Patents

Literature

287results about How to "Solve the problem of water seepage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

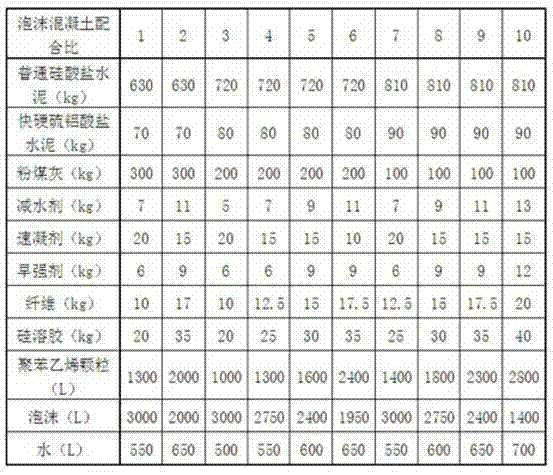

Foam concrete with large-dosage polystyrene particles and preparation method thereof

ActiveCN102503526AImprove thermal insulation performanceHigh electrical insulationCement mixing apparatusCeramicwareFoam concreteAluminate

The invention provides a foam concrete with large-dosage polystyrene particles and a preparation method thereof, which solve problems of water leakage and frost resistance of the foam concrete. The foam concrete comprises components in part as follows: 63-81 parts of ordinary portland cement, 63-81 parts of quick-hardening sulphoaluminate cement, 10-30 parts of coal ash, 0.5-1.3 parts of water reducing agent, 1-2 parts of accelerating agent, 0.6-1.2 parts of early strength agent, 1-2 parts of fiber, 2-4 parts of silica sol, and 50-70 parts of water. The percentage in volume (liter) of the polystyrene particles in added water is 200-400percent, and the percentage in volume (liter) of foam in the added water is 100-600percent. In the preparation process, the treated polystyrene particles stand for 10 min, and the foam can be added after standing uniformly-stirred cement slurry for 20 min. On the premise of ensuring the intensity, the foam cement disclosed by the invention has the advantages of higher heat preservation and heat-shielding performance, higher electric insulating performance, lower volume weight and lower water absorption. The problems of the water leakage and the frostresistance of the foam cement can be solved.

Owner:SHENYANG JIANZHU UNIVERSITY

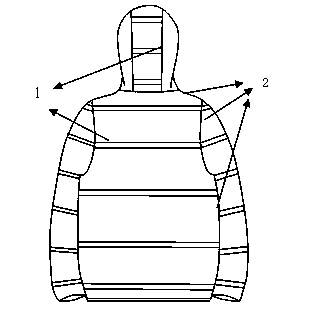

Waterproof down jacket making method and waterproof down jacket

InactiveCN103799596AImprove waterproof performanceImprove heat retention and down-resistanceOvergarmentsClothes making applicancesEngineering

The invention discloses a waterproof down jacket making method and a waterproof down jacket. The method includes the first step of material selection, the second step of tailoring, the third step of quilting and seamless attachment, the fourth step of adhesive strip pressing and repair adhesive reinforcement, the fifth step of down filling and sealing, the sixth step of seam wrapping of interlayer fabric and lining fabric, and the seventh step of the arrangement of a zipper on a top fly and welting of a lower hem, cuffs and a cap mouth. Then, the waterproof down jacket is obtained. Because coated or film-pasted fabric is adopted as surface-layer fabric, the waterproofness of the down jacket is greatly improved; because the surface-layer fabric is free of stitches and cut piece joints are pressed by waterproof adhesive strips or adhesive tape, the problem that water seeps in from the stitches is solved; meanwhile, the warm-keeping performance and down leakage preventing performance of the whole down jacket are improved as well.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

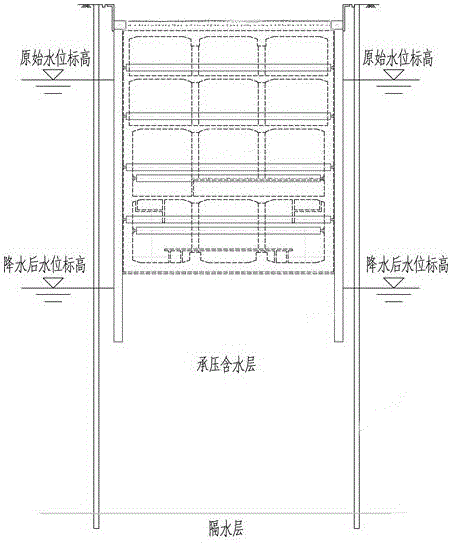

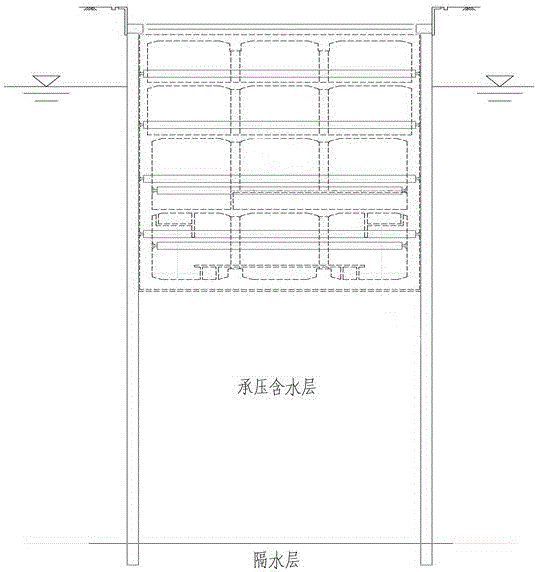

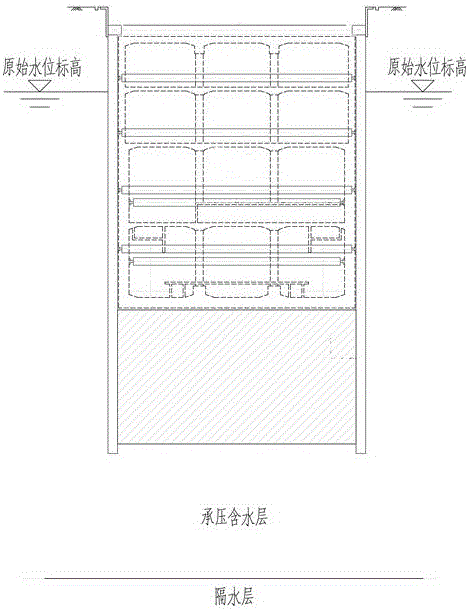

Strongly-permeable stratum deep foundation pit bottom sealing water stopping structure and construction method thereof

ActiveCN105002913AImprove reliabilityImprove waterproof performanceProtective foundationExcavationsSlurry wallReinforced concrete

The invention discloses a strongly-permeable stratum deep foundation pit bottom sealing water stopping structure, which comprises diaphragm walls, underwater plain concrete boards, reinforced concrete partition walls, uplift piles and inner supports, wherein the diaphragm walls are arranged around the foundation pit througgh casting; the inner supports support the diaphragm walls; the reinforced concrete partition walls are formed on the foundation pit below the diaphragm walls through casting; the reinforced concrete partition walls and the diaphragm walls of each two faces form a casting block in a surrounding mode on the foundation base; the uplift piles are casted on the foundation base inside the block; each underwater plain concrete board is formed through casting at each block opening formed by the reinforced concrete partition walls and the diaphragm walls in a surrounding mode; and the uplift piles are firmly embedded in the underwater plain concrete boards. The underwater plain concrete boards enhance overall strength and ridigity of the foundation pit bottom, dual effects of reinforced pit bottom and permeation prevention are provided, influences on stability of the pit bottom by high pressure water and raised pit bottom caused by excavation of the foundation pit can be effectively solved, and lateral displacement of the pit wall and settlement deformation of the surrounding enviornment can be well reduced.

Owner:RANKEN RAILWAY CONSTR GROUP +1

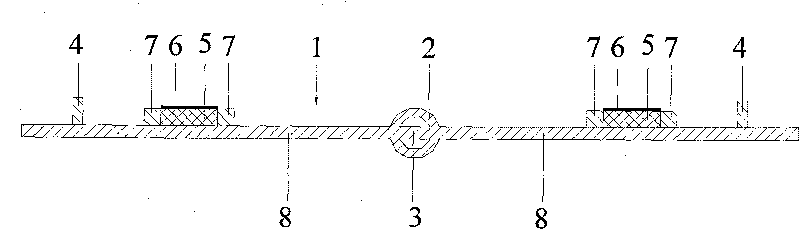

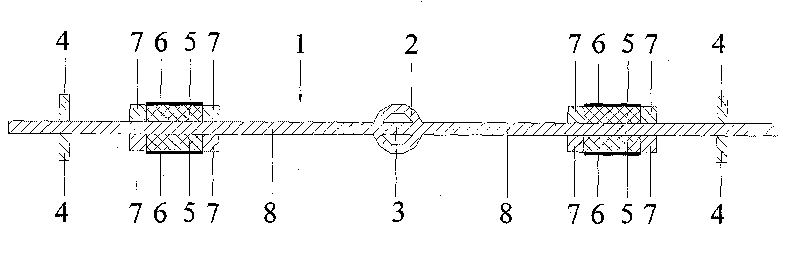

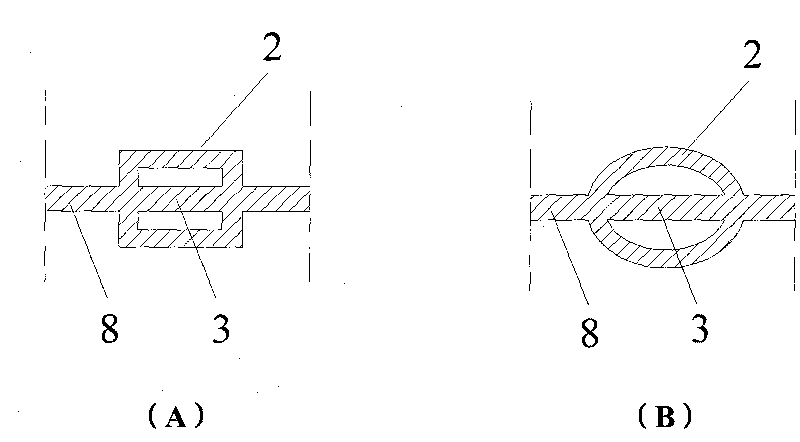

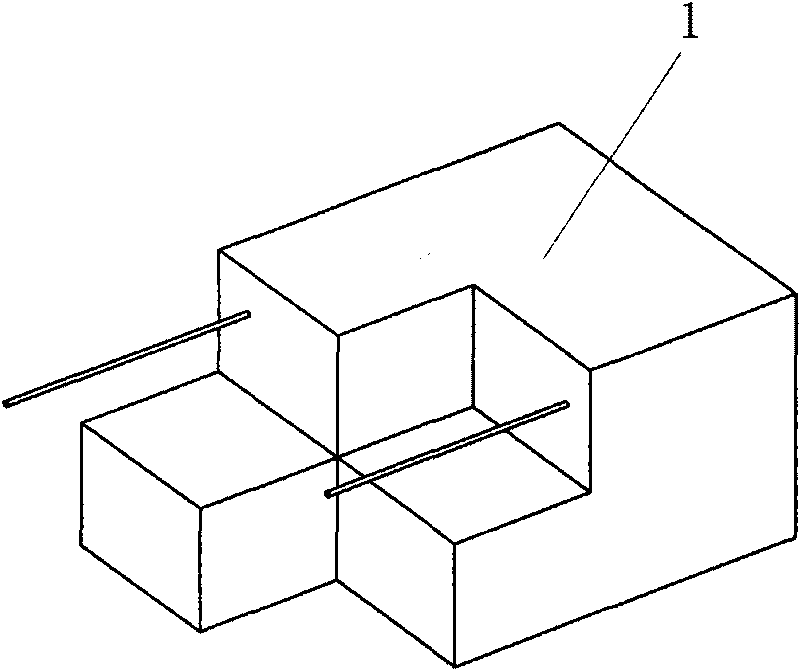

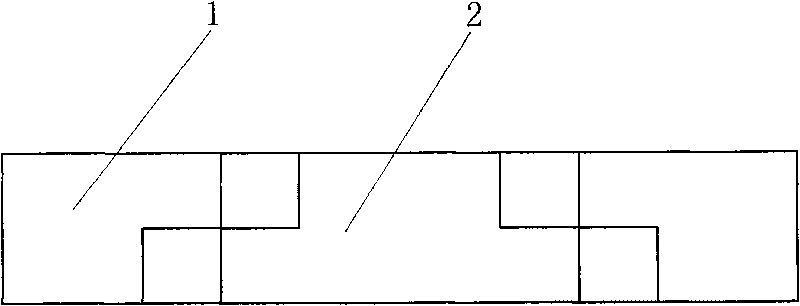

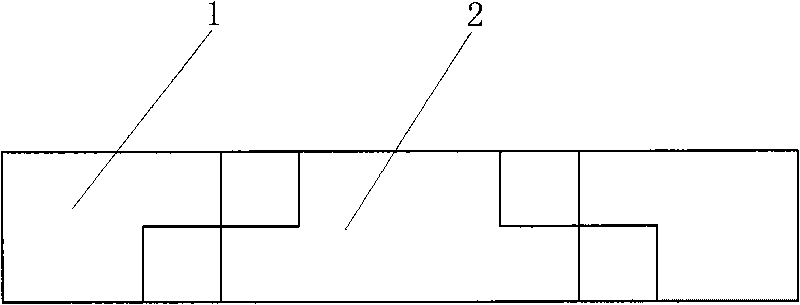

Composite type self-adhesion water stop band, manufacturing method and construction method

InactiveCN101691739APlay a buffer rolePrevent leakageUnderground chambersBridge structural detailsVulcanizationEngineering

The invention relates to a composite type self-adhesion water stop band, a manufacturing method and a construction method. The main body of the water stop band base material is a section bar on the whole and is composed of an expanding hole, an expanding band, water stop band substrates, a concave binding slot and a water stop rib. The middle part of the main body of the water stop band base material is provided with the expanding hole, the middle part in the expanding hole is provided with the expanding band, the two end parts of the main body of the water stop base material are provided with water stop band substrates, the concave binding slots are arranged on the water stop substrates, a binding layer is arranged in the concave binding slots and adopts non-vulcanization butyl rubber, ionic reaction is generated between the binding layer and calcium oxide in concrete, the binding layer and the calcium oxide are penetratively bonded together to form an impermeable layer to stop leakage. The invention has scientific design and reasonable structure, and solves the problem that water seepage easily occurs to the common water stop band as the concrete binding is unstable; when the concrete architecture generates elastic deformation under various loads, the expanding hole and the expanding band play the function of reinforcing and sealing, therefore, the invention can be widely applied to cast-in-place concrete construction operation of buildings and structures such as bridge opening, tunnels, hydropower stations and the like.

Owner:TIANJIN WATER RESOURCES RES INST

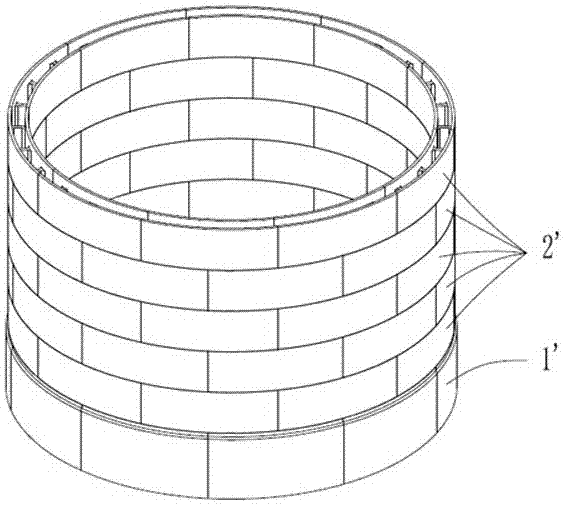

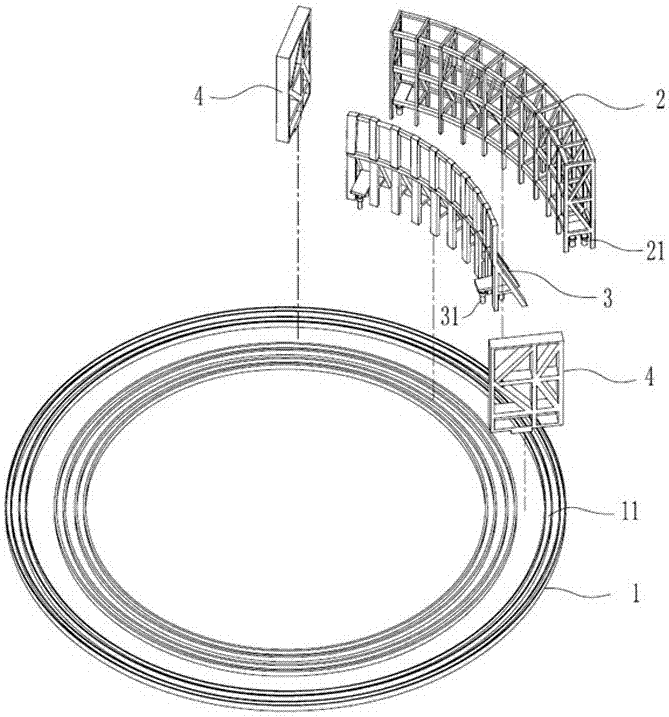

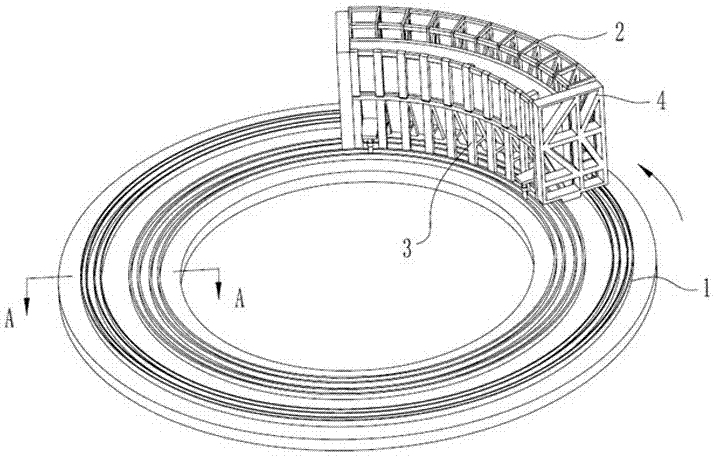

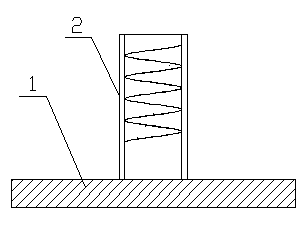

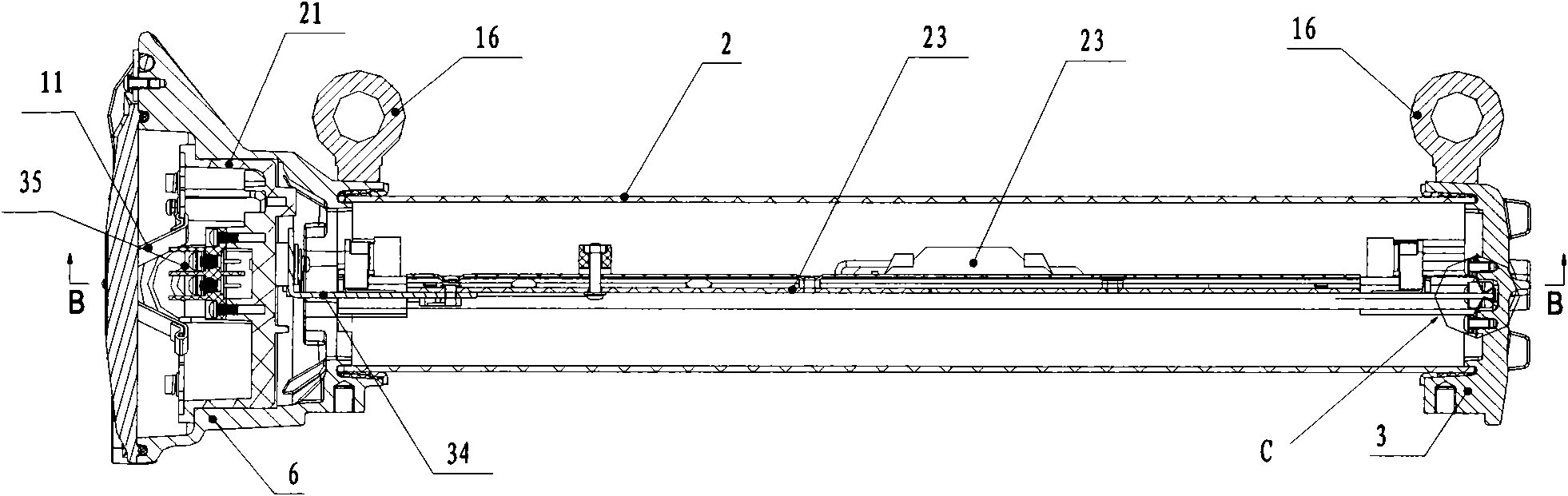

Sliding formwork component and open caisson blade foot layer sliding formwork construction method applying sliding formwork component

PendingCN107575023AGuaranteed vertical accuracyGuaranteed assembly qualityForms/shuttering/falseworksCaissonsSteel barBuilding construction

The invention discloses a sliding formwork component. The sliding formwork component comprises a sliding way, an outer template, an inner template, two side templates and a plurality of connecting fixing pieces. The sliding way is provided with a plurality of sliding grooves for installation of the outer template and the inner template. A plurality of outer stand bars are arranged at the bottom ofthe outer template. The outer stand bars are arranged on the outer side of the sliding way and can be installed and move along the sliding grooves. A plurality of inner stand bars are arranged at thebottom of the inner template. The inner stand bars are arranged on the inner side of the sliding way and can be installed and move along the sliding grooves. The side templates are arranged on the two side edges of the inner template and the two side edges of the outer template and are connected with the inner template and the outer template through the connecting fixing pieces. The invention further discloses an open caisson blade foot layer sliding formwork construction method. The method comprises the steps of field leveling, sliding way installing, steel bar bundling, template installing,concrete pouring, side template dismounting, template sliding and the like. According to the sliding formwork component and the method, the linear vertical perpendicularity after blade foot construction is finished can be ensured, and accordingly the assembling quality of upper-layer open caisson standard segments is guaranteed.

