Connecting structure for intermediate flange and rack of drilling pump

An intermediate flange and connecting structure technology, applied in pump components, mechanical equipment, variable capacity pump components, etc., can solve the problems of short life of the intermediate rod sealing ring, contamination of lubricating oil, and penetration of lubricating oil into the cylinder liner cavity, etc. Achieve high precision and ensure easy results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0037] The embodiments of the present invention are not limited to the following examples, and various changes made without departing from the gist of the present invention fall within the protection scope of the present invention.

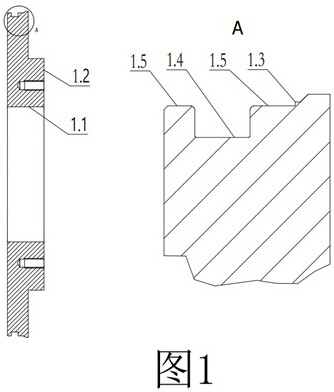

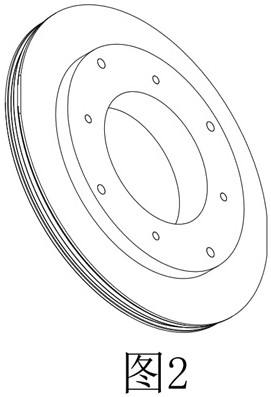

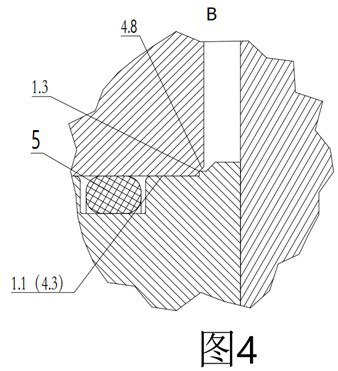

[0038] see Figure 1 to Figure 11, the present embodiment is a drilling pump intermediate flange and frame connection structure, including intermediate flange 1, pressure plate 2, M12 bolt 3, frame 4, O-ring 5, machine tool 6, boring tool disc 7, boring tool Rod 8, comparison intermediate flange 9, boring cutter head 10, machine tool spindle 11, machine tool spindle box 12, M16 bolt 13, flat gasket 14, comparison frame 15, inner hole 1.1, end face 1.2, edge 1.3, O shape Groove 1.4, outer circle 1.5, axis line 1.6, crosshead cavity 4.1, cylinder liner cavity 4.2, inner hole 4.3, crosshead slideway hole 4.4, crosshe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com