Straddle type monorail transit track beam spherical steel support

A straddle-type monorail and track beam technology, which is applied in tracks, roads, buildings, etc., can solve the problems of reducing the service life of the bearing, the large size of the bearing, difficult construction and maintenance, etc., and achieves good lateral bending resistance. Choose a wide range of effects with easy quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

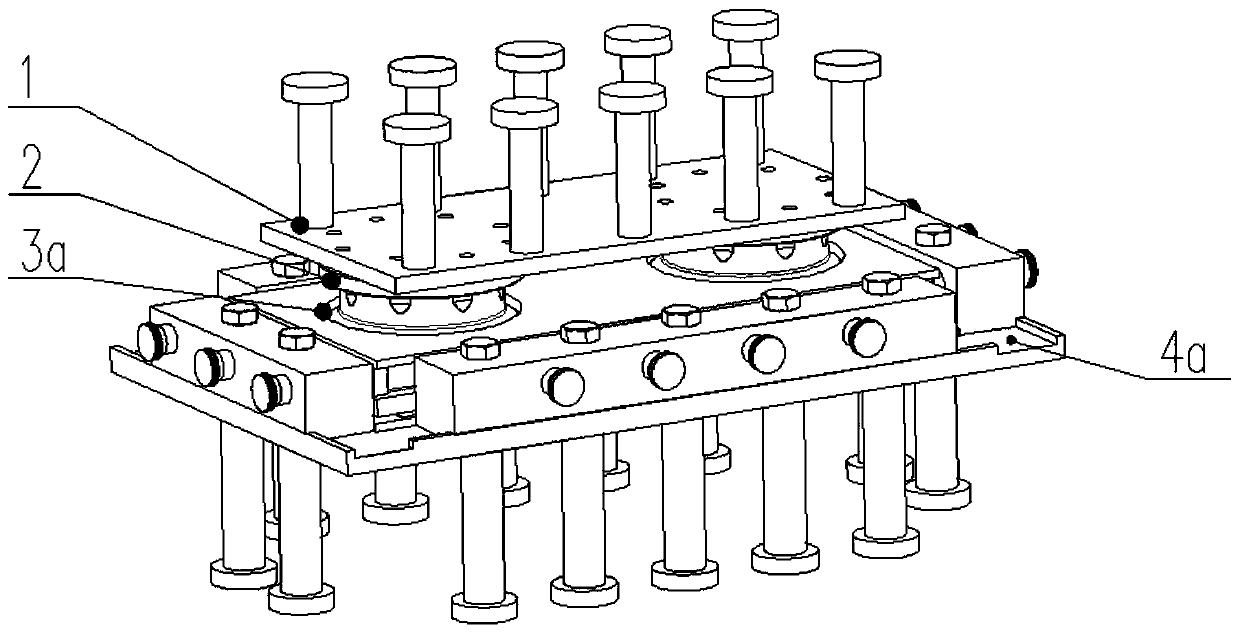

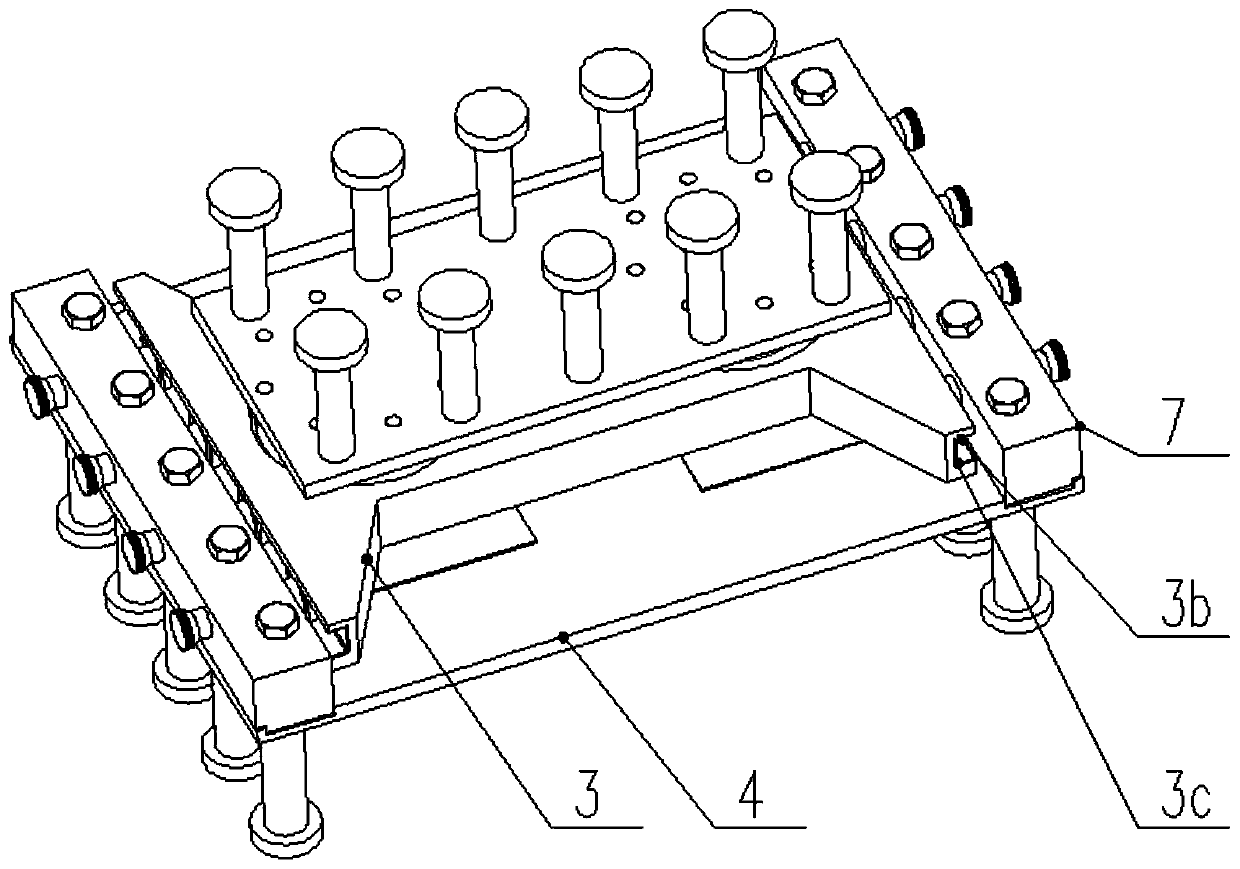

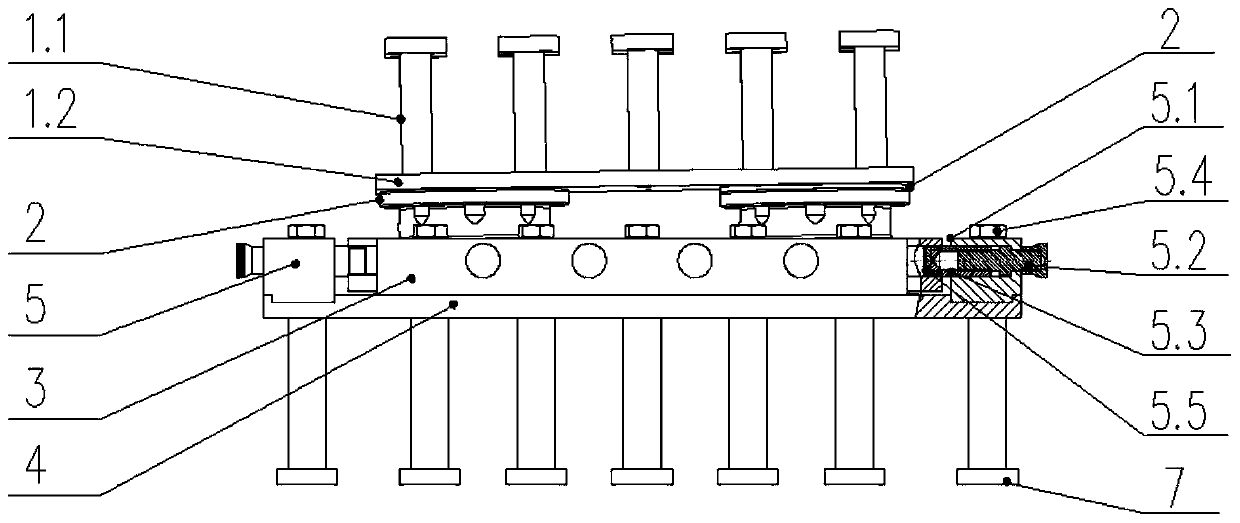

[0030] see Figure 1 to Figure 4 , shows the straddle type monorail traffic track beam spherical steel bearing of the present invention.

[0031] The straddle-type monorail traffic track beam spherical steel support includes an upper anchor unit 1, a tensile and compressive rotation mechanism 2, a base 3, a bottom plate 4, a support level adjustment mechanism 5, a support height and lateral angle adjustment mechanism and a lower Anchor unit 7.

[0032] Wherein, the upper anchoring unit 1 is pre-embedded in the prefabricated PC beam, which is fixed to the tensile and compression rotating mechanism 2 below by bolts, and the lower anchoring unit 7 is poured on the abutment, and is connected to the bottom plate 4 and the upper part of the bolt by bolts. The support level adjustment mechanism 5 is connected, and the upper surface of the base plate 4 is provided with a base 3 that can be adjusted horizontally through the support level adjustment mechanism 5, and the upper surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com