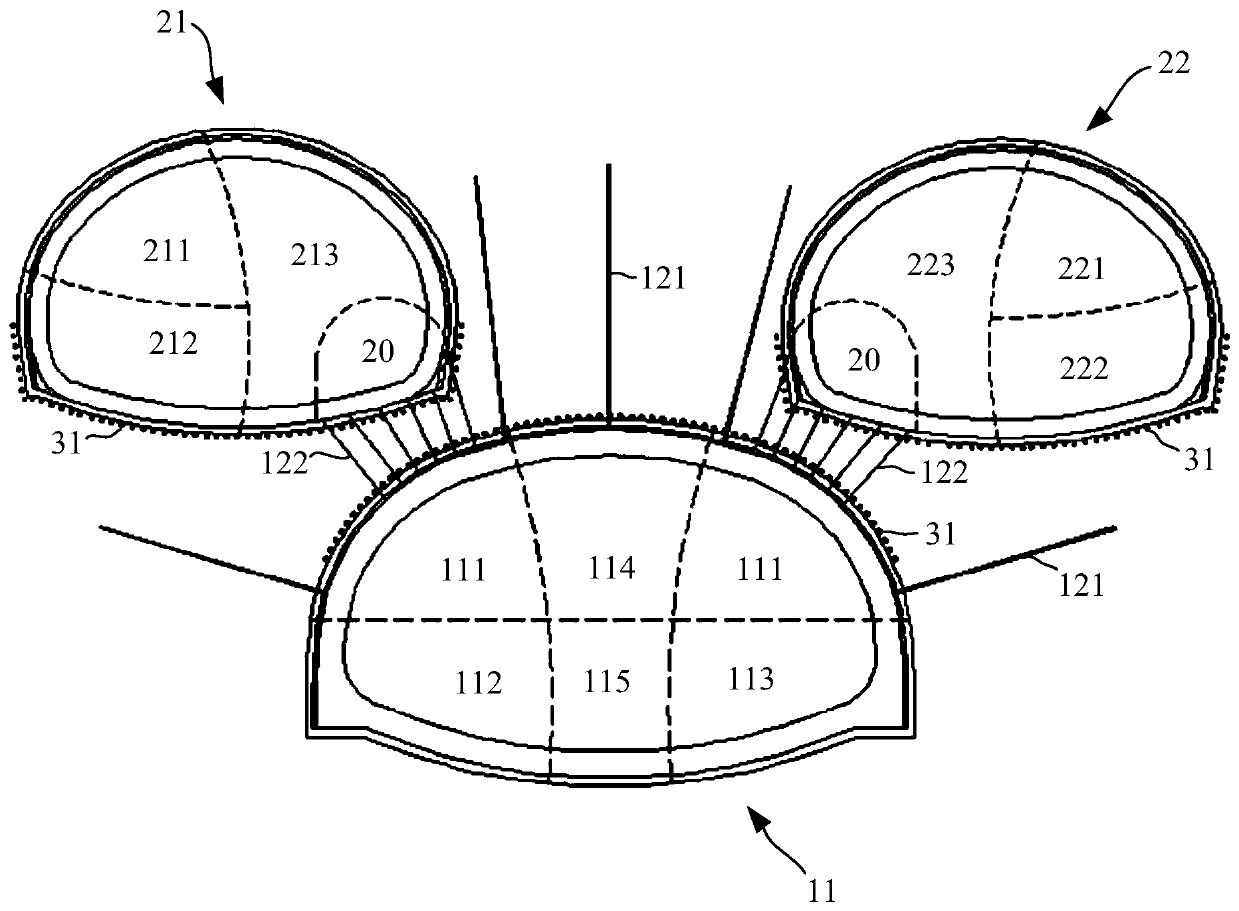

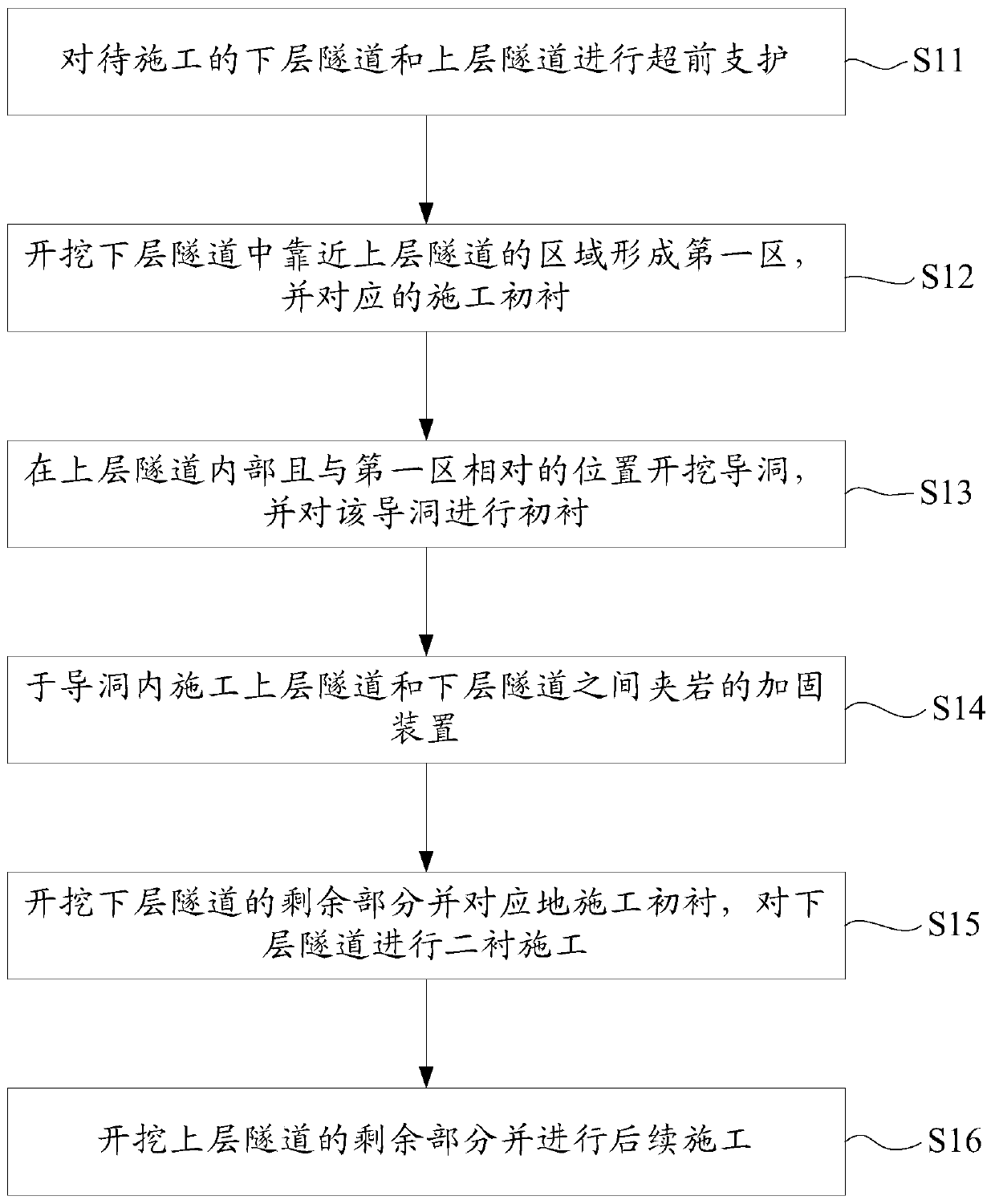

Construction method of small-clear-distance laminated tunnel

ActiveCN109356592ASolve complexitySolve quality problemsUnderground chambersTunnel liningMechanical equipmentBuilding construction

The invention relates to a construction method of a small-clear-distance laminated tunnel. The construction method comprises the following steps that a to-be-constructed lower layer tunnel and a to-be-constructed upper layer tunnel are subjected to in-advance support; the area, close to the upper layer tunnel, in the lower layer tunnel is excavated to form a first area, and corresponding construction of primary lining is conducted; a pilot tunnel is excavated at the position, opposite to the first area, inside the upper layer tunnel, and subjected to primary lining; a reinforcing device for sandwiched rock between the upper layer tunnel and the lower layer tunnel is constructed in the pilot tunnel; the rest part of the lower layer tunnel is excavated to subjected to corresponding construction of primary lining, and the lower layer tunnel is subjected to secondary lining construction; and the rest part of the upper layer tunnel is excavated and subjected to subsequent construction. According to the construction method, the pilot tunnel is arranged on the upper layer tunnel to enable a vibration wave to be propagated in air so as to reduce the influence of blasting of the upper layertunnel on a lower layer tunnel support structure and the sandwiched rock, mechanical equipment can be directly arranged in the pilot tunnel for operation, work such as sandwiched rock drilling is conducted from top to bottom, the problem that the small-clear-distance laminated tunnel is difficult to construct is solved, and thus the construction process is safer.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Multi-cable compounded damping cable

InactiveCN106638311AIncrease the itineraryAchieving shock resistanceBridge structural detailsEngineeringAbsorption effect

The invention discloses a multi-cable compounded damping cable. The technical key point lies in that the multi-cable compounded damping cable comprises a main cable and at least one secondary cable distributed around the main cable, and the at least one secondary cable is located on the upper portion of the main cable. The lower ends of the main cable and the secondary cables are connected with a concrete anchor fixed to the ground. The upper end of the main cable is connected with an upper anchoring end stand column fixedly connected with a structure through a main cable shock absorption device. The upper ends of the secondary cables are connected with the upper anchoring end stand column fixedly connected with the structure through a secondary cable shock absorption device. Hanging rods are arranged between the main cable and each secondary cable as well as between the secondary cables. According to the multi-cable compounded damping cable, the multi-cable compounded damping cable can be installed between two structures which are at a long distance and move relatively, and has the energy dissipation and shock absorption effects basically equal to those of a damper installed between two structures very close to each other.

Owner:HUNAN UNIV OF SCI & TECH

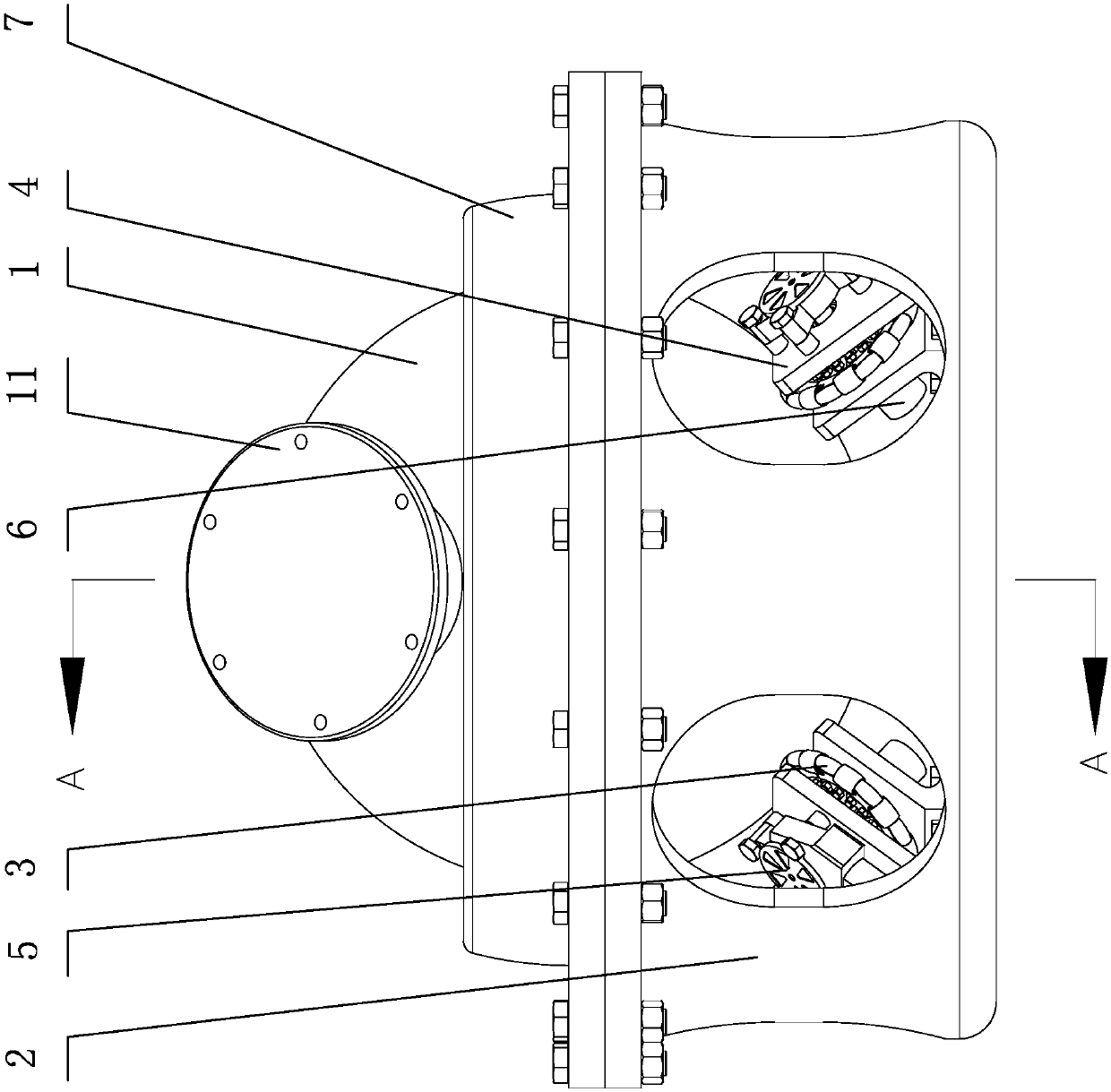

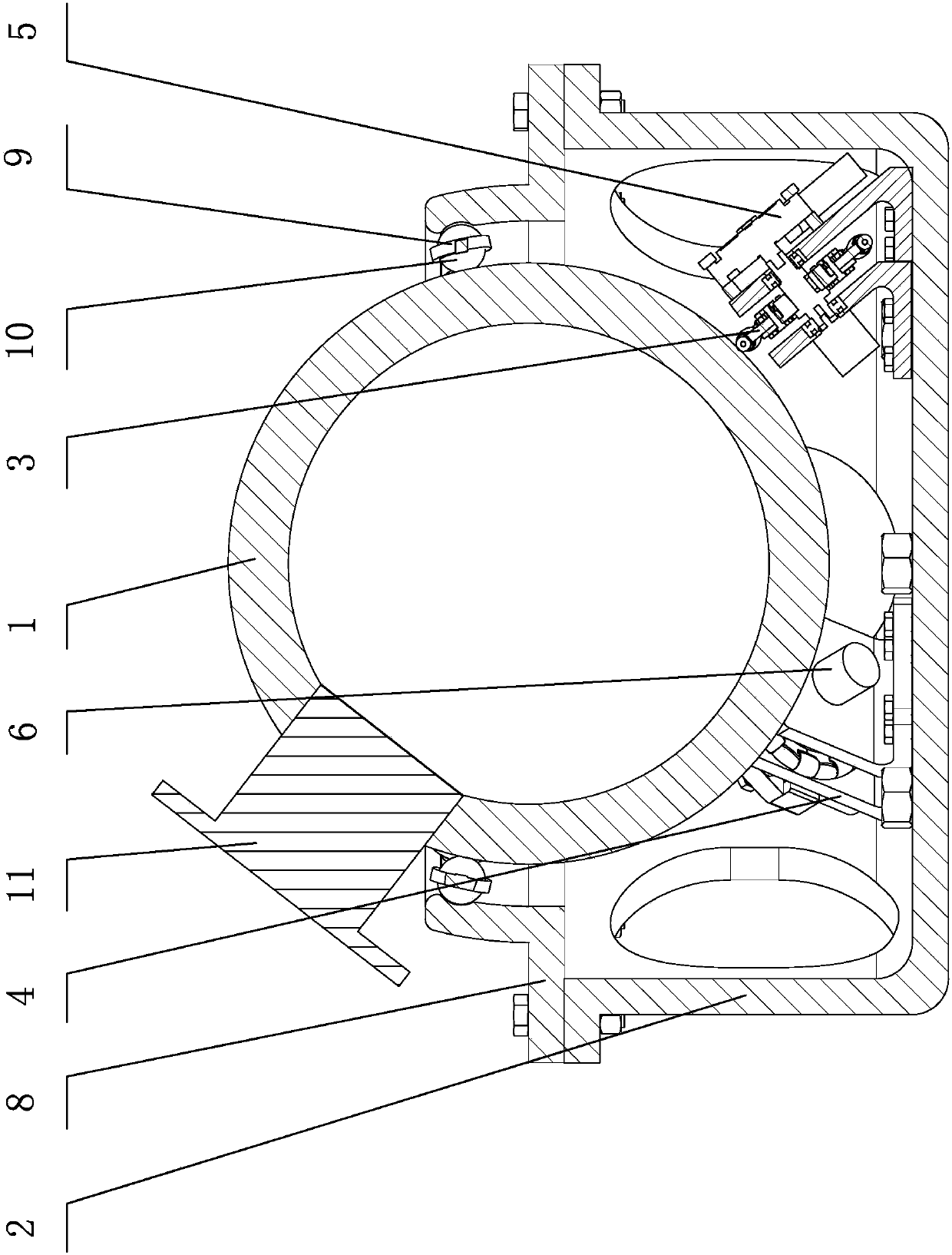

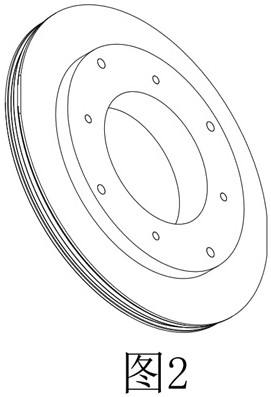

Straddle type monorail transit track beam spherical steel support

A straddle type monorail transit track beam spherical steel support comprises an upper anchorage unit, tensile and compressive rotating mechanisms, a base, a bottom plate, a support horizontal adjusting mechanism and a lower anchorage unit; multiple tensile and compressive rotating mechanisms are arranged between the upper anchorage unit and the base; the lower anchorage unit is connected with thebottom plate at the upper part and the support horizontal adjusting mechanism; and the base capable of performing horizontal adjustment by using the support horizontal adjusting mechanism is arrangedon the upper surface of the bottom plate. According to the straddle type monorail transit track beam spherical steel support, the structure is simple, the operation is convenient, the loading and unloading are convenient, the size of a support is effectively reduced, the weight of the support is reduced, the cost can be preferably reduced, the application range is enlarged, better transverse anti-bending capacity is realized, the running safety is effctively guaranteed, the additional force to a bridge is smaller, and the straddle type monorail transit track beam spherical steel support is beneficial for guaranteeing the service life of the bridge.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +1

