Three-directional mechanical test platform

A mechanical test and platform technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of difficulty in ensuring the independence of three-way loading, unable to meet the test requirements, and small range of motion, and achieve accurate loading directions. , The effect of large allowable load and large range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

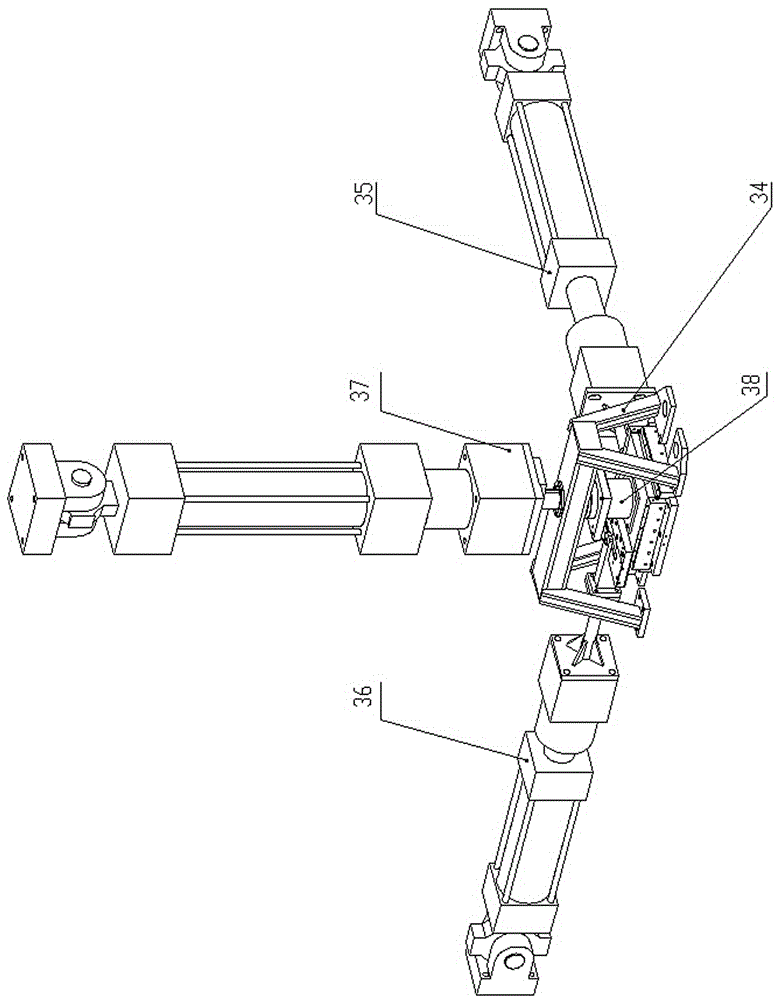

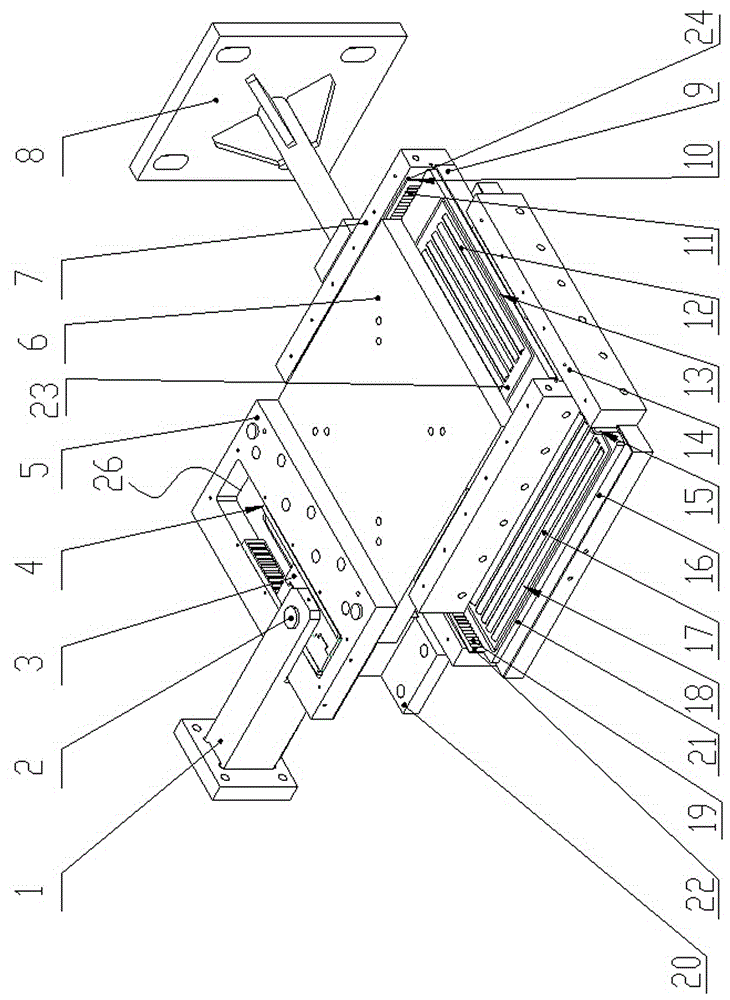

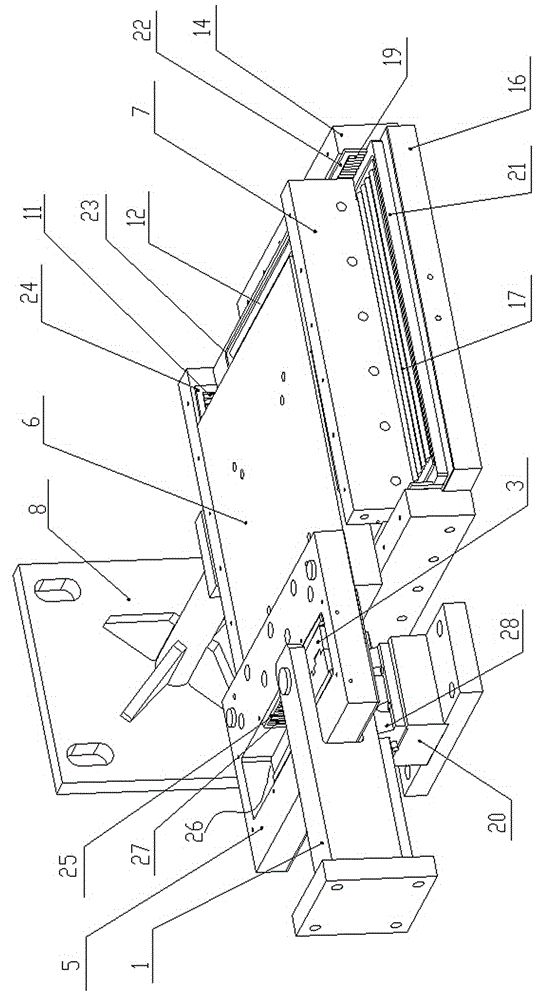

[0033] Combine below Figure 1 to Figure 6 The structure and working process of the present invention are further described.

[0034] A three-way mechanical test platform of the present invention comprises a three-layer structure consisting of an upper load-bearing plate 6, a middle load-bearing plate 9 and a lower force-bearing plate 16, the two sides of the lower force-bearing plate 16 along the X direction An X-direction rail 14 is fixedly arranged on the side, the middle bearing plate 9 is located between the X-guiding rails 14, and an X-direction roller row 18 is arranged between the middle bearing plate 9 and the lower bearing plate 16, An X lateral roller row 15 is arranged between the middle bearing plate 9 and the X guiding rail 14; the X directional roller row 18 is composed of an X directional roller column 17 and an X directional roller cage 21. The X-direction roller cage 21 is provided with X-direction roller positioning holes (not marked in the drawings) that mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com