Handling manipulator assembly

A manipulator component and manipulator technology, which is applied to manipulators, program-controlled manipulators, mechanical equipment, etc., can solve the problems of complex second variants, and achieve the effect of high mobility and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

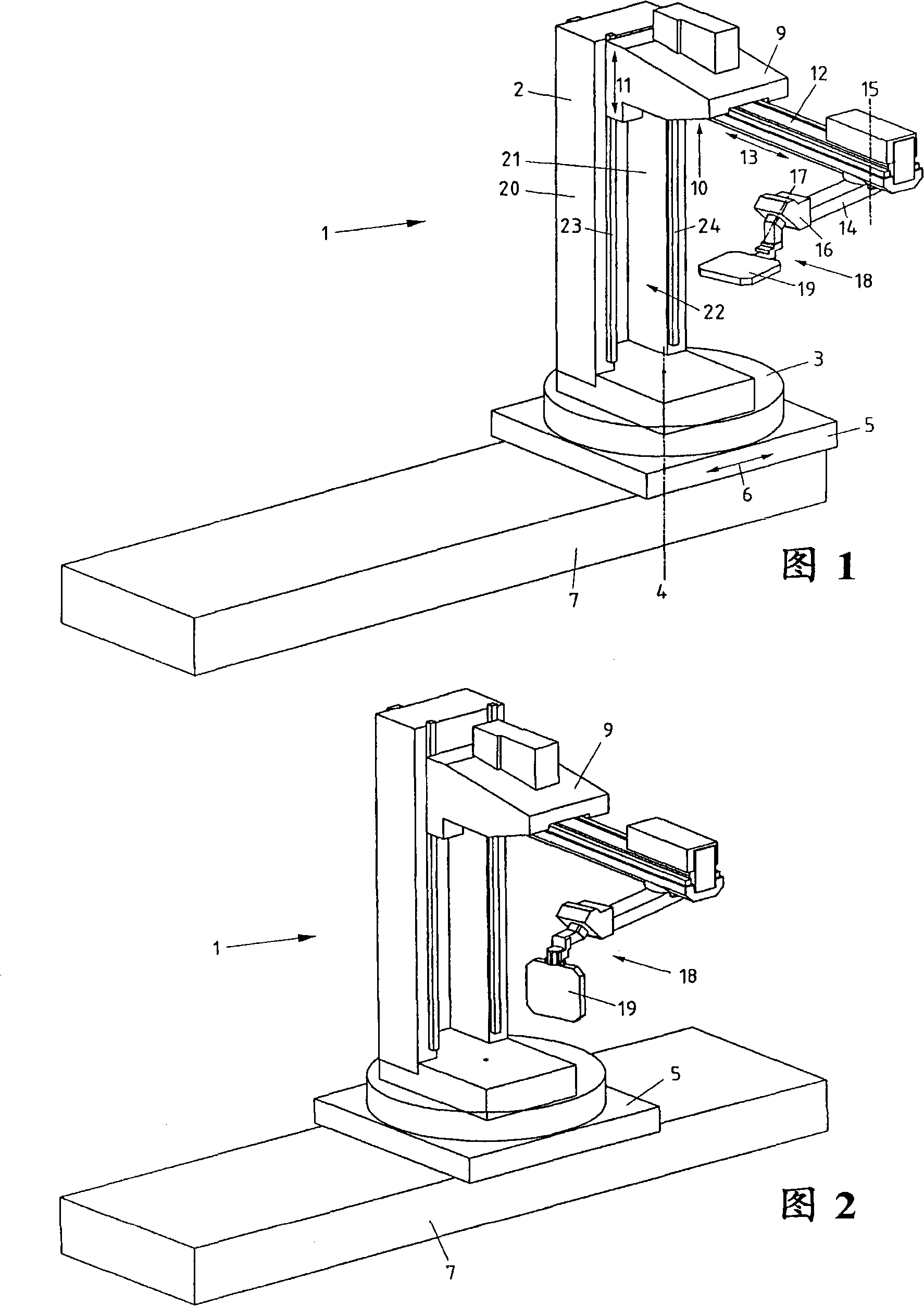

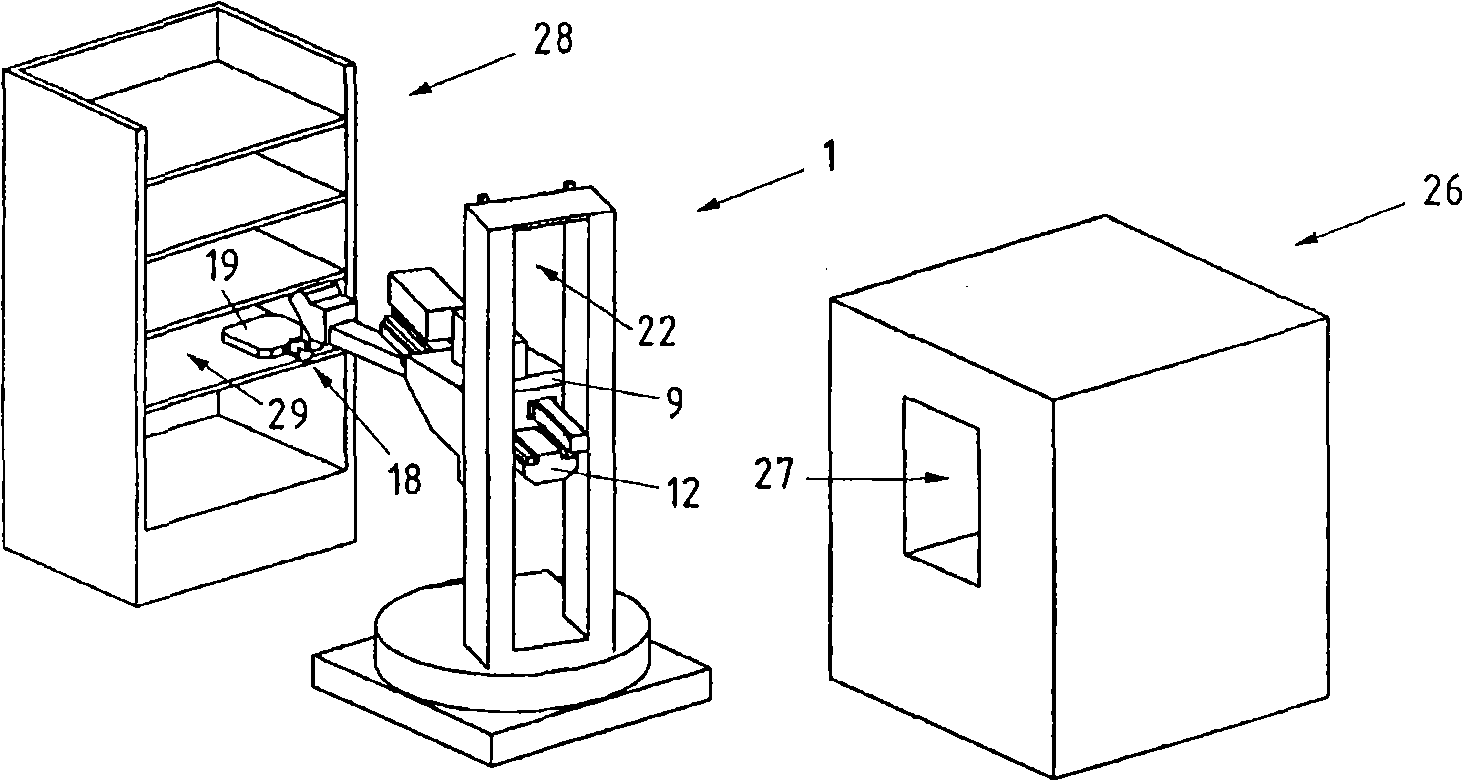

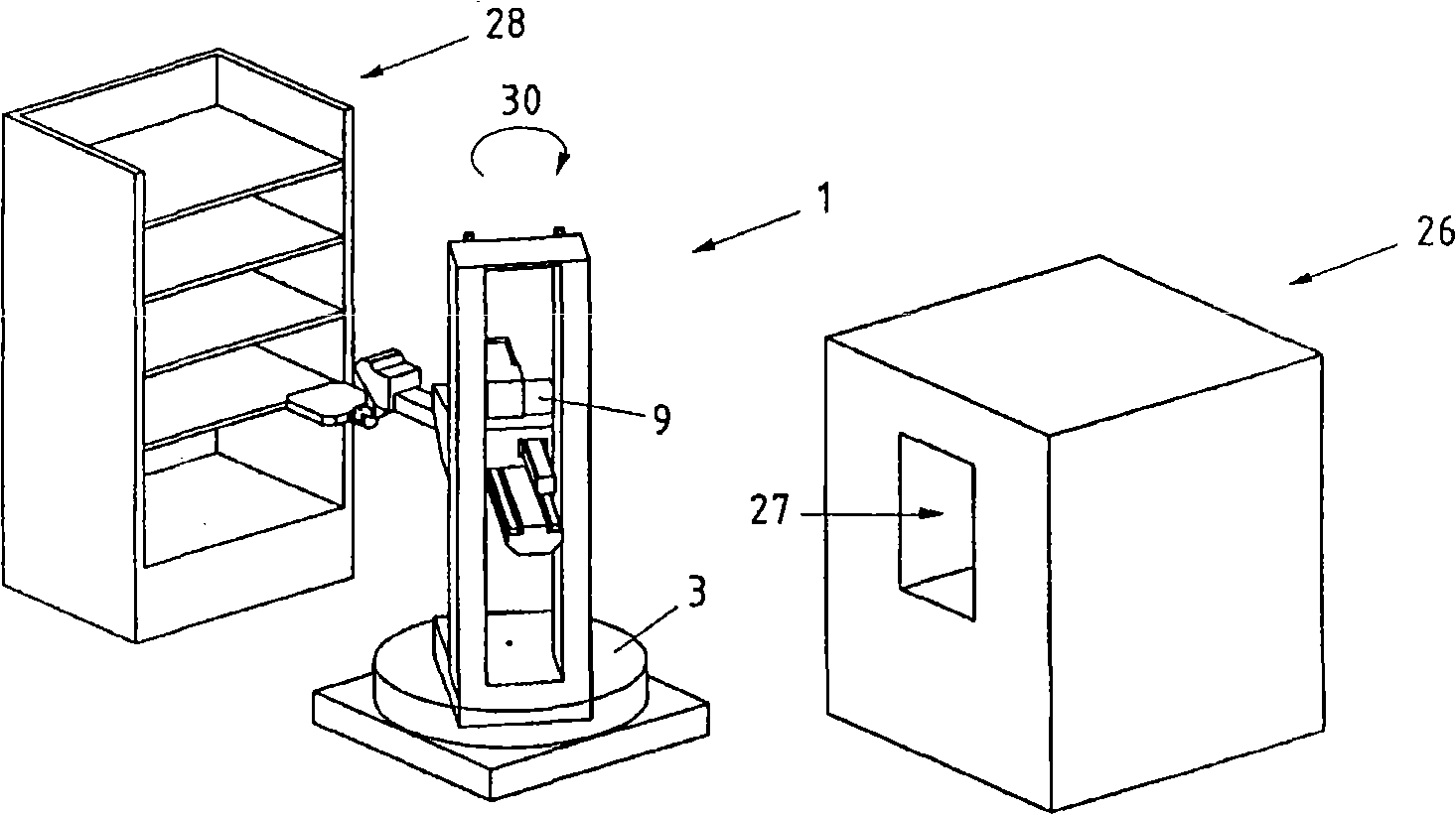

[0020] Referring now to FIG. 1 , there is illustrated an exemplary aspect of a manipulator assembly according to the present invention to explain its basic configuration. The manipulator assembly 1 comprises a vertical main support 2 placed on a turntable 3 . In the present embodiment, the main support 2 is positioned centrally on the turntable 3, however it could also be positioned off-centre. A turntable 3 rotating around a vertical axis 4 is secured to a horizontally traveling main slide 5 which can travel on a slide 7 as indicated by the double arrow 6 . A vertical slide 9 designed for vertical travel is placed on the vertical main support 2 . Here again, the direction of travel of the vertical slide 9 is indicated by a double arrow 11 . The vertical carriage 9 comprises a stable support body 9 a, on the underside 10 of which is arranged a horizontal extension arm 12 designed for horizontal travel, the direction of travel of which is likewise indicated by a double arrow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com