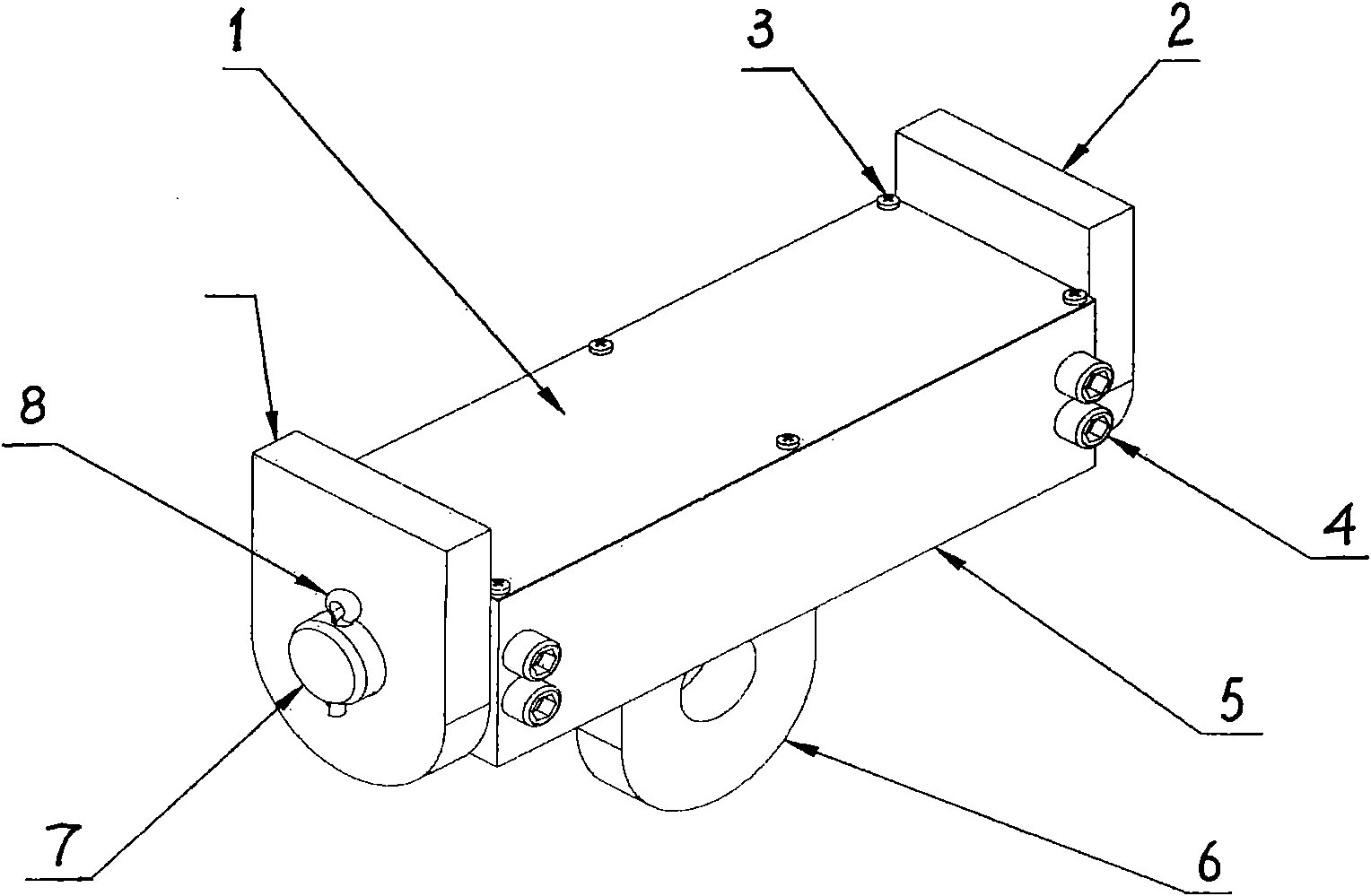

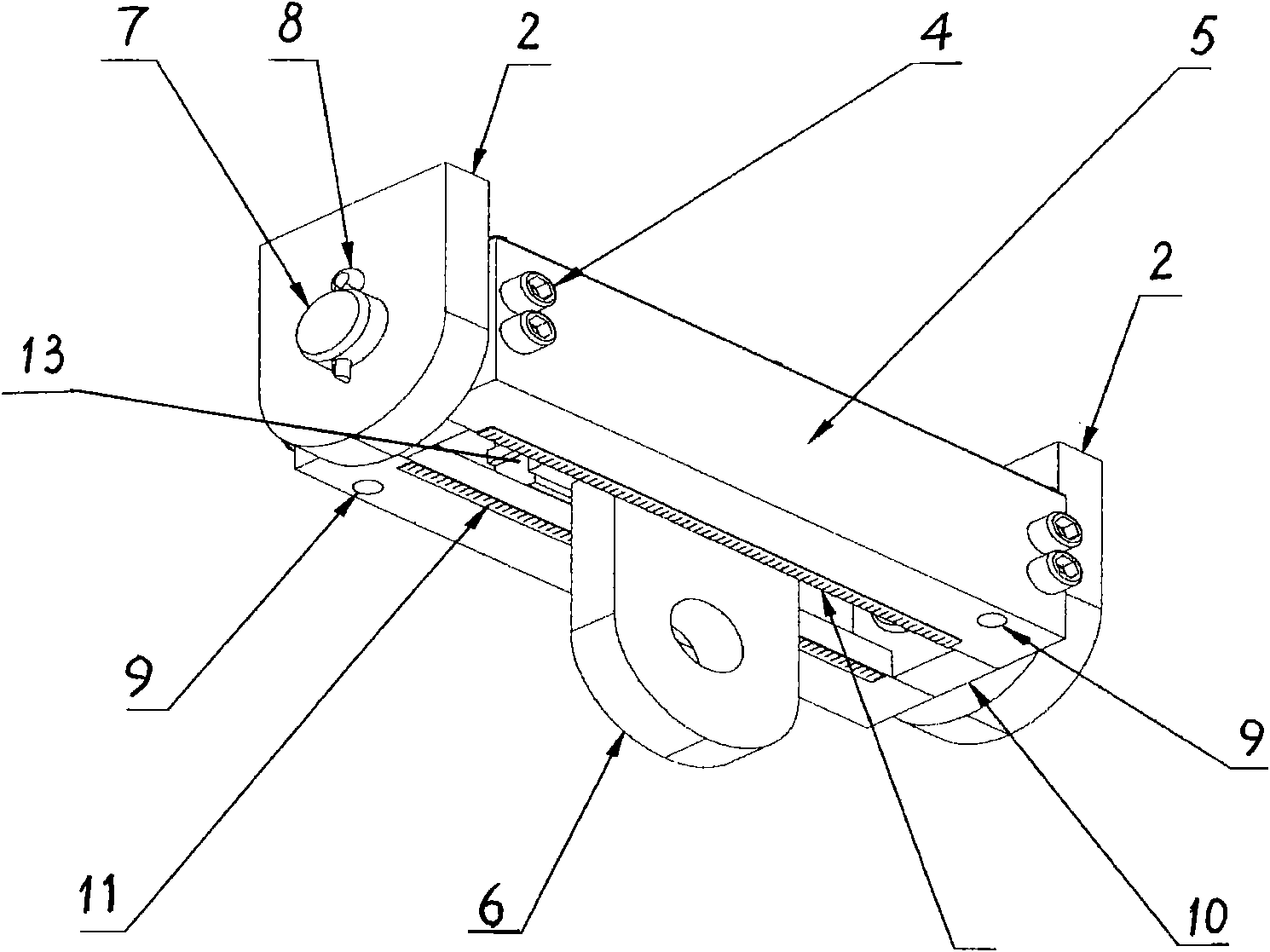

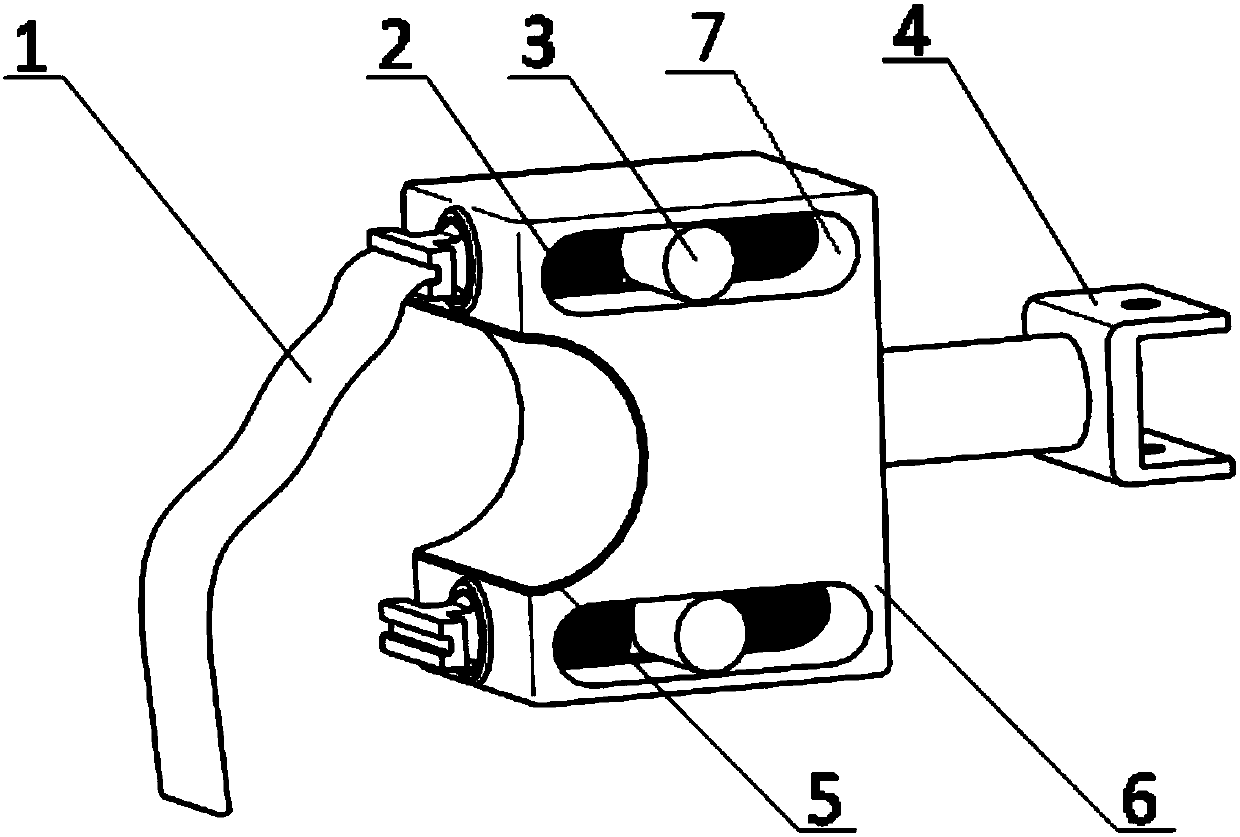

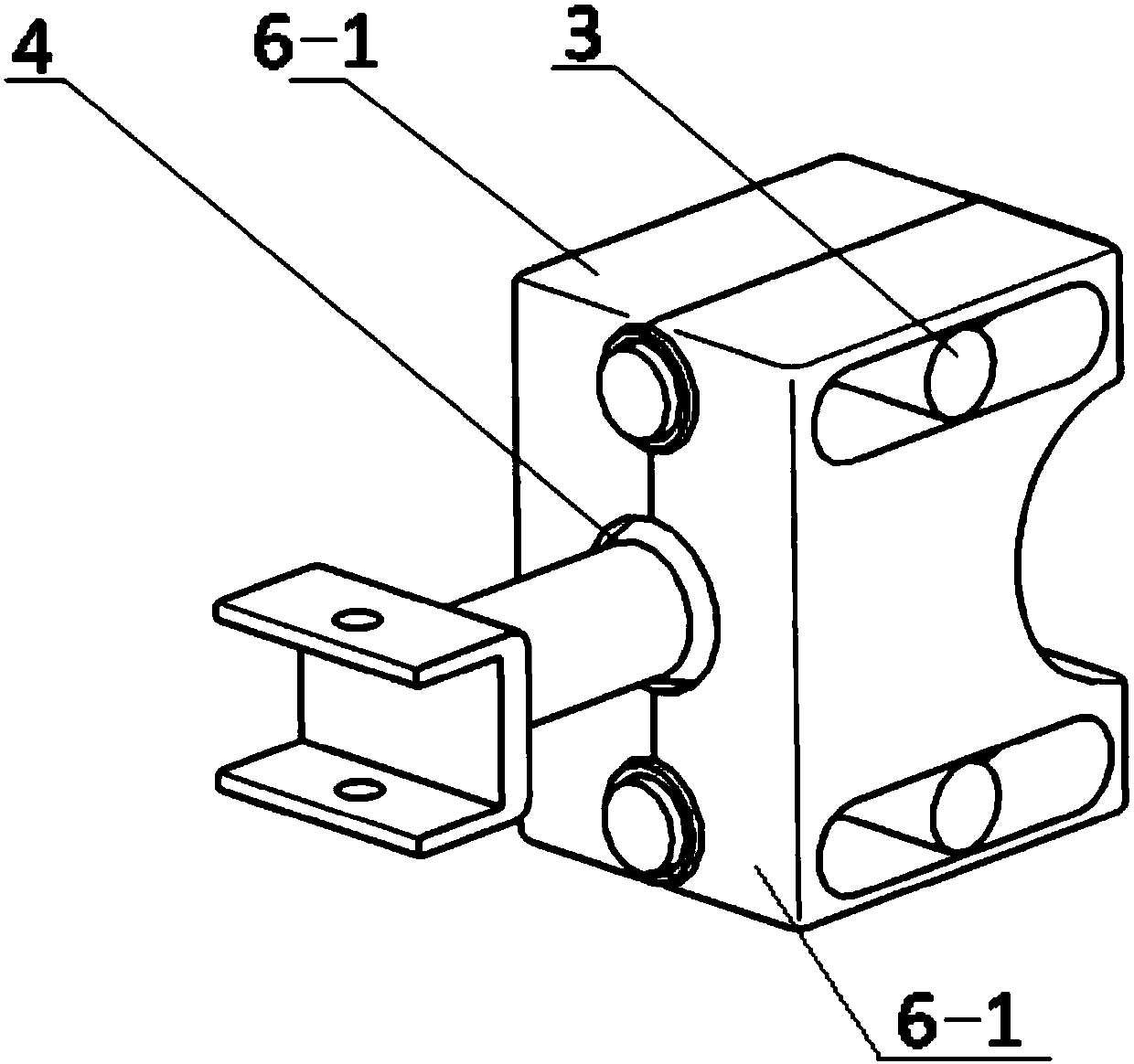

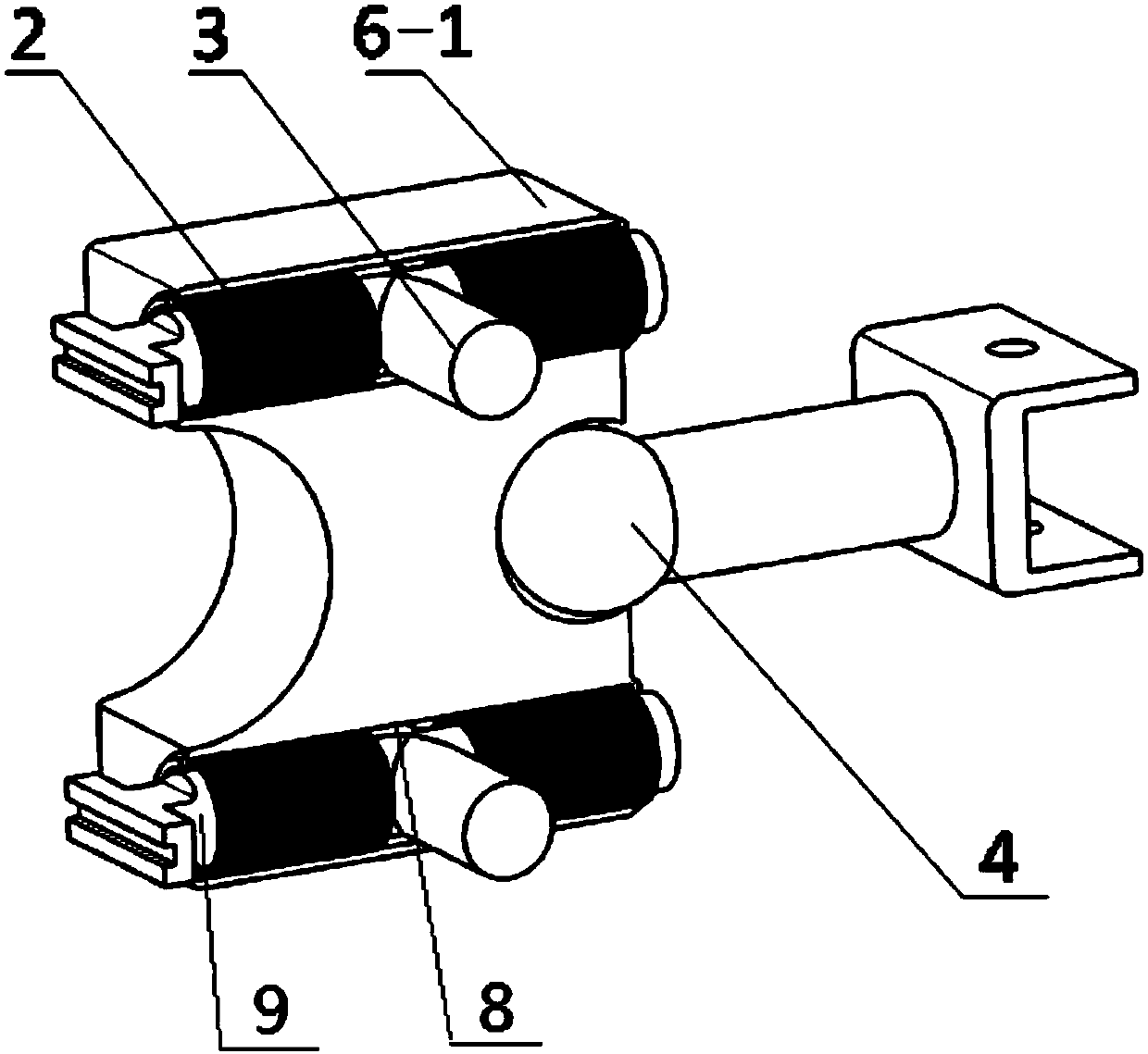

Rolling bearing root part for support hanger

InactiveCN101586697AReduce additional forceGuaranteed uptimePipe supportsRolling-element bearingThermal expansion

The invention discloses a rolling bearing root part for a support hanger, comprising a foraminate welding slice, a trolley upper protective plate, a welding side slice, trolley guide rails, a pin shaft, a level bubble, a trolley guide rail end block, a trolley scale, a first inside assembly, a second inside assembly, a cart upper protective plate, a cart fastening screw, cart rails, a rolling ball guide groove, a cart guide rail end block and a cart scale, wherein the first inside assembly is inlaid in the trolley guide rails through a rolling ball interface thereof, the second inside assembly is inlaid in the cart rails through a rolling ball interface thereof, the level bubble and the scale are arranged at the lower end of each trolley guide rail, and the scale is arranged at the lower end of each cart rail. The invention has the advantages that the rolling bearing root part for the support hanger has little frictional resistance coefficient to greatly reduce additional force of the support hanger to piping thermal expansion, can mark two dimensional displacement, can enhance the safety of running of piping equipment, enable the equipment running to be more stable, reduces the maintenance time, prolongs the service life, enhances the comprehensive benefit of construction, and can be widely applied to industries such as the power industry, the petrochemical industry, the metallurgical industry and the like.

Owner:申松林

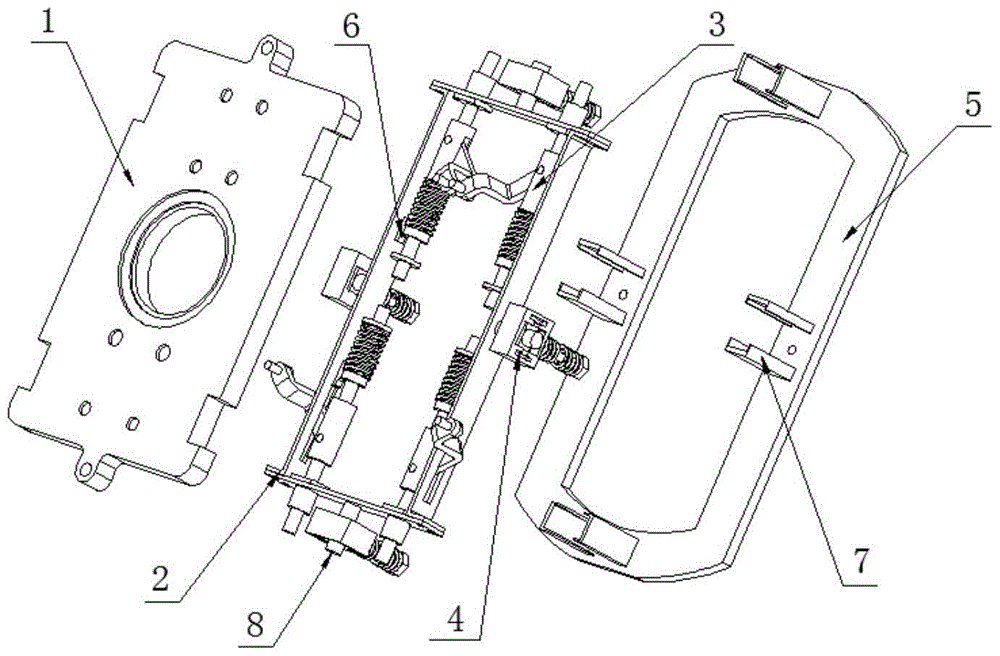

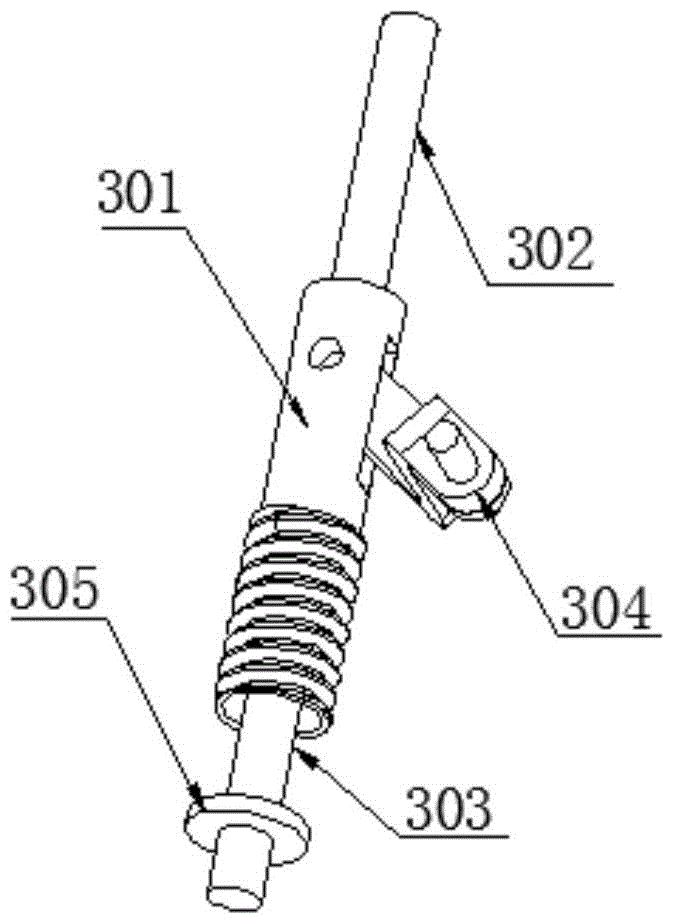

Outward opening door unlocking device for fatigue test of automobile door

PendingCN107907349AReduce momentary impactAvoid destructionVehicle testingMachine part testingManufacturing technologyCar door

The invention relates to an outward opening door unlocking device for a fatigue test of an automobile door, and belongs to the field of automobile component testing and manufacturing technologies. Thedevice is mainly used for performing a fatigue durability test on the automobile door. The device mainly comprises an elastic rope, a sliding block mechanism, a U-shaped base, a spherical hinge structure, a rubber gasket and the like, wherein the rubber gasket is installed in a U-shaped opening of the U-shaped base and used for eliminating an impact force generated by opening and closing the doortogether with the elastic rope, the sliding block mechanism comprises moving blocks, sliding blocks and springs, and the sliding block mechanism is used for counteracting an elastic distance betweenthe mechanisms, so that the automobile door is ensured not to be excessively opened or closed. The spherical hinge is used for eliminating the additional torque of the mechanism, thereby avoiding an additional force from being applied to a handle of the automobile door. The outward opening door unlocking device is simple in structure and easy to implement, can greatly improve the test accuracy andhas popularization values.

