Driver with single point supporting

A driving device and single-point support technology, which is applied in transmission devices, gear transmission devices, belts/chains/gears, etc., can solve problems such as increasing axial dimensions, reduce lateral dimensions, ensure concentricity, and reduce vibration effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

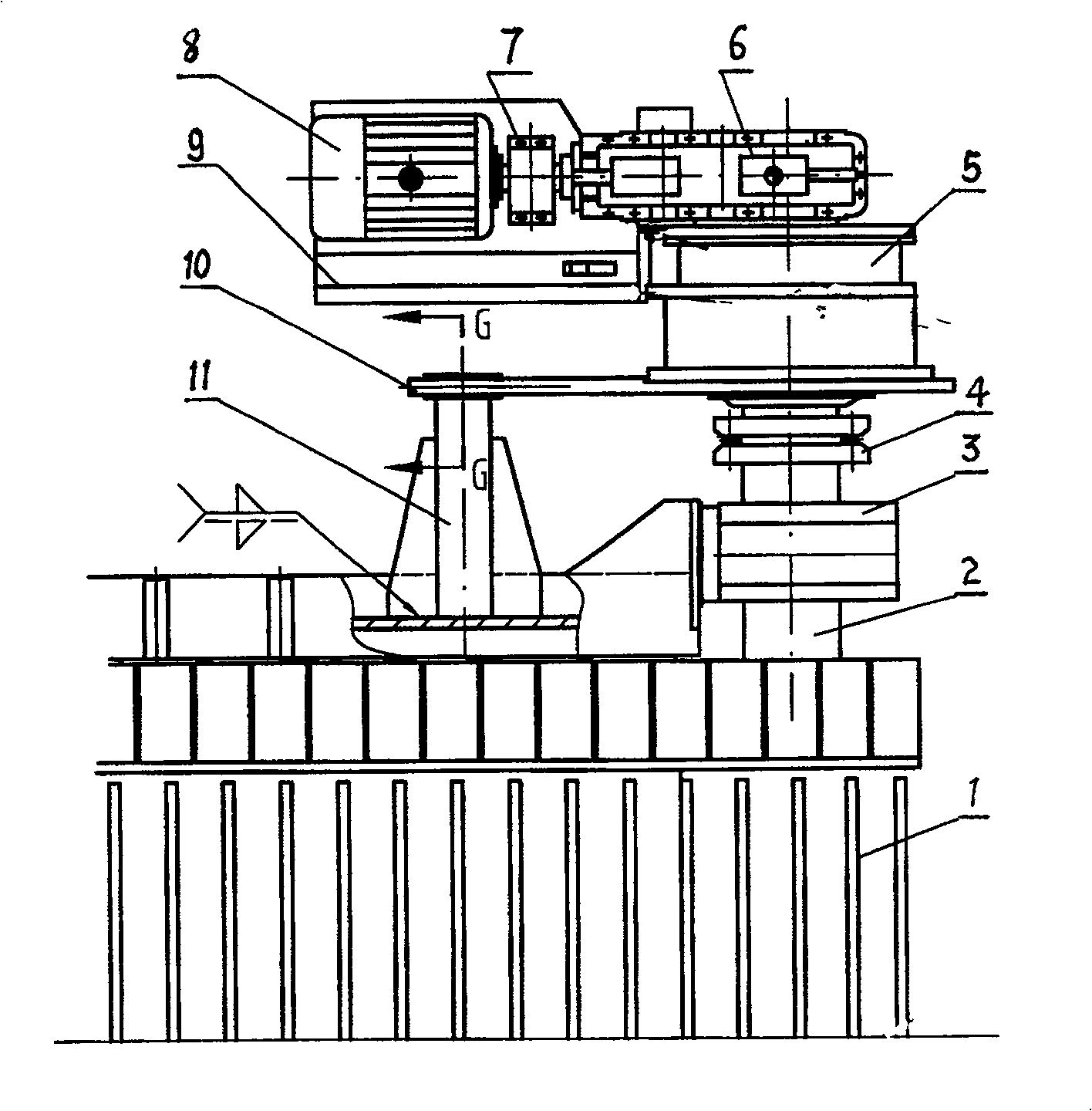

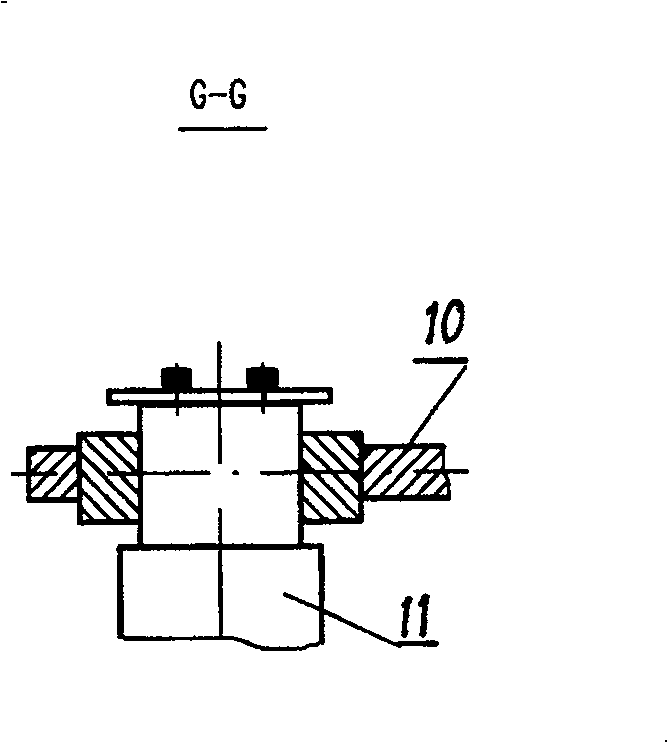

[0013] Single point bearing drive for heavy duty apron feeders, see Figure 1-3 : including motor 8, drive frame 9, right-angle reducer 6, planetary reducer 5 and its planetary reducer housing 19, characterized in that the driving device is suspended on the drive shaft of the main machine: the motor 8 is connected