A centering non-contact axial force loading device and method

A loading device and axial force technology, applied in the field of testing, can solve the problems of bending moment component at the shaft end, affecting test accuracy, affecting the force state of the system under test, etc., and achieve the effect of small additional force and accurate loading direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

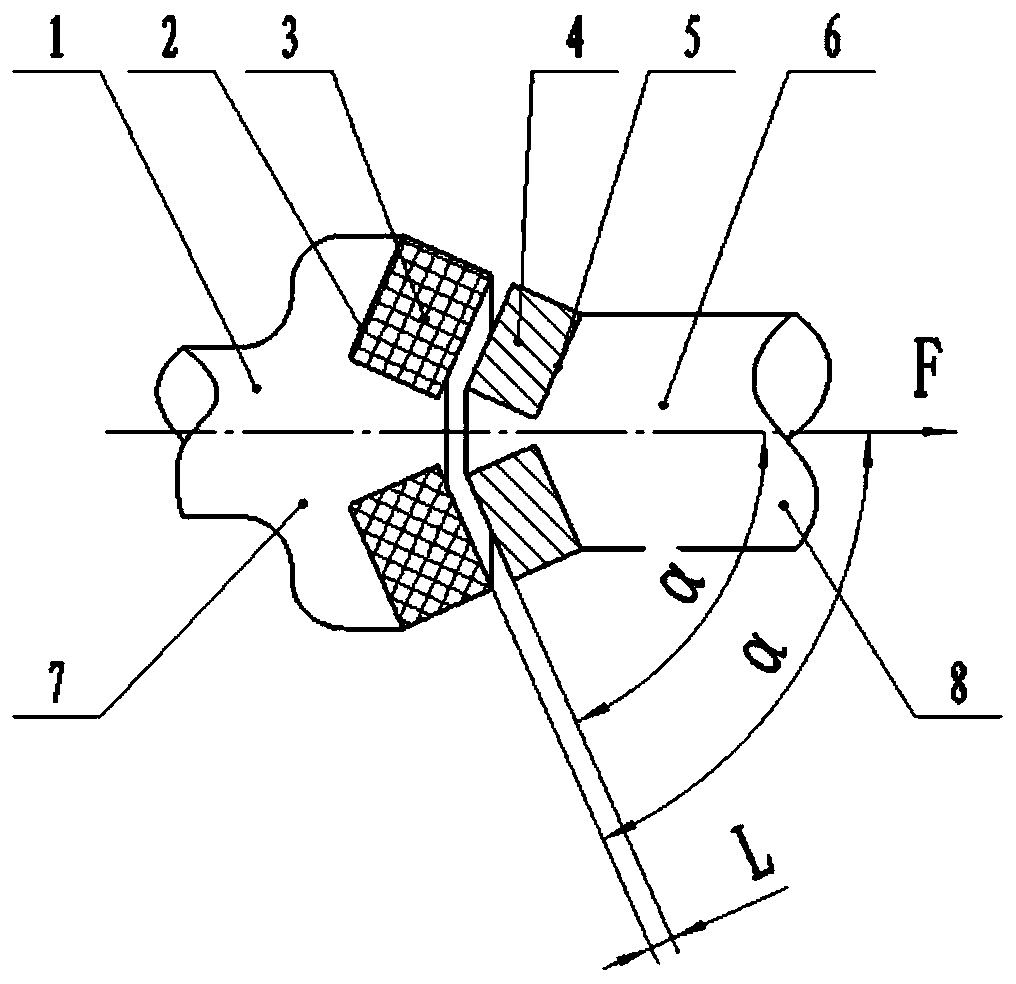

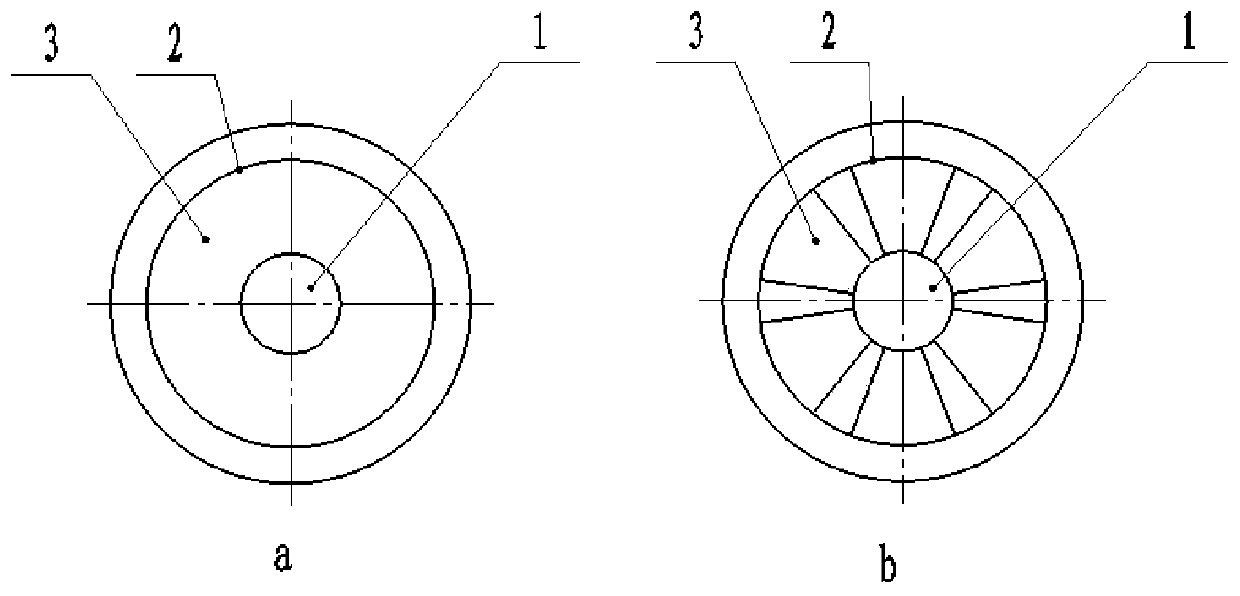

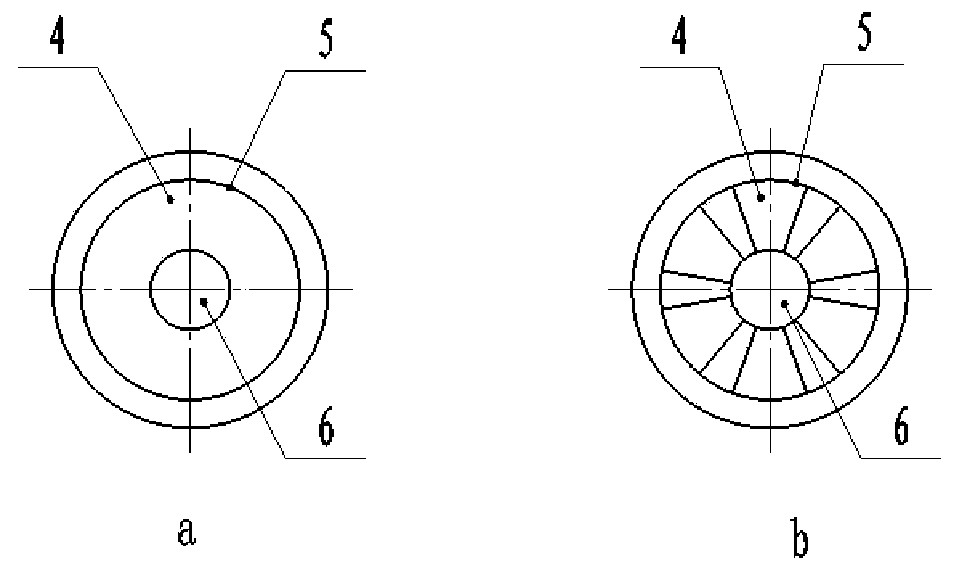

[0020] Such as figure 1 As shown, a centering non-contact axial force loading device includes a loading shaft 1, a loading shaft magnetic steel mounting groove 2, a loading magnetic steel 3, a loaded magnetic steel 4, a loaded shaft magnetic steel mounting groove 5 and a loaded shaft 6. The loading magnet 3 is cemented in the loading magnet installation groove 2 of the loading shaft 1 to form the loading body 7; the loaded magnet 4 is cemented in the loaded shaft magnet installation groove 5 of the loaded shaft 6 to form a loaded body 8; the loading body 7 is close to the loaded body 8, constituting a loading device; the angle between the loading shaft magnetic steel installation groove 2 and the loaded shaft magnetic steel installation groove 5 is 0°<α<90°.

[0021] A centering non-contact axial force loading method, based on the use of the aforementioned loading device, the device is placed in a gas or liquid environment, and the angle α between the magnetic steel installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com