Owner:中铁科建有限公司

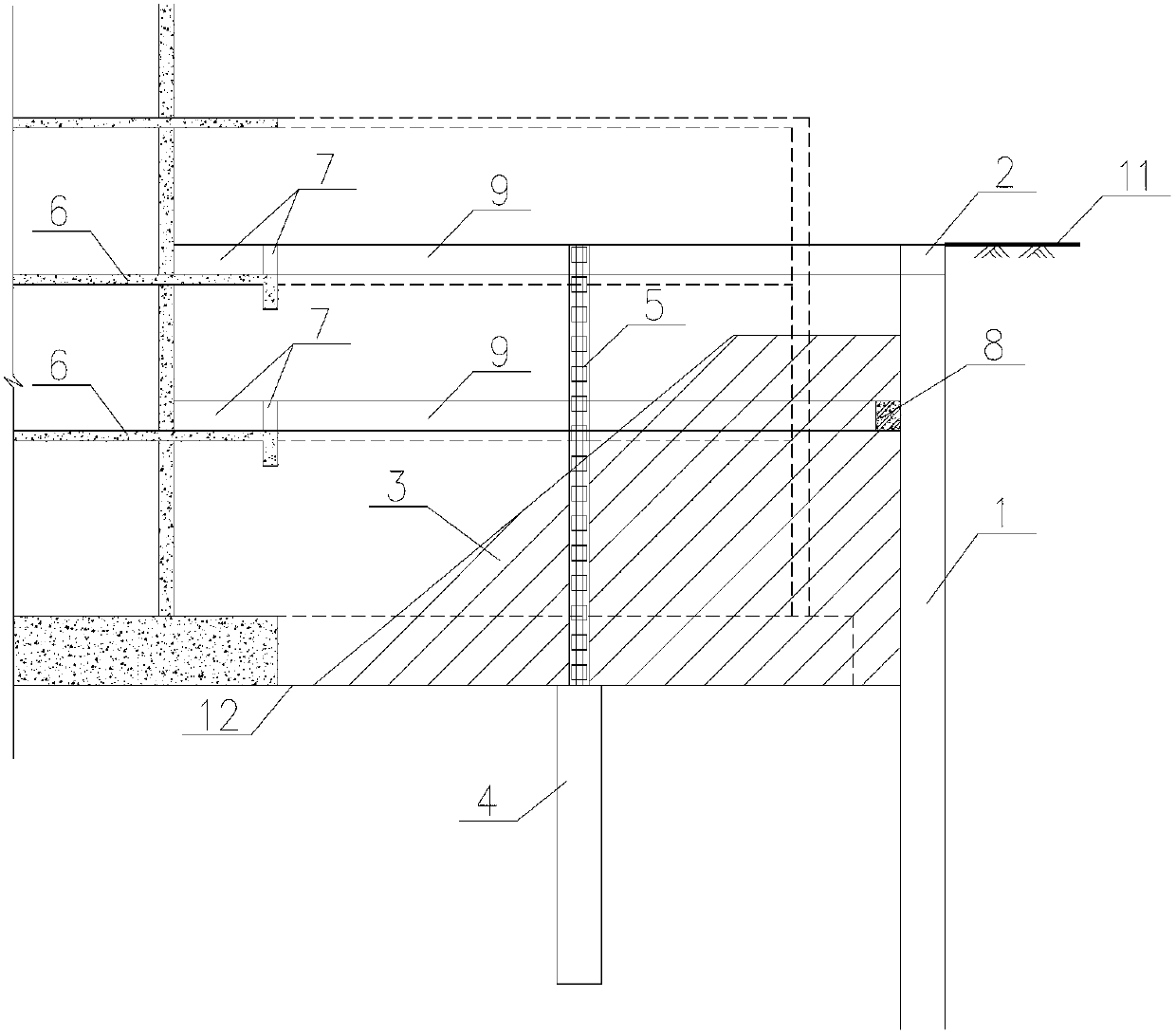

Cast-in-place section concrete construction method of assembling-type concrete structure

ActiveCN103422674AHigh lateral compressive strengthAvoid crackingBuilding material handlingStructural engineeringUltimate tensile strength

The invention relates to construction methods of assembling-type concrete structures, in particular to a cast-in-place section concrete construction method of an assembling-type concrete structure. The cast-in-place section concrete construction method comprises the steps that when an outer wall body is prefabricated, embedded parts and steel bar meshes are buried and additionally arranged inside an outer wall protective layer of a cast-in-place section correspondingly; a cast-in-place section formwork is connected to the inner side of a wall body structural layer through mutual-pulling screws and buckling pieces, wherein one end of each mutual-pulling screw is connected with a sleeve and the other end of each mutual-pulling screw penetrates out through a reserved hole in the cast-in-place section formwork, and the mutual-pulling screws are sleeved with PVC casing pipes. Cast-in-place section concrete is poured in grouting holes reserved inside the wall body structural layer. After the cast-in-place concrete reaches designed strength, the buckling pieces can be loosened, the cast-in-place section formwork can be disassembled, the mutual-pulling screws are rotated to enable the mutual-pulling screws to be separated from the sleeves, and then the mutual-pulling screws are drawn out from the PVC casing pipes. The cast-in-place section concrete construction method of the assembling-type concrete structure solves the problems that the surface of a warm-keeping protection layer cracks and deforms due to the through-wall screws and water seepage occurs in an outer wall, reduces the workload of outer wall face repairmen, and improves the pouring efficiency of the cast-in-place section concrete.

Owner:CHINA 22MCC GROUP CORP

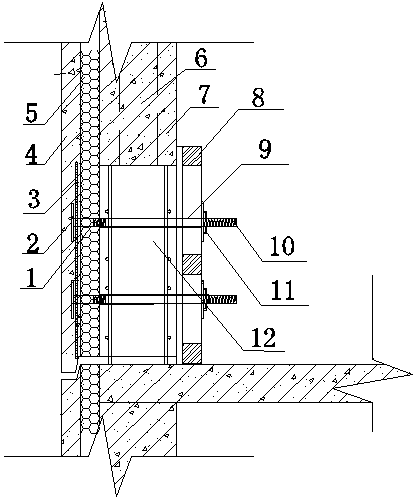

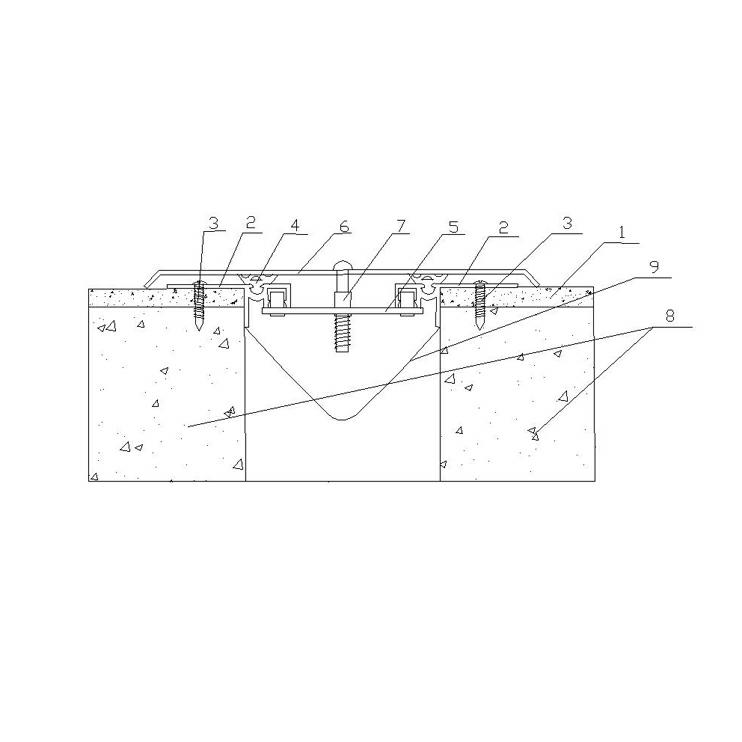

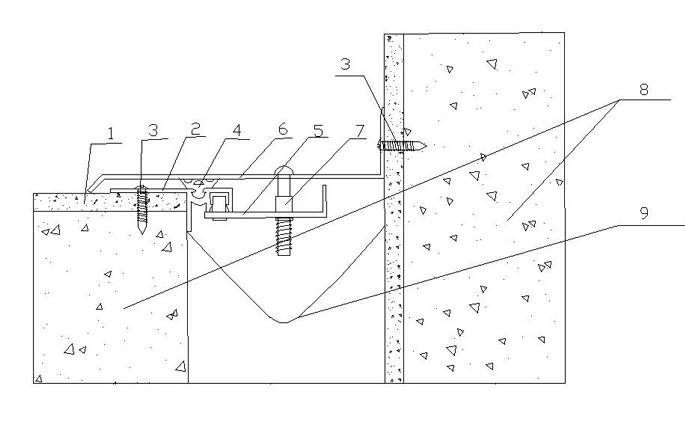

Expansion joint-adjustable dual-waterproof installation construction process

ActiveCN102140848AHigh practical valueNeat appearanceBuilding material handlingArchitectural engineeringExpansion joint

The invention discloses an expansion joint-adjustable dual-waterproof installation construction process, comprising the following process steps of: plastering wall surfaces positioned on the expansion joint; carrying out construction measurement on both sides of the expansion joint; adhering waterstops; installing and fixing an aluminum alloy base; sizing the edges of the aluminum alloy base; embedding rubber strips; assembling and fixing a slide rod and a cover plate; processing the expansion joint, and cleaning an exterior. The invention has the advantages of firm installation, dual waterproofing, large expansion amount and elegant appearance without the raised margins of the cover plate.

Owner:CHINA ZHONGSHE CONSTR ENG GROUP

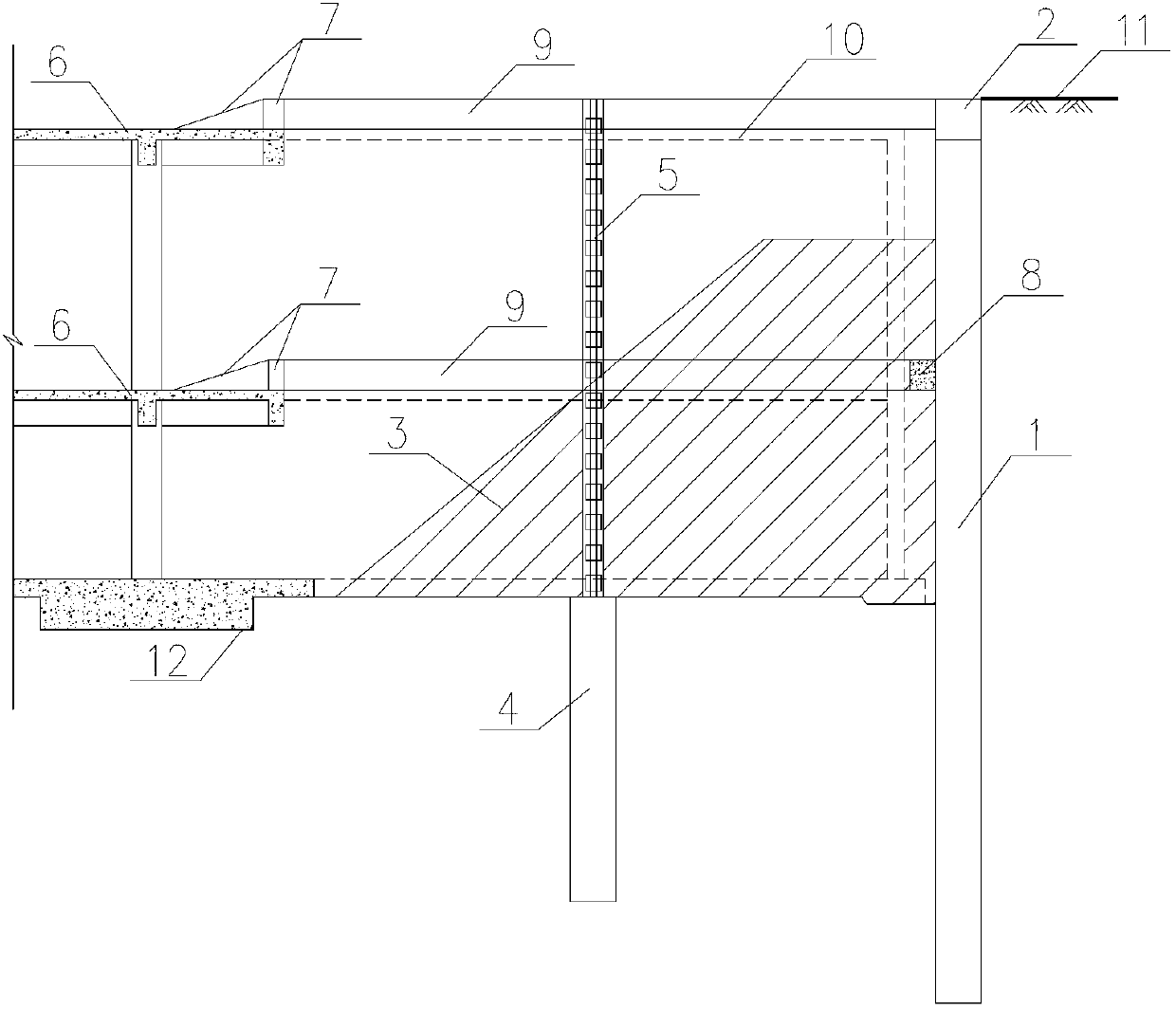

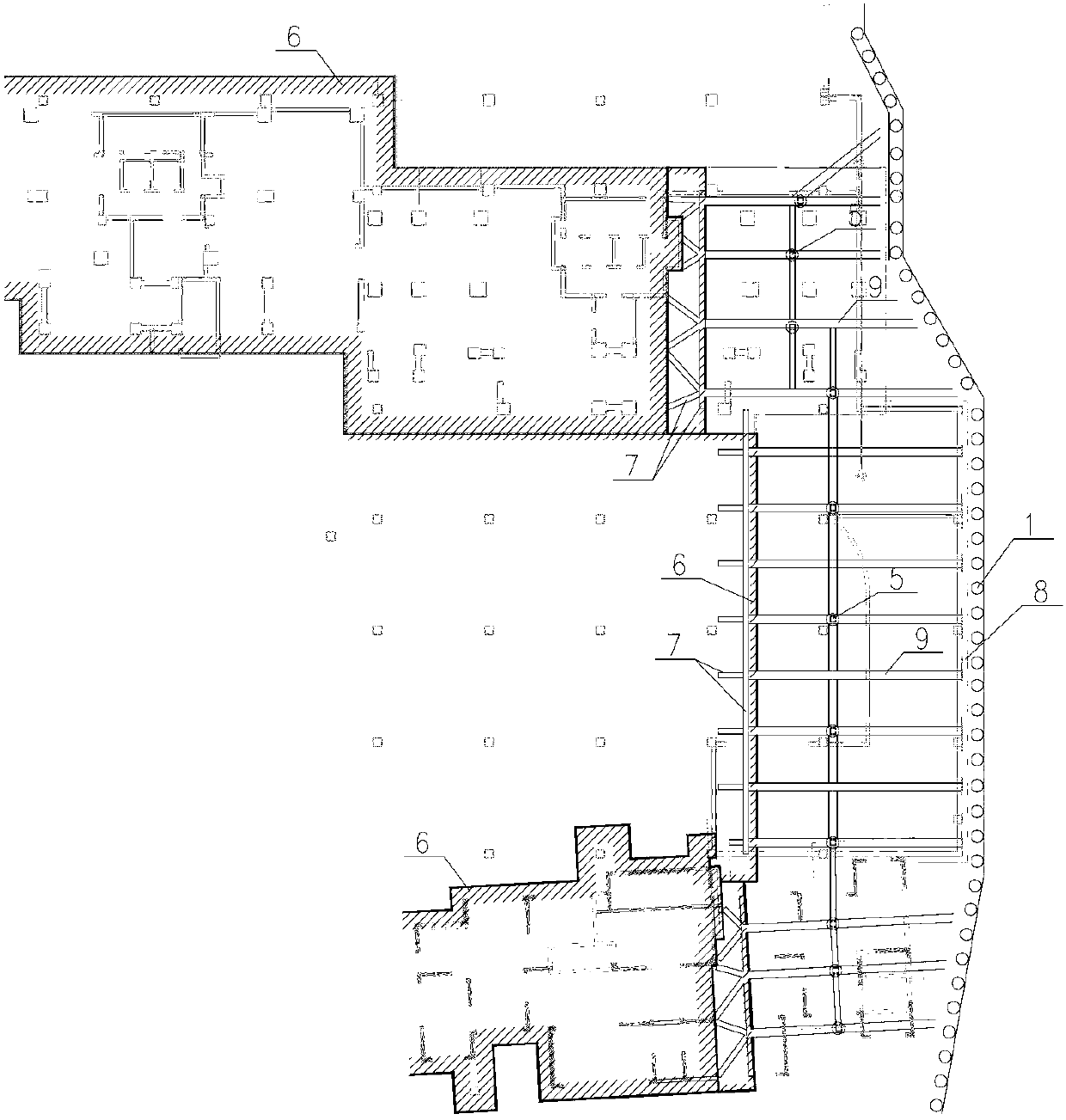

Foundation ditch construction method of horizontal bracing structure of central island floor slaps

InactiveCN103103988AControl deformationIncrease horizontal stiffnessExcavationsFloor slabStructural engineering

The invention discloses a foundation ditch construction method of a horizontal structure of central island floor slaps. The method comprises the following steps: constructing an envelope enclosure on the side wall of the foundation ditch; excavating the earthwork of the middle portion of the foundation ditch to the bottom and naturally carrying out the construction to plus-minus zero to form the central island structure; leaving a soil slope on the foundation ditch except for the central island structure; arranging supporting seats and the horizontal supporting structures on the edges of the floor slaps of the plus-minus zero layer from the floor slaps of the central island to floor slaps of the foundation ditch bottom layer in sequence, and fixing one end of the horizontal supporting structure on each supporting seat and fixing the other end of the horizontal supporting structure on the envelope enclosure structure and evacuating the soil slope which is under the horizontal supporting structure arranged by the floor slaps of the layer to the bottom elevation of the horizontal supporting structure of the next layer of floor slaps; and constructing naturally the surrounding areas to the plus-minus zero. The foundation ditch construction method of the horizontal bracing structure of central island floor slaps has the advantages that the central island floor slaps are used for adding horizontal supportings to the surrounding envelope enclosure structures. Compared with the existing steel inclined sturts which are used frequently, horizontal stiffness is improved, supporting atress is more clear, the deformation of the foundation ditch can be better controlled and safety is increased.

Owner:ANHUI URBAN CONSTR DESIGN & RES INST

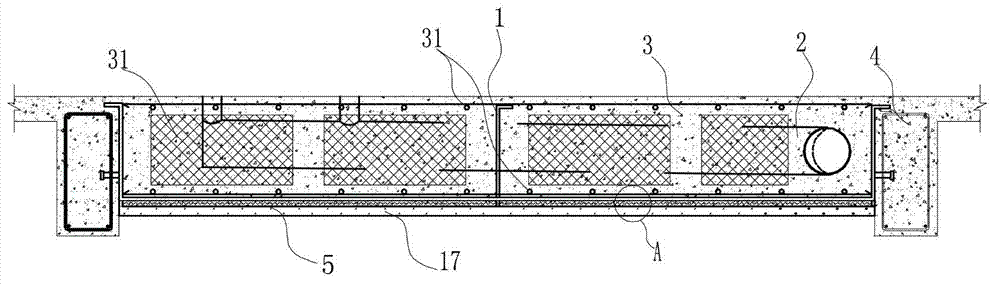

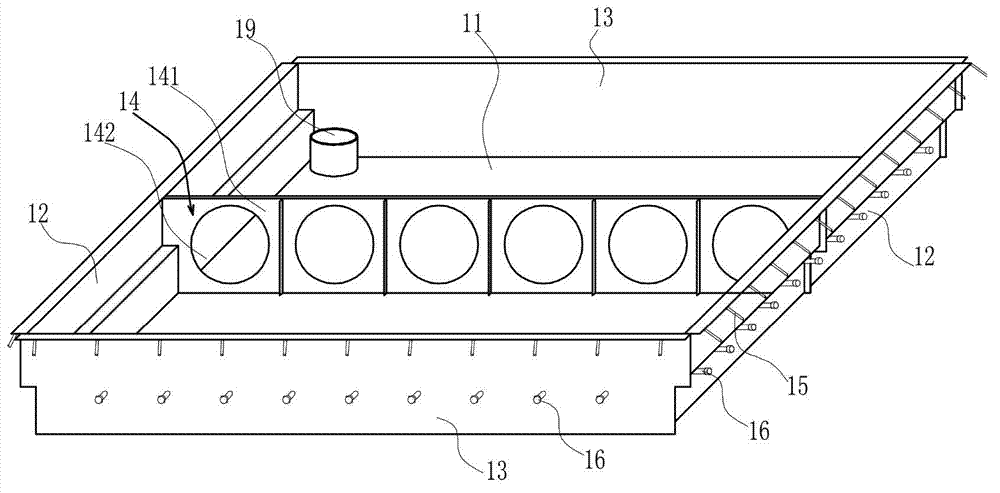

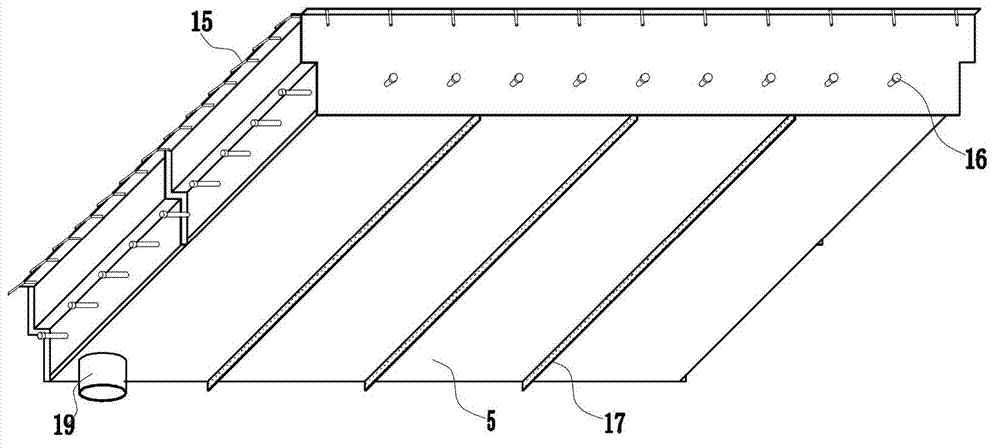

Fireproof power cable trench

PendingCN108695807ARealize the effect of self-extinguishing fireAvoid secondary failureCable installations on groundFire rescuePower cableElectric cables

The invention belongs to the technical field of power facilities and particularly relates to a fireproof power cable trench. The fireproof power cable trench comprises multiple trench bodies; each trench body comprises a bottom plate, side baffles and a cover plate; one accommodating cavity and multiple discharge ports are arranged in the side baffles and on the cover plate; the discharge ports are located at the inner side of the cable trench; the accommodating cavity and the multiple discharge ports are communicated; the accommodating cavity is internally provided with a fireproof material;and the discharge port is provided with a plugging mechanism. Through improving the structure of the trench body, the accommodating cavity with the fireproof material is arranged in the side baffles and the cover plate, self extinguishing is carried out while waiting for rescue, and secondary fault of a power device is avoided.