Owner:SHANDONG UNIV

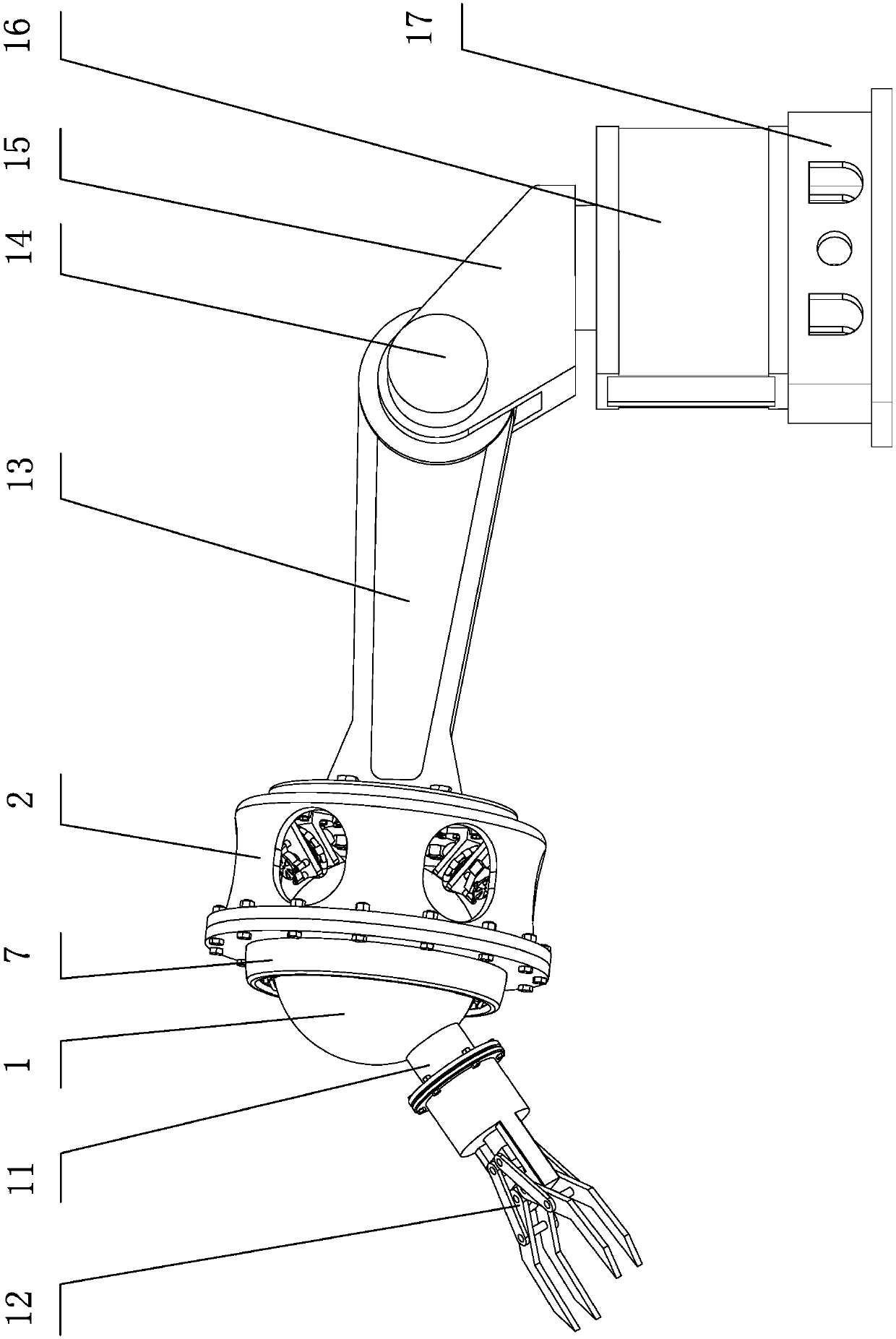

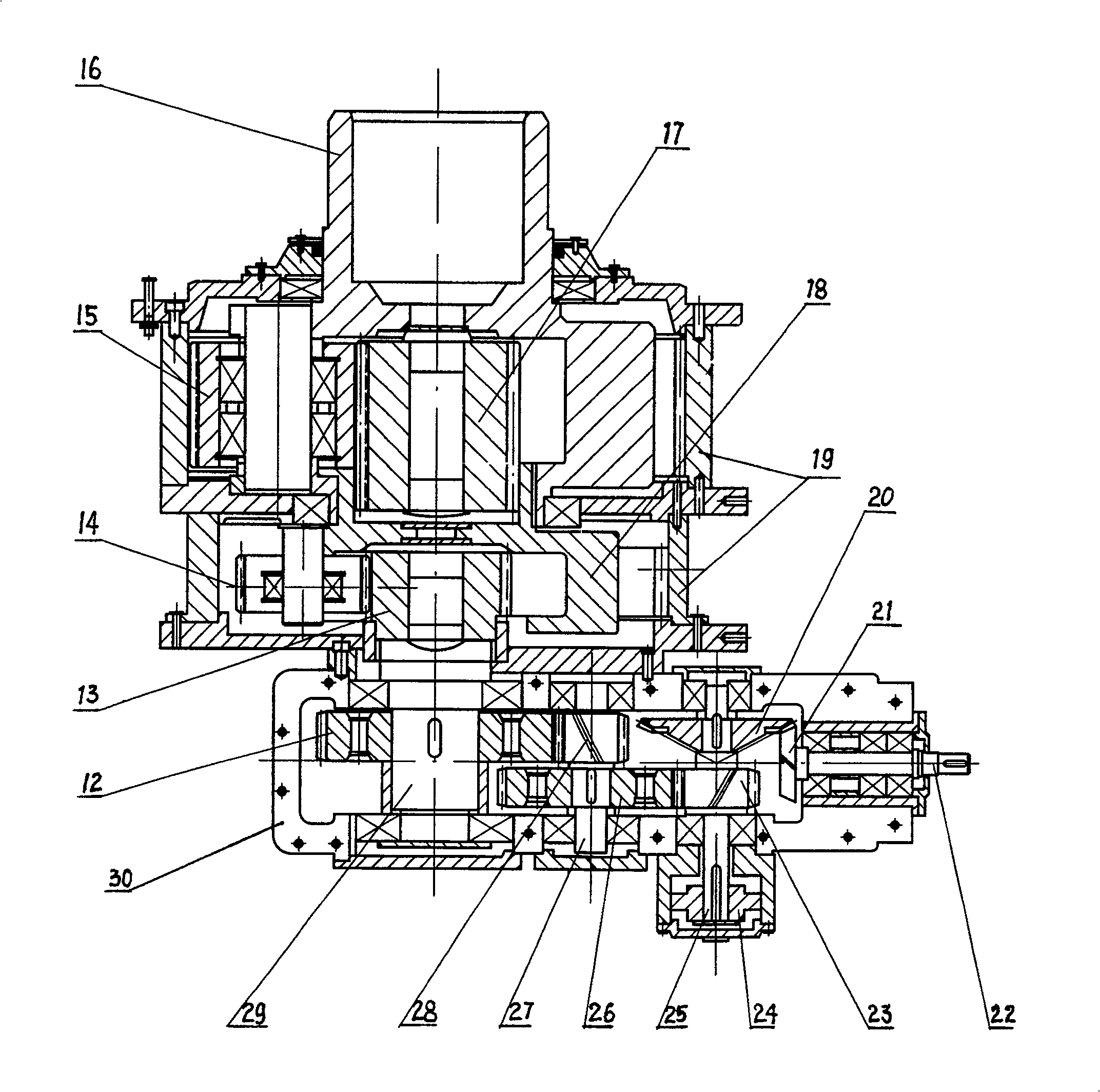

Robot wrist joint mechanism driven by omnidirectional wheels

The invention discloses a robot wrist joint mechanism driven by omnidirectional wheels. The robot wrist joint mechanism comprises a ball joint and is characterized in that the lower half ball of the ball joint is arranged in a ball joint cup-shaped rack and is friction contact three single-row omnidirectional wheels evenly distributed on the inner periphery of the ball joint cup-shaped rack, the three single-row omnidirectional wheels are mounted through corresponding wheel racks, the rotation central lines of the three single-row omnidirectional wheels inclines downwards and intersect at onepoint, the intersection point is locate right below the ball center of the ball joint, each wheel rack is provided with a ball joint motor for driving the corresponding single-row omnidirectional wheel and an encoder for detecting the corresponding single-row omnidirectional wheel, the ball joint cup-shaped rack is provided with a disconnection preventing component acting on the upper half ball ofthe ball joint, and the upper half ball of the ball joint is provided with a platform seat allowing an operation tool to be mounted. The robot wrist joint mechanism has the advantages that the positions and postures of mechanical tongs in a three-dimensional space can be regulated and changed, and the robot wrist joint mechanism is stable in motion, flexible in steering and small and exquisite insize.

