Method for preventing well wall from crack by dynamic earth layer reinjecting water

A technology of water reinjection and water injection wells, which is applied in the direction of sinking, shaft equipment, earthwork drilling and mining, etc. It can solve the problems of hidden dangers in mining activities, cure the symptoms but not the root cause, reduce the vertical additional force, etc., and achieve good development prospects and effects Good, additional force reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

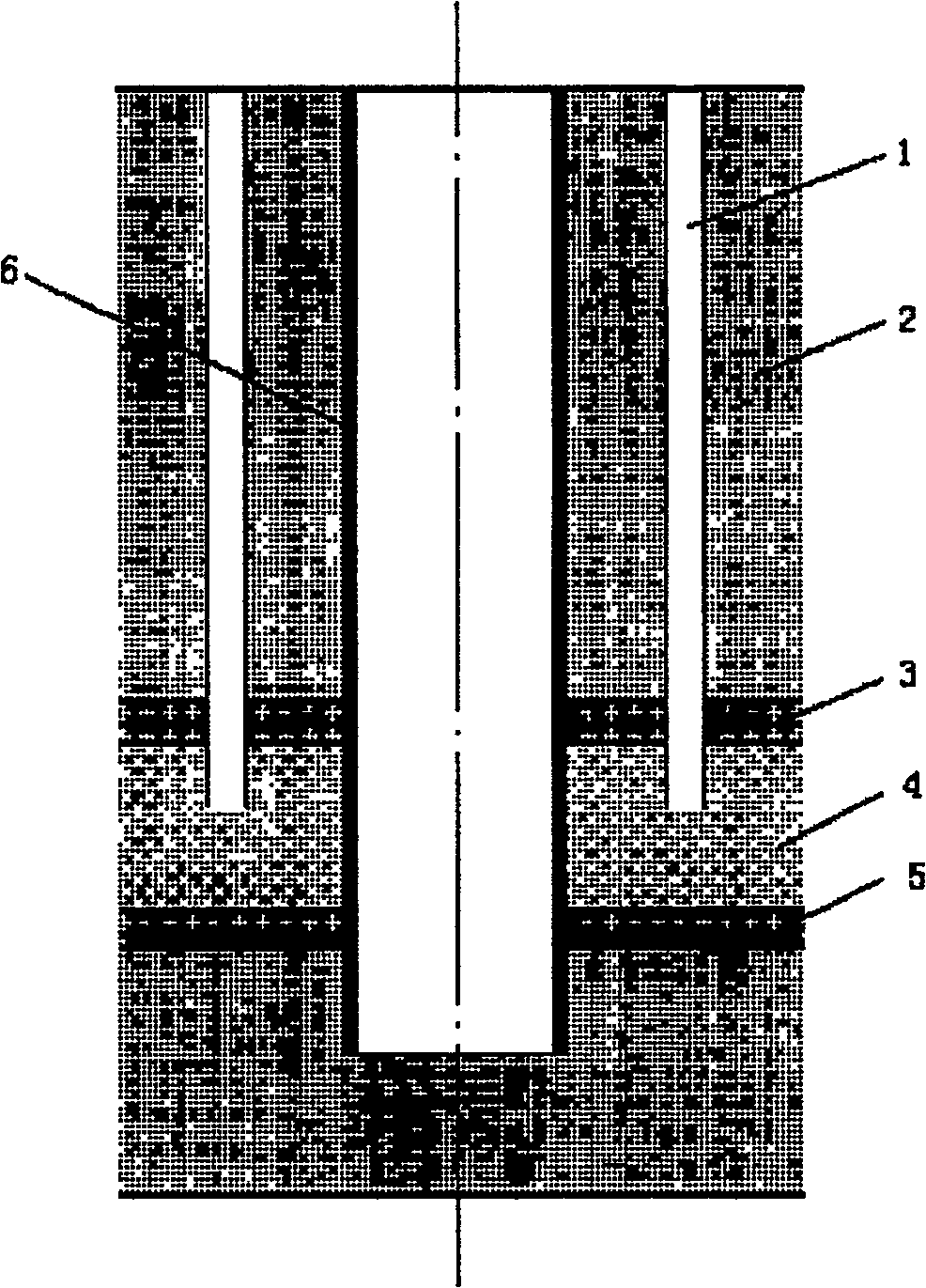

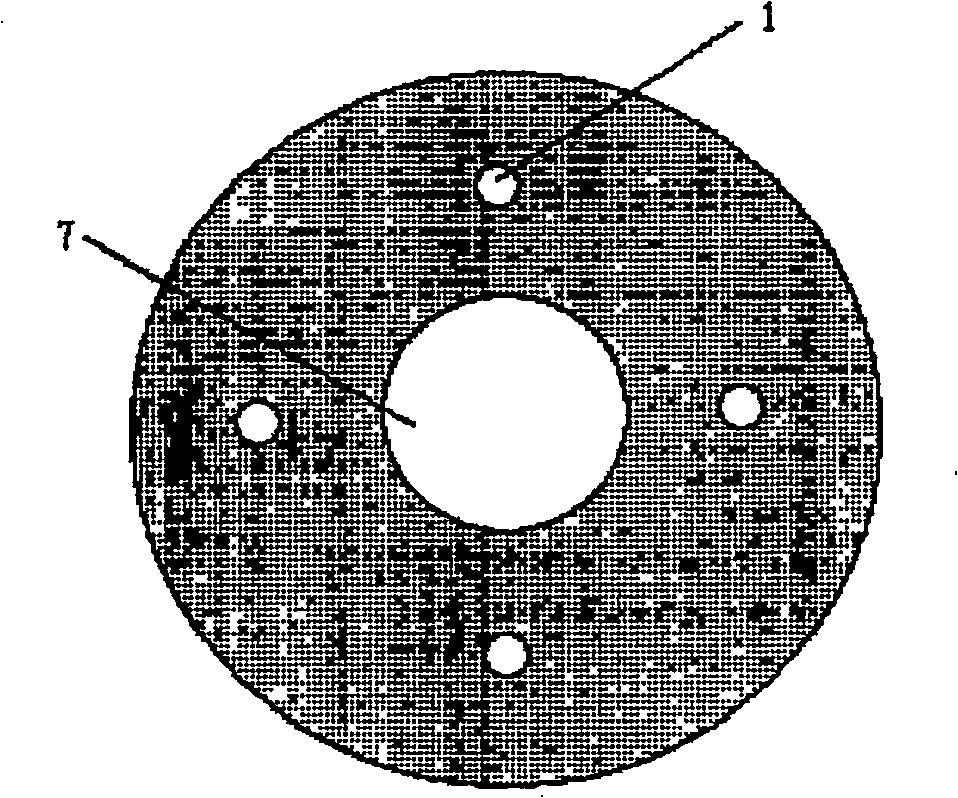

[0010] The method for preventing and controlling well wall rupture by dynamic reinjection of strata in the present invention first conducts on-the-spot investigation on the wellbore 7, and obtains that the distribution of main strata is as follows: thick topsoil layer 2, water-resisting layer 3, key aquifer 4, and rock water-resisting layer 5 , after analyzing the damage of the borehole wall and the additional force of the borehole wall, the total water injection volume, the number and way of water injection well 1 layout, the distance between water injection well 1 and wellbore 7, and the drilling depth of water injection well 1 are designed. The water injection pressure is determined according to the actual water pressure drop in the key aquifer 4, which is the water pressure difference in the aquifer caused by exploitation, which can be measured by a pore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com