Owner:国网河南省电力公司桐柏县供电公司

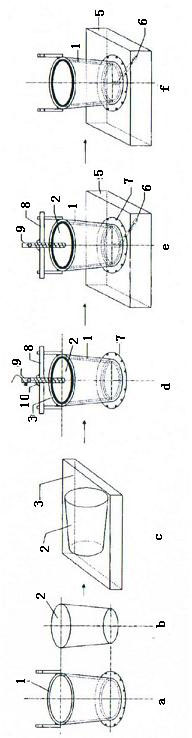

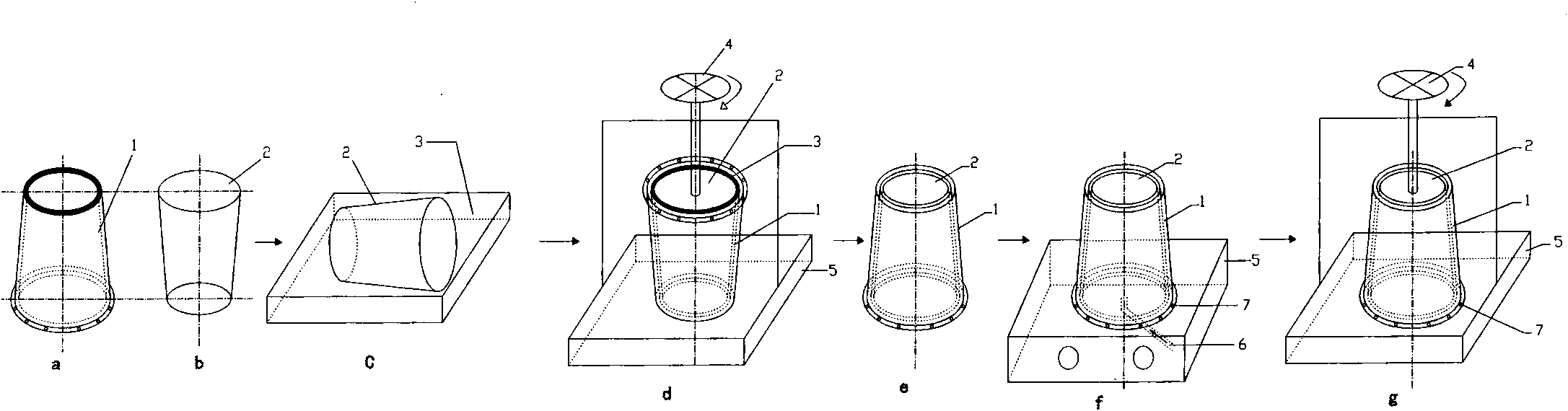

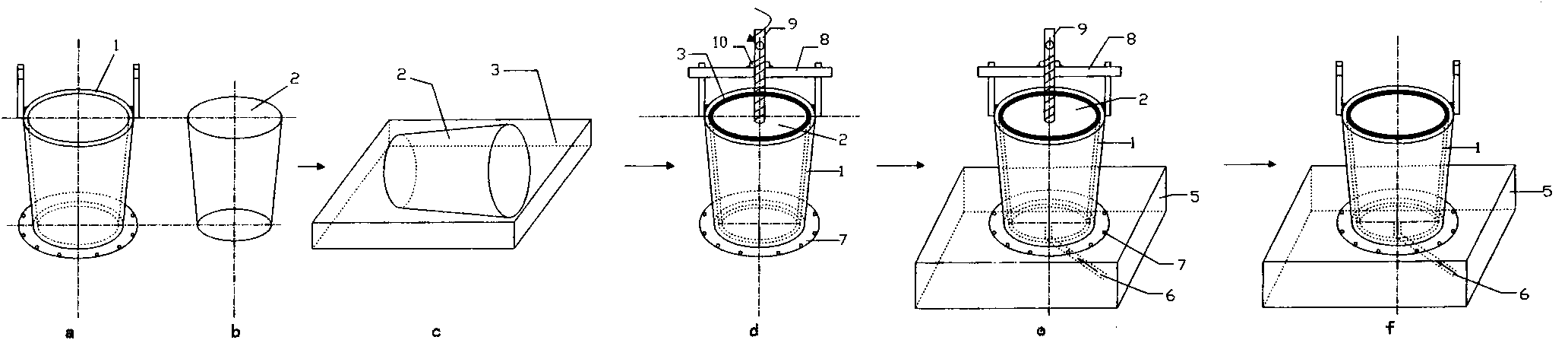

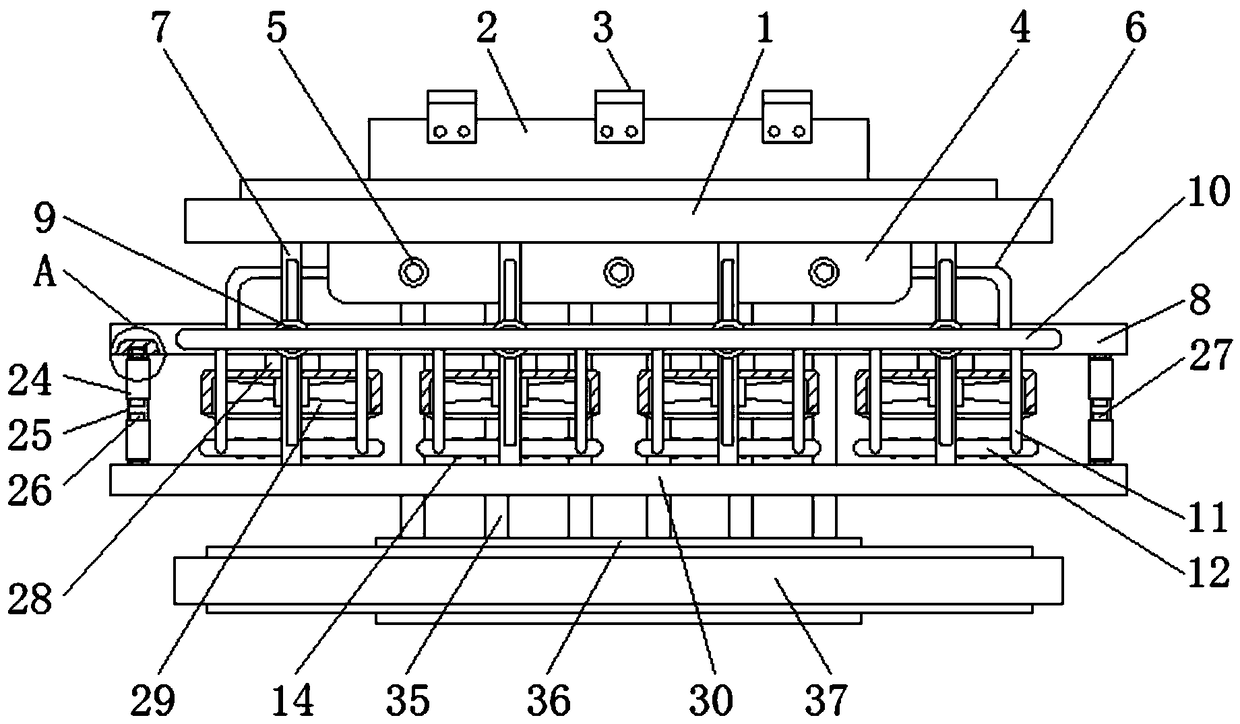

Method for testing permeability resistance of concrete

ActiveCN102608014AEasy to assemble and disassembleGood sealing effectPreparing sample for investigationPermeability/surface area analysisWaxWrench

The invention relates to a method for testing the permeability resistance of concrete, and belongs to the field of tests. The method is characterized by comprising the following steps of: a, heating a test mold for concrete permeability resistance test to 65-70 DEG C in an oven; b, carrying out roll coating of hot wax on the periphery of a test block; c, quickly putting the wax coated test block into the test mold, wherein the diameter of the top of the test mold is greater than that of the bottom of the test mold; d, tightening an ejection device to press the test block into the test mold, and implementing wax sealing between the test block and the test mold; e, fixing the test mold filled with the test block on a tester platform by using bolts; f, opening a pressure water valve to pressurize the test block, and performing permeability resistance test; g, keeping the water pressure unchangeable after the test is completed, loosening screw caps of the ejection device by using a spanner, and extruding the test block out from the test mold by virtue of pressure water; and h, closing the pressure water valve, detaching the fixing bolts between the test mold and the tester platform, taking the test mold out, and thus completing the test.