Owner:GUILIN UNIV OF ELECTRONIC TECH

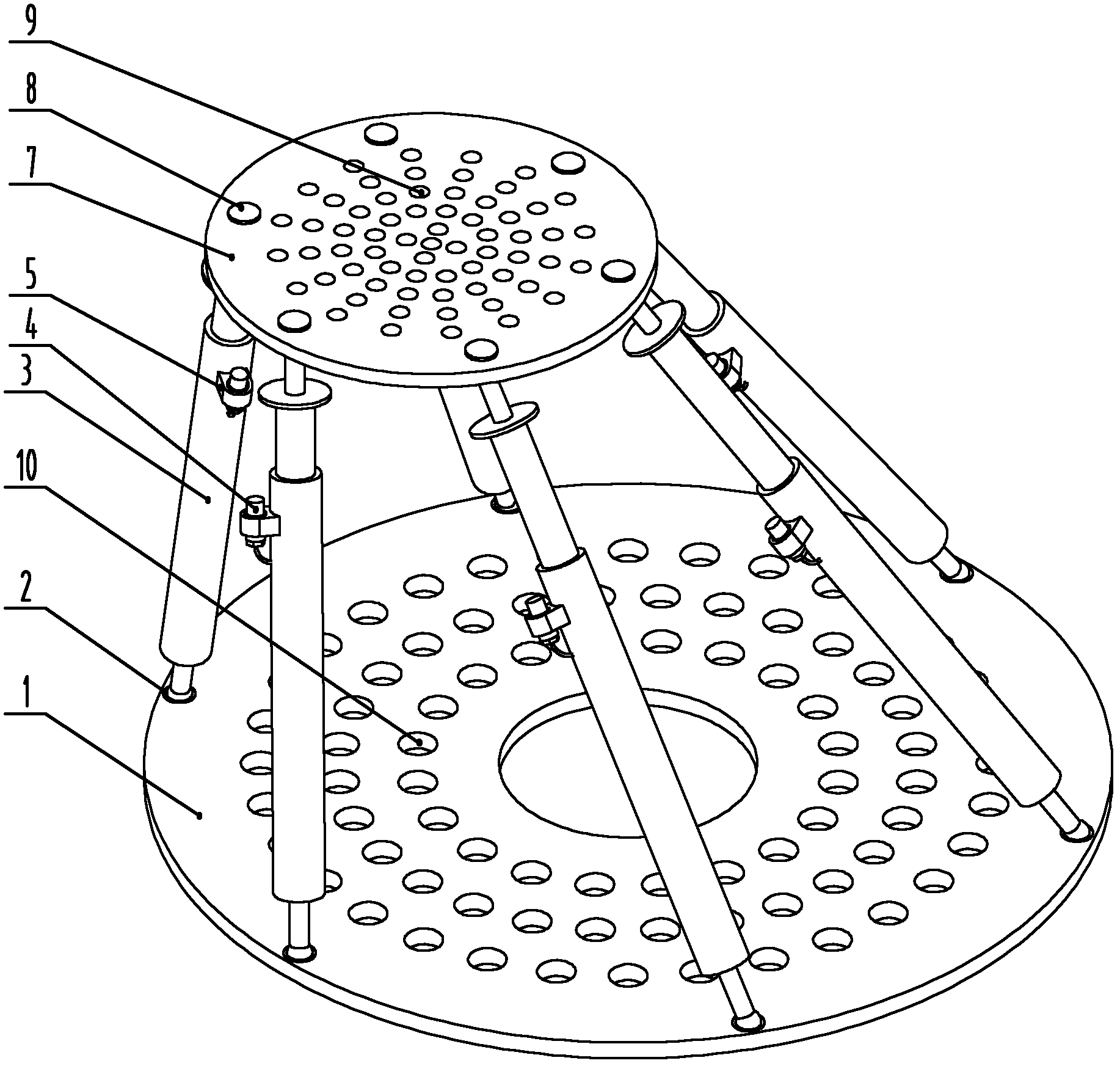

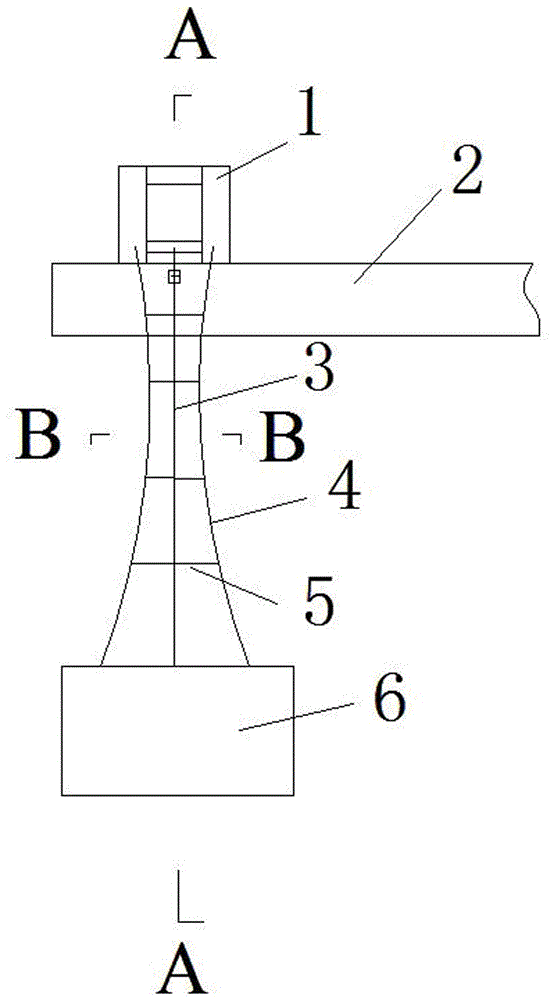

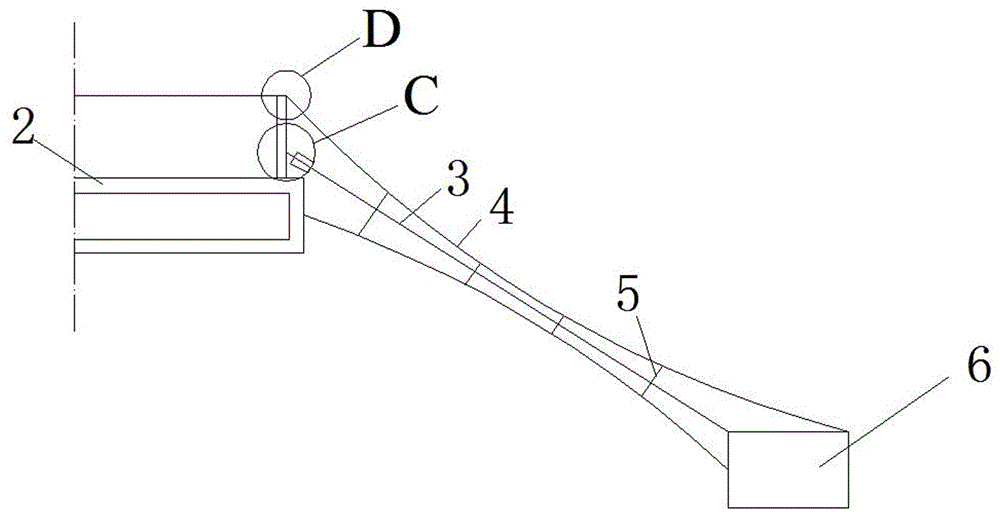

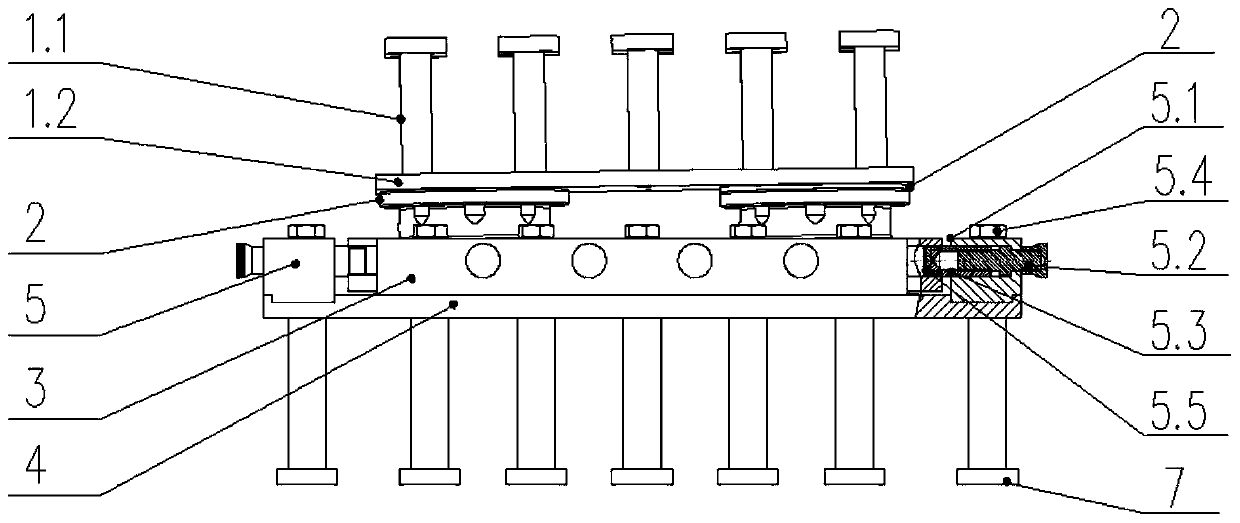

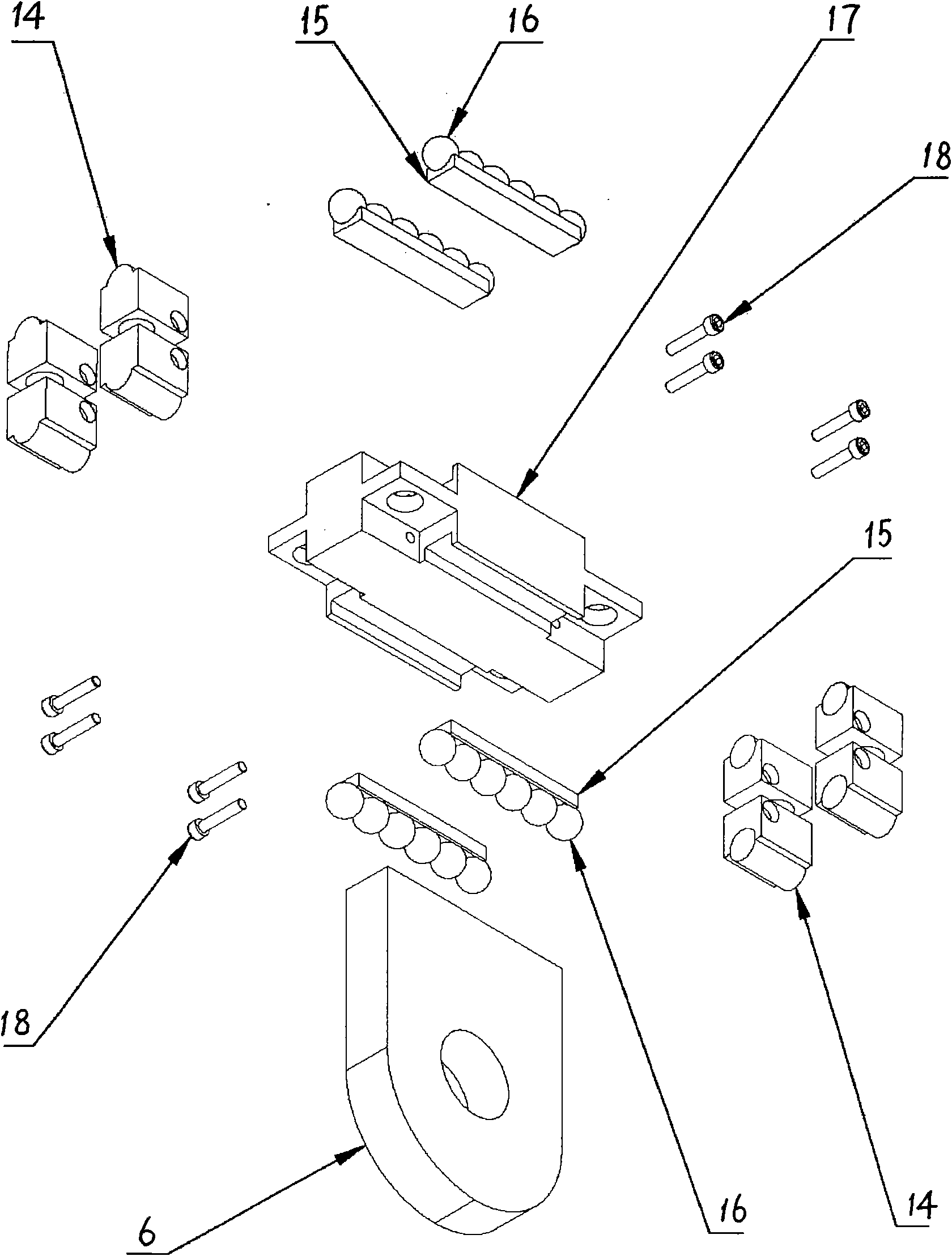

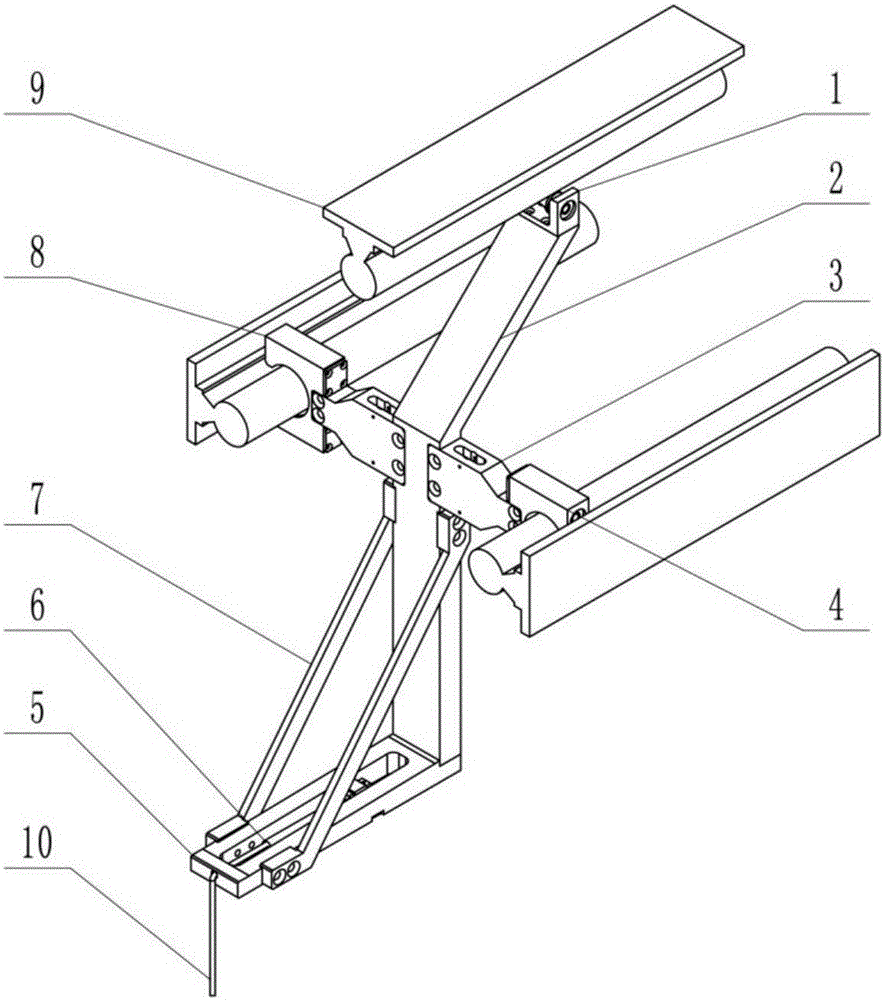

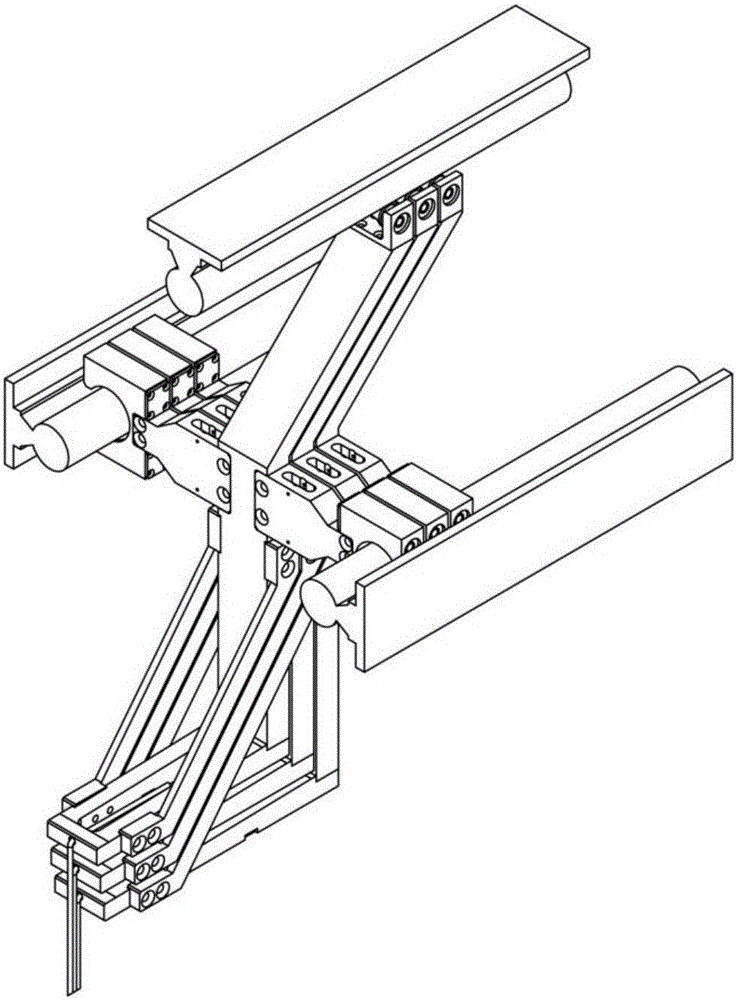

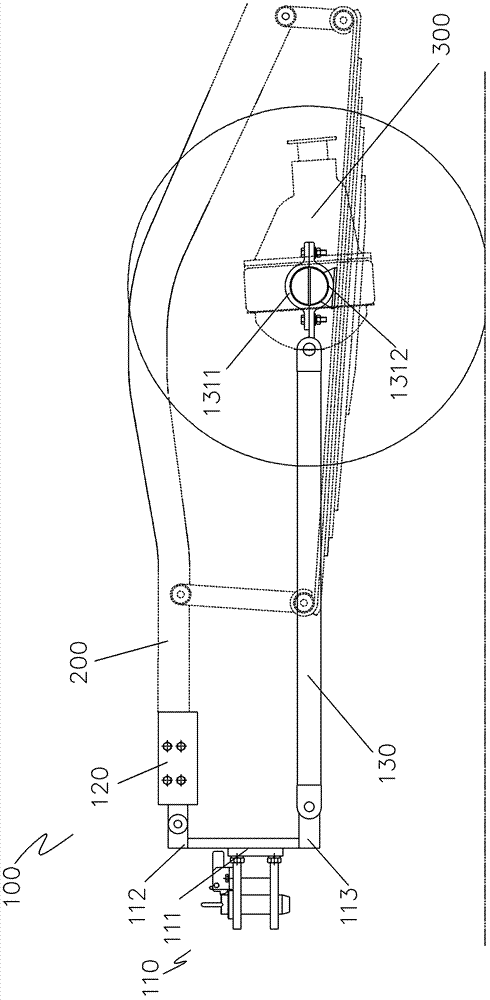

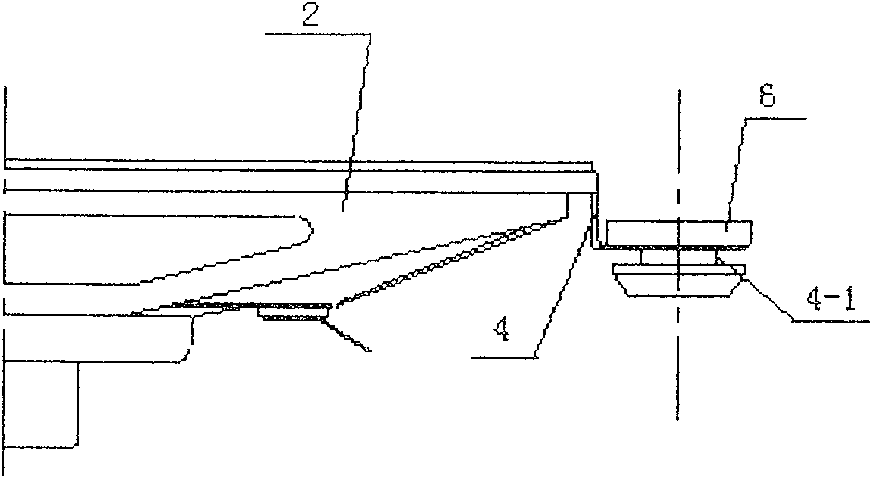

Gravity discharge device for ground-spreading flexible solar wing

InactiveCN105836158AAchieve gravity unloadingReduce additional forceGround installationsCantileverGravitation

The invention discloses a gravity unloading device for a ground-deployed flexible solar wing. Using the present invention can be applied to the extremely small spacing when the solar panels of the flexible solar wing are folded, can realize the gravitational unloading of the flexible solar wing, and can passively follow the movement of the flexible solar wing in the deployment direction of the solar wing, effectively ensuring the accuracy of the ground test precision and accuracy. The present invention includes a first limit roller device, a column, a beam, a roller device, a cantilever, an adjuster, a second limit roller device and a sling, wherein the cantilever is vertically fixedly connected to one end of the column and forms a "Z" shape with the column ;The beam is fixedly connected to the bending part of the column, and through the three roller devices, it can effectively reduce the excessive additional force and additional moment introduced by the unloading tooling. The first limit roller device and the second limit roller device are on the contact surface with the guide rail. There is a limit chute on the top to avoid vibration and shock.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Saddle structure with cable twisting limiting function

PendingCN110707633AAvoid installationAvoid entanglementElectrical apparatusMachines/enginesElectromagnetic interferenceTower

The invention discloses a saddle structure with a cable twisting limiting function. The structure comprises a transition saddle, a limiting swing arm and a first cable separation assembly, the transition saddle and the limiting swing arm are hinged to the two ends of the limiting swing arm respectively, so the first cable separation assembly swings only in the vertical direction. The transition saddle comprises a support and a cable bridge used for carrying a cable, the support is installed on a tower drum, the limiting swing arm is hinged to the support, and a plurality of branching holes areformed in the first cable separation assembly. The suspension cable is isolated and clamped by the cable separation assembly, so that the cables are prevented from being wound and collided during yawing, and damage and electric leakage caused by mutual friction of cable sheaths are avoided. When the cable is arranged, a three-phase one-group arrangement mode is adopted, electromagnetic interference is reduced, current transmission quality is ensured, the limiting swing arm ensures that the cable only moves up and down and does not twist or swing, and stress of the cable is effectively reducedwhile abrasion of the cable is further avoided.

