Aerodynamic shape and design method of two-way flying wing aircraft

A technology of aerodynamic shape and aircraft, applied in the direction of full-wing aircraft, aircraft parts, aircraft control, etc., can solve the problem of insufficient control ability of the shape of the rudder surface, and achieve the effect of solving the insufficient control ability, easy implementation, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

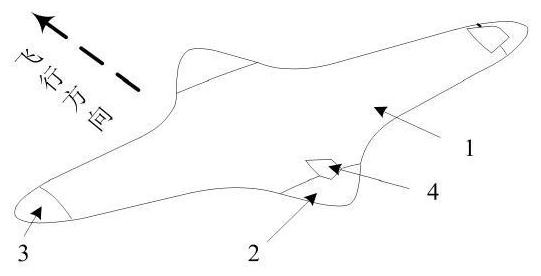

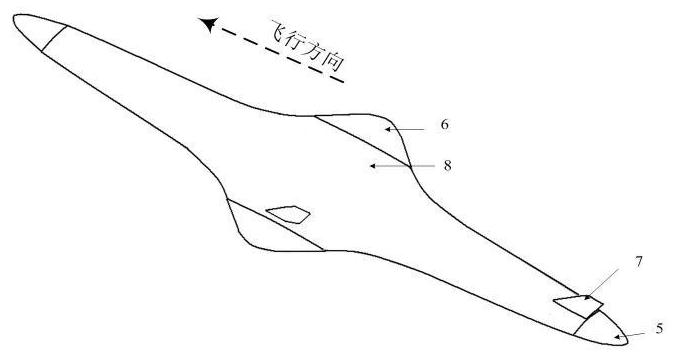

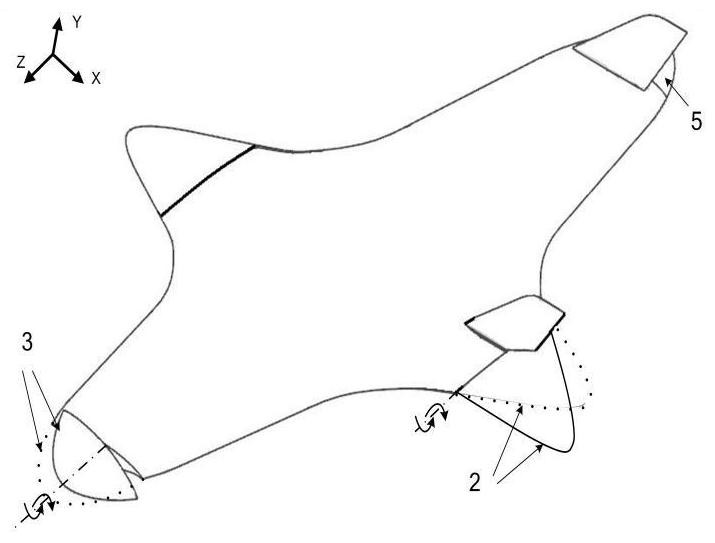

[0038] Embodiment 1, as figure 1 and figure 2 As shown, the present invention proposes an aerodynamic shape of a two-way flying wing aircraft, comprising a low-speed mode wing 1, a high-speed mode wing 8, a low-speed mode aileron 3, a high-speed mode aileron 6, and a low-speed mode elevator 2 , high-speed mode elevator 5, low-speed mode vertical tail 4 and high-speed mode vertical tail 7;

[0039] The high-speed mode wing 8 in the low-speed mode is the low-speed mode fuselage of the aircraft, the low-speed mode aileron 3 adopts the low-speed mode wing 1 without the high-speed mode elevator side wingtip as the full-motion control surface, and the low-speed mode elevator 2. The tail end of the low-speed mode fuselage is used as the rudder surface, and the low-speed mode vertical tail 4 is located on the symmetrical plane of the upper surface of the low-speed mode fuselage of the aircraft and before the low-speed mode elevator 2 .

[0040] The low-speed mode wing 1 in the high...

Embodiment 2

[0049] Embodiment 2, according to another aspect of the present invention, the present invention provides a kind of design method of aerodynamic profile of two-way flying-wing aircraft, and design method is as follows:

[0050] Determine the position of the low speed mode elevator, low speed mode aileron, high speed mode elevator and high speed mode aileron;

[0051] According to the longitudinal stability matching requirements of the aircraft in the low-speed mode and high-speed mode, the area of the elevator rudder surface in the low-speed mode and the elevator rudder surface area in the high-speed mode of the aircraft are respectively designed. Cause problems such as excessive hinge torque, the deflection angle of the elevator is constrained by the non-failure of the rudder surface, the area of the rudder surface of the low-speed mode elevator is 5% to 10% of the projected area of the whole machine, and the maximum available deflection angle of the rudder surface is -3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com