Owner:INSTALLATION BRANCH WEIHAI CONSTR GRP CO LTD +1

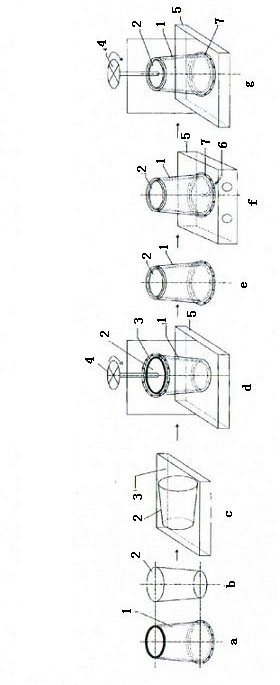

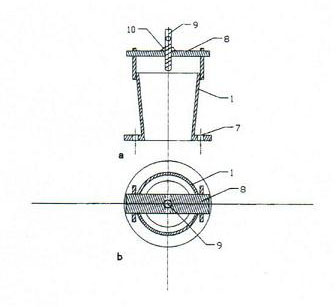

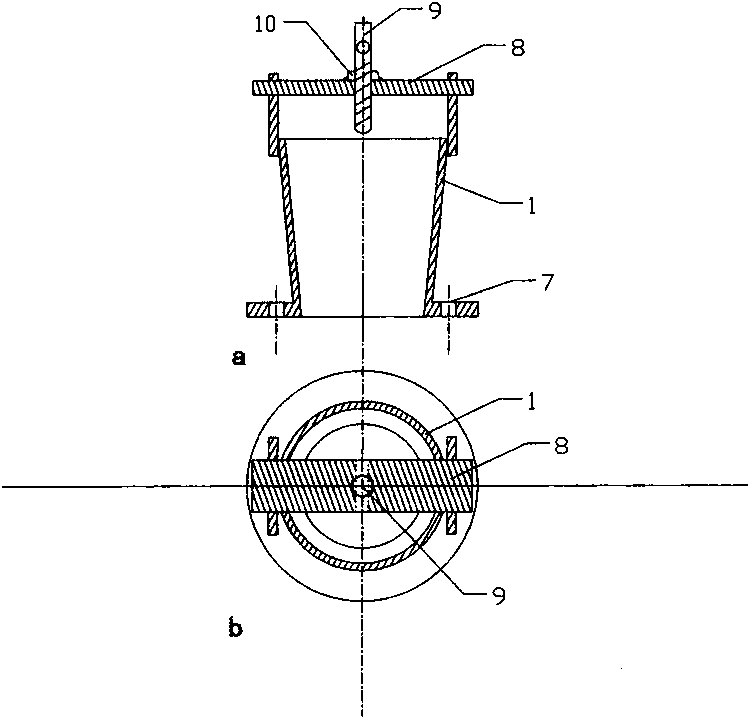

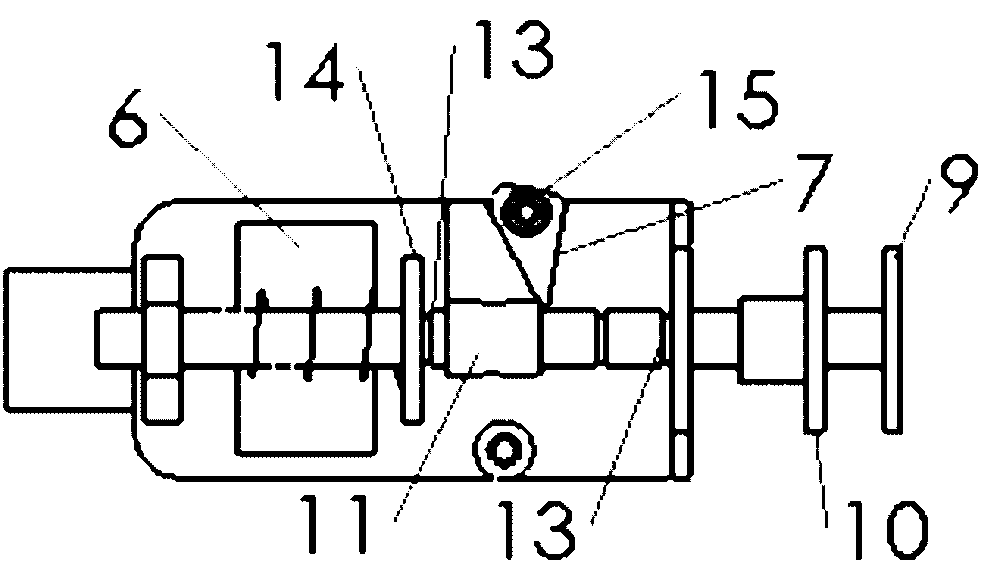

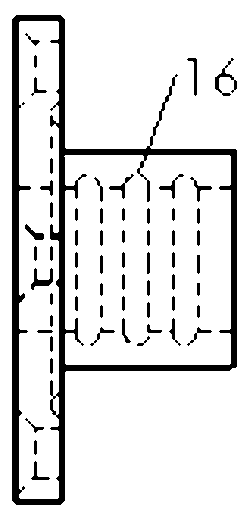

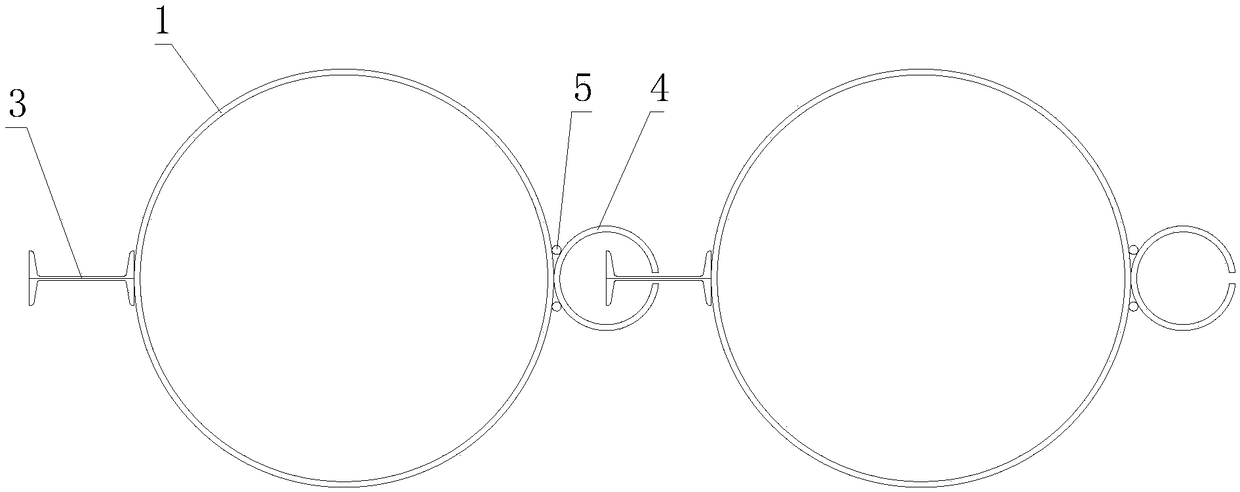

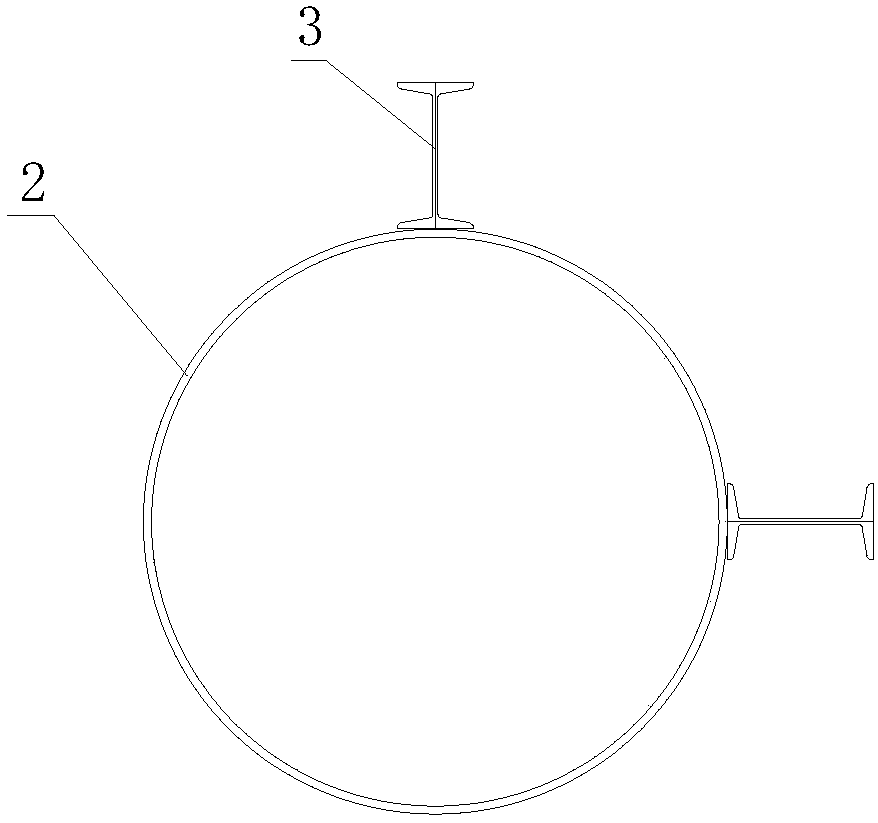

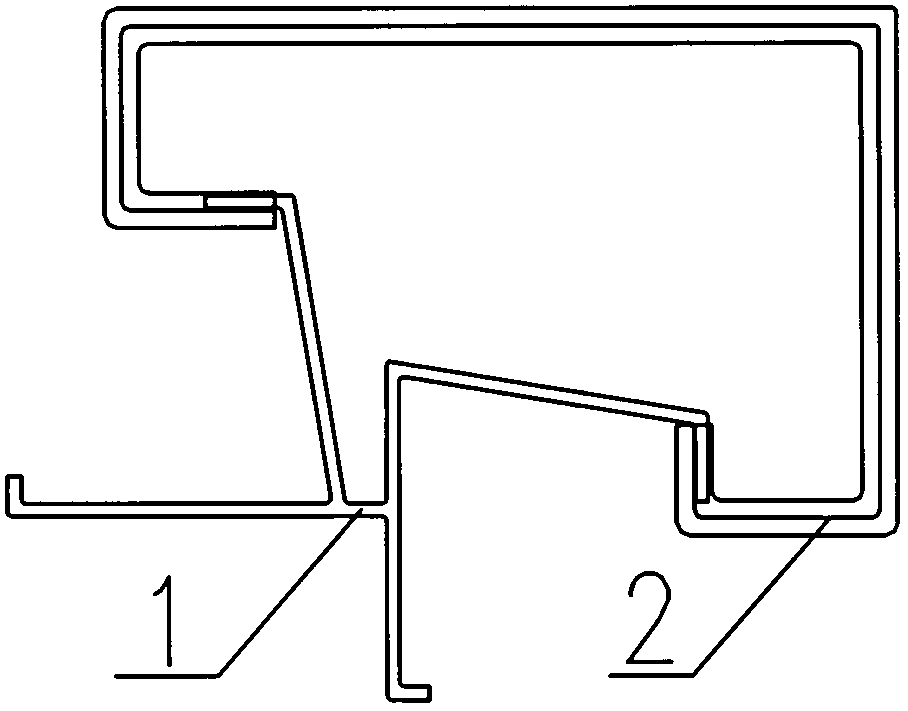

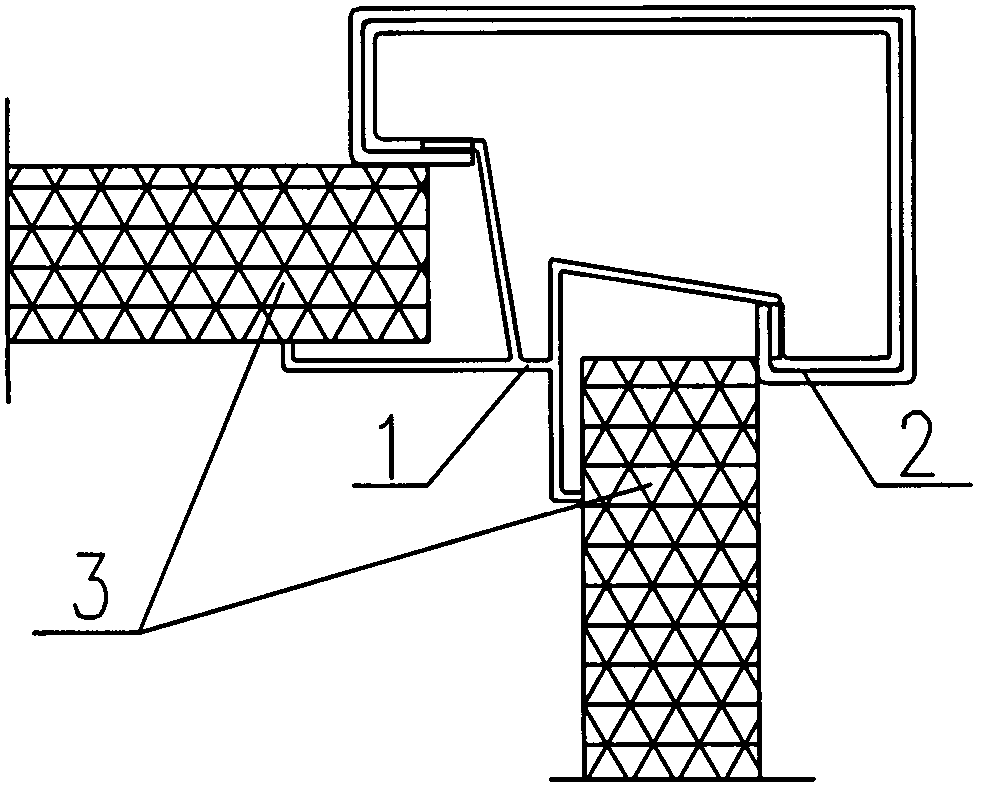

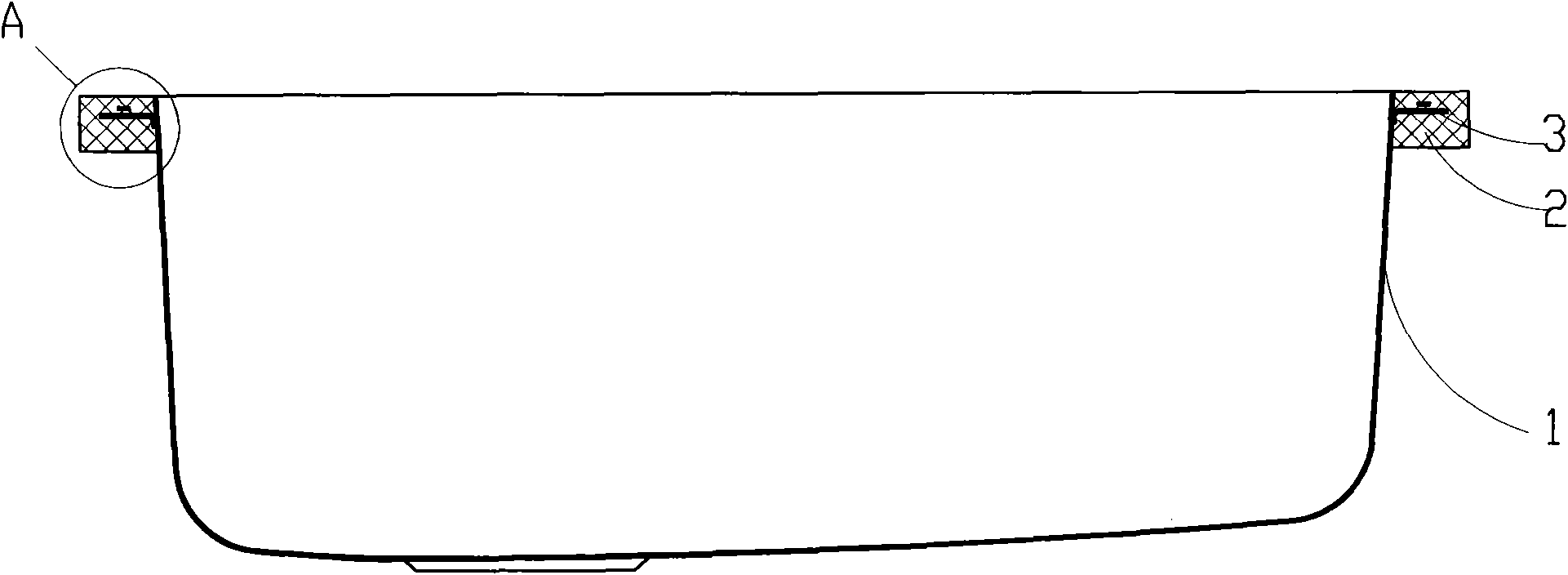

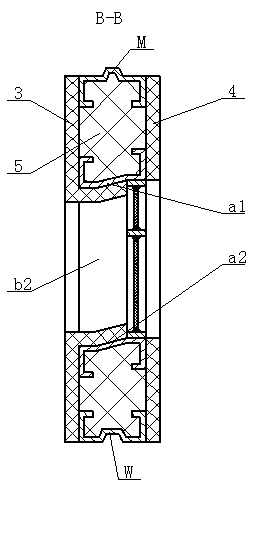

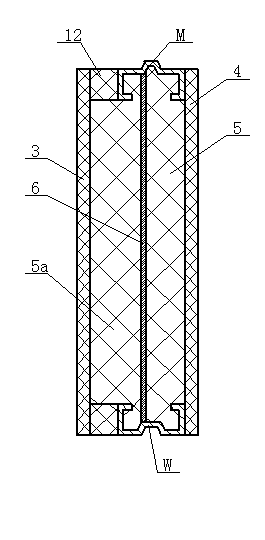

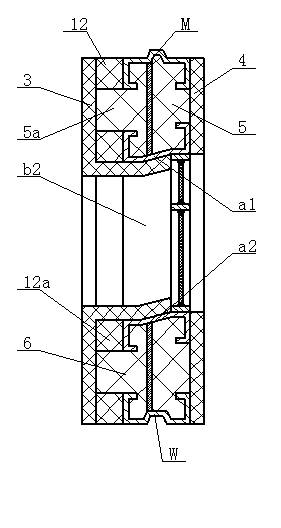

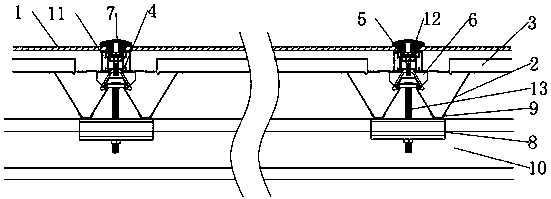

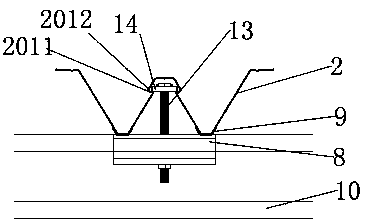

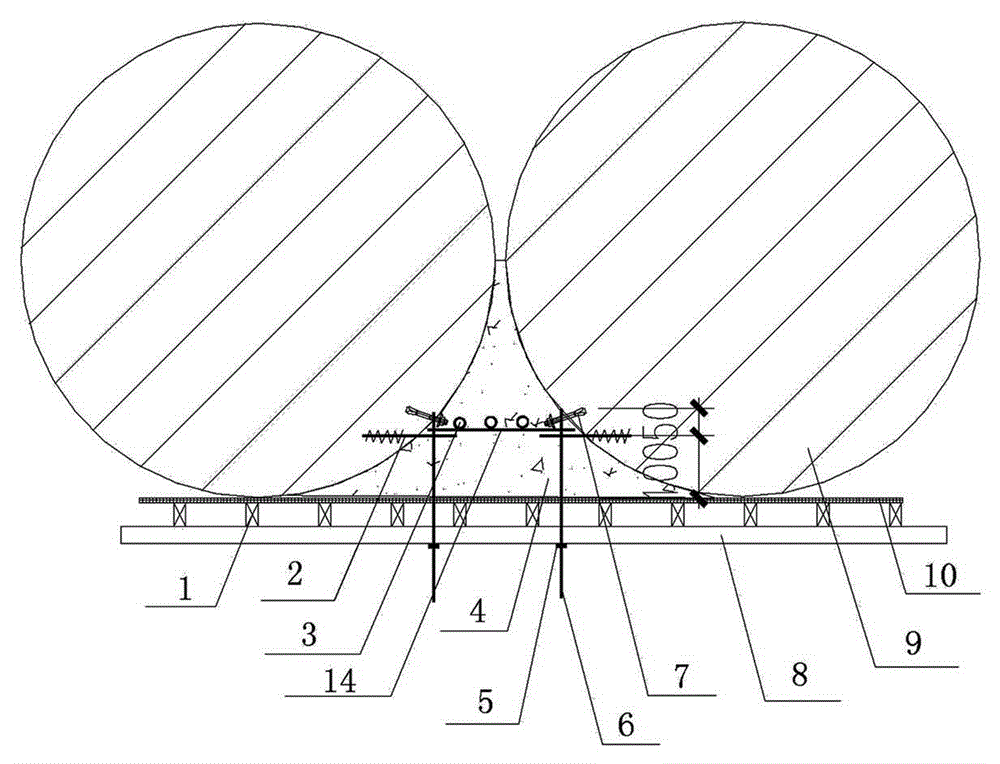

Test die for concrete impermeability test

InactiveCN102042946AEasy to take outSolve the damagePreparing sample for investigationPermeability/surface area analysisWaxEngineering

The invention discloses a test die for a concrete impermeability test, which has certain improvements on the conventional test die for the concrete impermeability test. Referring to a detailed drawing 1, permanent screw-down pressing devices (8, 9 and 10) are arranged on an original test die; for the improved test die, the operations of dismounting the pressing devices, reversely placing the pressing devices on a tester platform and the like are not needed after finishing the wax-sealing between a test block and the test die, but, the pressing devices are not dismounted and the test die is not placed reversely, and the pressing devices are directly placed and fixed on the tester platform to perform a test after screwing down the test block and pressing the test block against the test die, thereby overcoming the influence on the accuracy of the test result due to the water seepage which is caused by wax-sealing cracking between the test block and the test die because of the operations of dismounting a pressure device, cooling the test die, placing the test die reversely and the like. So the improved test die provides a forceful guarantee for the accuracy of the concrete impermeability test result and convenient operation, and obtains a very good effect in application.

Owner:INSTALLATION BRANCH WEIHAI CONSTR GRP CO LTD +1

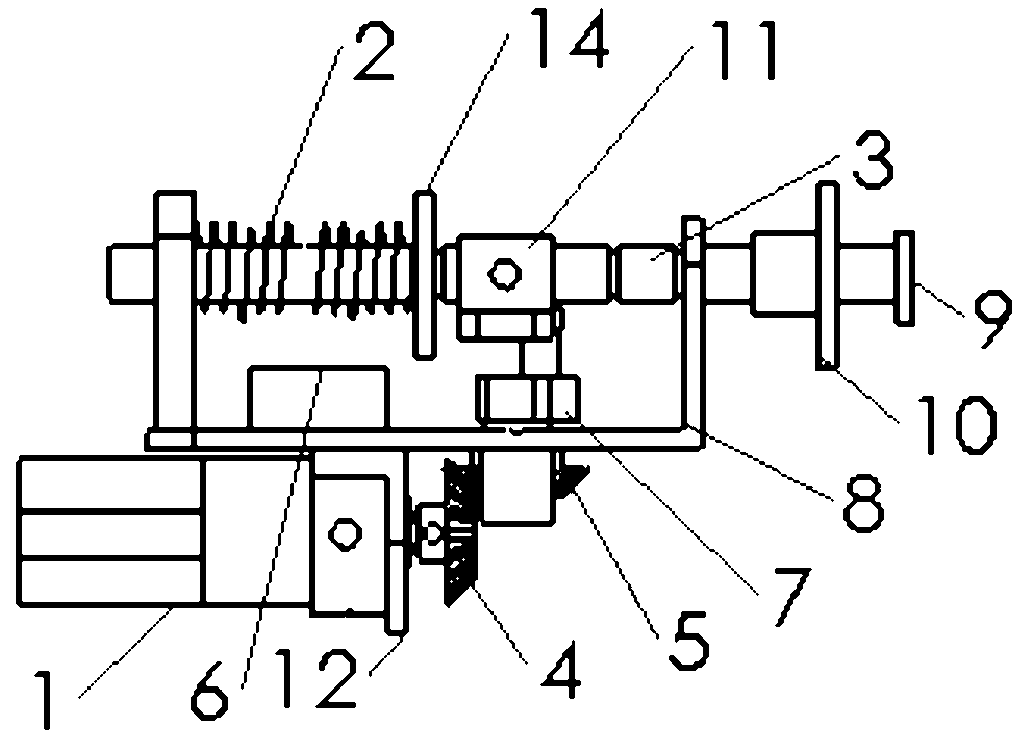

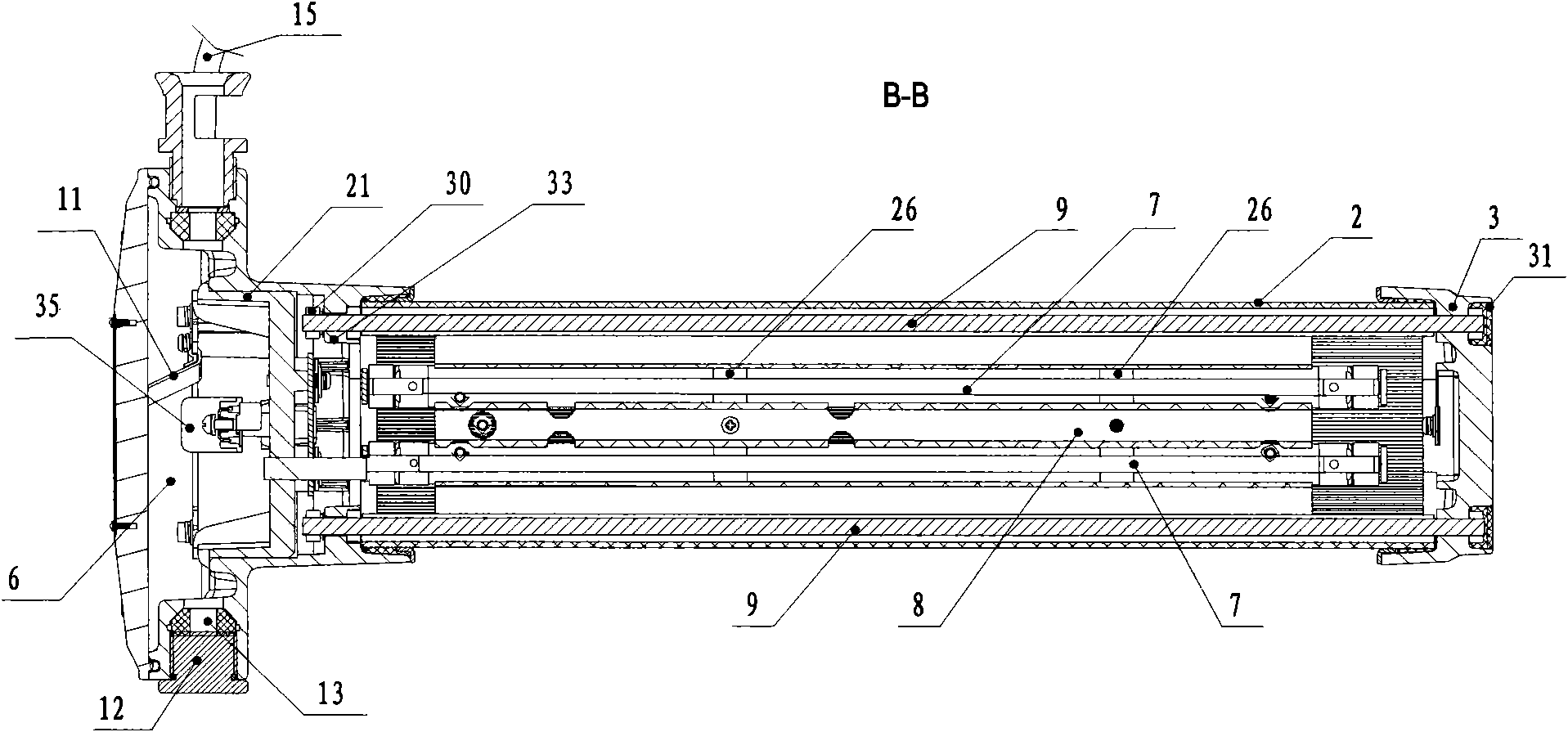

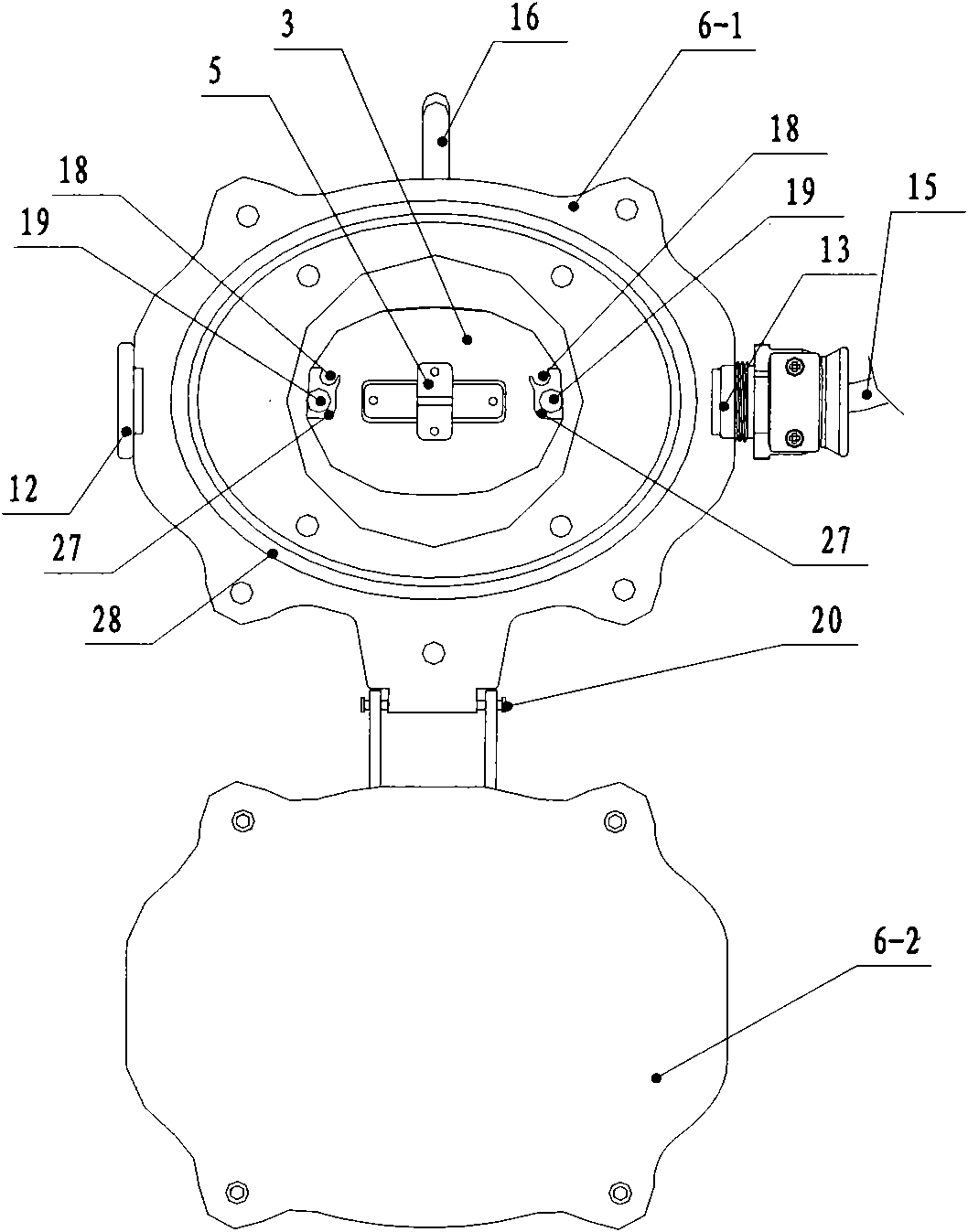

Crank type underwater robot ejection device

InactiveCN101870350AImprove work efficiencyImprove Delivery AccuracyUnderwater equipmentSpring forceSelf locking

The invention discloses a crank mechanism-based underwater robot ejection device, and belongs to the field of amphibious robot preparation. The device adopts a motor to drive a bevel gear so as to drive a crank mechanism, uses the crank mechanism to compress a spring and releases the compression energy of the spring at a proper position so that a spring force is acted on an object to fulfill the purpose of ejection. The space is effectively utilized by adopting a bevel gear driving mechanism, and the volume of the ejection device is greatly reduced. The device can realize self-locking function and continuous ejection, and can solve practical masks of object carrying, transfer, multi-robot cooperation and the like of a small scale robot. The device is used for ejecting a lightweight object to reach an ideal position, and can be used for reinforcing mutual cooperation among multiple robots. At the same time, the device improves the work efficiency of a machine, saves the energy and improves the object transfer accuracy.