Owner:CSIC CHONGQING HAIZHUANG WINDPOWER EQUIP

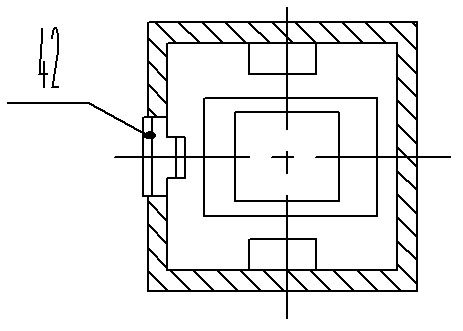

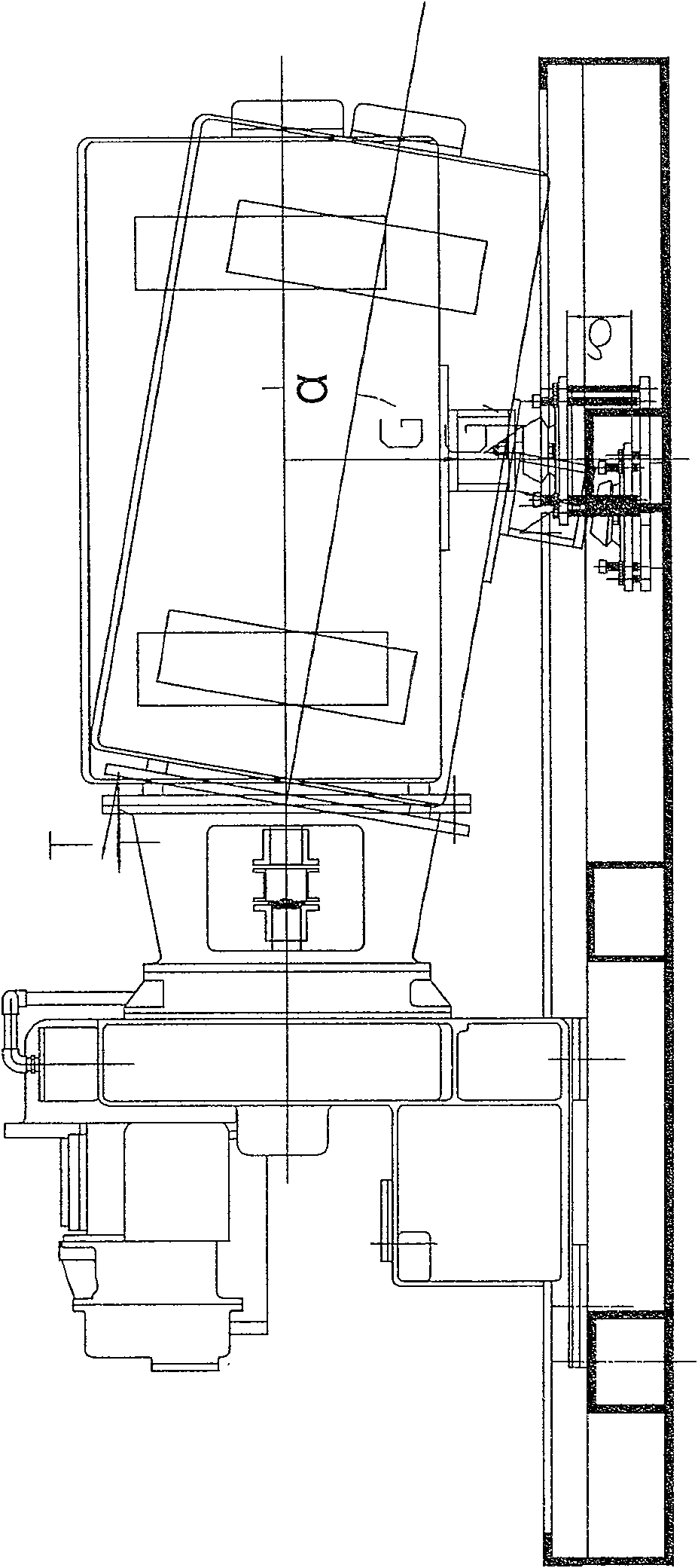

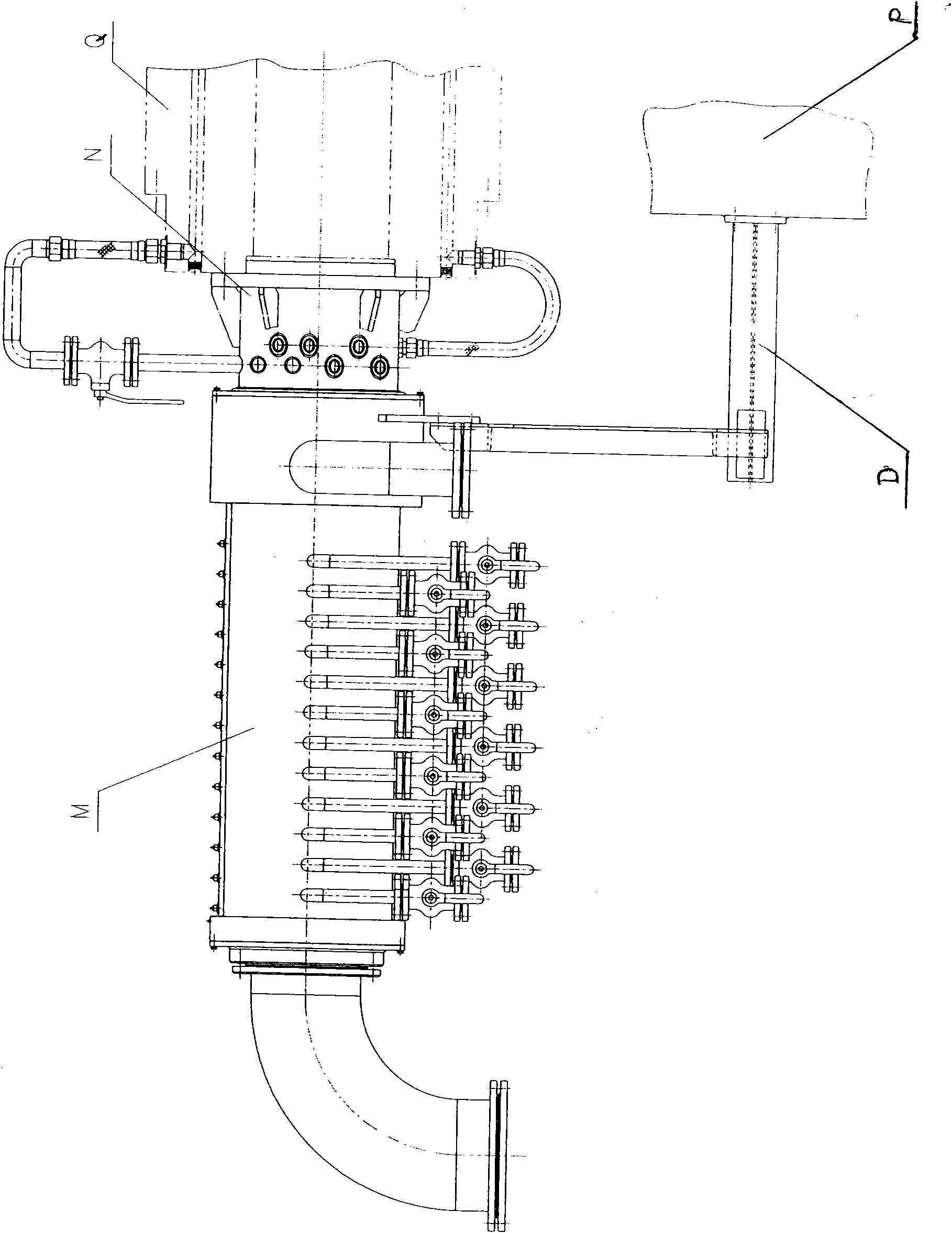

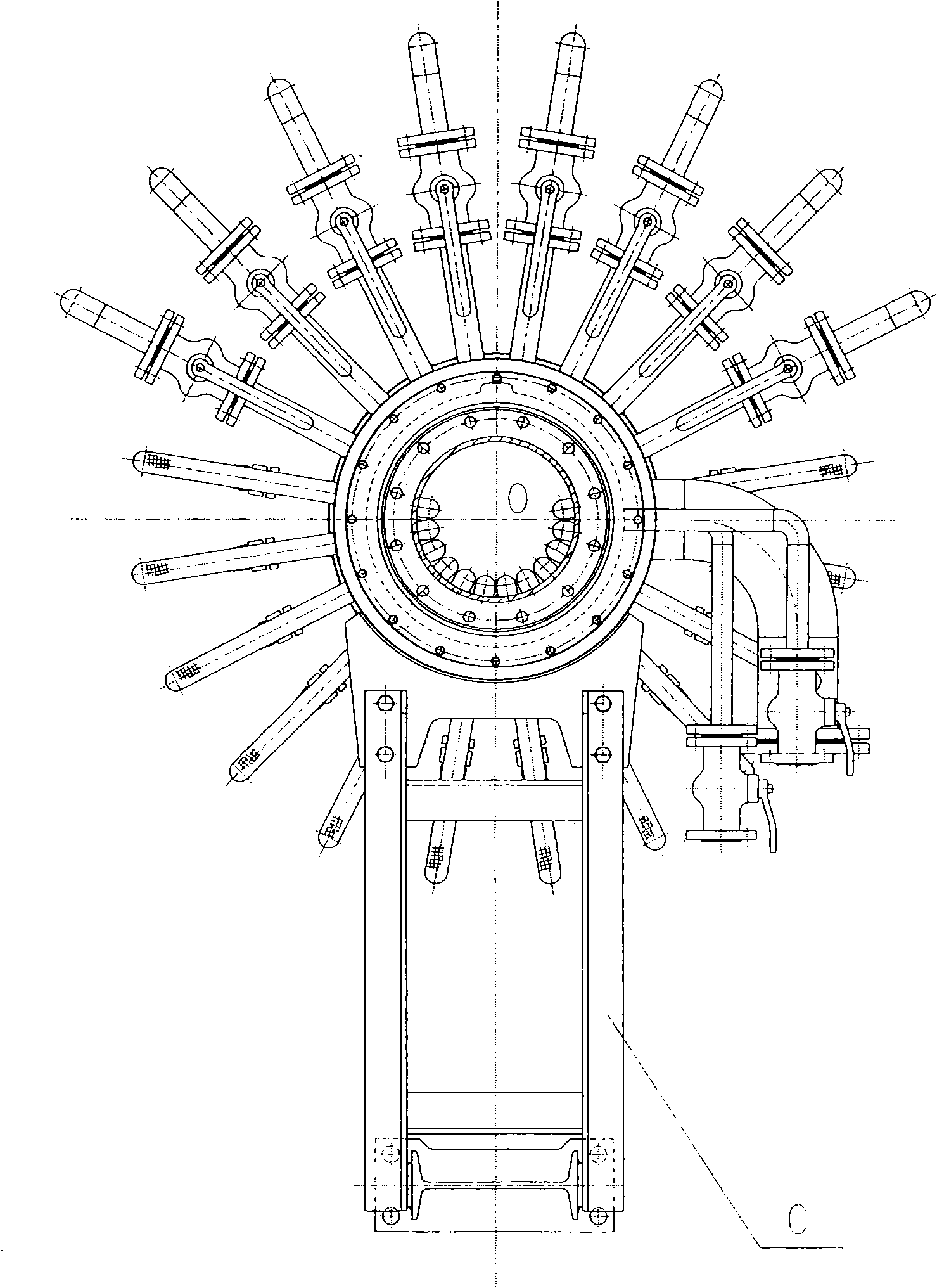

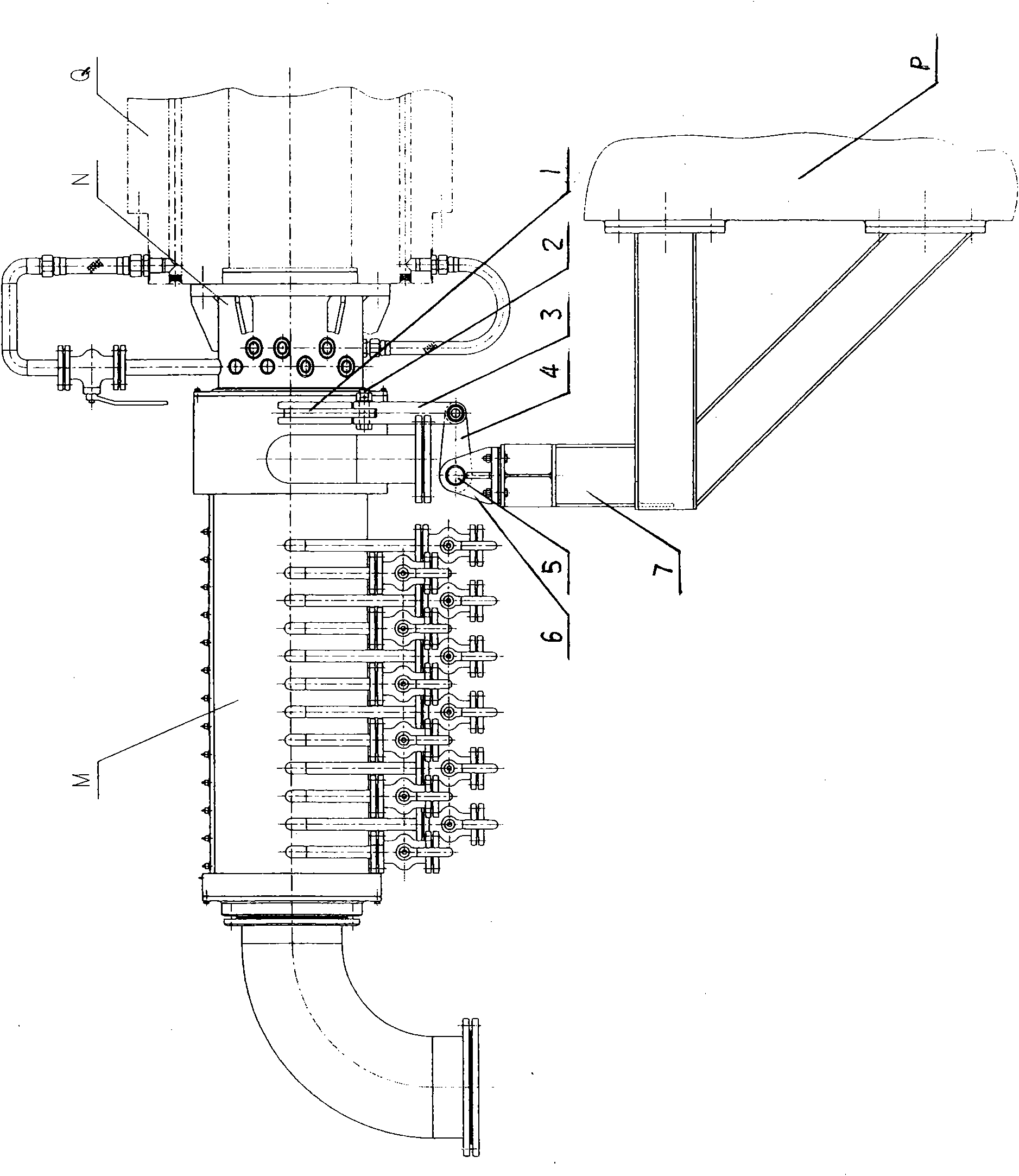

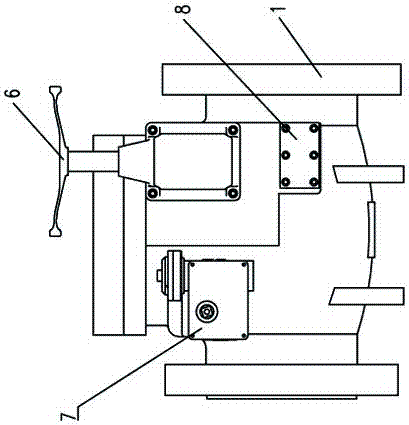

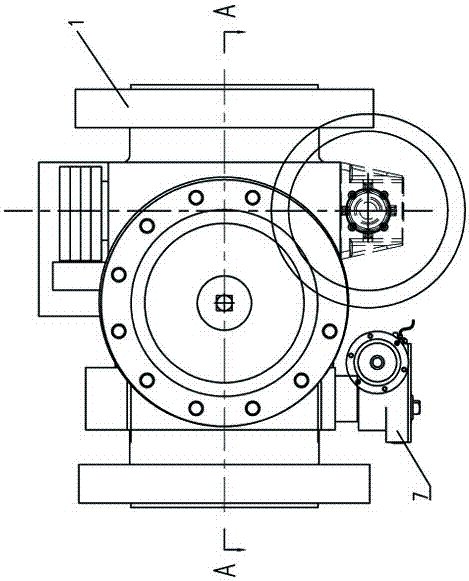

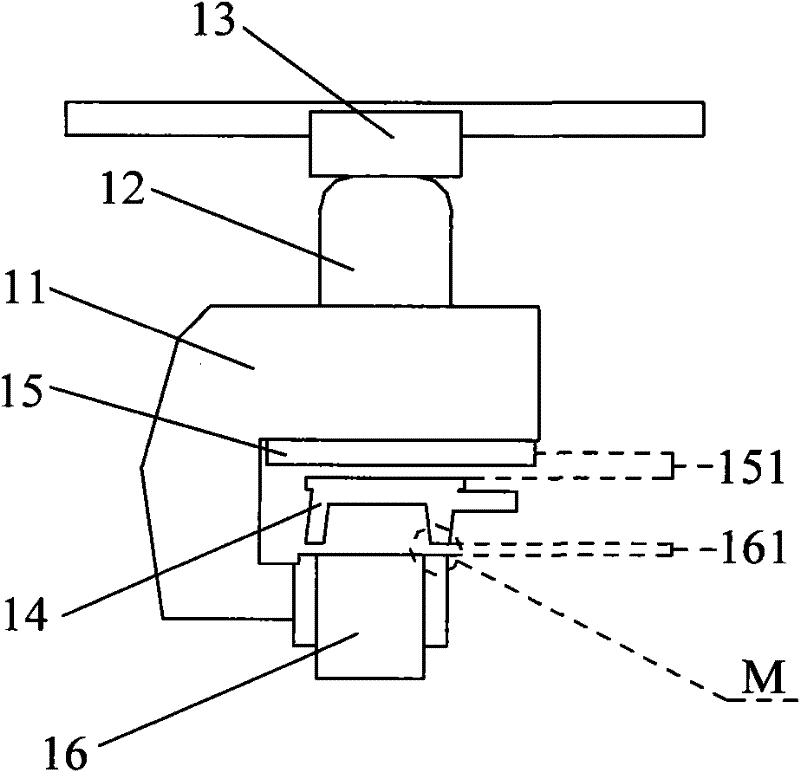

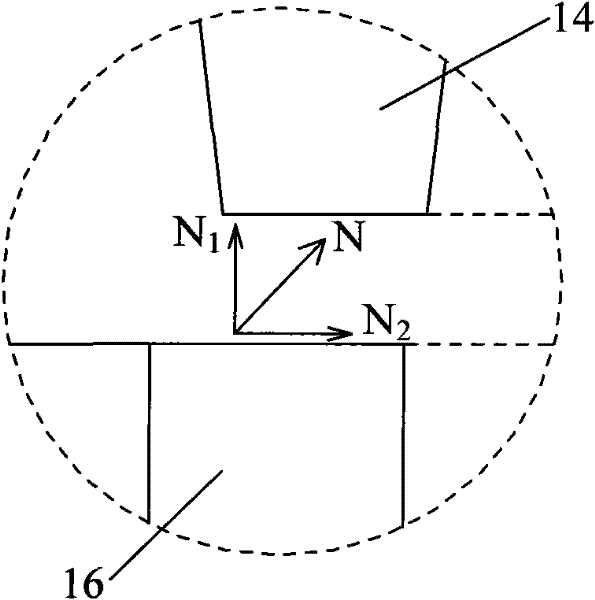

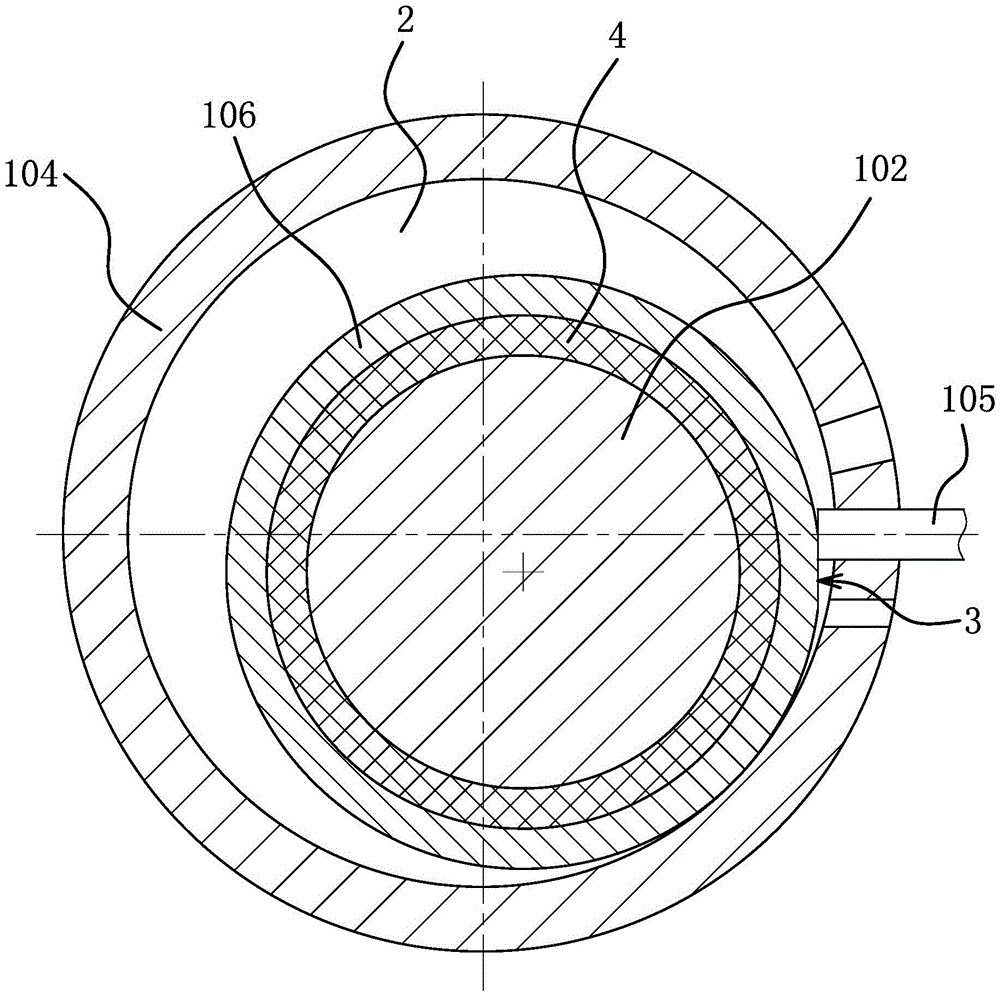

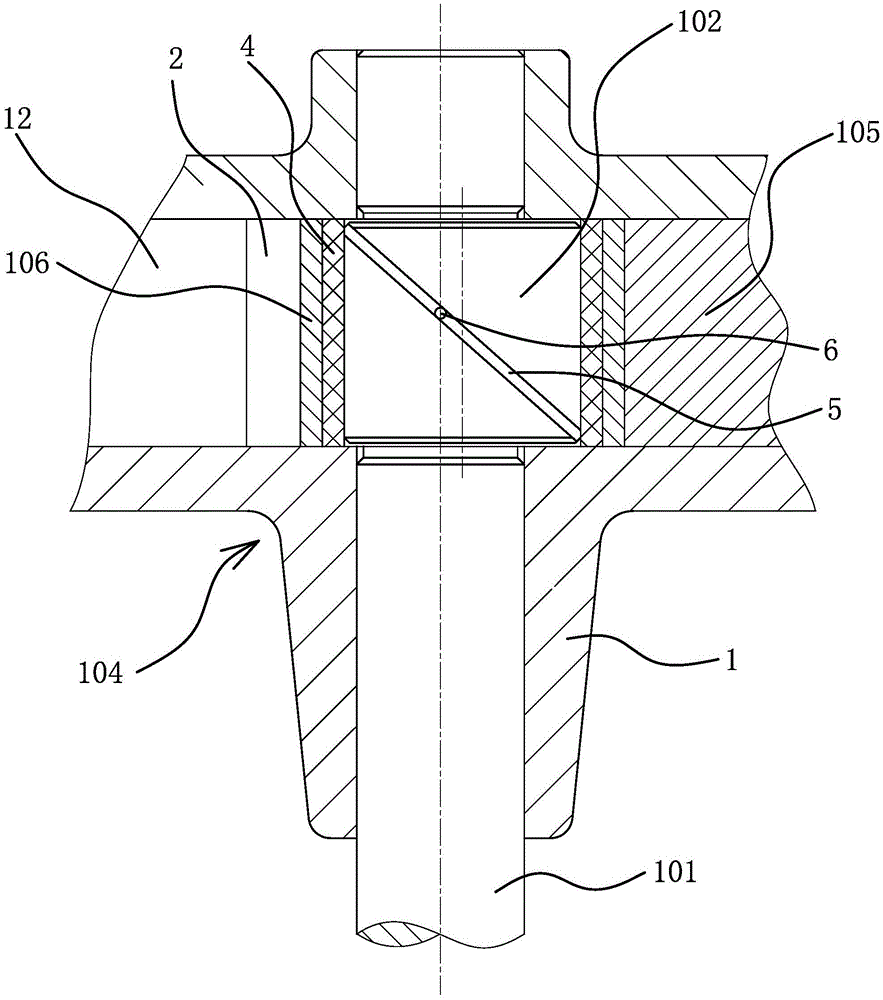

Anti-rotation device of rotary joint

ActiveCN101603112AReduce additional forceCompact structureManufacturing convertersEngineeringMechanical equipment

The invention belongs to the technical field of mechanical engineering, in particular discloses an anti-rotation device of a rotary joint, mainly comprising a rotary joint outer sleeve M and a rotary joint spindle N. A fixed plate is fixedly connected with the rotary joint outer sleeve M, one end of a connecting rod is hinged on the fixed plate by a pin shaft, and the other end of the connecting rod is hinged on a crank by the pin shaft; one end of the crank is hinged on the connecting rod by the pin shaft, and the other end of the crank is fixedly connected with a torsion rod; both ends of the torsion rod are respectively sleeved in bracket holes; a bracket is connected with a support by bolts, and the support is fixed on a converter bearing seat bracket by bolts. The anti-rotation device of the rotary joint has compact structure, light weight, reliable and high-efficiency work, low operation cost, good safety performance and long service life, is in an ideal structural mode of preventing the rotation of the converter rotary joint, not only can be applied to a converter, but also can be widely applied to various similar mechanical equipment in other industries.

Owner:CISDI ENG CO LTD

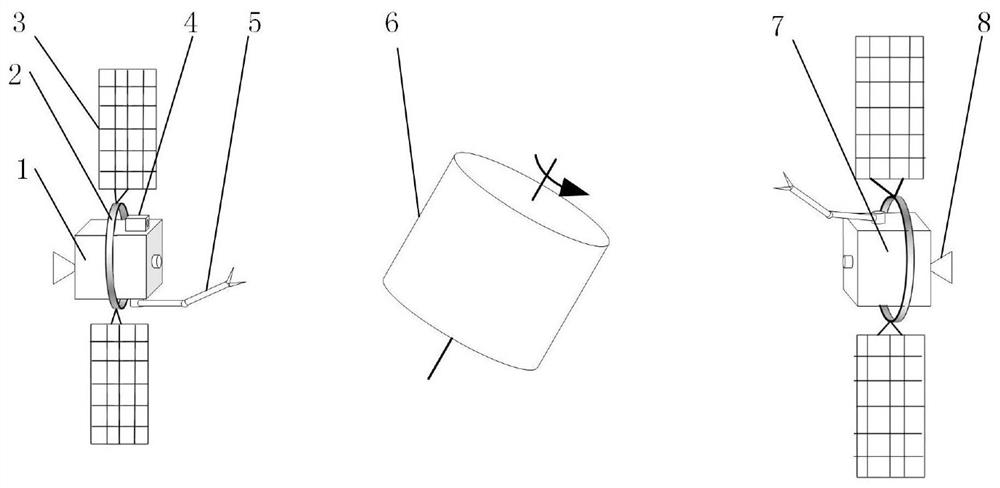

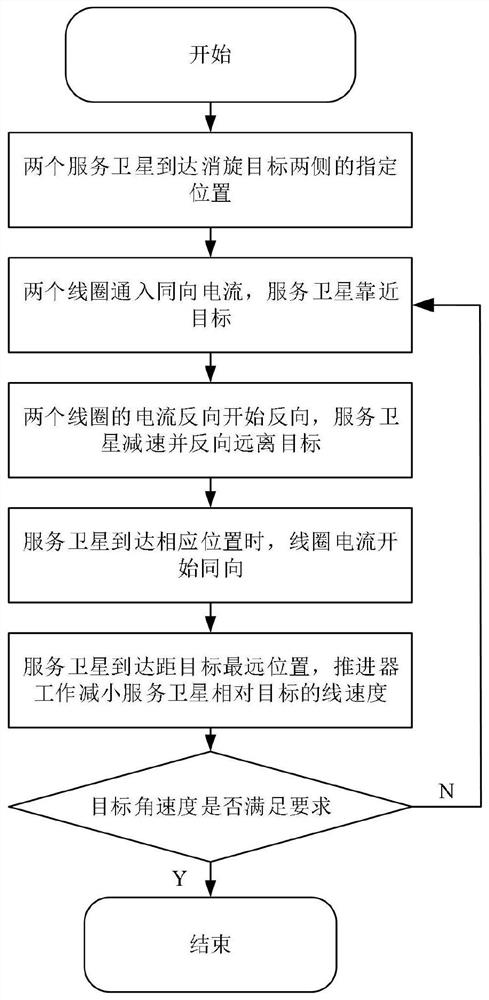

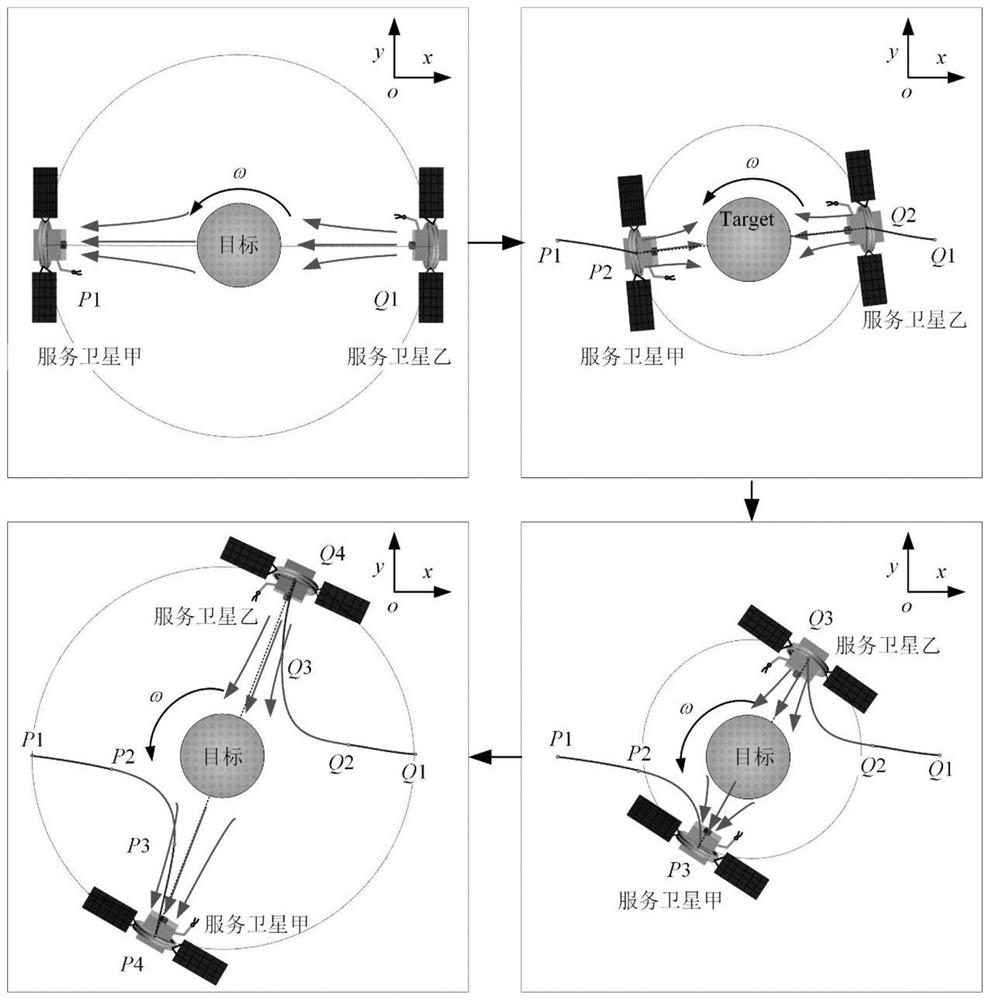

Space tumbling target non-contact racemization method based on double-satellite electromagnetic formation satellite

PendingCN113608539ATo achieve the purpose of slowing downIncrease the safety distanceAttitude controlElectrical conductorClassical mechanics

The invention discloses a space tumbling target non-contact racemization method based on a double-satellite electromagnetic formation satellite. According to the method, two small satellites carrying high-temperature superconducting coils are utilized to form an electromagnetic formation to reach the two sides of a non-cooperative target, and a space controllable magnetic field for enveloping the target is built; and the two service satellites continuously approach to and move away from the target by controlling the magnitude and direction of the current of the satellite-borne coils and the attitude of the formation satellites. The non-contact electromagnetic effect of the target and the coil system is achieved through eddy current torque induced by movement of a conductor on the target relative to a coil magnetic field, the angular momentum of the target is absorbed, and the angular momentum of the service satellite system is consumed at the farthest point through a propellant. The invention aims to solve the problem that capturing is difficult to implement due to complex rolling motion of the non-cooperative target.

Owner:HARBIN INST OF TECH

Construction method of small clear distance laminated tunnel

ActiveCN109356592BConstruction safetyAvoid damageUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention relates to a construction method of a small-clear-distance laminated tunnel. The construction method comprises the following steps that a to-be-constructed lower layer tunnel and a to-be-constructed upper layer tunnel are subjected to in-advance support; the area, close to the upper layer tunnel, in the lower layer tunnel is excavated to form a first area, and corresponding construction of primary lining is conducted; a pilot tunnel is excavated at the position, opposite to the first area, inside the upper layer tunnel, and subjected to primary lining; a reinforcing device for sandwiched rock between the upper layer tunnel and the lower layer tunnel is constructed in the pilot tunnel; the rest part of the lower layer tunnel is excavated to subjected to corresponding construction of primary lining, and the lower layer tunnel is subjected to secondary lining construction; and the rest part of the upper layer tunnel is excavated and subjected to subsequent construction. According to the construction method, the pilot tunnel is arranged on the upper layer tunnel to enable a vibration wave to be propagated in air so as to reduce the influence of blasting of the upper layertunnel on a lower layer tunnel support structure and the sandwiched rock, mechanical equipment can be directly arranged in the pilot tunnel for operation, work such as sandwiched rock drilling is conducted from top to bottom, the problem that the small-clear-distance laminated tunnel is difficult to construct is solved, and thus the construction process is safer.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

