Rotary parallel piston compressor

A rotary and compressor technology, applied in the direction of rotary piston machinery, rotary piston pump, rotary piston/swing piston pump components, etc., can solve the problem of increased piston pressure, reduced compressor efficiency, and parts processing Difficulty and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

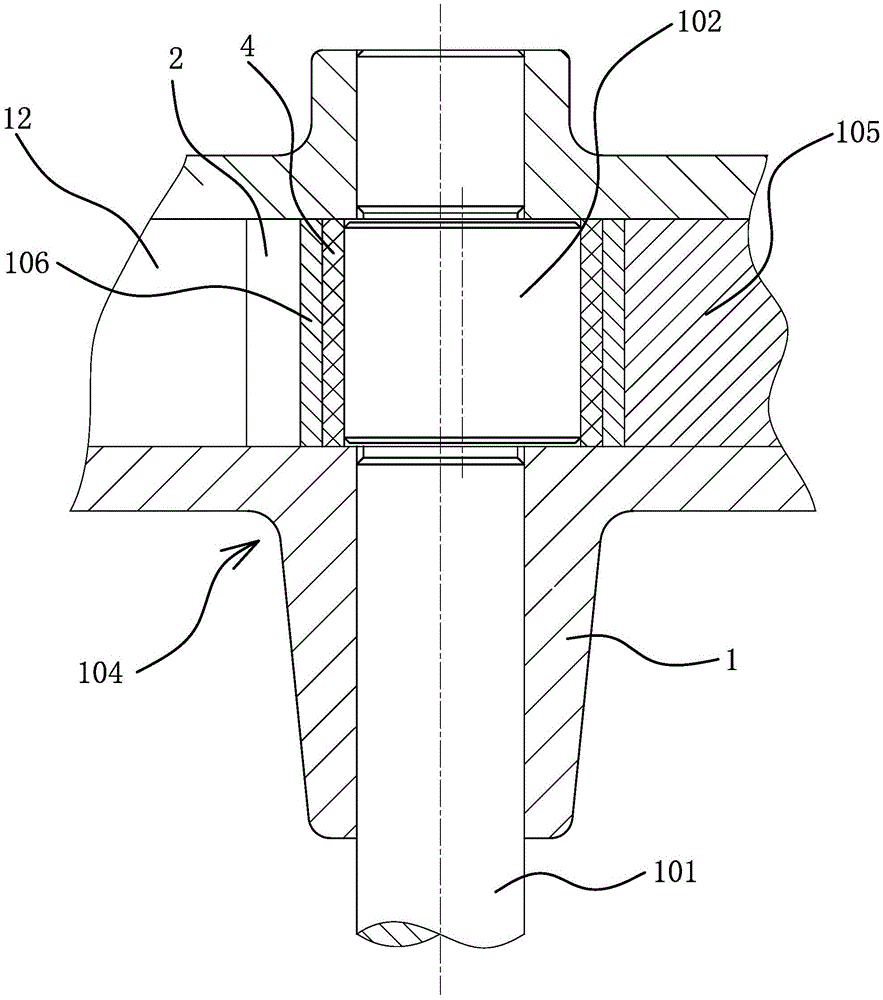

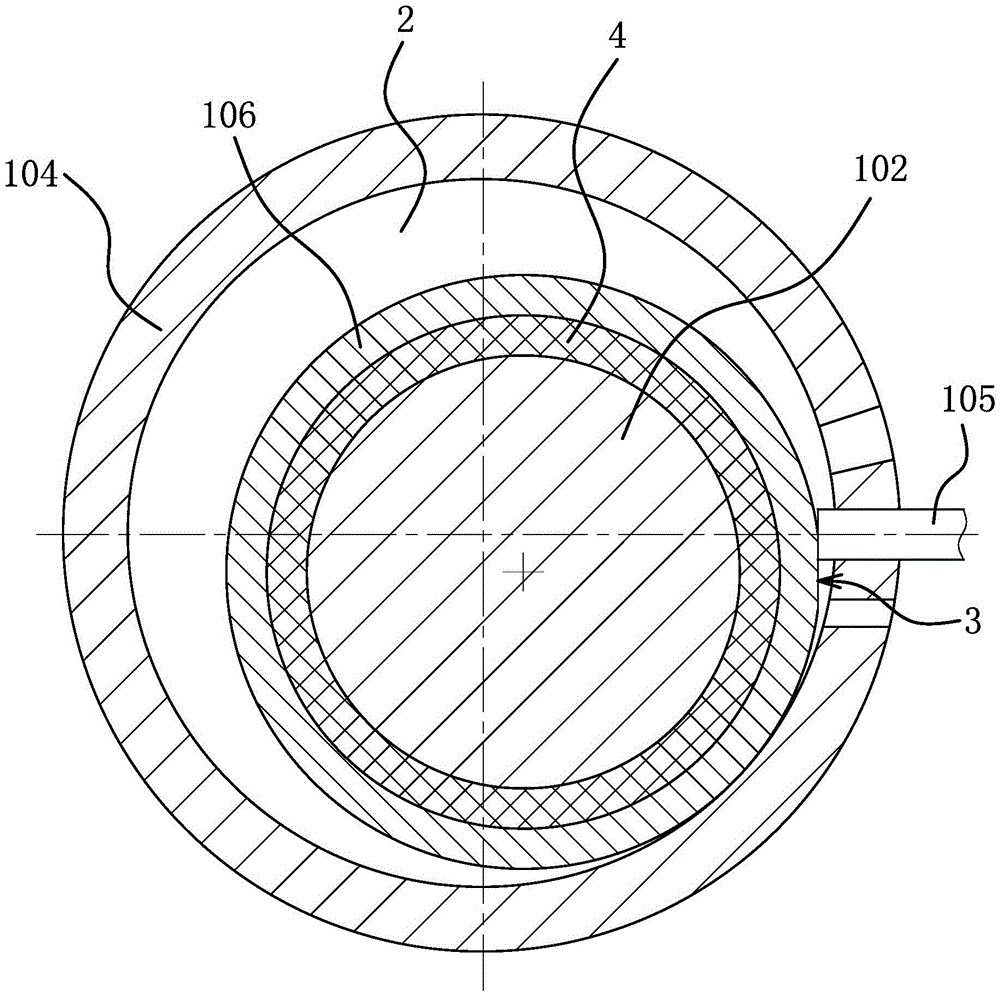

[0040] Such as figure 1 with figure 2 As shown, the rotary translational piston compressor includes a motor 103 , a cylinder 104 , a crankshaft 101 , blades 105 , a piston 106 and a spring 111 .

[0041] The cylinder 104 includes a cylinder body 12 and a cylinder head 1 , and a piston chamber 2 and vane grooves are provided in the cylinder 104 .

[0042] The crankshaft 101 has an eccentric portion 102 , the crankshaft 101 passes through the piston cavity 2 of the cylinder 104 , and the eccentric portion 102 is located in the piston cavity 2 . The rotating shaft of the motor 103 is connected with the crankshaft 101 .

[0043] The vane 105 is embedded in the vane slot and can slide along the side wall of the vane slot. The piston 106 is sleeved on the eccentric portion 102 . The spring 111 is located in the vane groove, one end of the spring 111 abuts against the other end of the vane 105 , the other end of the spring 111 abuts against the cylinder 104 , and the spring 111...