Owner:PEKING UNIV

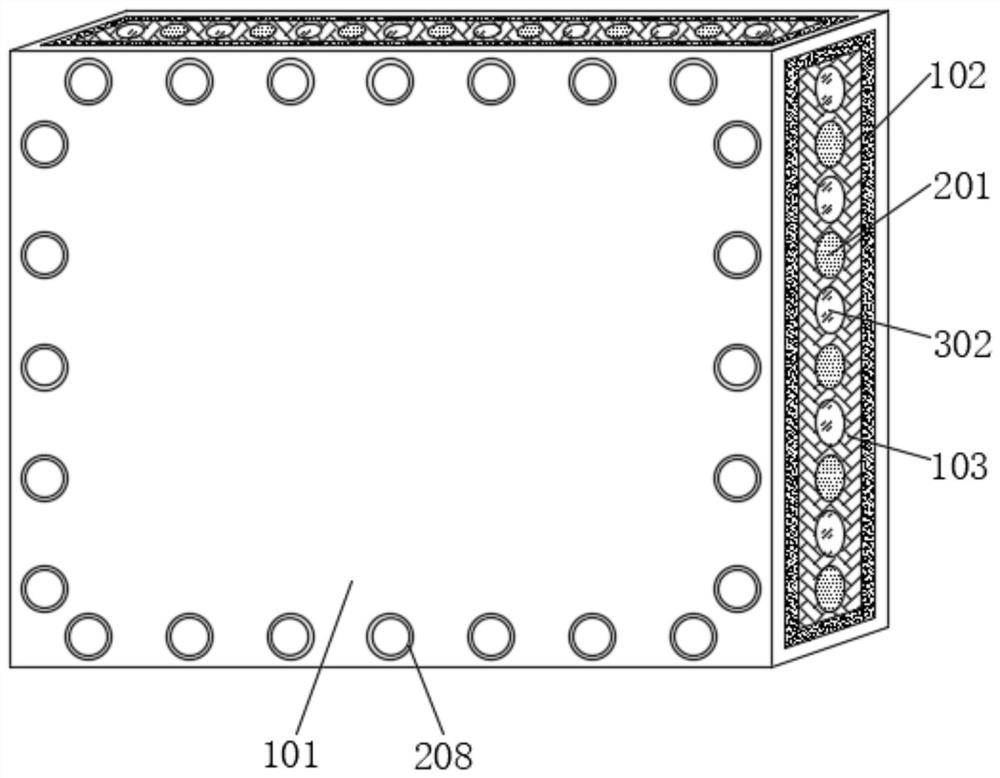

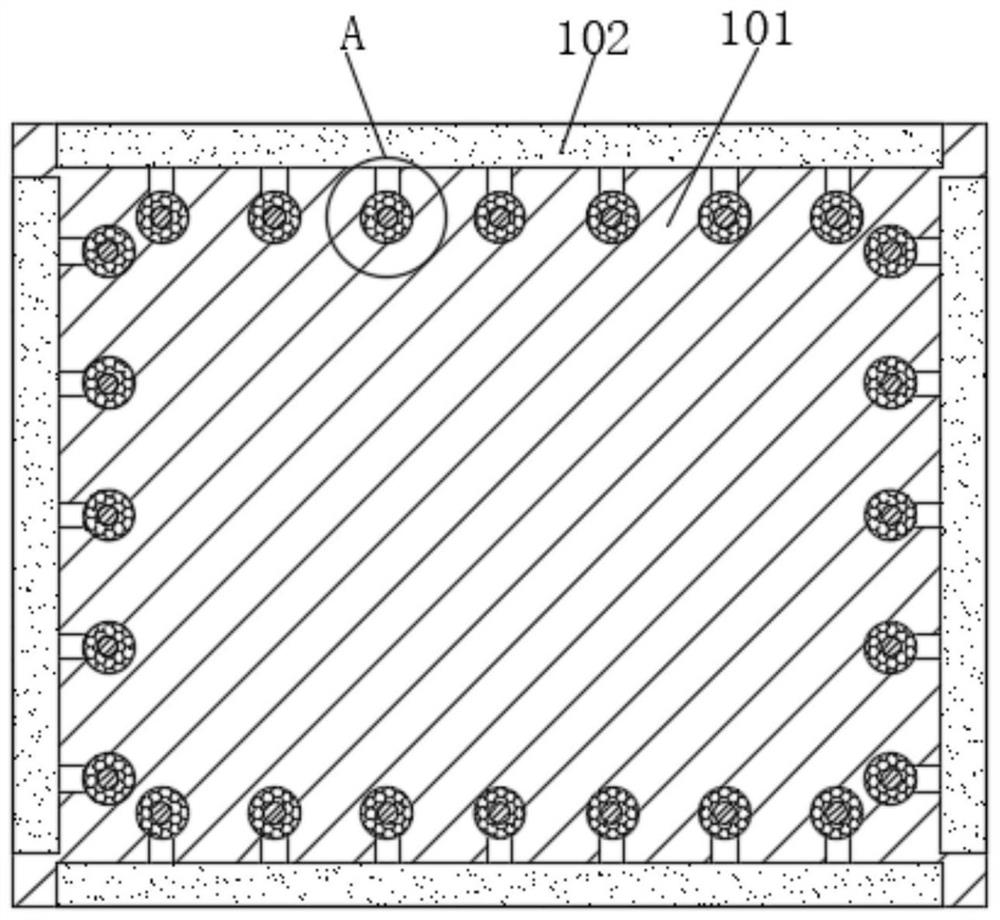

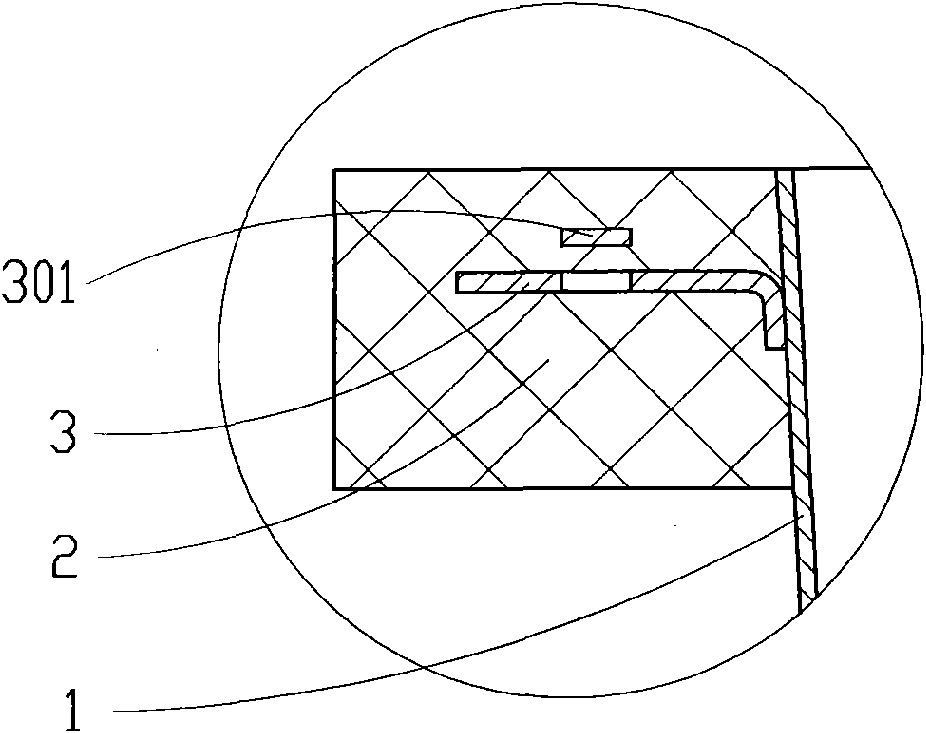

Self-joint-filling water-removing type anti-seepage building outer wall

ActiveCN112064810ASolve the problem of water seepageEffective protectionBuilding repairsBuilding insulationsArchitectural engineeringStructural engineering

The invention discloses a self-joint-filling water-removing type anti-seepage building outer wall, and belongs to the technical field of outer wall seepage prevention. The self-joint-filling water-removing type anti-seepage building outer wall comprises an outer wall body, wherein waterproof groove-shaped frames are mounted on the upper side wall face, the lower side wall face, the left side wallface and the right side wall face of the outer wall body in an inlaid mode correspondingly, and each waterproof groove-shaped frame is filled with a matched reinforcing filling block. Aiming at the problem that water seepage is prone to occurring at the connecting positions of the four side wall faces of the outer wall, specially-made water removing assemblies are arranged at the four side wall faces of the outer wall, when water seepage occurs at the connecting positions of the side wall faces, the water removing assemblies can absorb and evaporate the seeped water to remove the seeped water,thus the seeped water is prevented from seeping to the inner wall face, and the inner wall face is effectively protected; and meanwhile, a self-joint-filling assembly is further arranged, when waterseepage occurs, the self-joint-filling assembly can be automatically triggered to fill a gap, the problem that water seepage is prone to occurring at the connecting positions of the side wall faces ofthe outer wall is fundamentally solved, and the phenomenon that the water seeping to the inner wall face is connected to the side wall faces is completely eradicated.

Owner:深圳市卓航装饰工程有限公司

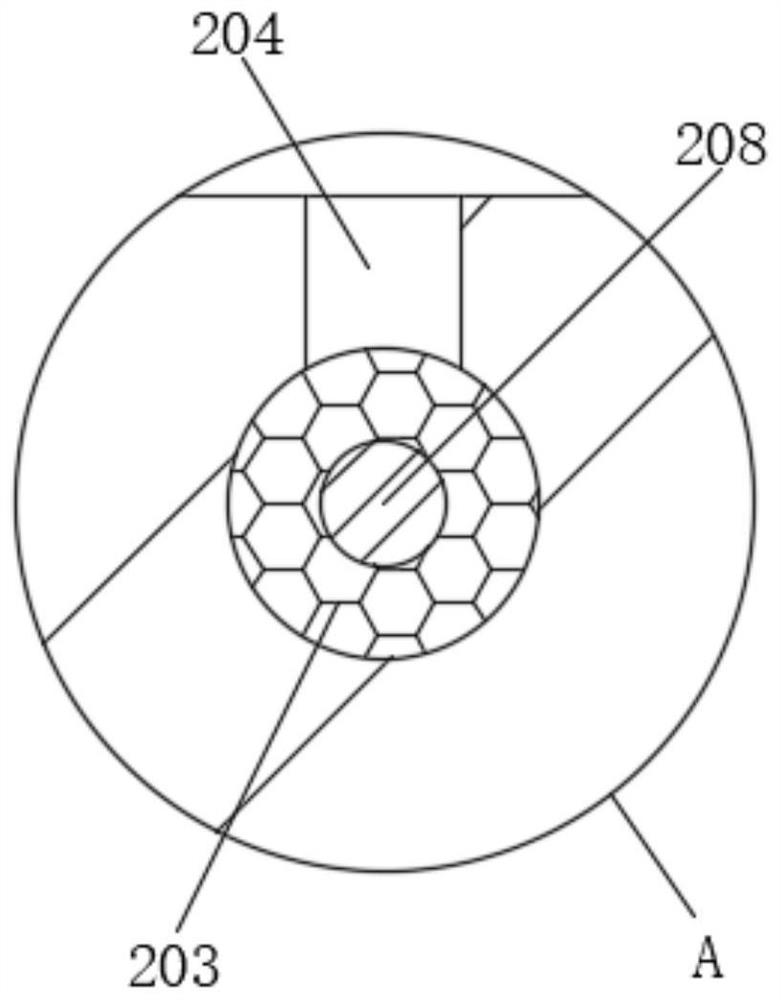

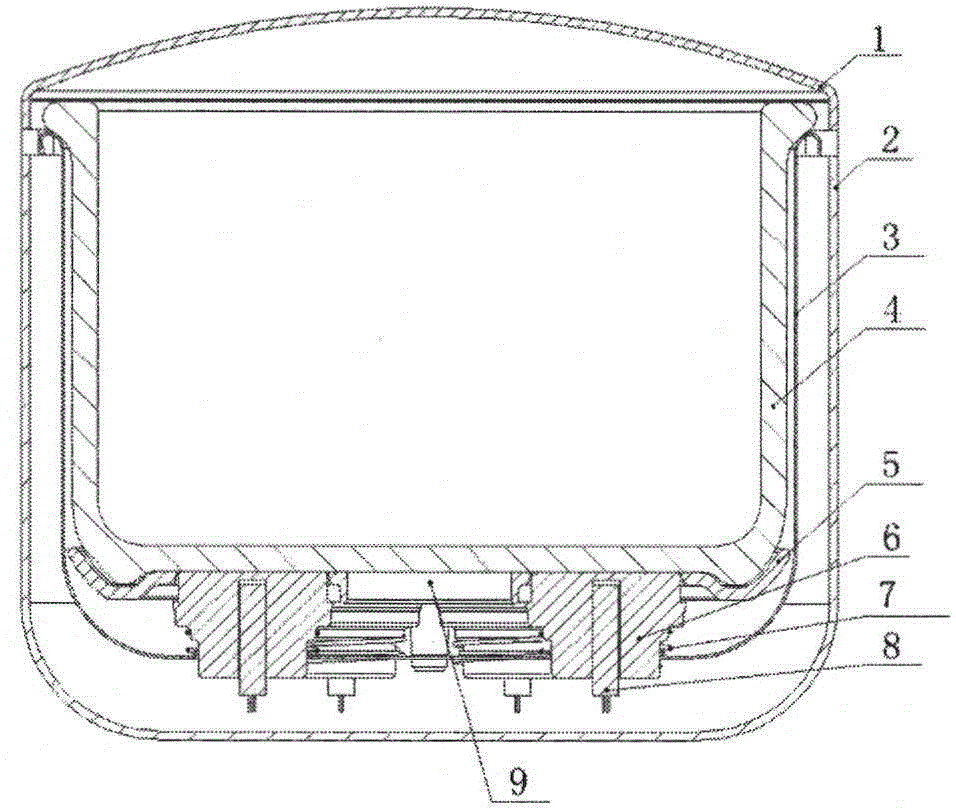

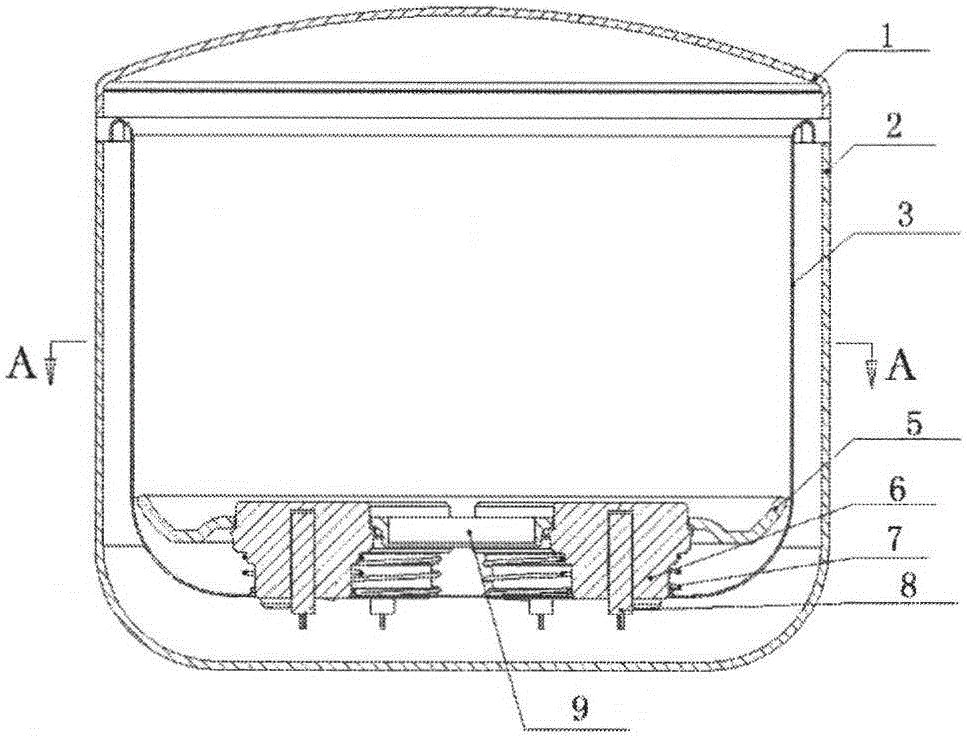

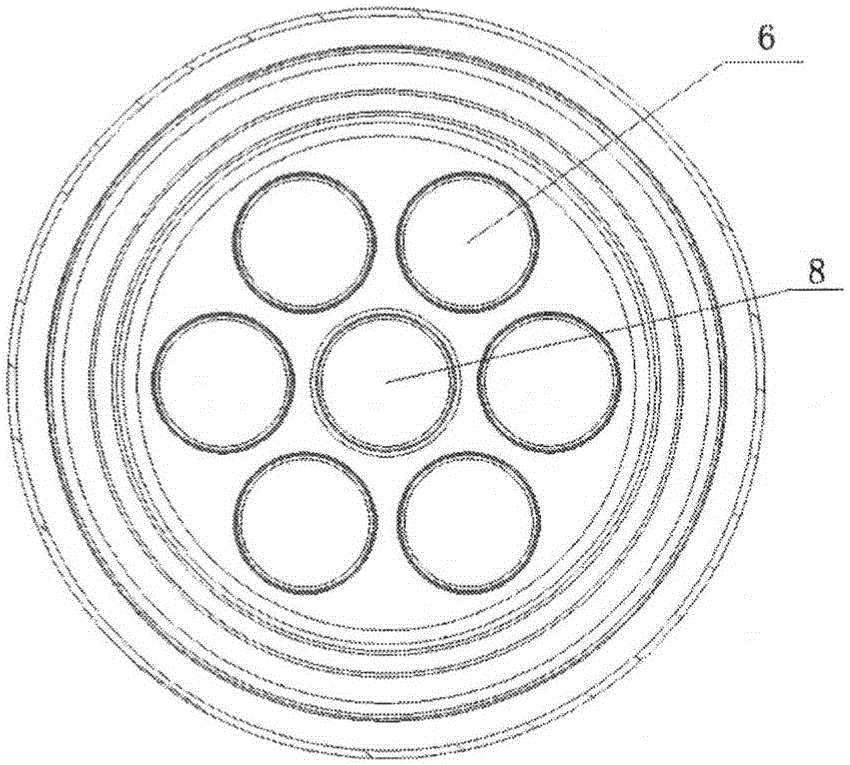

Electric cooker with multi-point floating type heating disc and heating method of electric cooker

PendingCN105030045AHeating evenlyImprove energy efficiencyWarming devicesEngineeringThermal efficiency

The invention discloses an electric cooker with a multi-point floating type heating disc. The electric cooker comprises an outer cover, a pot cover, a heat preservation cover arranged in the outer cover, a ceramic inner pot arranged in the heat preservation cover, a heating assembly arranged between the outer side of the bottom of the ceramic inner pot and the inner side of the bottom of the heat preservation cover, and a central cover. The heating assembly comprises the heating disc and a plurality of electric heating pipes. Floating heating blocks are arranged on the electric heating pipes. Each floating heating block comprises an upper heat transfer section and a lower heat transfer section, wherein a limiting check ring is arranged between the upper heat transfer section and the lower heat transfer section, and the lower heat transfer section is sleeved with a compression spring. A plurality of through holes matched with the upper heat transfer sections are formed in the heating disc. The area of the limiting check rings is larger than the area of the through holes. The bottoms of the compression springs abut against the inner side of the bottom of the heat preservation cover, and the upper ends of the compression springs abut against the limiting check rings. The length of the upper heat transfer sections is larger than the depth of the through holes. The bottoms of the electric heating pipes are exposed out of the heat preservation cover. The electric cooker has the advantages that the ceramic inner pot with the non-wear bottom can be heated more uniformly, heat efficiency is higher, and the structure is simple.