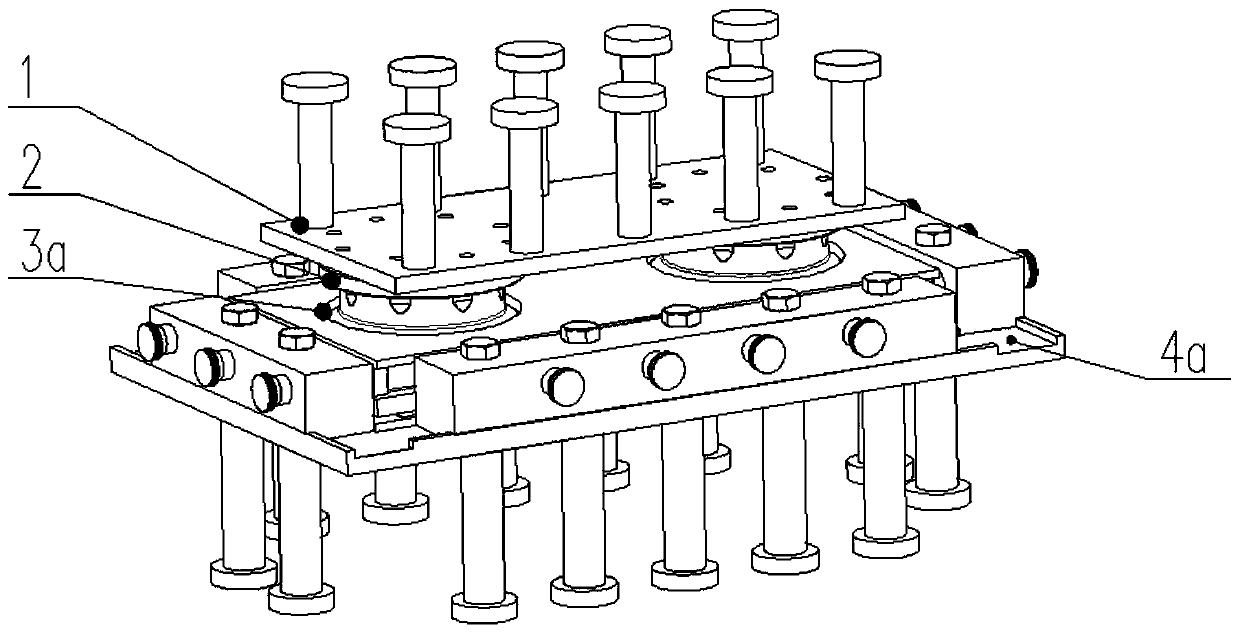

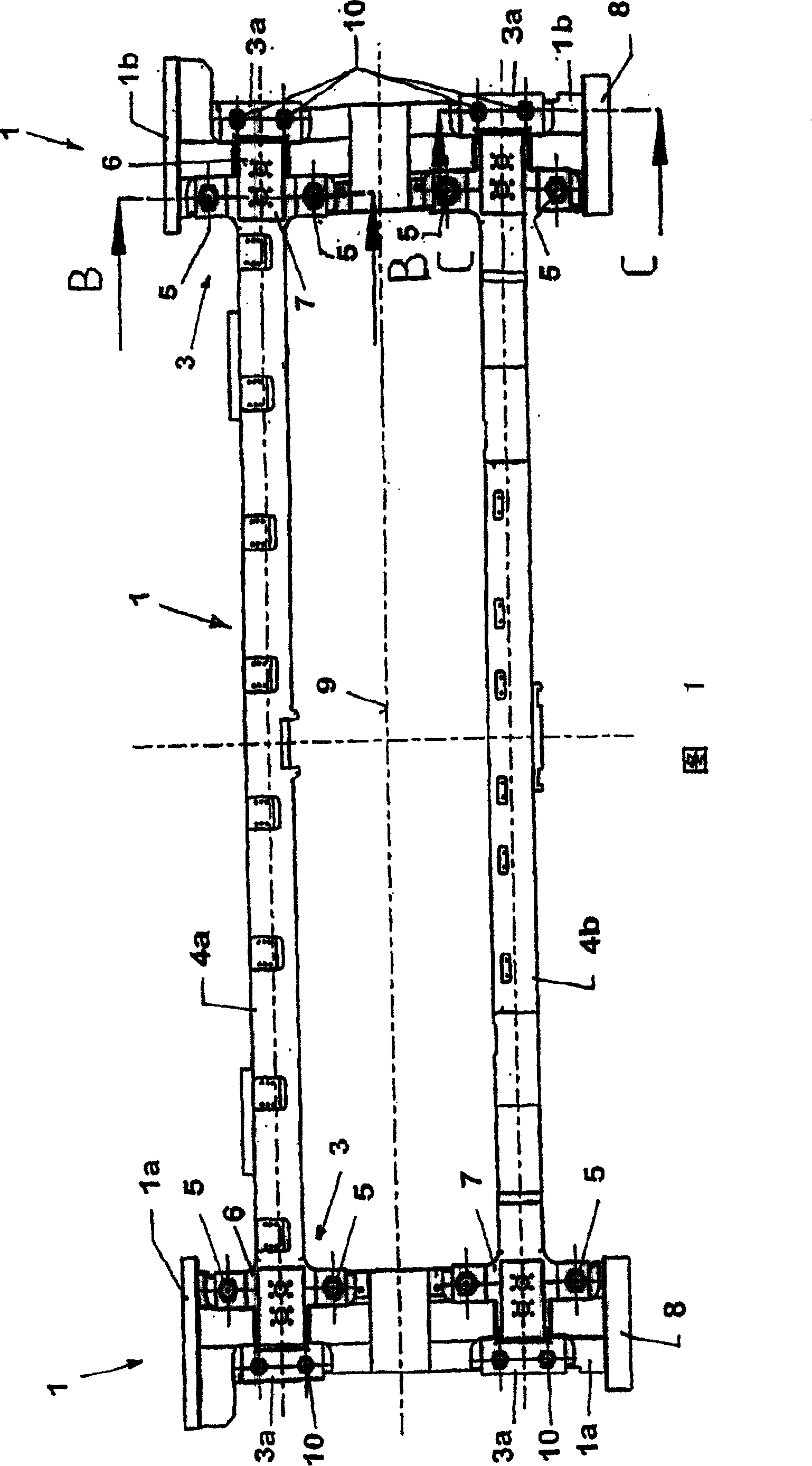

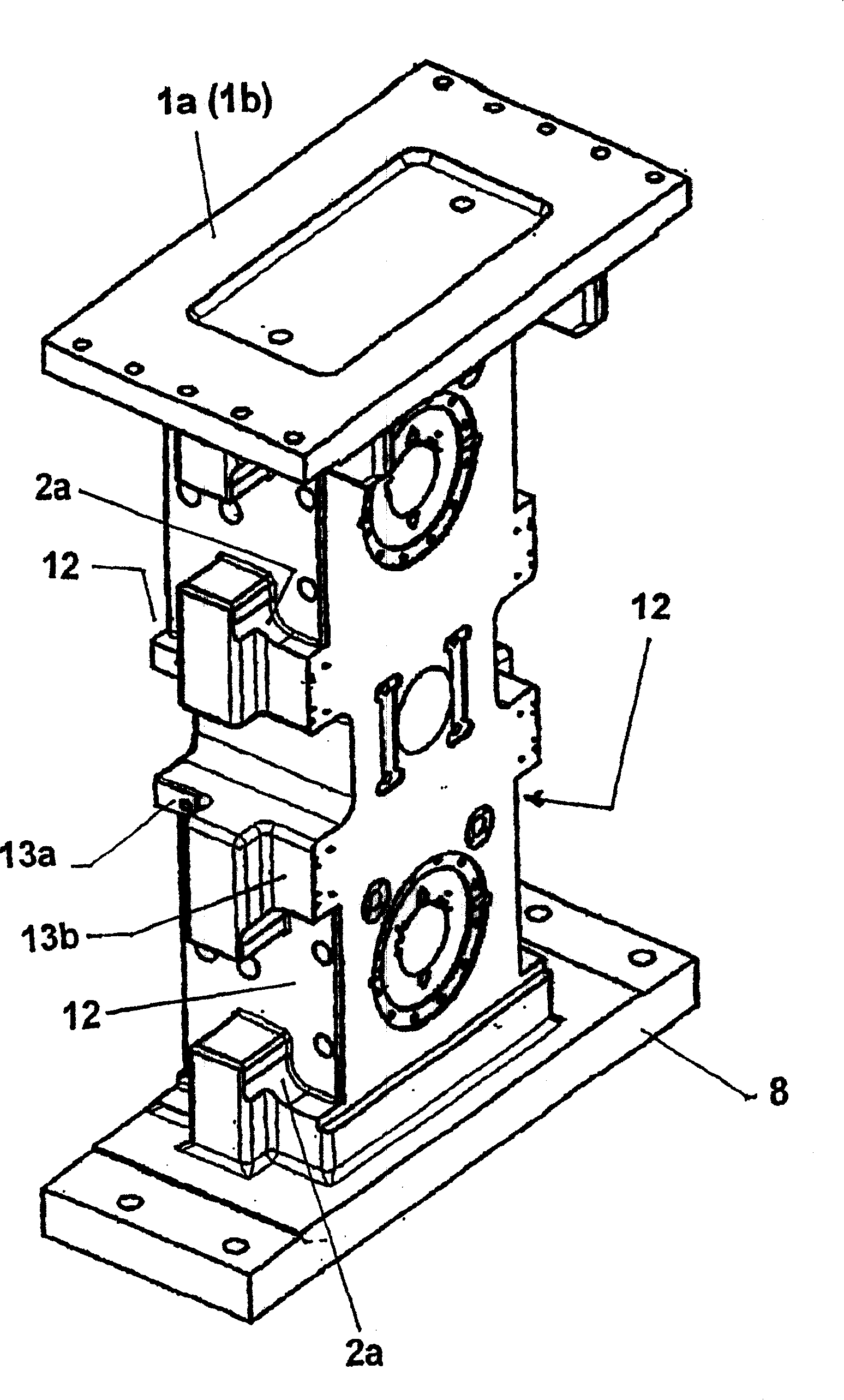

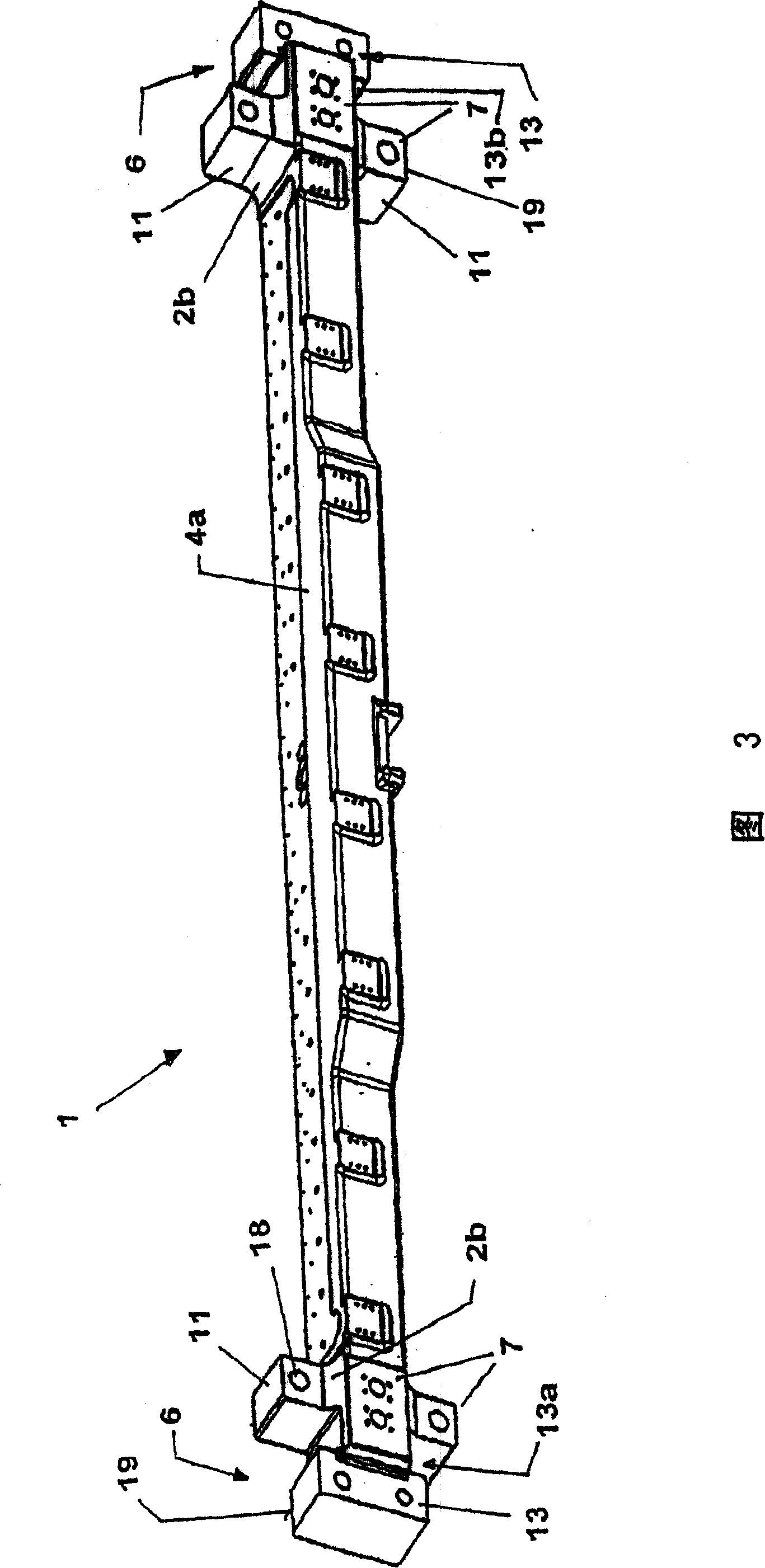

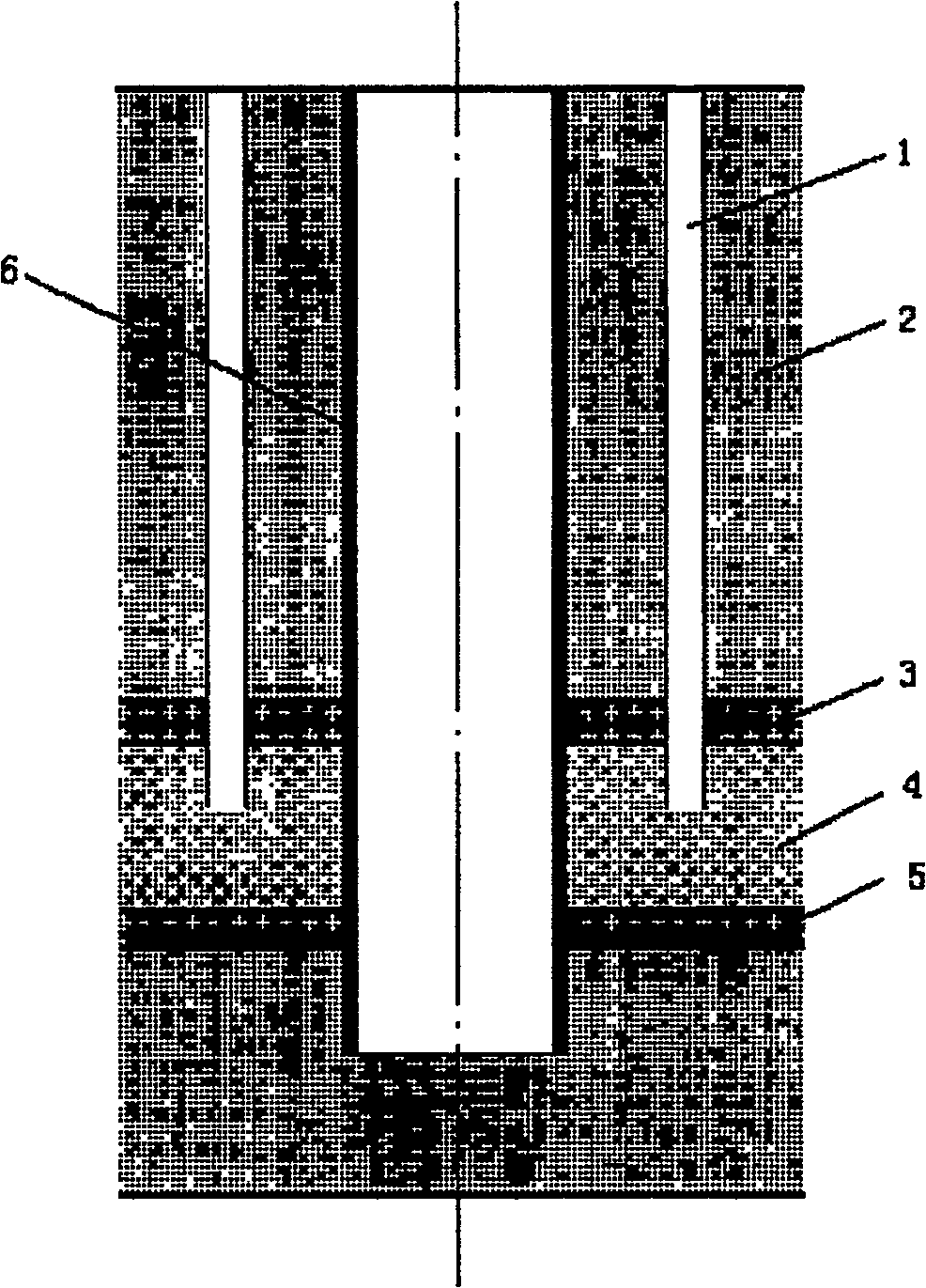

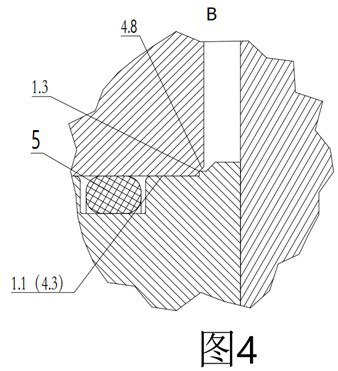

Multi-part roll stand for edgers in rolling mills

ActiveCN100384554CReduce additional forceSmall shrinkageMetal rolling stand detailsMetal rolling arrangementsCruciformEngineering

Disclosed is a roll stand for edgers in rolling mills. Said roll stand is embodied in several pieces, comprising two crossheads (1a, 1b) and four longitudinal bars (4a, 4b) as main components (1) as well as one respective common cruciform (7) junction point (3) for the crosshead (1a, 1b) and the longitudinal bars (4a, 4b), which is located at the ends (6) of the longitudinal bars. Pretensioned through bolts (5) that act as a joint are used at least at the top ends (6) of the longitudinal bars.

Owner:SMS DEMAG AG

Method for preventing well wall from crack by dynamic earth layer reinjecting water

A method for dynamically injecting water back into stratum and preventing the cracking of shaft wall features that the water injecting well is arranged on the ground for injecting the water back into the water bearing stratum to restore its water pressure and decrease the vertical force acting on shaft wall, so preventing the cracking and deformation caused by mining. Said water may be the underground water discharged by mining coal.