to the drive shaft through the coupling 7 Orthogonal reducer 6 is connected, the final output hollow shaft of planetary reducer 5 is directly sleeved on the drive shaft 2 of apron feeder 1, locked by locking disc 4, and one end of torque rod 10 is connected with planetary reducer 5 Blue plate connection, the other end of the torque rod 10 is rotatably connected with one end of the support column 11, see figure 2 , the other end of support column 11 is welded together with the frame of feeder 1.

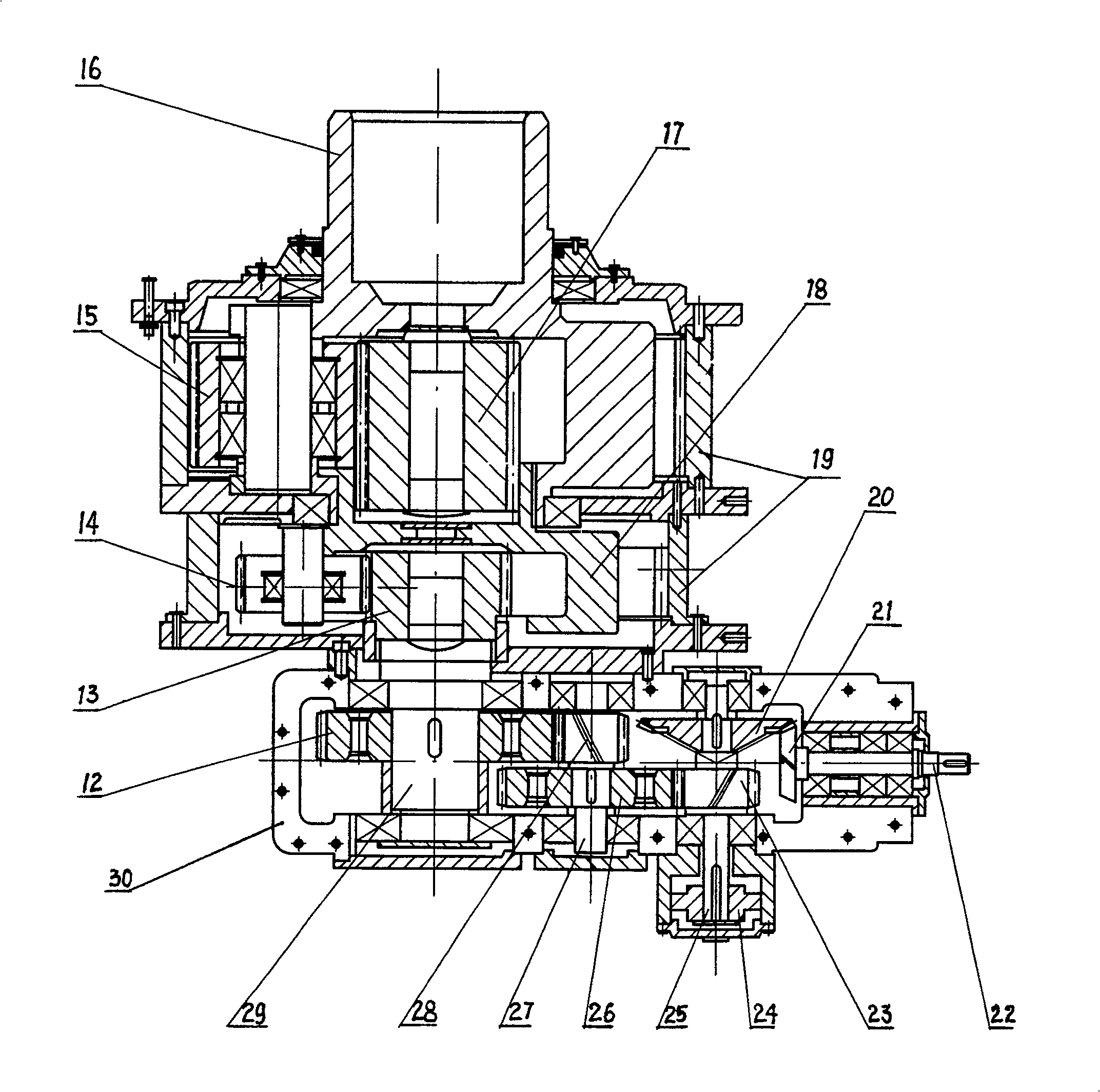

[0014] The right-angle reducer 6 in the right-angle planetary reducer can use DCY type products, see image 3 : The feature of the orthogonal planetary reducer is that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com