Owner:HANGZHOU YONGYAO TECH

Novel prefabricated concrete hollow slab girder and construction process for building roads and bridges by using same

The invention discloses a novel prestressed concrete hollow slab beam, comprising a hollow cubic body, two heads. Two ends are integrated with the body and steel bar is pre-buried in it. The head is rabbet solid body. The invention also discloses a construction process for roads and bridges adopting said hollow slab beam. Relative temporary supports are set on the top of capping beam or abutment. The hollow slab beam is set on temporary supports. Fixed supports are set on the top of capping beam or abutment; pre-buried steel bars between adjacent heads and in body are connected; the cast-in-case concrete connecting part and integrated padding block for connecting the body and adjacent heads are cast in scene so that padding block is set on the fixed support in horizon. Said procedures are iterated so that the surface of road and bridge is connected by hollow slab beam. Because special designing slab beam and step pouring technology are adopted in the invention, the demand of prior new criterion is satisfied expediently. At the same time integrity and durability of slab beam are strengthened and the period of design and construction is shortened.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD +1

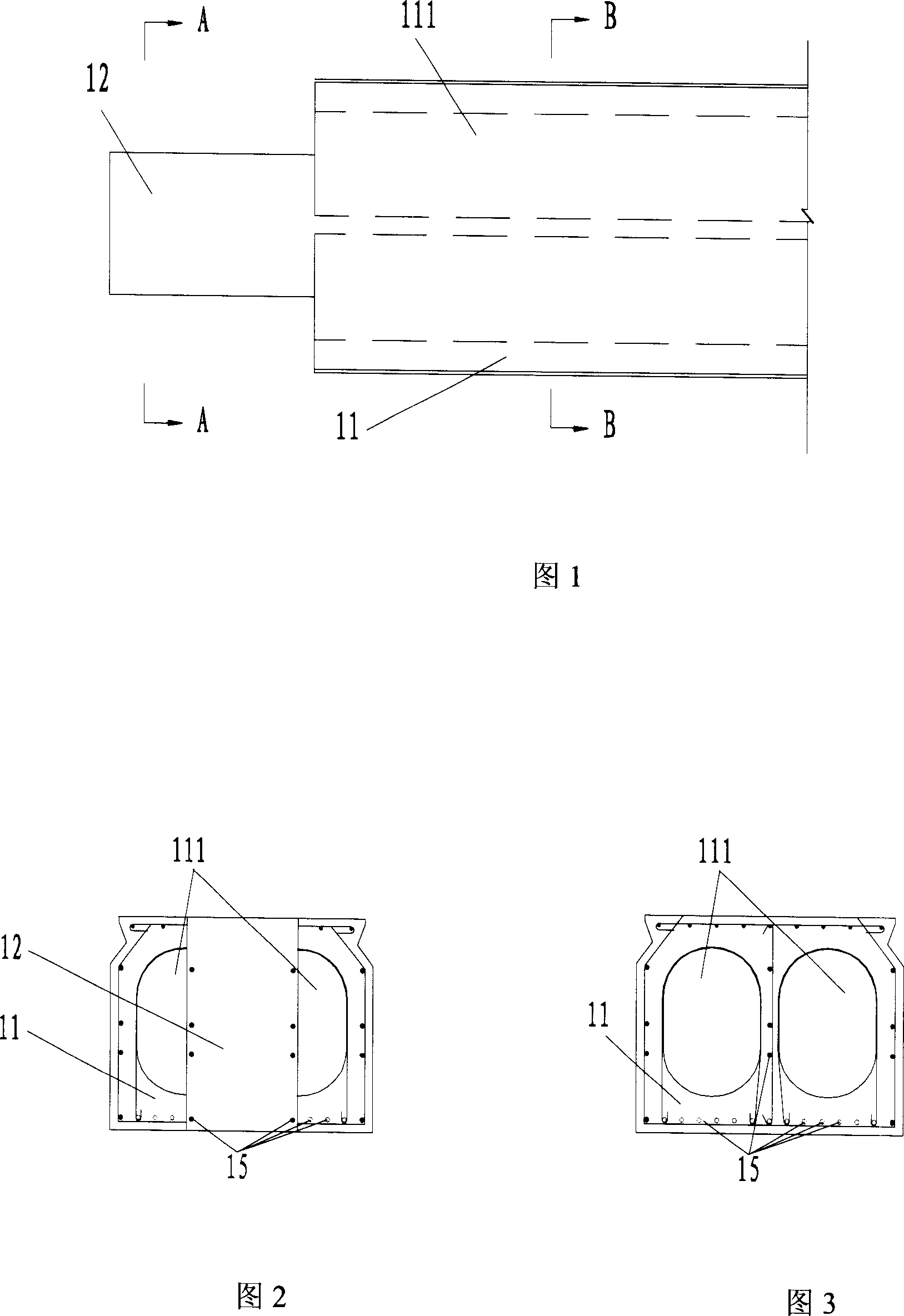

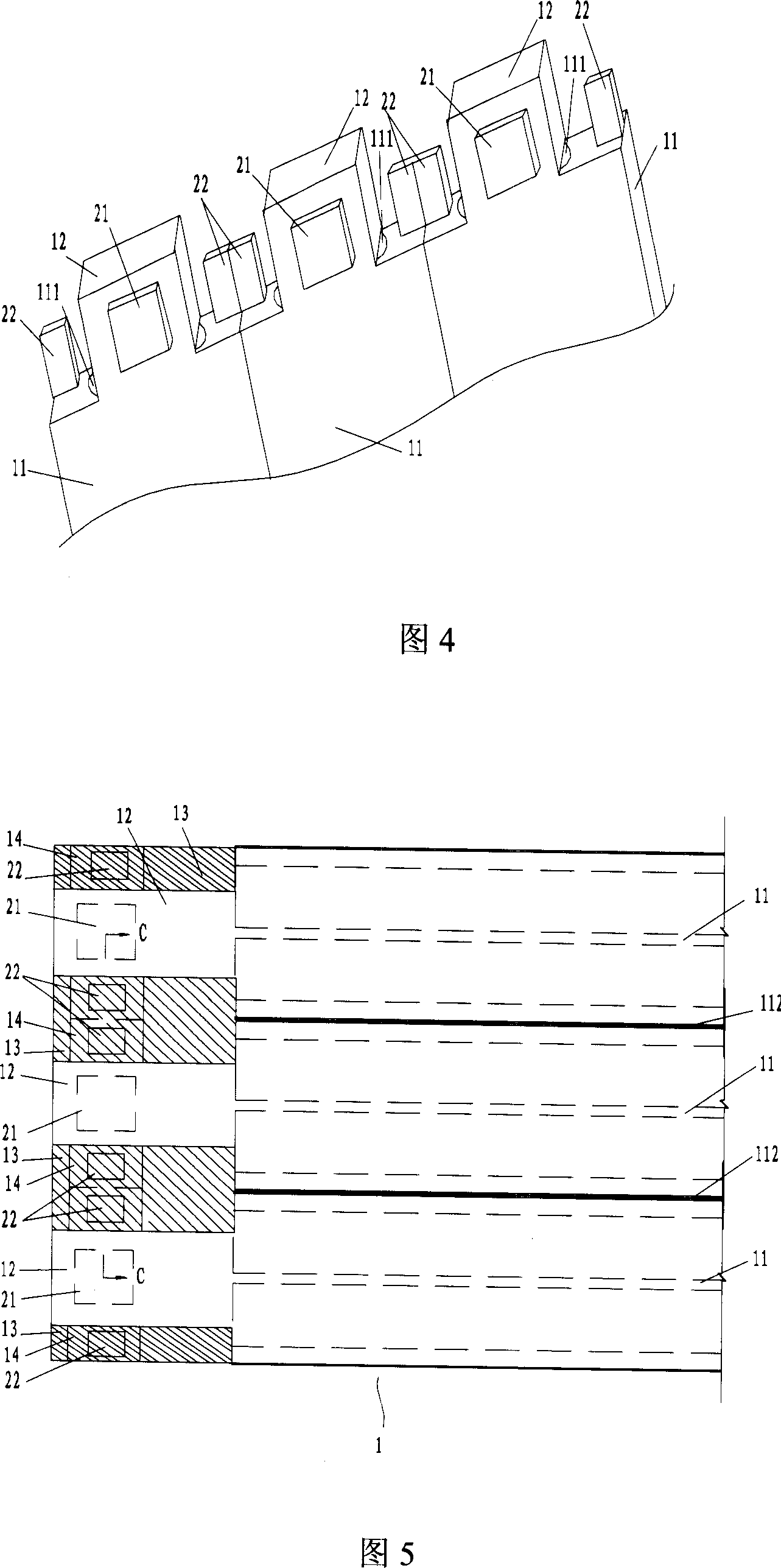

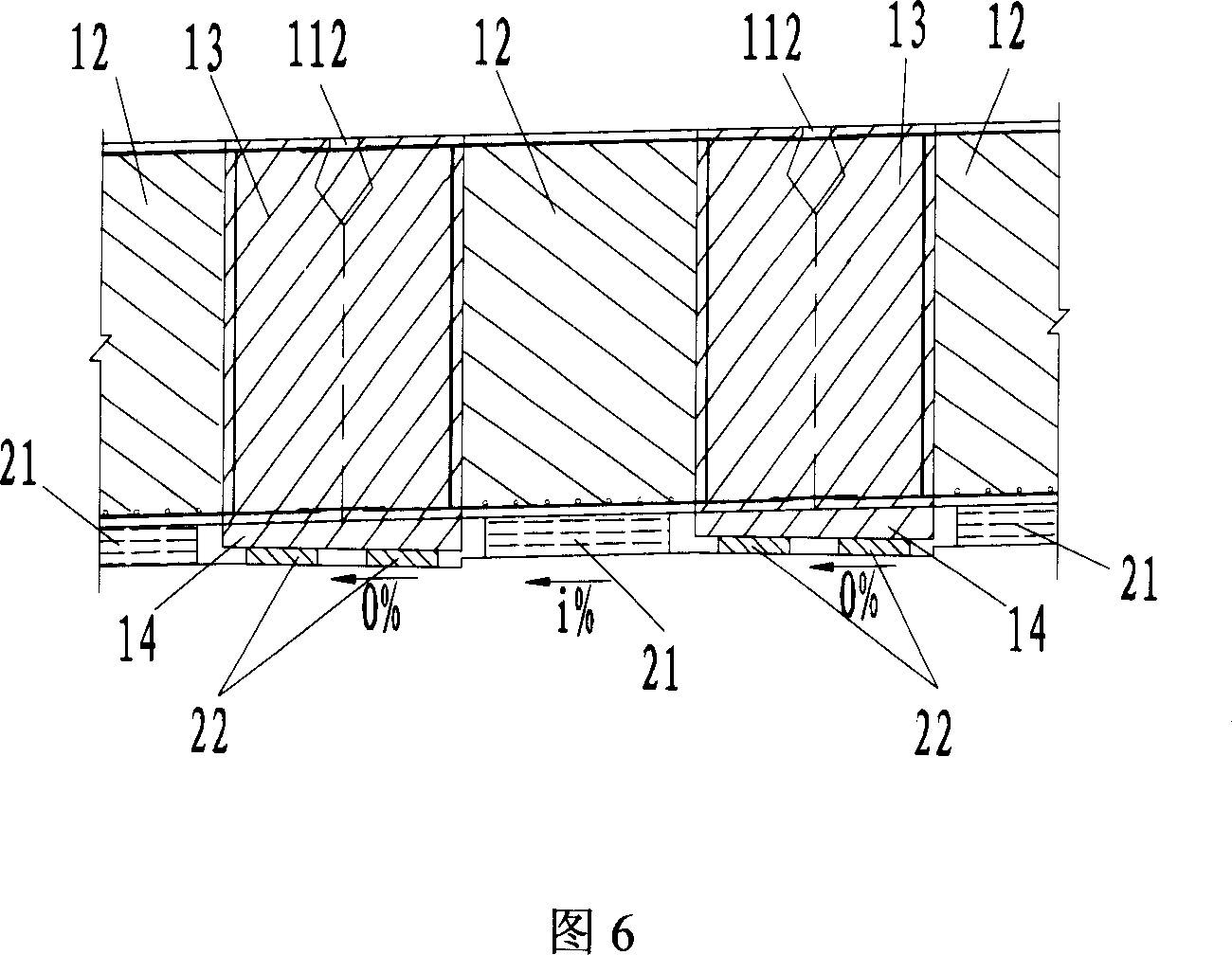

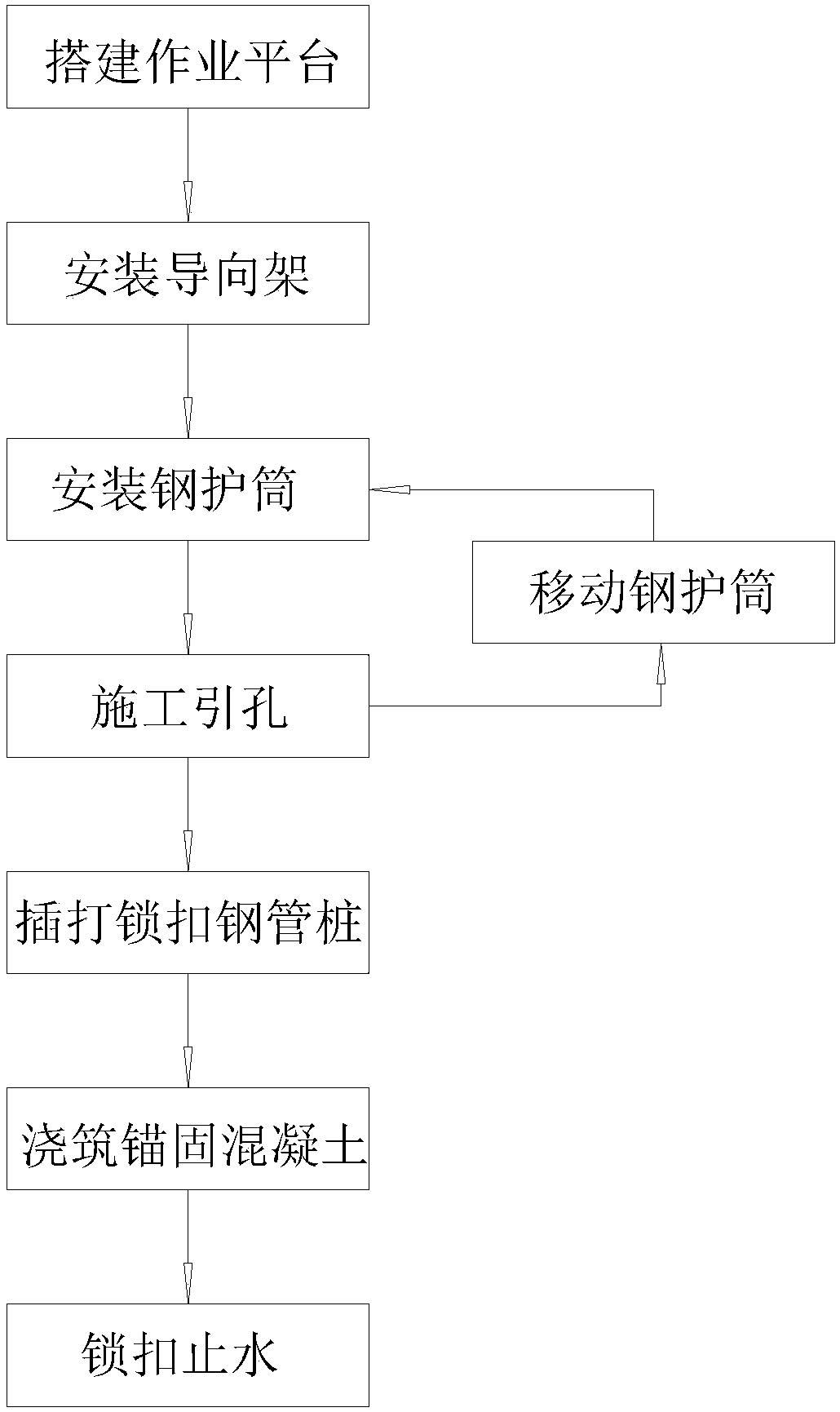

Latch steel pipe pile cofferdam construction method

The invention discloses a latch steel pipe pile cofferdam construction method. Through searching of a bending moment balance point, a rock inserting depth is calculated, and meanwhile, the material stress is within a safety value; before a steel pipe pile is inserted, a hole is led firstly, then, the steel pipe pile is inserted in, and anchoring concrete is cast in a pipe until a cofferdam is gathered, so that the problem of incapability of inserting the latch steel pipe pile into rock or incapability of stabilizing the steel pipe when a covering layer is shallow is solved, and the problems ofbottom permeation of the latch steel pipe and insufficient anchoring force in a rock layer are solved; in deep water rock layer excavation, such high-risk operations as underwater blasting and underwater excavation are prevented; for a steel cofferdam, steel can be fully recovered; and pouring of bottoming concrete is canceled to save materials.

Owner:中铁八局集团第二工程有限公司

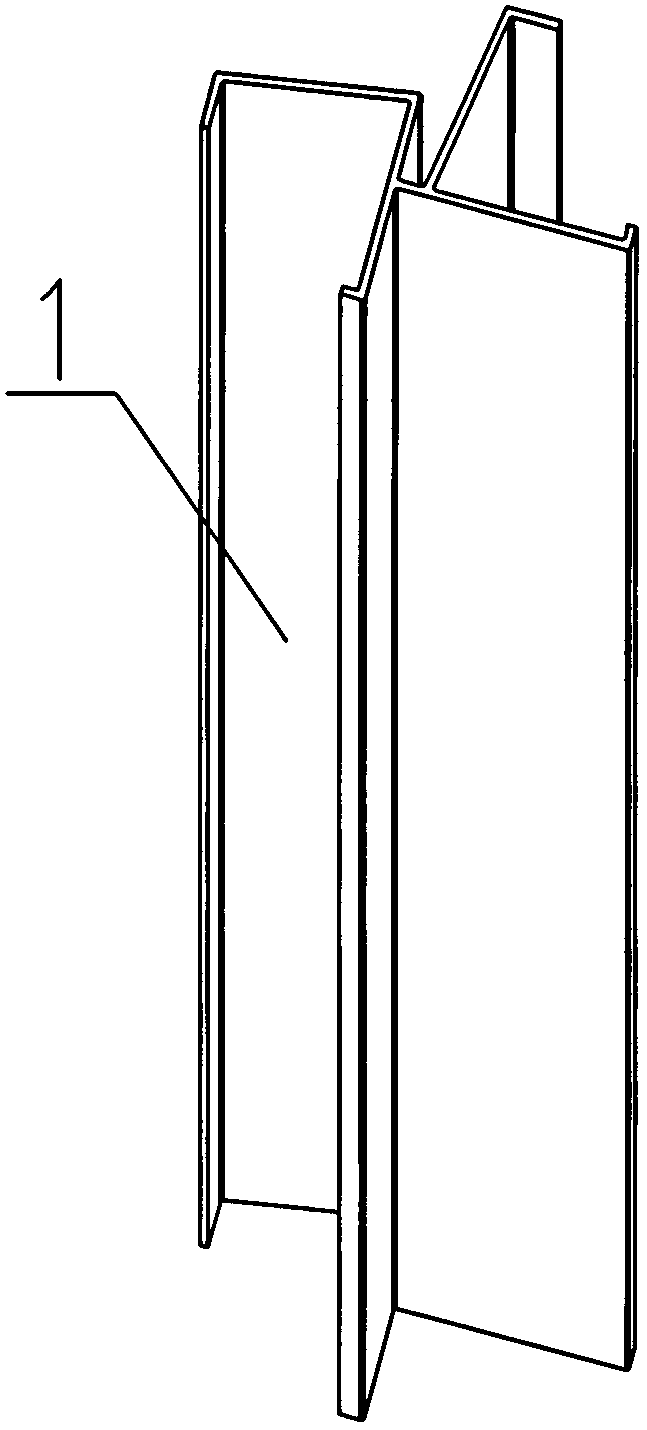

Clamping groove device for fixing wall plates

The invention discloses a clamping groove device for fixing wall plates. The clamping groove device for fixing the wall plates comprises a steel angle and a clamping groove; the clamping groove is provided with four sides, wherein two sides are inserted into the notches in the two sides of the steel angle; the steel angle and the clamping groove are fixed by sleeving mutually; one section of a wall plate is embedded into the clamping groove to achieve the effect of connecting the wall plates in a corner.

