Variable pressure angle cam contour line design method applicable to sudden variable load

A cam profile, cam profile technology, applied in the direction of cams, mechanical equipment, components with teeth, etc., can solve the problems of mismatching and unsuitable load characteristics, and achieve the advantages of improving service life, convenient processing and reducing energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

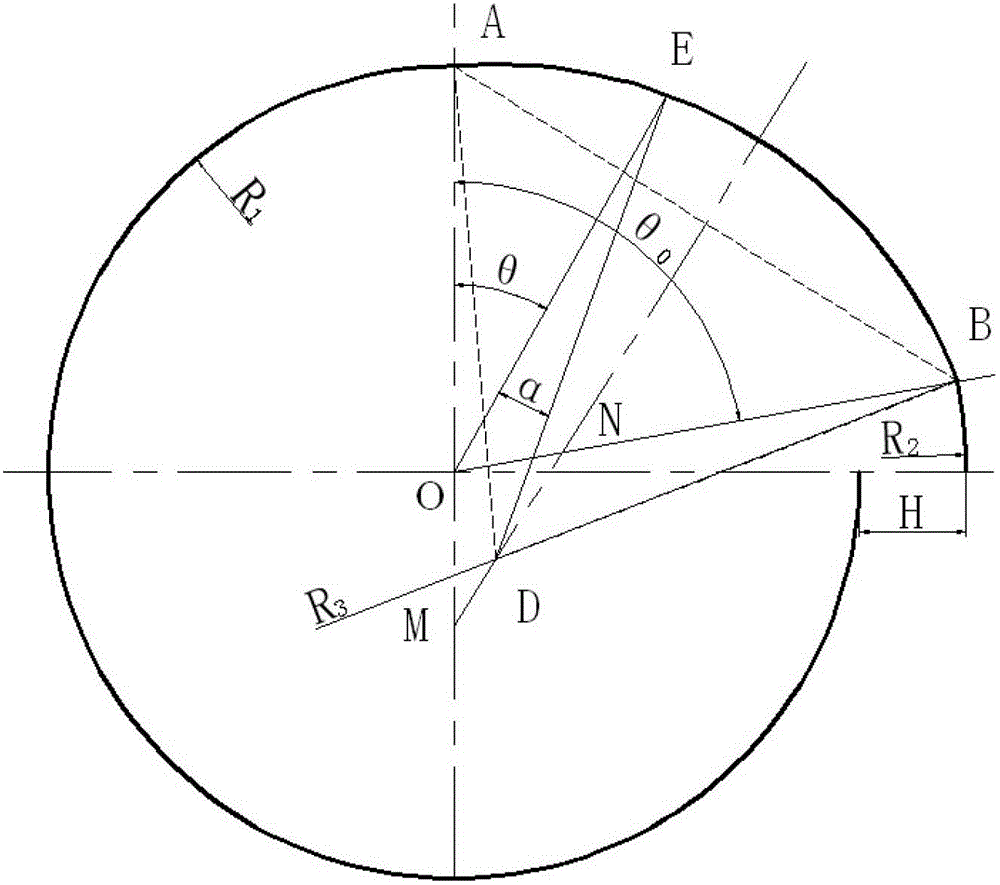

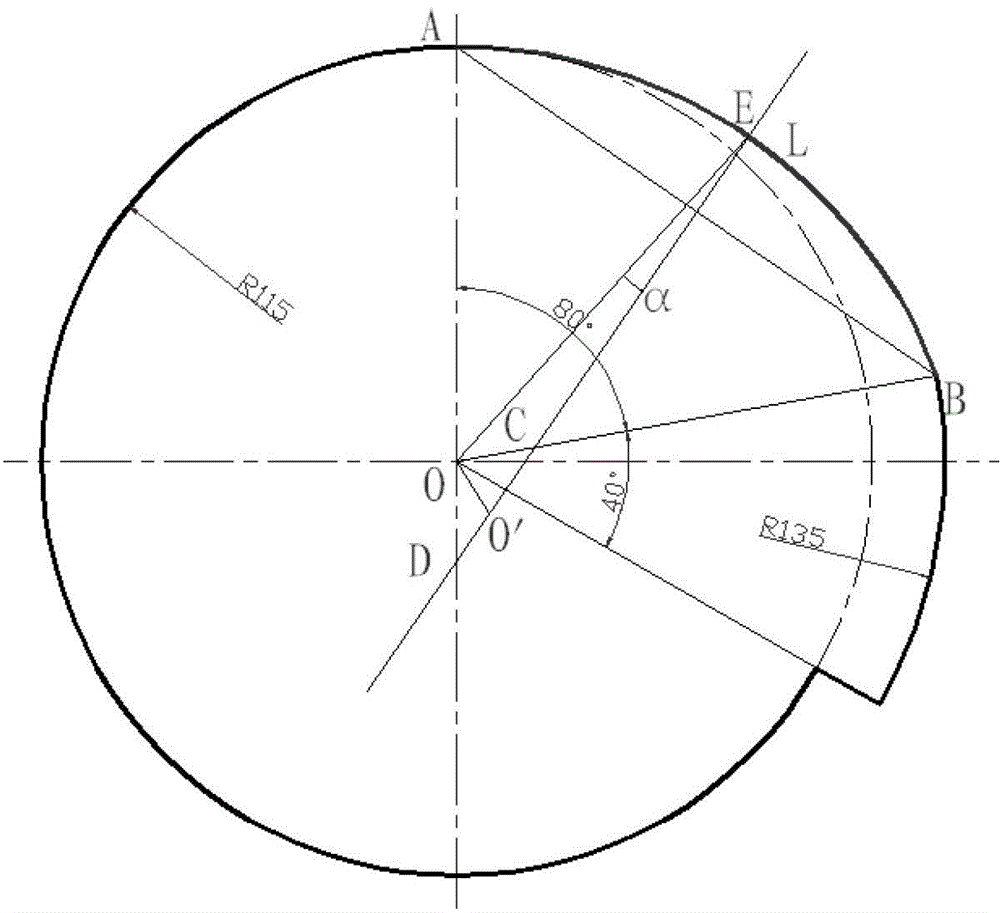

[0043]Taking the cam profile curve design of a 60MN free forging hydraulic press as an example, the minimum radius of the cam is 100mm, and the radius of the roller is 15mm. The lift angle is 80°, the far repose angle is 40°, the gap between the ejector rod and the valve stem is 3-5mm, and the lift is 20mm. The calculation method is as follows. Cam theoretical working curve such as figure 2 shown. The lift curve is arc segment AB, where the coordinates of point A are (0,115), and the coordinates of point B are (135cos80°, 135sin80°). So we can know the expression of the perpendicular line L of the straight line AB, that is, the center O' of the arc AB is on the straight line L. In order to satisfy the requirement that the minimum radius of the cam is 115mm and the maximum radius is 135mm, the center of the circle actually moves in the CD segment. Among them, point C is the intersection point of OB, and point D is the intersection point of the extension line of AO. If the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com