Owner:CHINA UNIV OF MINING & TECH

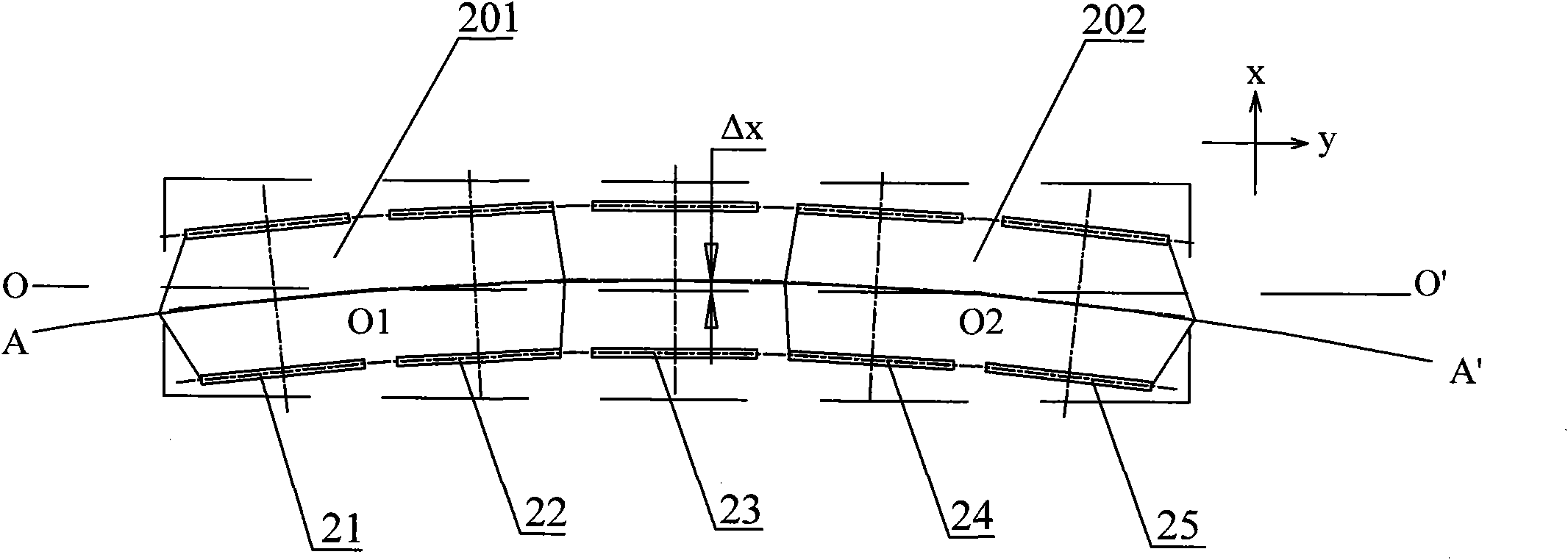

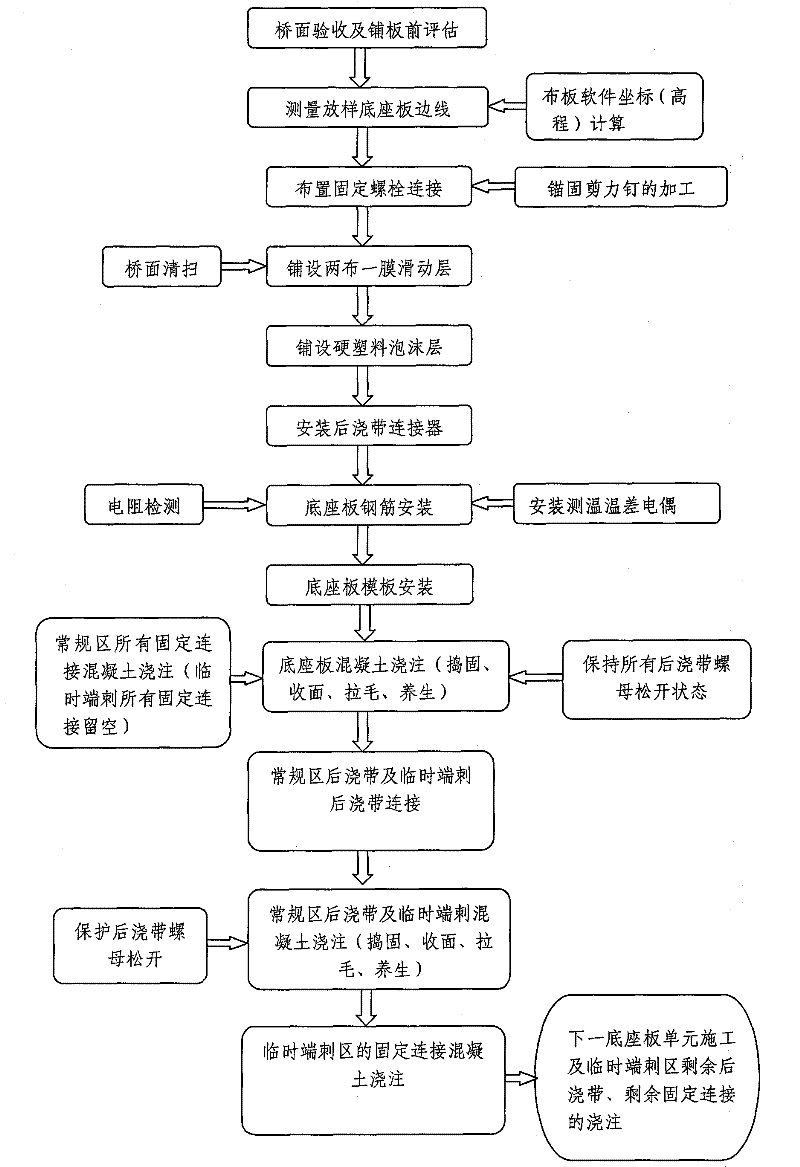

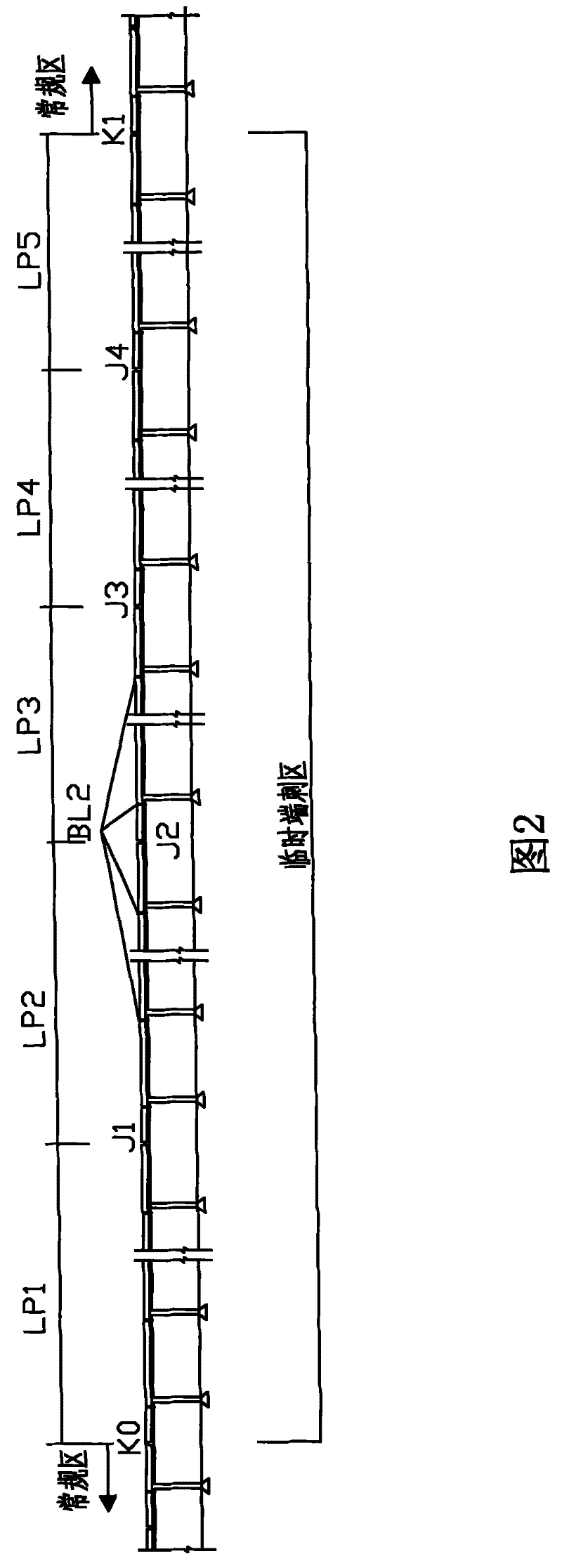

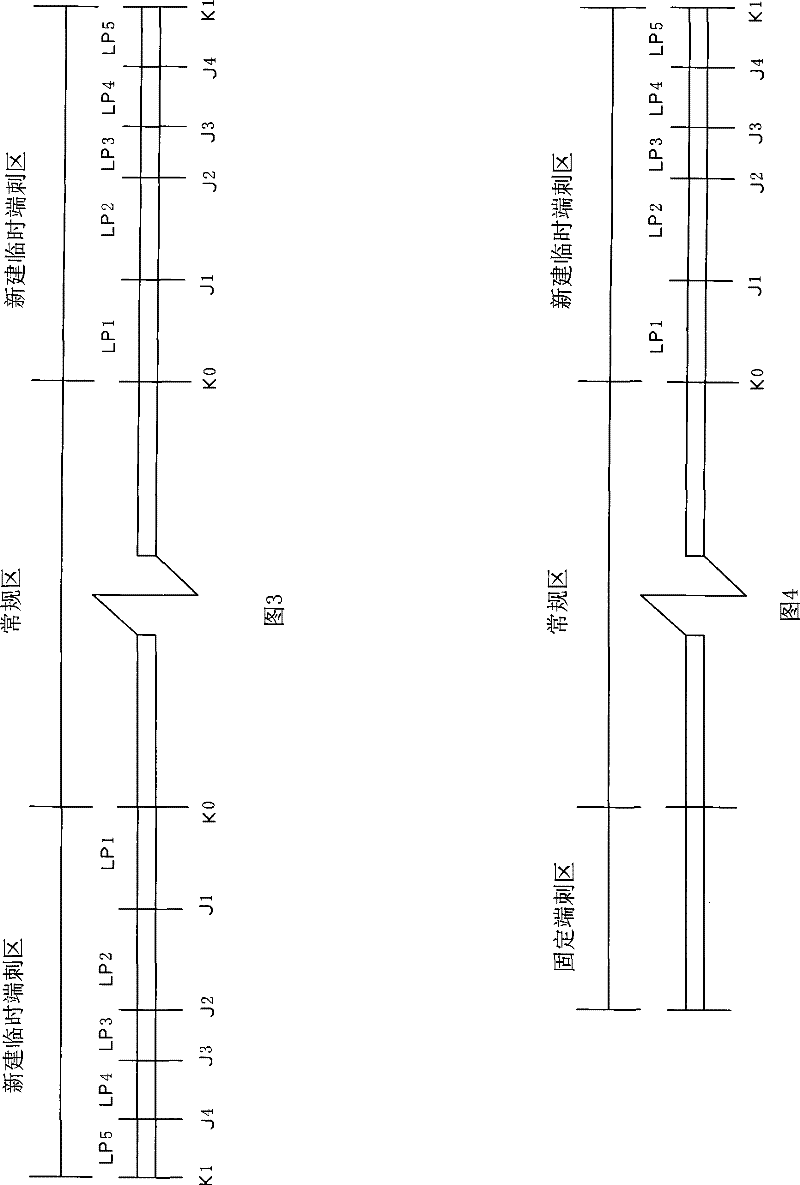

Unballasted track bed plate construction method

ActiveCN101195983BReduce additional forceImprove connection strengthRailway track constructionArchitectural engineeringBridge deck

The invention relates to a construction method of the bottom seat plate of the ballastless track, which belongs to a construction process method of tracks. The purpose of the invention is to provide a reliable construction method of the bottom seat plate of the ballastless track on bridges to meet the quality and accuracy requirement of the bottom seat plate of the ballastless track. The construction method comprises the following steps: step one, firstly, the bridge floor is checked and accepted and assessed before planking; secondly, the stakingout connecting line of the bottom seat plate is measured; thirdly, the connection of the fixed bolt is arranged; fourthly, a sliding layer with two cloth and one film is laid on the bridge floor of the box-beam bridge; step two, a hard plastics foam layer is laid on the two ends of the beam slot; step three, a post casting strip connector is installed; step four, firstly, tooth socket welding studs are installed; secondly, bottom seat plate reinforcing bars are installed; step five, bottom seat plate mould plates are installed; step six, the concrete of the bottom seat plate is cast; step seven, the cast post casting strip and the weldingstud tooth socket are fixedly connected, and the connection of the bottom seat plates is completed.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

safety shut-off valve

The invention provides a safety shut-off valve which comprises a valve body, an upper cover plate, a shut-off component and a hand wheel assembly. A circulation channel is arranged in the valve body. The hand wheel assembly is connected with the shut-off component. The hand wheel assembly drives the shut-off component to shut off the circulation channel in the valve body when the pressure is abnormal. The shut-off component comprises a valve plate assembly, a main shaft assembly and a reset shaft assembly. The main shaft assembly and the reset shaft assembly are arranged on the valve body in parallel. One end of the valve plate assembly is connected with the main shaft assembly. The valve plate assembly can rotate relative to the main shaft assembly. The main shaft assembly is connected with the hand wheel assembly. When the safety shut-off valve works, the other end of the valve plate assembly is erected on the reset shaft assembly, and the safety shut-off valve is in the opened position; when the safety shut-off valve fails, the hand wheel assembly drives the main shaft assembly to rotate so as to drive the valve plate assembly to rotate so that the valve plate assembly can rotate to press a shut-off boss in the valve body, and the safety shut-off valve is in the closed position. The safety shut-off valve is better in stability and high in operation safety coefficient, and the load is distributed reasonably due to the double-shaft type structural design.

Owner:TERRENCE ENERGY

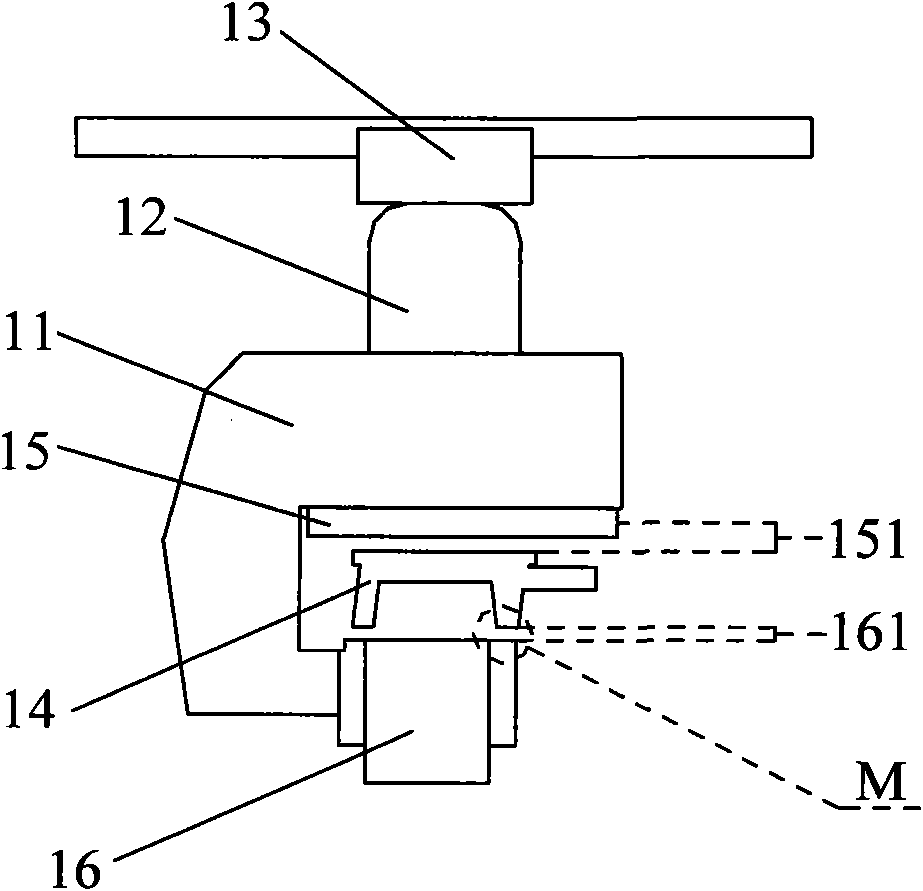

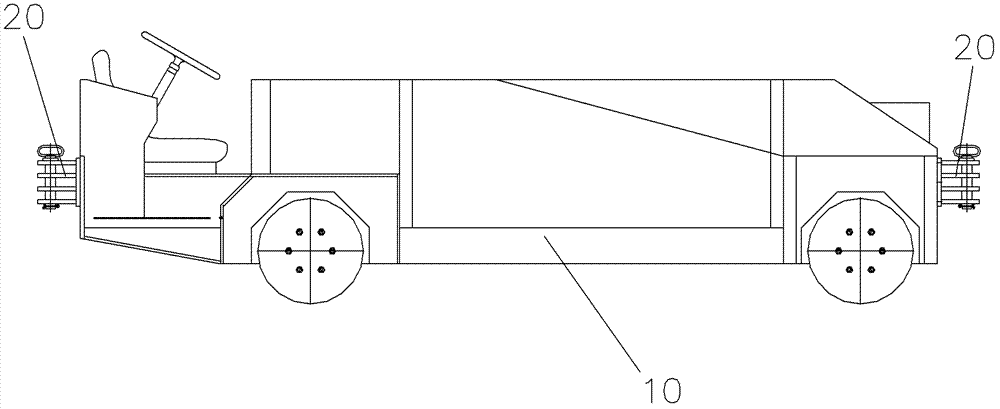

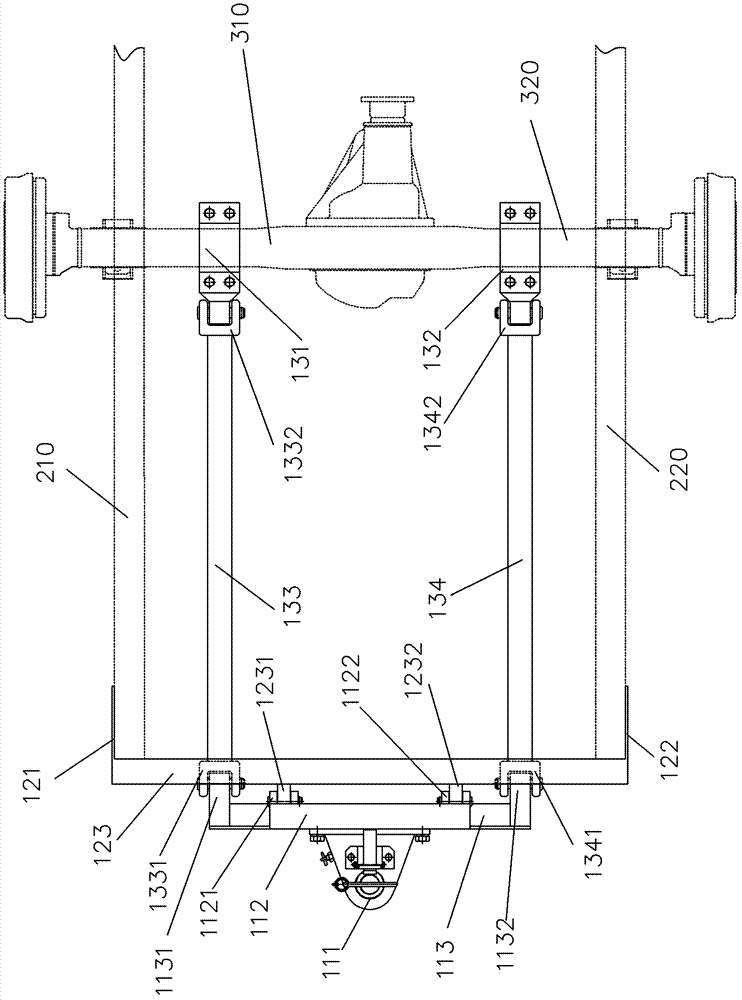

Aircraft tractor and traction mechanism used thereon

ActiveCN103303489BReduce stressSimple structureLaunching/towing gearTowing devicesVehicle frameAirplane

The invention relates to an aircraft tractor and a traction mechanism used thereon. The traction mechanism comprises a traction bolt component, a frame connecting piece, and a rear axle connecting piece, wherein the frame connecting piece comprises a crossbeam, and a vertical plate fixedly connected with a frame of the aircraft tractor and connected with the crossbeam; the rear axle connecting piece comprises a direct connecting piece and a connecting rod; one end of the direct connecting piece is fixedly connected with a rear axle of the aircraft tractor, and the other end of the direct connecting piece is hinged with the connecting rod; the traction bolt component comprises a traction bolt body, an upper part connecting body connected with the upper part of the traction bolt body, and a lower part connecting body connected with the lower part of the traction bolt body; the upper part connecting body is hinged to the crossbeam; the lower part connecting body is hinged to one end of the connecting rod far from the direct connecting piece. The traction mechanism can reduce the stress of the aircraft tractor and reduce the additional force generated because the direction of the tractive force is inconsistent with the direction of motion in the traction process.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

Magnetic levitation steering mechanism

ActiveCN102019938BImplement vertical scrolling linksLarge vertical forceBogie-underframe connectionsElectric propulsionBogieAir spring

The invention provides a magnetic levitation steering mechanism which is installed between a vehicle body and a steering frame of a magnetic levitation vehicle, and the steering mechanism is an arc movable sliding table, wherein the upper part of the sliding table is connected with the vehicle body, and the lower part of the sliding table is connected with the steering frame; the upper part and the lower part of the sliding table make relative movement with a circular arc movement trail. The arc movable sliding table specifically includes: a roller seat and a rollway body, wherein the rollway body is connected to the vehicle body as an upper part of the sliding table, the roller seat is connected to the steering frame as a lower part of the sliding table; the rollway body is in an arc structure of which an upper flat surface is fixedly connected to the vehicle body and a lower flat surface is in contact with the roller seat, the two moving relatively in a circular arc track. The introduction of the magnetic levitation steering mechanism realizes that a moving point of a steering module forming the steering frame makes arc movement around a relative rest point to drive the vehicle body and the steering frame to make circular arc relative movement together, so that the vehicle passes through a curve track smoothly, and the service life of an air spring and the steering frame is prolonged.

Owner:CRRC TANGSHAN CO LTD +2

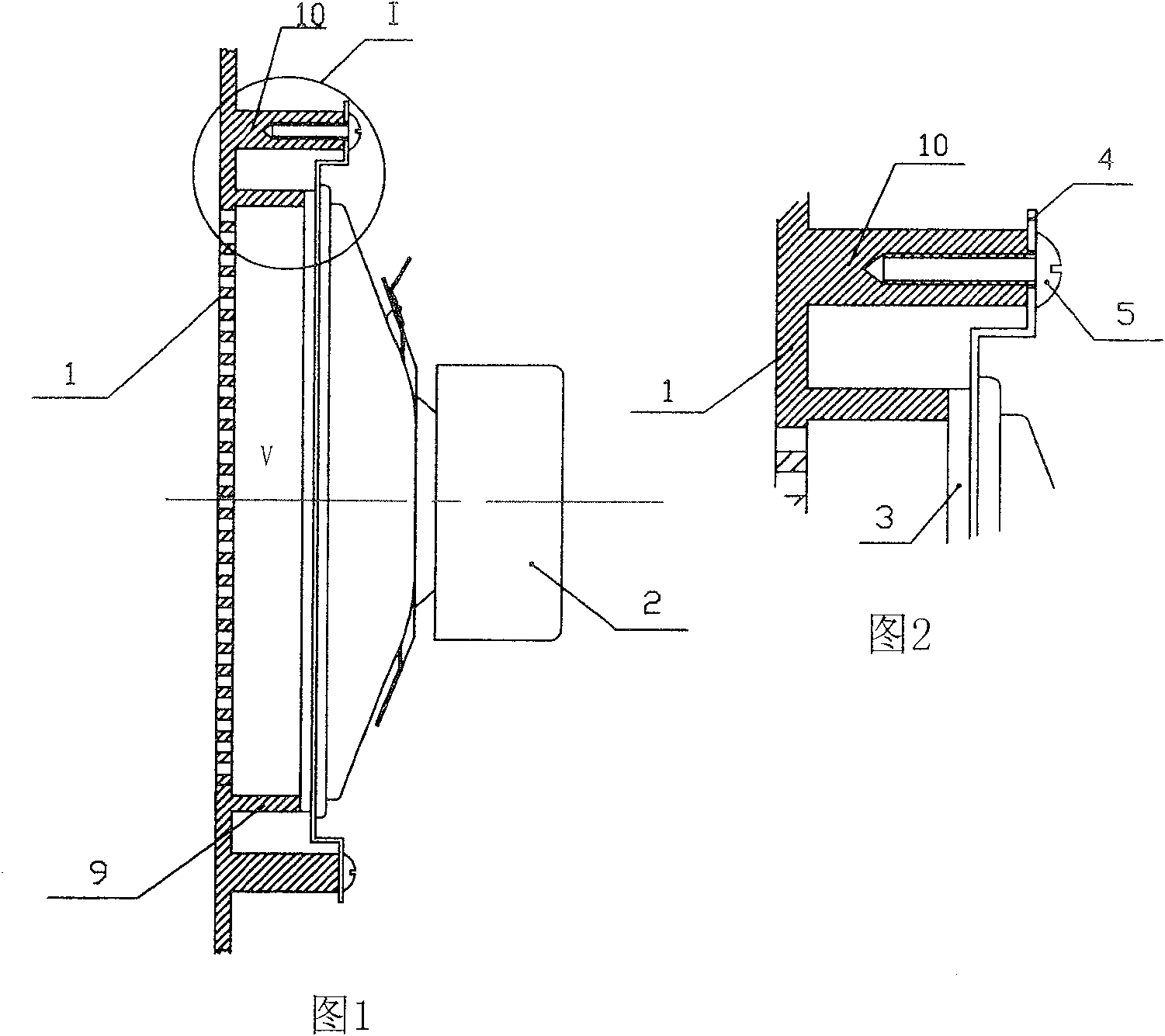

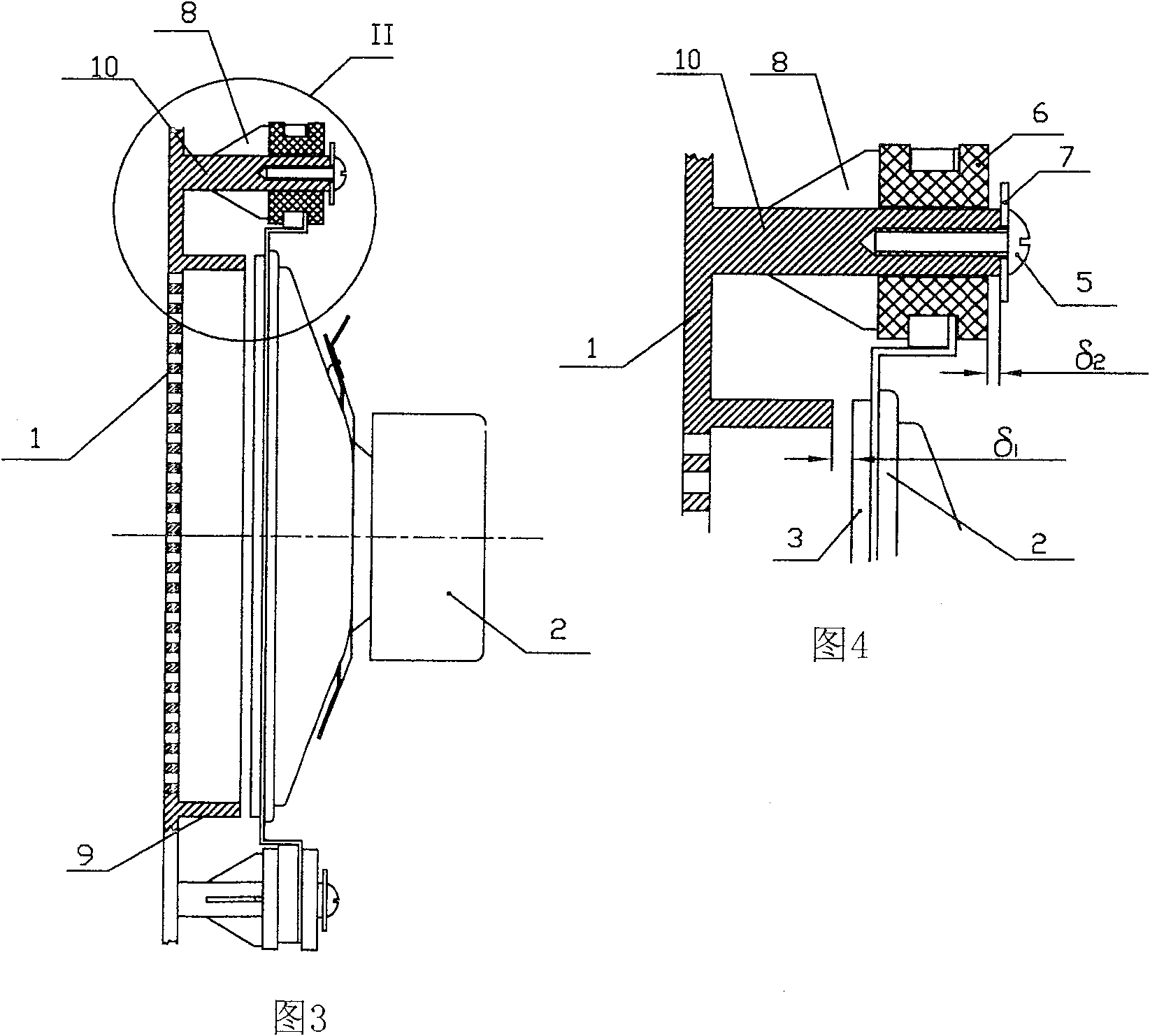

TV with built-in speaker

ActiveCN100583967CReduce additional forceImprove low frequency responseTelevision system detailsColor television detailsEngineeringLoudspeaker

The invention provides a TV set with a built-in loud speaker and capable of solving the problems of the prior art such as TV vibration and poor low-frequency response of a loud speaker. The invention adopts the following technical proposal: a clearance Delta 1 is arranged between a loud speaker and a loud speaker holder; a speaker frame is movably sleeved on the double-ended bolt of a casing; both the inside and the outside of the double-ended bolt are provided with stop blocks; the speaker frame is arranged between the inside stop block and the outside stop block with a clearance Delta 2 set aside. The TV set overcomes the technical prejudice of acoustic short circuit close connection and adopts a clearance structure form different from close connection, thereby solving the problems such as TV vibration and poor low-frequency response.