Owner:SUZHOU TIANDI COLORBOND MFG

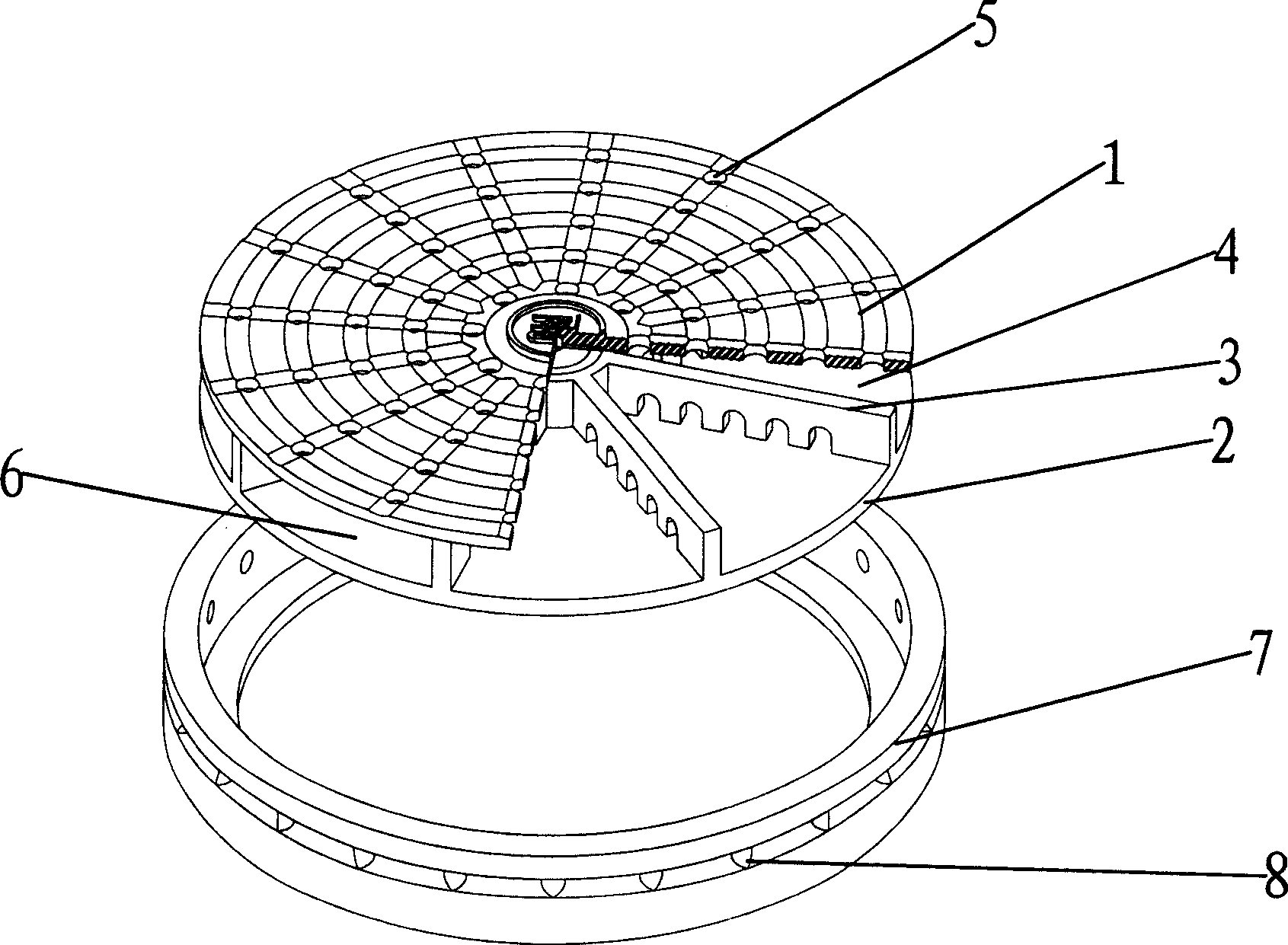

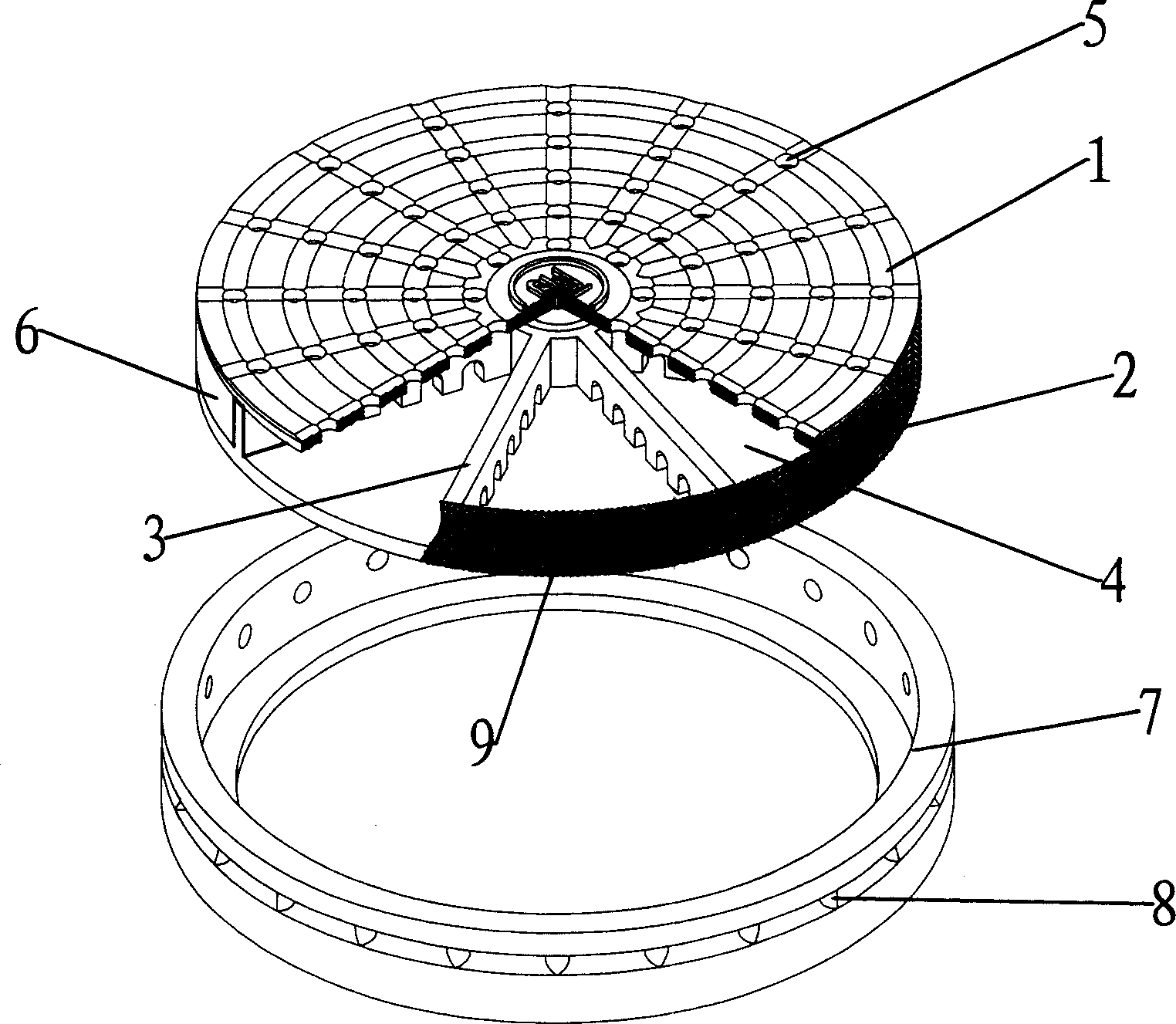

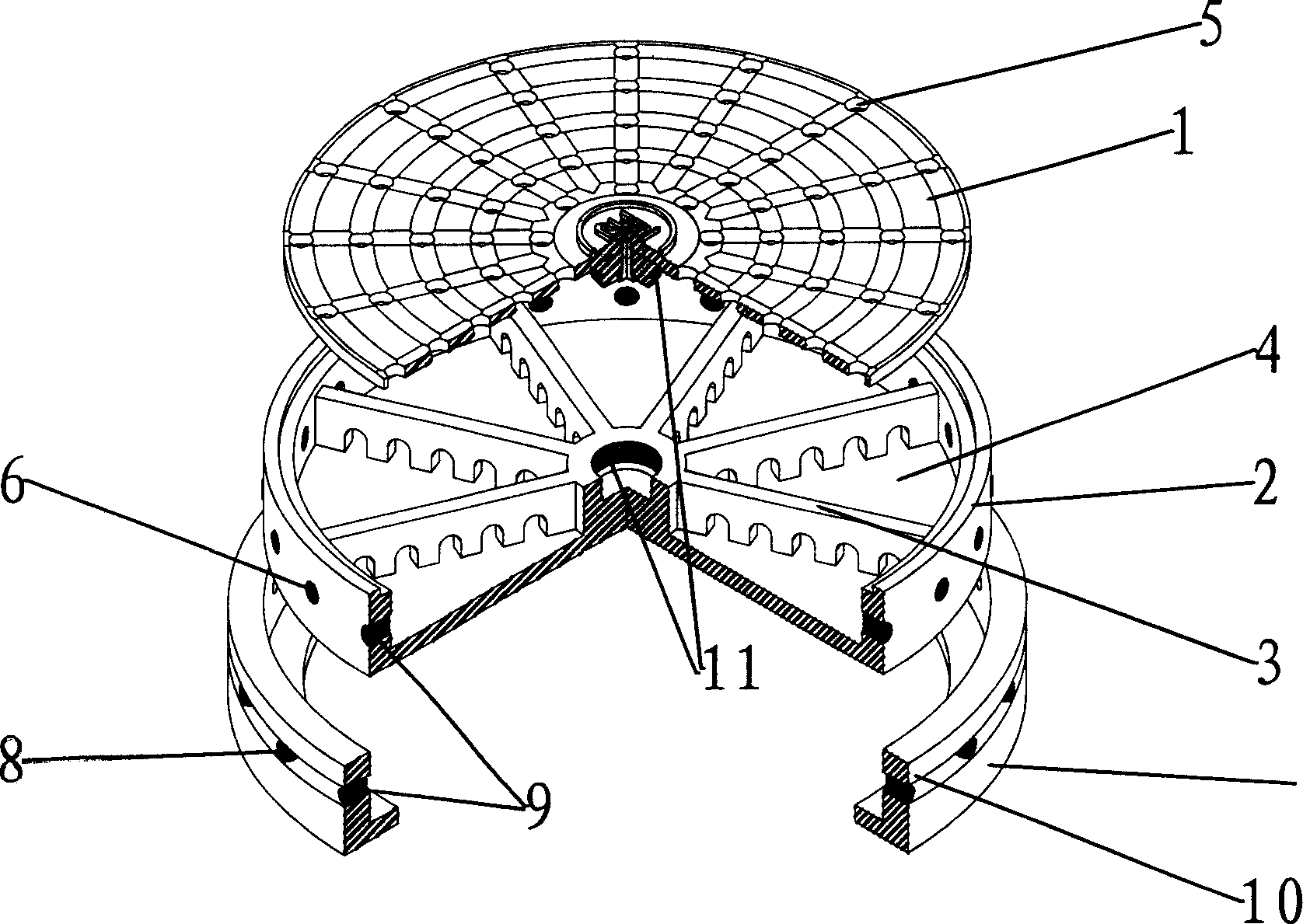

Greening wellhead

InactiveCN1699704AImprove the growing environmentAvoid connectionArtificial islandsUnderwater structuresEngineeringPlant growth

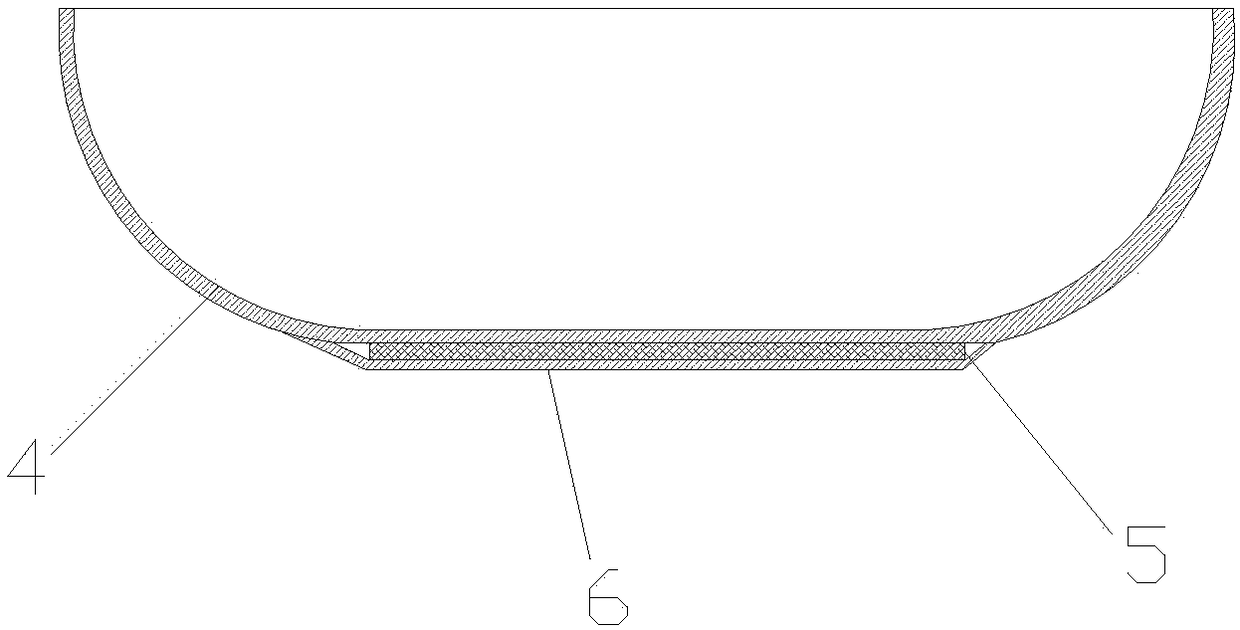

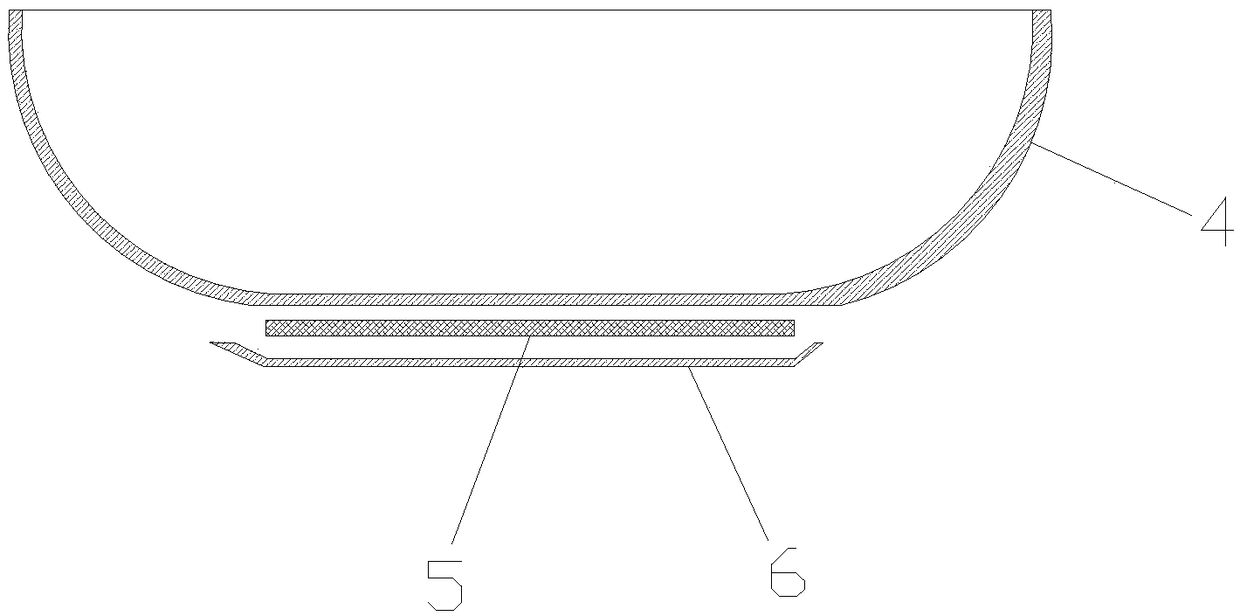

The present invention relates to a kind of green wellhead lid suited to the corresponding well-ring. The said wellhead lids are divided into upper lid body (1) and lower lid body (2), and between them is equipped with a supporting structure (3) and also between them, a well lid hollow intra-cavity is formed (4). On the said upper lid body, are holes (5) plantation; the upper end of the said holes for plantation (5) is situated at the top of the upper lid body, the lower end of the holes for plantation (5) is linked with the wellhead hollow intra-cavity; on the sideline of the said well lid and the well lid hollow intra-cavity (4) are openings (6); the said openings (6) and corresponding well ring (7) is connected to the outside rim of the side wall of the well ring. This invention improves the environment for the growth of plants on the wellhead.

Owner:梁彬

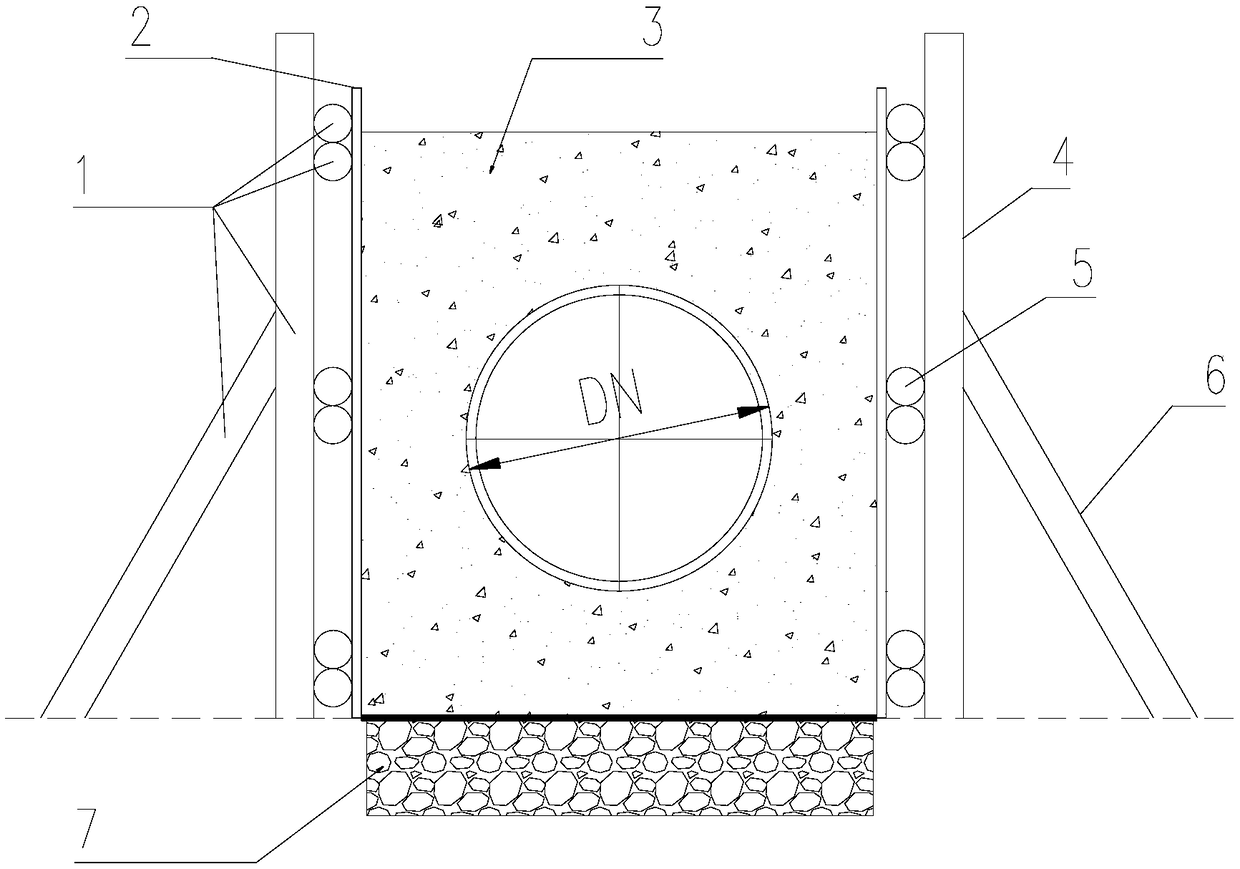

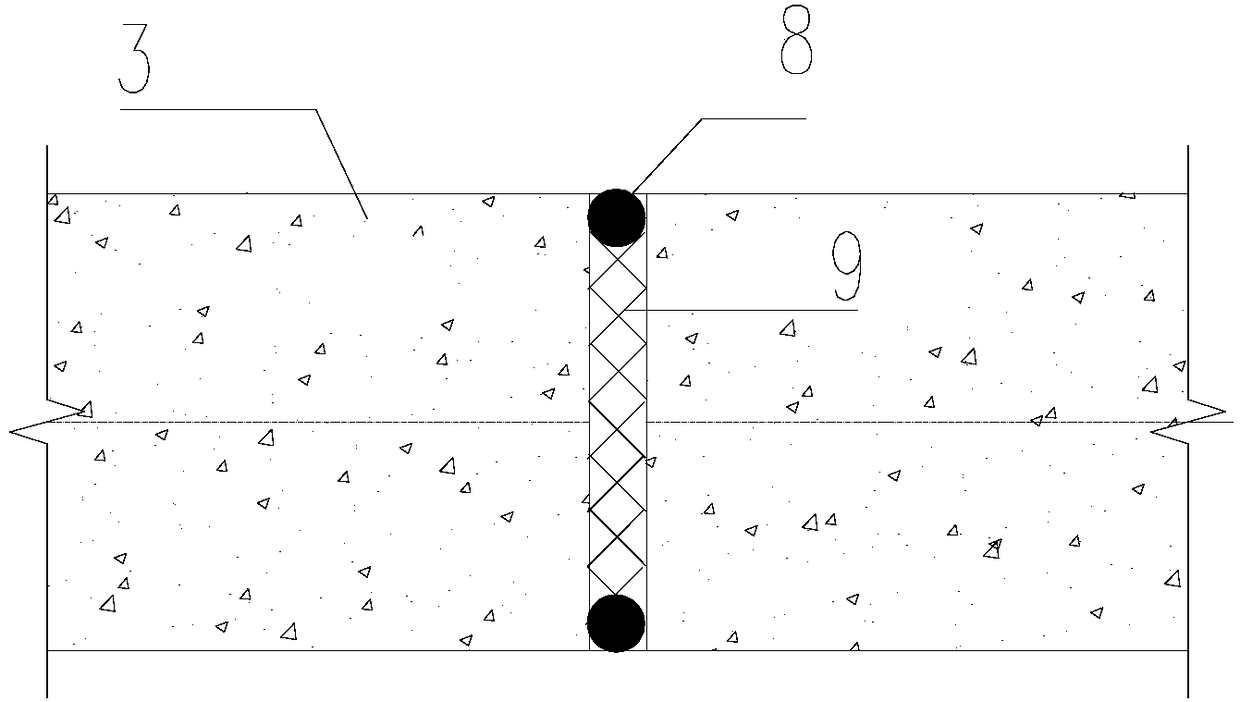

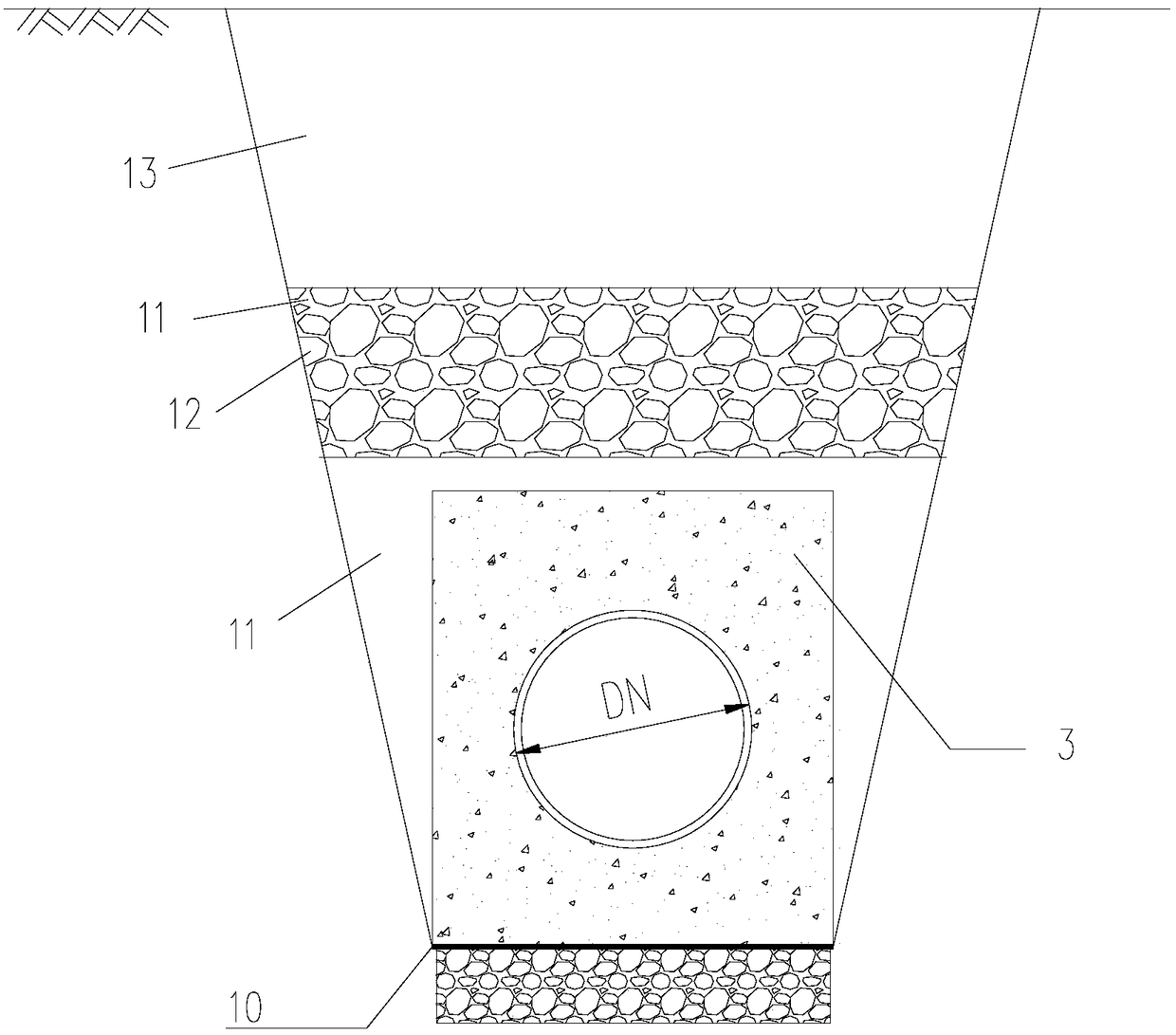

Underground pipe embedding construction method

The invention provides an underground pipe embedding construction method. The method comprises the steps of 1, pipeline trench digging; 2, cushion construction; 3, pipeline installation and fixing; 4,pipe embedding concrete formwork construction; 5, pipe embedding concrete construction; 6, treatment of pipe embedding concrete construction joints; 7, trench backfill. The construction method solvesthe technical problems of the instability of a pipe and water seepage and leakage in pipe joints, and moreover, the method has the advantages of environmental friendliness and safe and civilized construction.