Embodiment 2

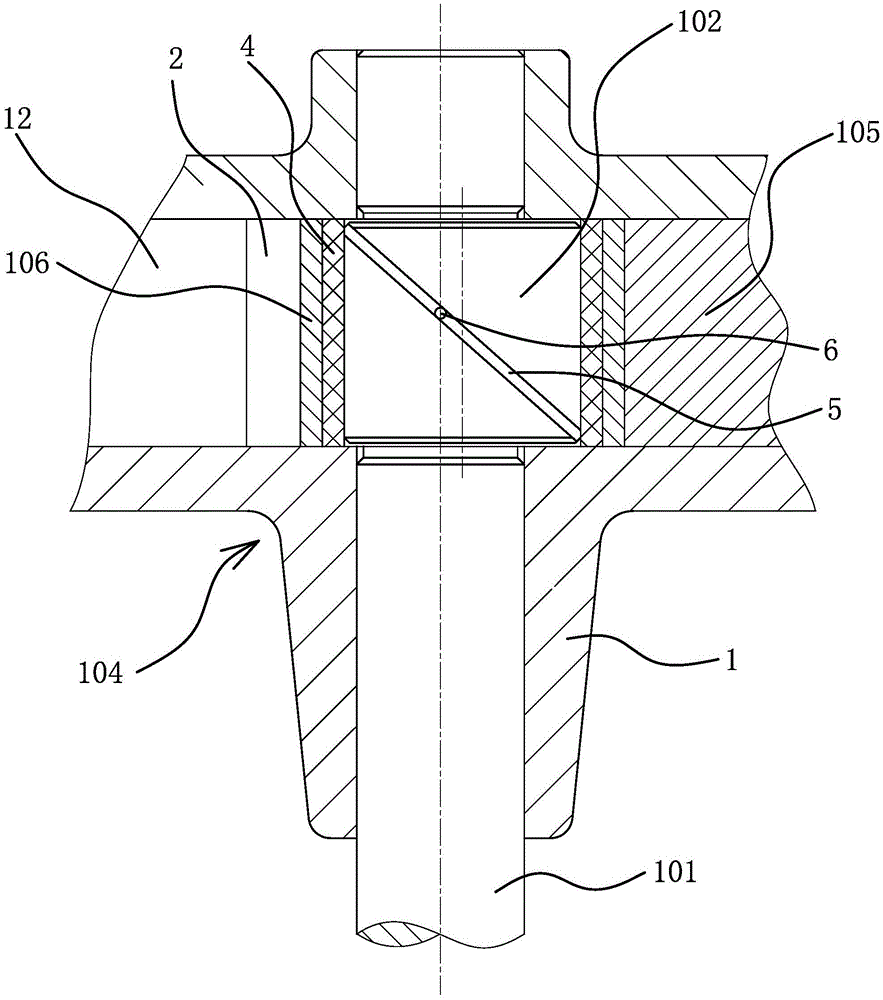

[0049] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: image 3 with Figure 4 As shown, in order to further reduce the coefficient of friction between the piston 106 and the eccentric part 102, a first helical groove 5 is provided on the outer surface of the eccentric part 102, and an oil supply passage communicating with the first helical groove 5 is provided in the crankshaft 101. 6. When the rotary translational piston compressor works, lubricating oil enters the gap between the anti-friction sleeve 4 and the eccentric part 102 through the oil supply channel 6 . The provision of the first spiral groove 5 makes it easier for lubricating oil to fill the above-mentioned gaps, that is, to avoid the phenomenon of oil shortage in the above-mentioned gaps during high-speed operation. Supplying lubricating oil in the above-mentioned gap can also take away the heat generated by friction, so as to prevent the a...

Embodiment 3

[0051] The structure and principle of the present embodiment are basically the same as those of the second embodiment, the difference is that: Figure 5 As shown, the rotary translational piston compressor also includes a second helical groove 7 located on the outer surface of the anti-friction sleeve 4, and the anti-friction sleeve 4 is provided with a cavity connecting the second helical groove 7 and the inner cavity of the anti-friction sleeve 4. The first communication hole 8 . That is, lubricating oil enters the gap between the anti-friction sleeve 4 and the piston 106 through the first communication hole 8 ; the second spiral groove 7 makes it easier for the lubricating oil to fill the gap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com