Unballasted track bed plate construction method

A technology of ballastless track and construction method, which is applied in the direction of track, track laying, track maintenance, etc., and can solve problems such as high construction precision requirements, large technical management span, and difficulty in forming base plates for large super-high sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0124] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

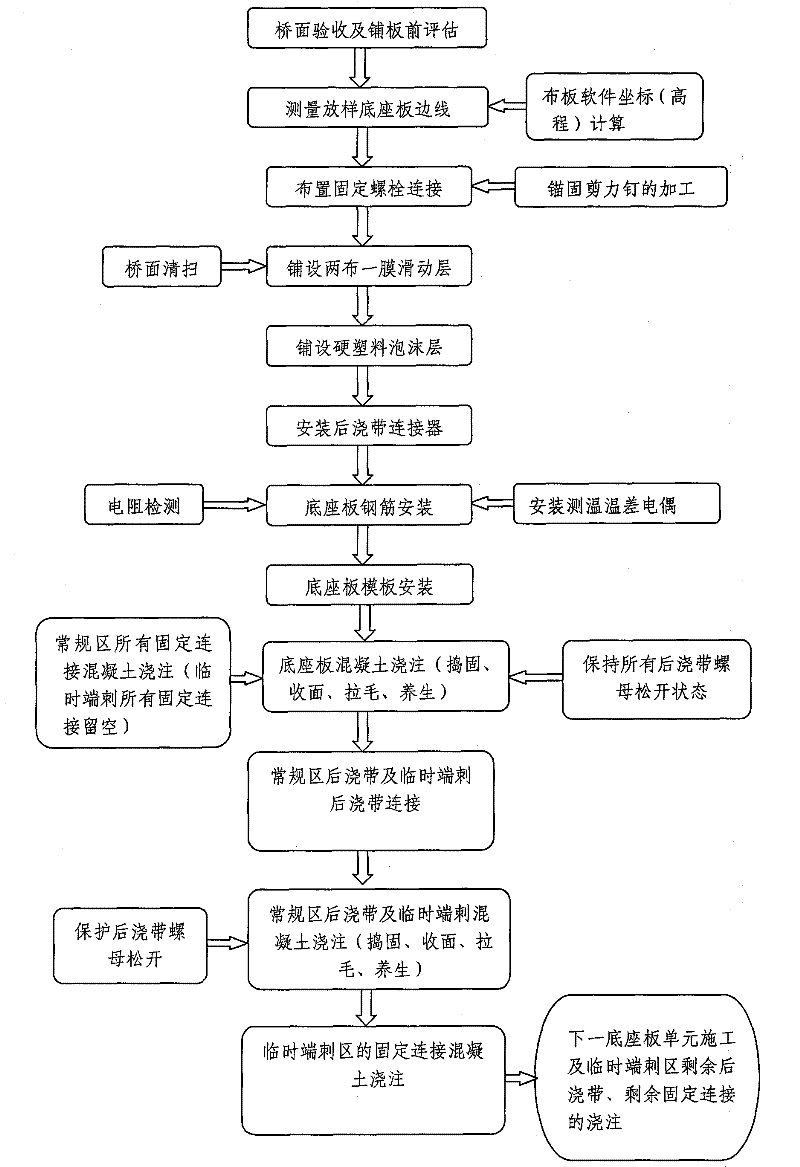

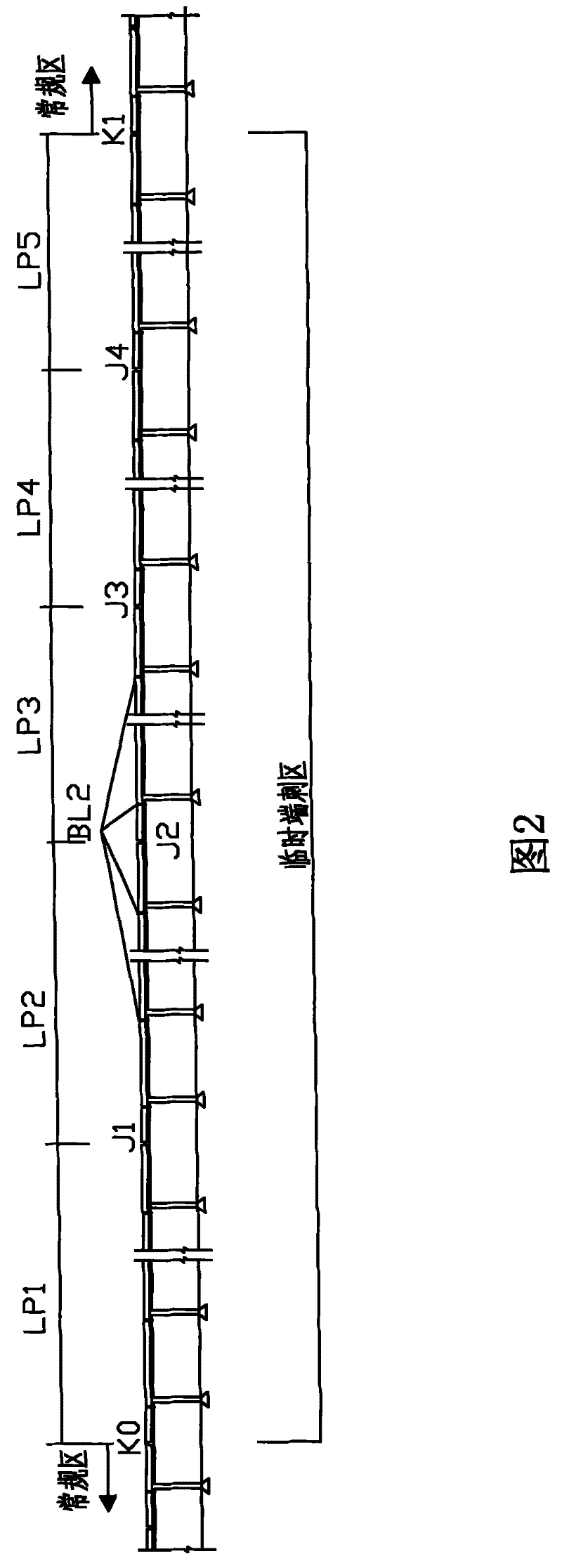

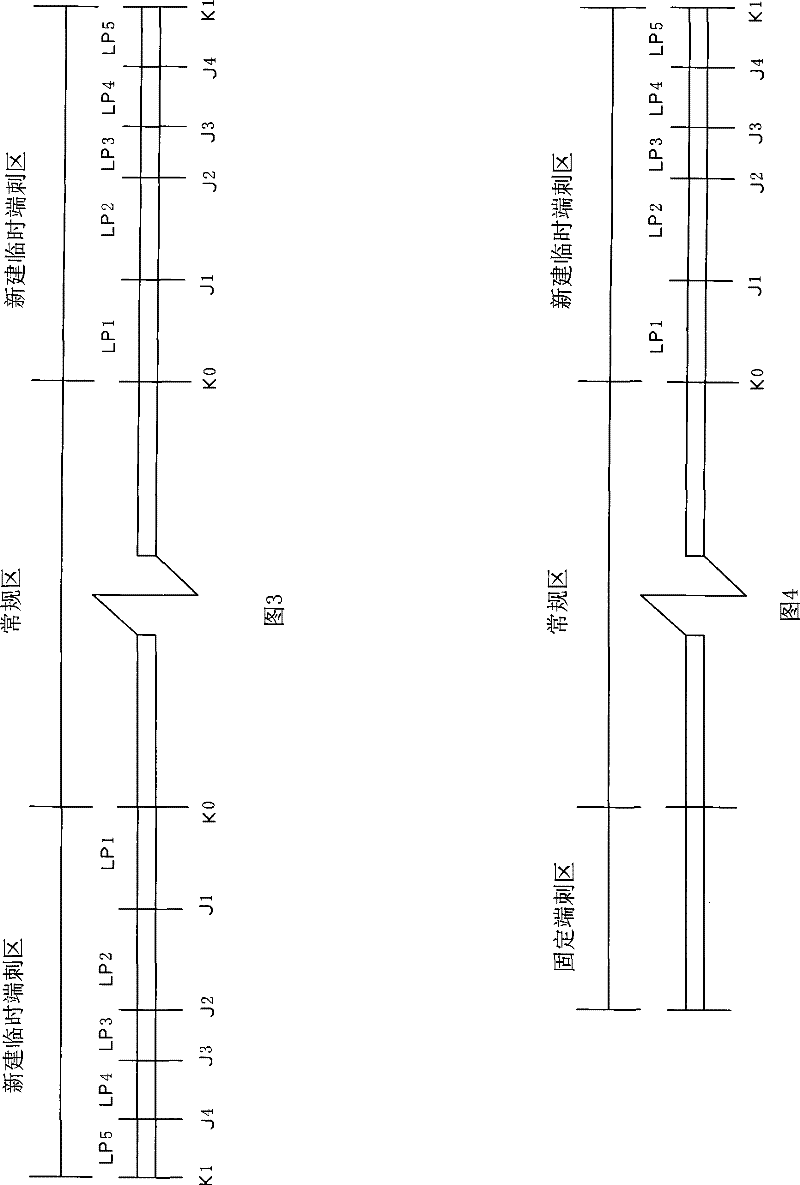

[0125] Such as figure 1 As shown, the construction method of the ballastless track base plate includes the following steps:

[0126] a01. Bridge deck acceptance and pre-planning assessment;

[0127] a02. Measure the wiring of the stakeout base plate;

[0128] a03. Arrange the fixed bolt connection;

[0129] a. Lay a sliding layer of two cloths and one film on the bridge deck;

[0130] b. Lay a hard plastic foam layer at both ends of the beam joint;

[0131] c. After installing the post-cast connector;

[0132] d0. Install alveolar shear studs;

[0133] d. Install the reinforcement of the base plate;

[0134] e. Install the base plate template;

[0135] f. pouring base plate concrete;

[0136] g. The construction of the post-cast belt and the shear tooth groove, and the connection of the base plate is completed.

[0137] The specific m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com