Owner:HISENSE VISUAL TECH CO LTD

Variable pressure angle cam contour line design method applicable to sudden variable load

The invention discloses a variable pressure angle cam contour line design method applicable to sudden variable load. R1 refers to the radius of a base circle omicron, R2 refers to the farthest dwell arc radius, AB arc refers to a cam contour line with the radius of R3, and alpha refers to a theoretical working curve pressure angle. When the normal values R1 and R2 are given, a graph of relation between a lift range h and the pressure angle alpha can be determined under different R3 values. An optimal arc radius value R3 corresponding to the pressure angle alpha changed along with the lift range h under sudden variable load can be found through the graph. The variable pressure angle cam contour line design method applicable to sudden variable load has the advantages that the pressure angle is extremely small in an open stage of a main valve core during opening of a cam and matched with characteristics of loads, and additional force applied to a top rod can be decreased.

Owner:CENT SOUTH UNIV

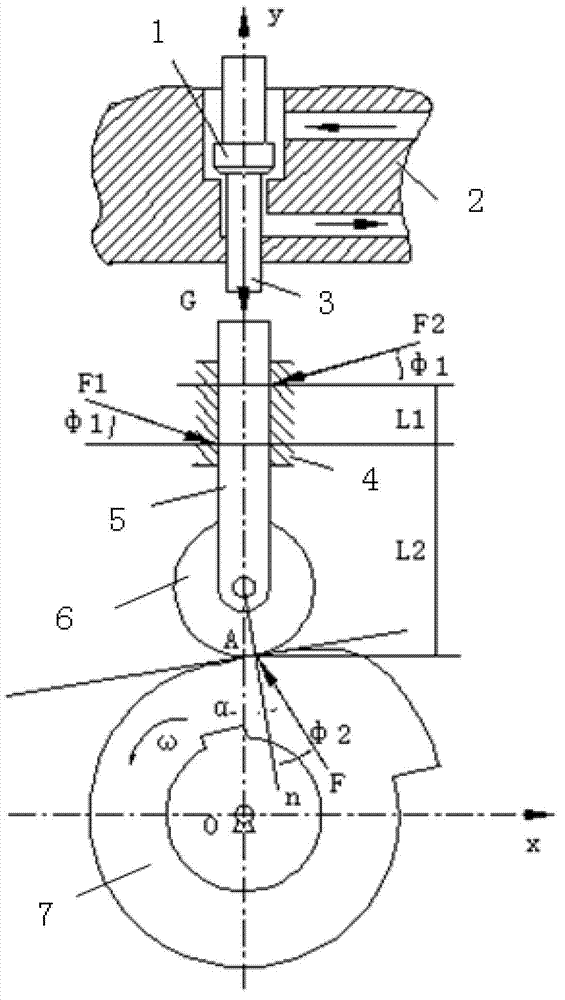

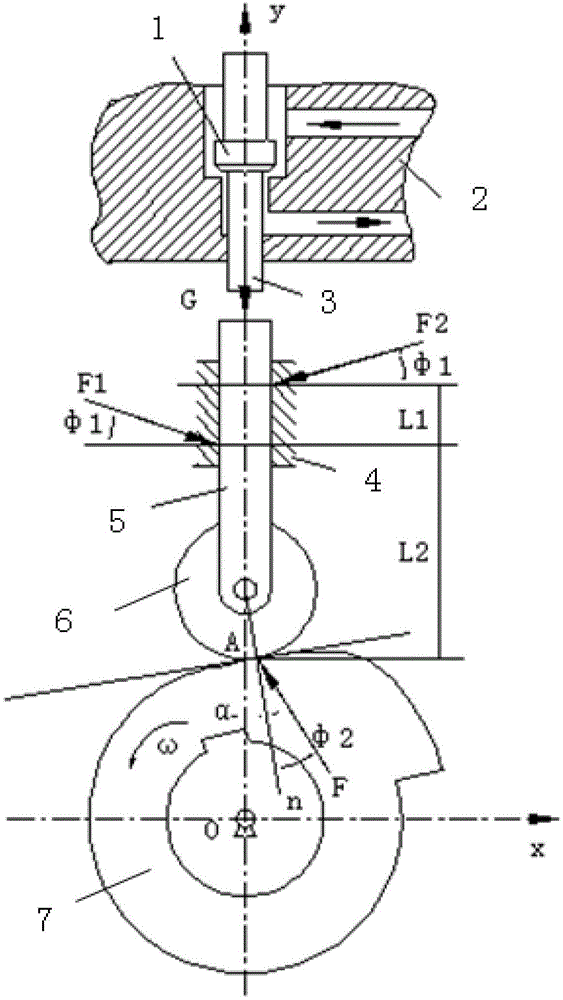

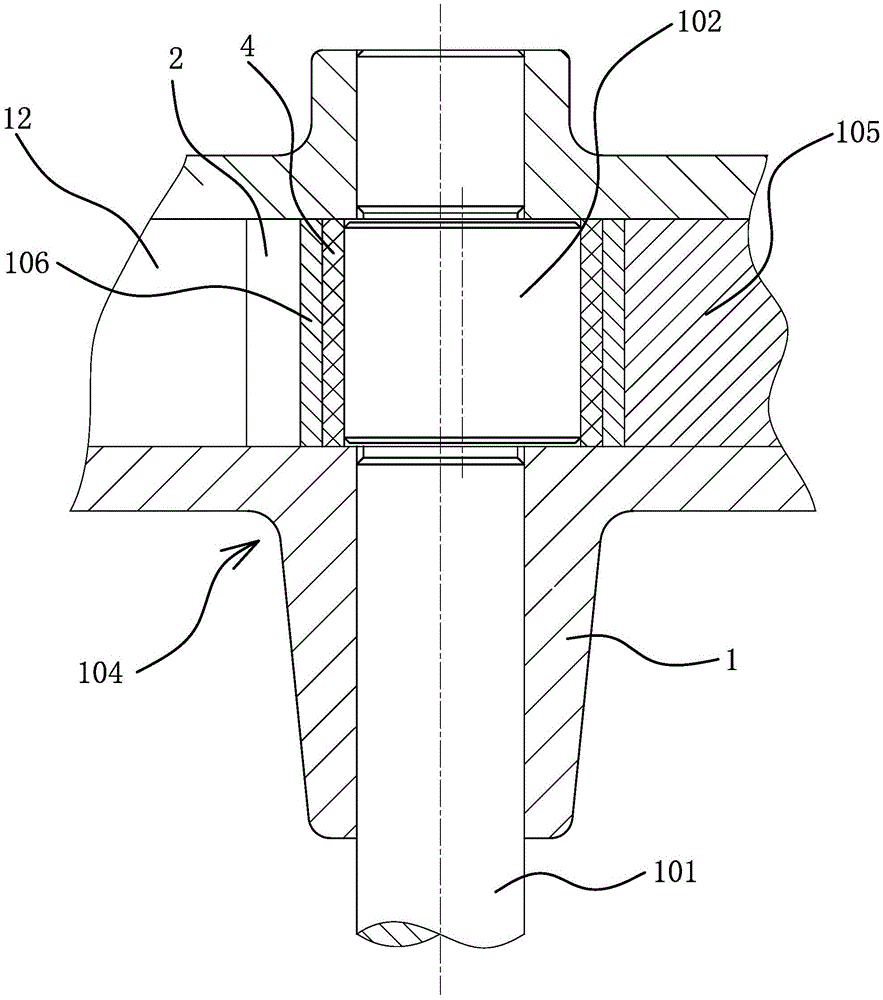

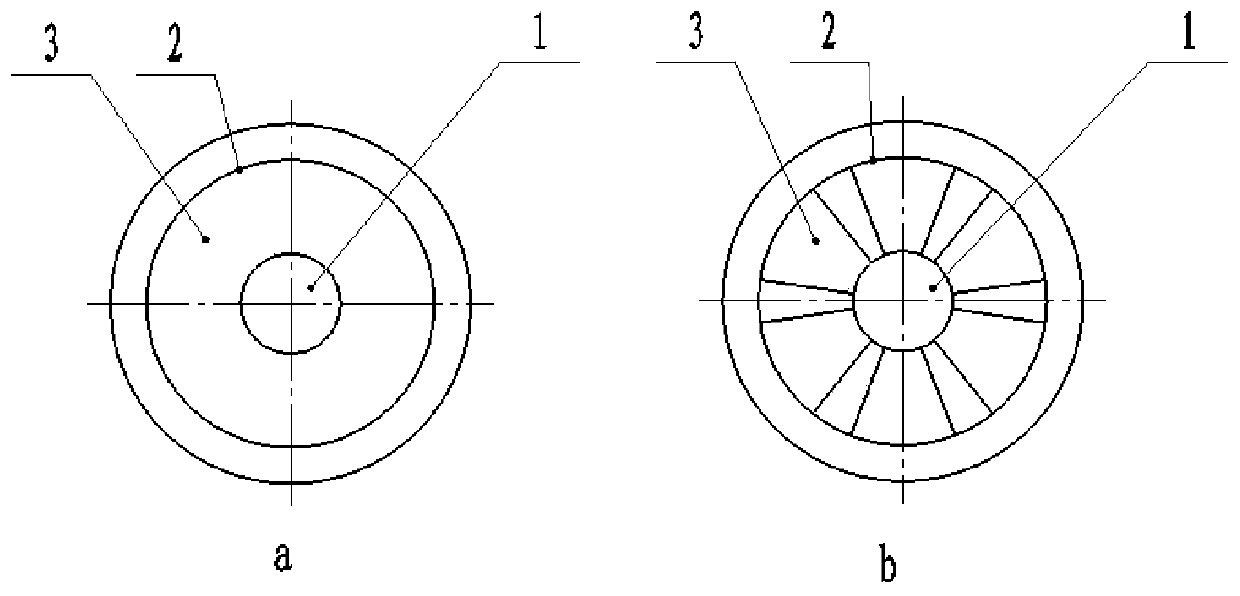

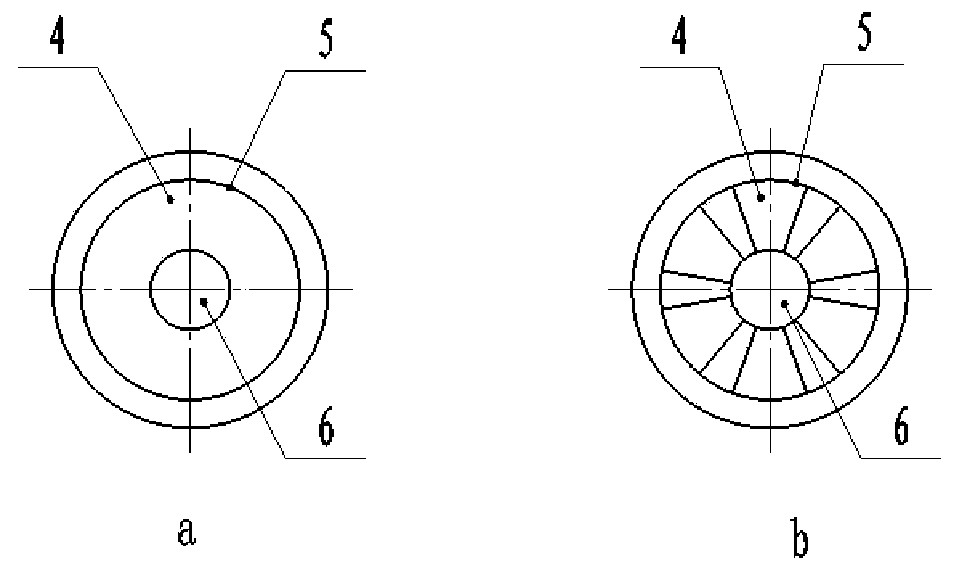

Rotary parallel piston compressor

ActiveCN103644117BReduce additional forceIncrease the sealing surfaceRotary piston pumpsRotary piston liquid enginesMechanical engineering technologyHigh pressure

The invention provides a rotary translation piston compressor, belonging to the technical field of mechanical engineering. The rotary translation piston compressor solves the problem that the elasticity strength of a spring needed by an existing rotary translation piston compressor is high. The rotary translation piston compressor comprises an air cylinder, a crankshaft and blades, wherein a piston is sleeved on an eccentric part, and a plane part is arranged on the peripheral surface of the piston; springs are arranged between the blades and the air cylinder; the blades prop against the plane part on the peripheral surface of the piston, and the end surfaces of the blades, propping against the piston, are planes; the eccentric part and the piston are connected with each other through a friction reducing mechanism which can enable the end surfaces of the blades to always prop against the plane on the peripheral surface of the piston. Plane friction and plane sealing are adopted between the blades and the piston of the rotary translation piston compressor so as to enlarge the sealing surface, and improve the sealing property. Meanwhile, due to the plane sealing, a high-pressure refrigerant can not enter the parts between the blades and the piston easily, so that the additional force of the high-pressure refrigerant to the moving direction of the blades in the operation of the compressor is reduced.

Owner:浙江百达精工股份有限公司

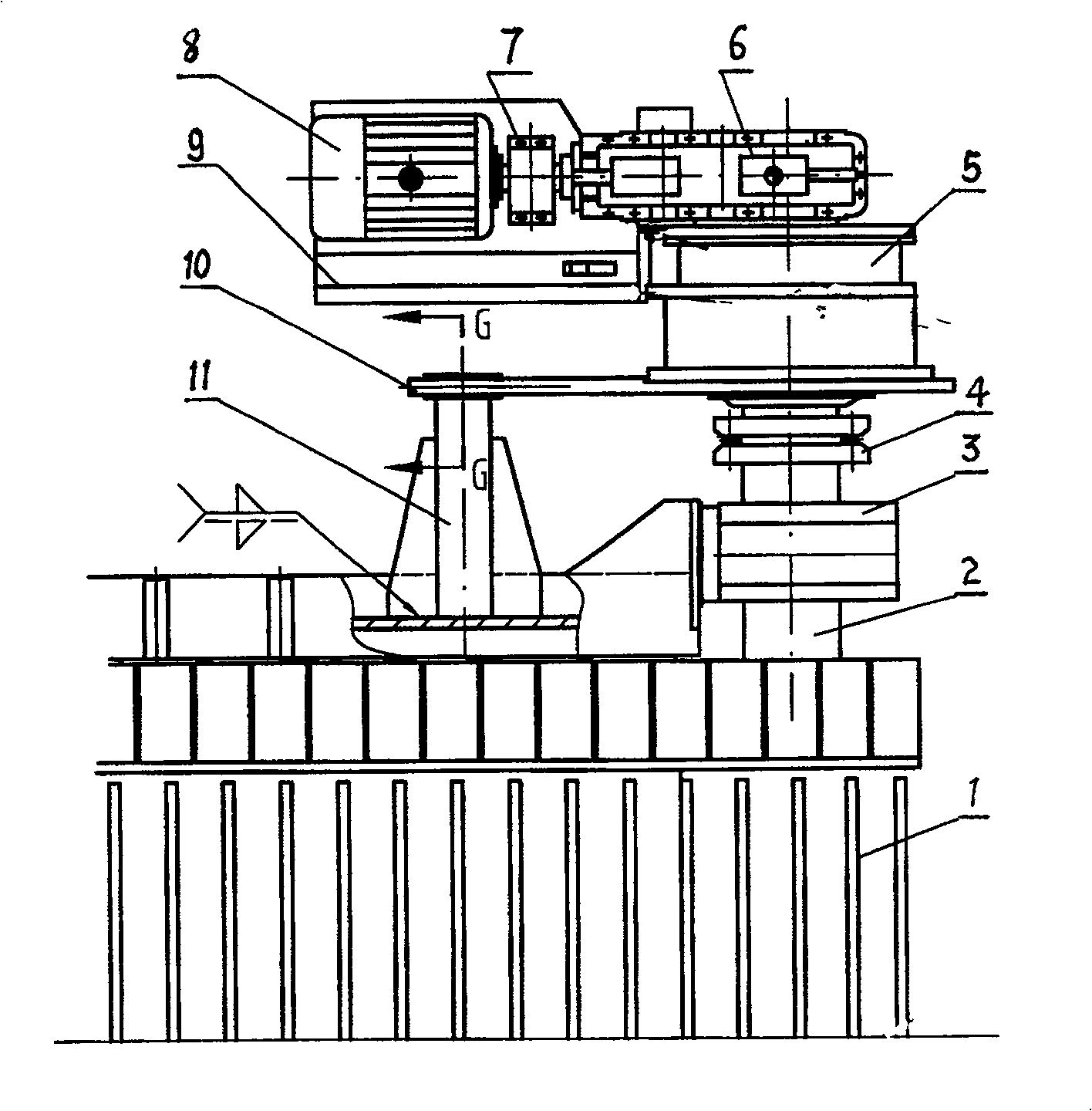

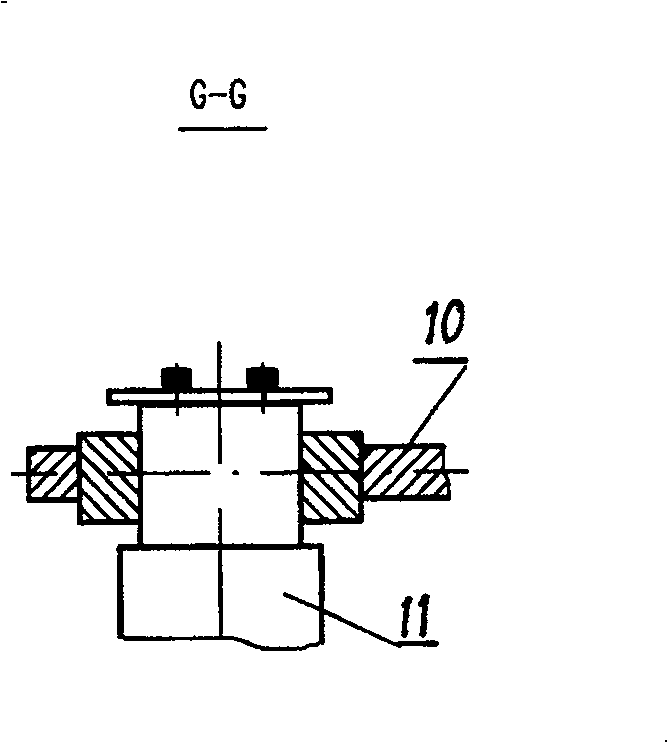

Driver with single point supporting

InactiveCN100412410CSolve the problem of non-concentricity of multi-point supportLow costToothed gearingsReduction driveCoupling

A single-point support driving device includes a motor, a frame and a perpendicular planetary speed reducer. The driving device is suspended on the driving shaft of the main motor. The motor is connected with the perpendicular planetary speed reducer via a coupling. A final stage output quill of the reducer is covered on the driving shaft of the main motor directly, and locked via a lock disc. One end of the torsion bar is connected with the flange plate of the reducer and the other end is in the rotatable connection with one end of the support post. The other end of the support post is welded together with the frame of the main motor.

Owner:沈阳矿山机械有限公司

A centering non-contact axial force loading device and method

ActiveCN107764537BAccurate loading directionReduce additional forceMachine part testingEngineeringAxial force

Owner:JINCHENG NANJING ELECTROMECHANICAL HYDRAULIC PRESSURE ENG RES CENT AVIATION IND OF CHINA

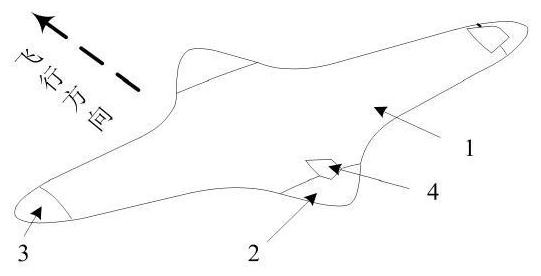

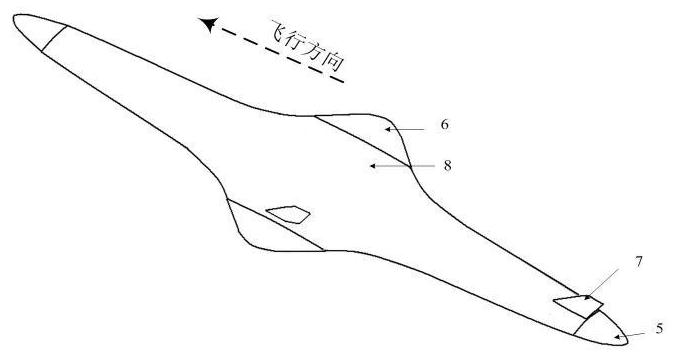

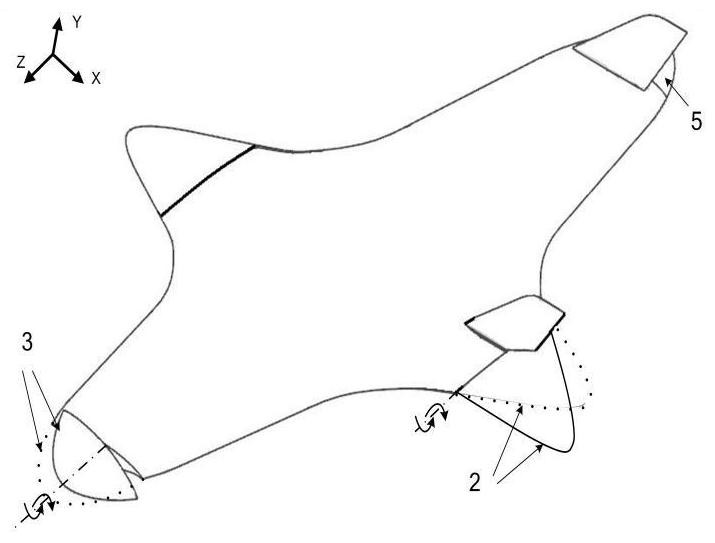

Aerodynamic shape and design method of two-way flying wing aircraft

ActiveCN109703758BSolve the problem of insufficient layout control abilityIncrease rudder surface control armAircraft controlAll-wing aircraftFlight vehicleControl theory

Owner:BEIJING AEROSPACE TECH INST

Connecting structure for intermediate flange and rack of drilling pump

PendingCN113700645AImprove coaxialityHigh mutual position accuracyPositive displacement pump componentsLiquid fuel engine componentsEngineeringMechanics

The invention discloses a connecting structure for an intermediate flange and a rack of a drilling pump, and relates to the field of petroleum engineering equipment, in particular to the connecting structure for the intermediate flange and the rack of the drilling pump. The connecting structure comprises the intermediate flange, a pressing plate, an M12 bolt, the rack and an O-shaped sealing ring. The positioning surface that requires high mutual position of the rack and the intermediate flange is installed and processed at one time, the precision is high, the rack and the intermediate flange are sealed by the O-shaped sealing ring on the circumference, and the connecting structure of the intermediate flange and the rack of the drilling pump can well ensure the high coaxiality precision of the axis of an inner hole of the intermediate flange and the axis of a crosshead slideway hole of the rack; and the high perpendicularity precision of the end face of the intermediate flange and the axis of the crosshead slideway hole of the rack is well guaranteed, the service life of a middle rod sealing ring is prolonged, and the long-standing and difficult problems that muddy water in a cylinder sleeve cavity permeates into a crosshead cavity and lubricating oil in the crosshead cavity permeates into the cylinder sleeve cavity are solved.

Owner:黄秀芳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com