Owner:CCFEB CIVIL ENG

Explosion-proofing fluorescent lamp

InactiveCN101608789ASimplify the assembly processAvoid position shiftGas-tight/water-tight arrangementsFluorescenceEngineering

The invention discloses an explosion-proofing fluorescent lamp, which comprises a seamless integrated-structure lamp shell made of a transparent material, wherein the axial both ends of the lamp shell are provided with openings; both end openings are connected with a front end cover and a rear end cover in a sealing way; the lamp shell is matched with the front end cover and the rear end cover to form a full-sealing structure; and the lamp shell is internally provided with a lamp tube and a positioning guide piece used for mounting the lamp tube. The explosion-proofing fluorescent lamp aims at the problems that the lamp shell and a transparent piece in the prior art have a splitting structure, the joint is easy to infiltrate water to influence the service life of the lamp and bring potential safety hazard, and the lamp tube is difficult to be mounted and positioned, and the invention provides the explosion-proofing fluorescent lamp, which has the advantages of transparent integrated structure of the lamp shell, convenient and rapid mounting and accurate positioning.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

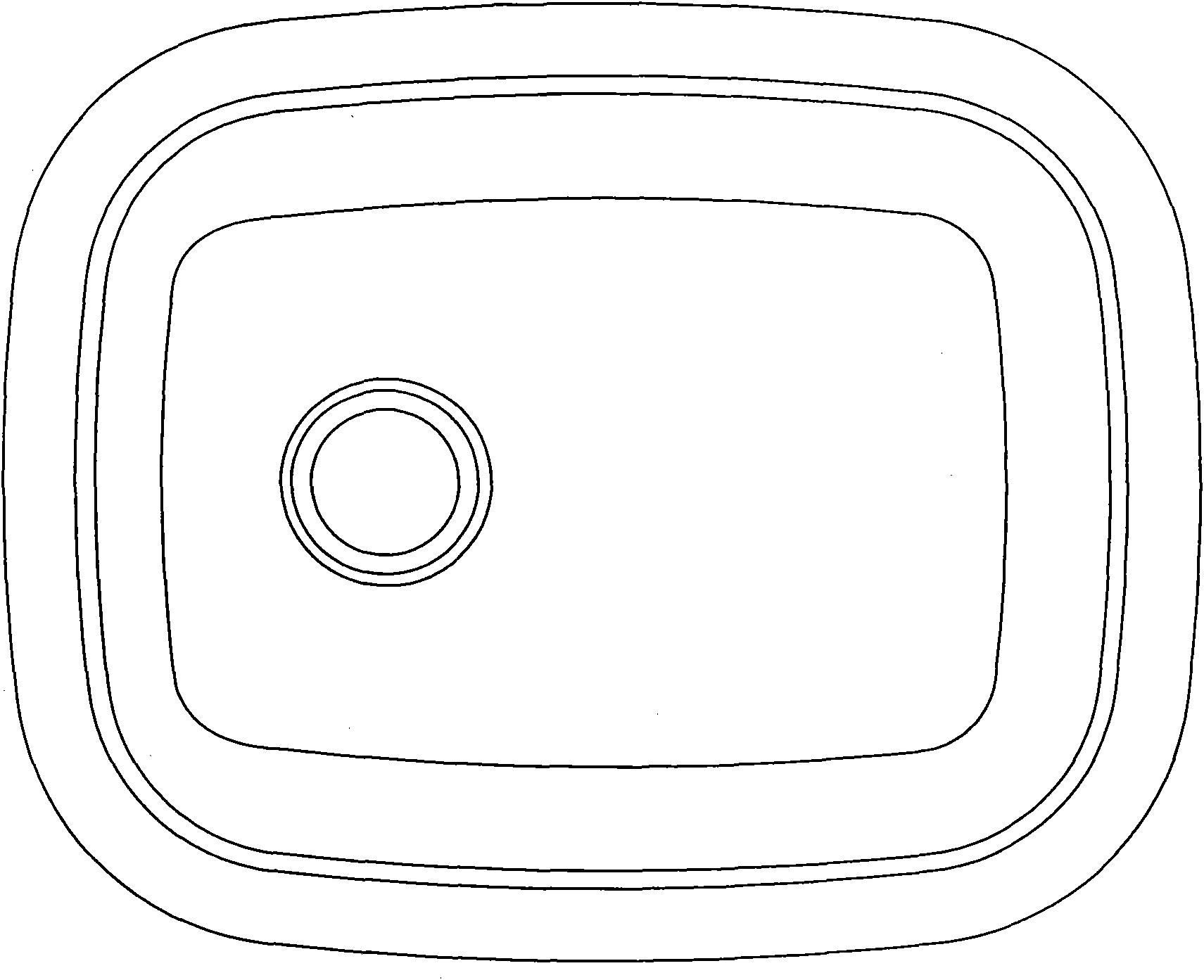

Embedded water tank and processing method thereof

InactiveCN101554316APromote mutual integrationFusion wellKitchenware cleanersDomestic plumbingEngineeringLate stage

The invention relates to an embedded water tank which comprises a tank body, a surrounding strip and a mounting plate, wherein, the surrounding strip and the tank body can be integrally molded, or separately molded, and then the surrounding strip is connected with the tank body in a way of welding or gluing; the mounting plate is made of mineral filling type polymer composite material and is attached on the surrounding strip by vacuum forming, thus the whole surrounding strip can be wrapped up. The surrounding strip is also provided with a convex part and a through area which are filled with the mounting plate made of the mineral filling type polymer composite material, so that the mounting plate can form a whole and firmly combined with the surrounding strip. In the process of late stage installation, the embedded water tank can realize seamless abutting joint together with a table-board of a cabinet table of an integral kitchen, so that the problem of water seepage possibly existing in the using process of the embedded water tank can be completely avoided. Furthermore, the embedded water tank is also suitable for a bathroom and public facilities.

Owner:GUANGDONG YINGAO KITCHEN UTENSILS

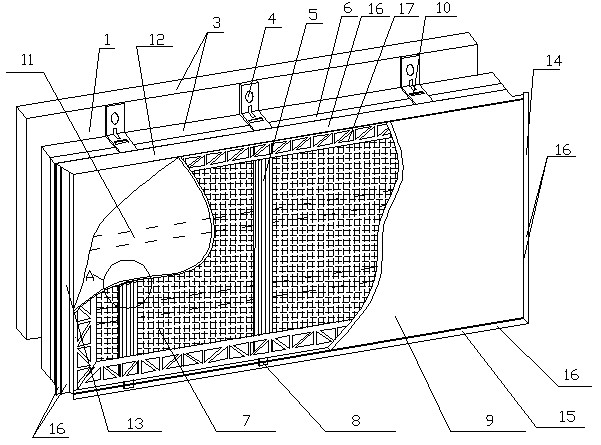

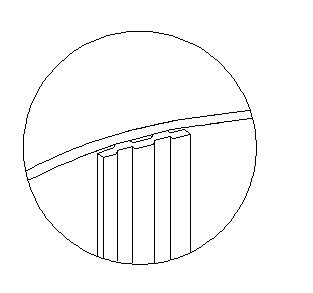

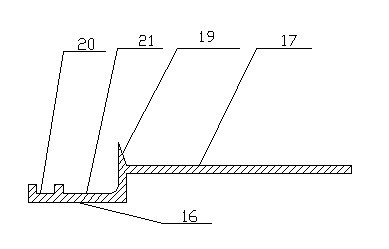

Waterproof thermal-insulation decorative wall board, casing for doors and windows, and installation method of casing

ActiveCN102587608AExtended service lifePrevent infiltrationCovering/liningsWindow/door framesThermal insulationEngineering

The invention belongs to the technical field of building materials, in particular to a waterproof thermal-insulation decorative wall board, a casing for doors and windows, and an installation method of the casing. The waterproof thermal-insulation decorative wall board comprises thermal-insulation boards including an upper layer and a lower layer staggered, a structural board and a facing board are sequentially attached to the surface of each thermal-insulation board, the structural board comprises a mesh layer, structural anchor bars and cement mix, each structural anchor bar is provided with a fixing hole, edge and corner lines are arranged between the structural board and the facing board, the edge and corner lines include functional areas and anchor areas, a separation frame is arranged at the connection of the functional areas and the anchor areas, the edge and corner lines include an upper edge and corner line I, a left edge and corner line II, a right edge and corner line III and a lower edge and corner line IV. According to the technical scheme, the waterproof thermal-insulation decorative wall board is simple in structure and convenient in use and serves as a fine exterior wall decoration, is evidently effective and has prominent substantial characteristics and evident progress.

Owner:山东名洋保温节能工程有限公司

Wallboard for building

ActiveCN103074958AShort preparation cycleNo post-maintenanceWallsHeat proofingEngineeringAbnormal shaped

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

Medical visible inpatient ward humidifying, heating and disinfecting system

ActiveCN108644892AChange lengthPlay a protective effectMechanical apparatusLighting and heating apparatusMedical wardEngineering

The invention discloses a medical visible inpatient ward humidifying, heating and disinfecting system which comprises a base, a supporting frame plate and a horizontal supporting plate. A central processor is installed on the upper portion of the base; a fixing plate is arranged above the central processor; an extension pipe is fixed to the front side of the supporting frame plate; the supportingframe plate is located in the middle of a supporting rod; a traveling groove is formed inside the horizontal supporting plate; and the horizontal supporting frame is located below a fan. According tothe medical visible inpatient ward humidifying, heating and disinfecting system, the position height of the supporting frame plate on the supporting rod can be adjusted through cooperation of the supporting rod and the supporting frame plate, the overall lengths of a protective sleeve and a detection rod are changed, the outer protective sleeve plays a role in protecting temperature sensors and humidity sensors on the detection rod, the multiple temperature sensors and the multiple humidity sensors can be exposed outside at the same time when the supporting frame plate ascends along the supporting rod, and when the supporting frame plate descends along the supporting rod, the temperature sensors and the humidity sensors can be stored into the protective sleeve.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

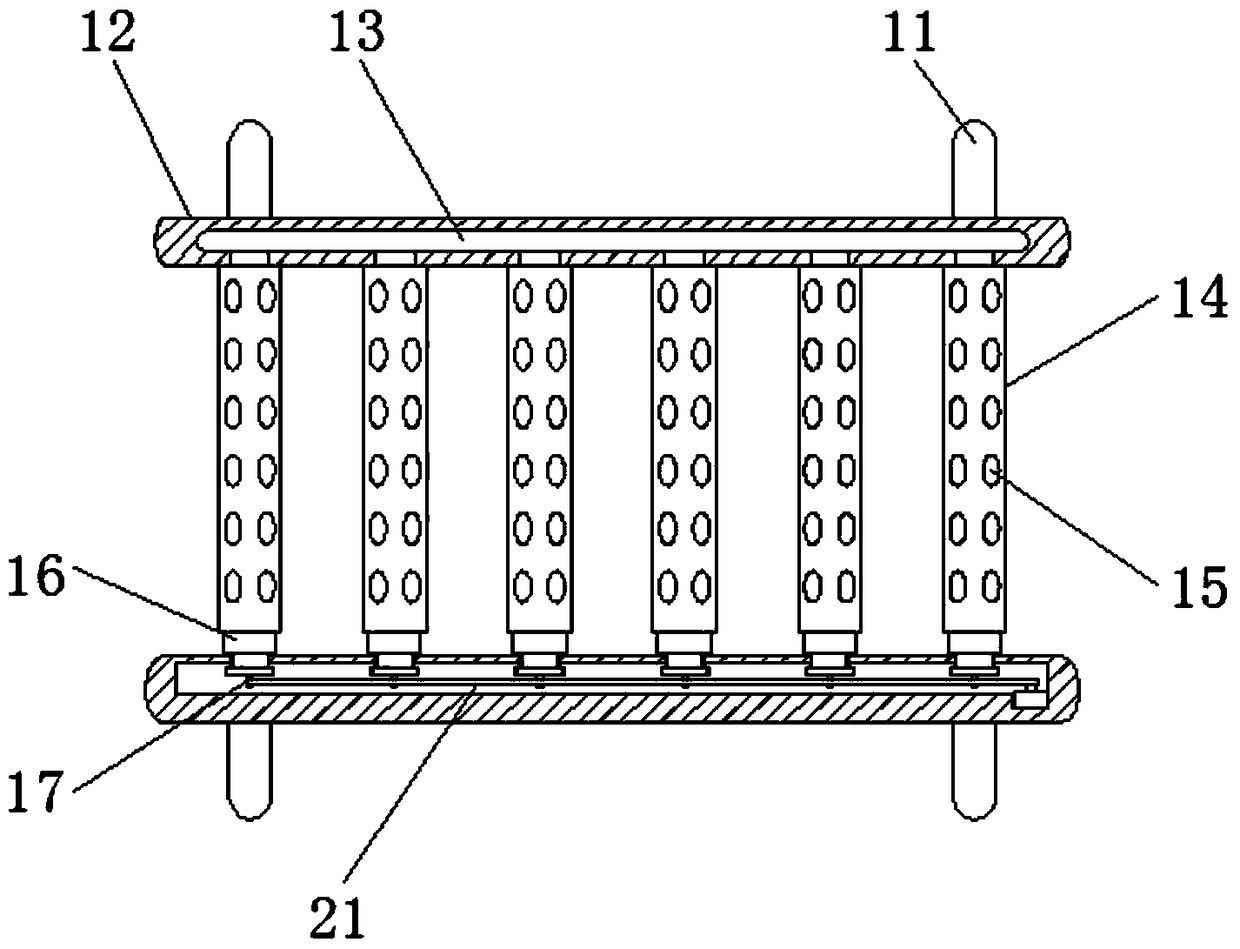

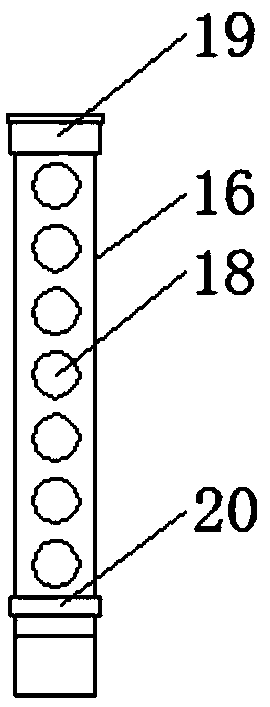

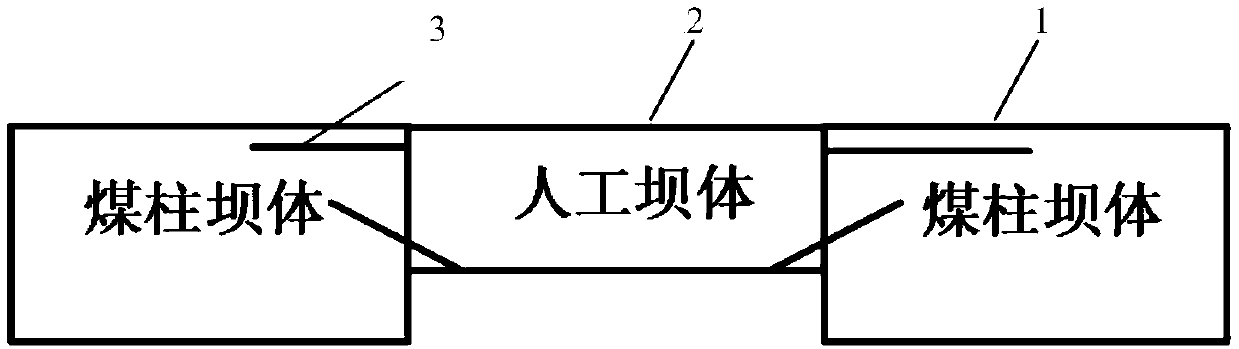

Underground reservoir system of sealed mining area

ActiveCN109538295ASolve the problem of water seepageSolve the leakMining devicesBrickInsulation layer

The invention provides an underground reservoir system of a sealed mining area. The system comprises mine column dam bodies on the two sides, an artificial dam body and a water insulation membrane composite plate which are arranged between the mine column dam bodies arranged on the two sides, the artificial dam bodies are composed of multiple concrete bricks, the water insulation membrane composite plate is arranged on the side, close to the reservoir, of the mine column dam bodies, the concrete bricks are produced by a manufacturing instrument of the concrete bricks, and the manufacturing instrument at least comprises a concrete brick mold. When the artificial dam body and the water insulation composite plate are installed, wall caving is conducted on the mine column dam bodies on the twosides firstly, mine column cutting is conducted mine column dam bodies to provide space for installing the water insulation composite plate, grouting reinforcing is conducted on the water insulationmembrane composite plate, finally the artificial dam body is installed, and a mine column cutting device is used for cutting the mine columns. The system has the advantages that the problems of waterseepage and leakage caused by top plate breaking and the existence of an insulation layer above a top plate are solved.

Owner:CHINA SHENHUA ENERGY CO LTD +1

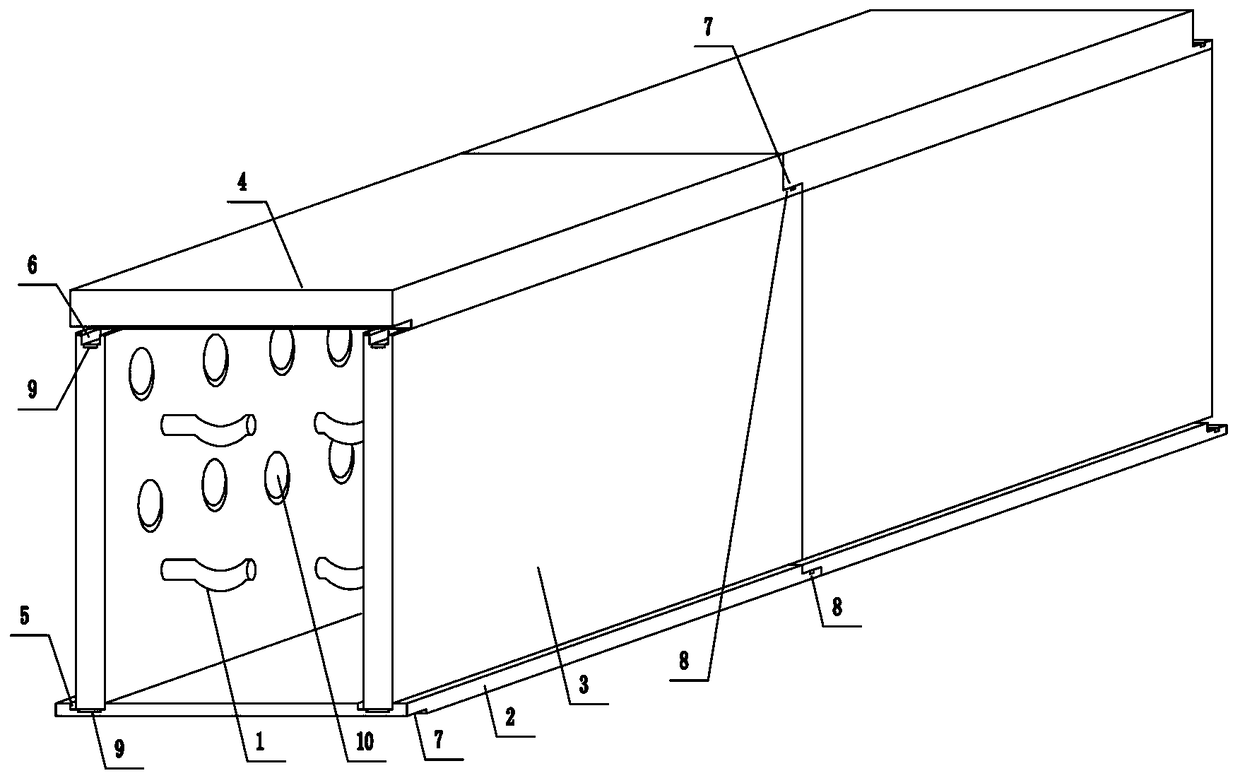

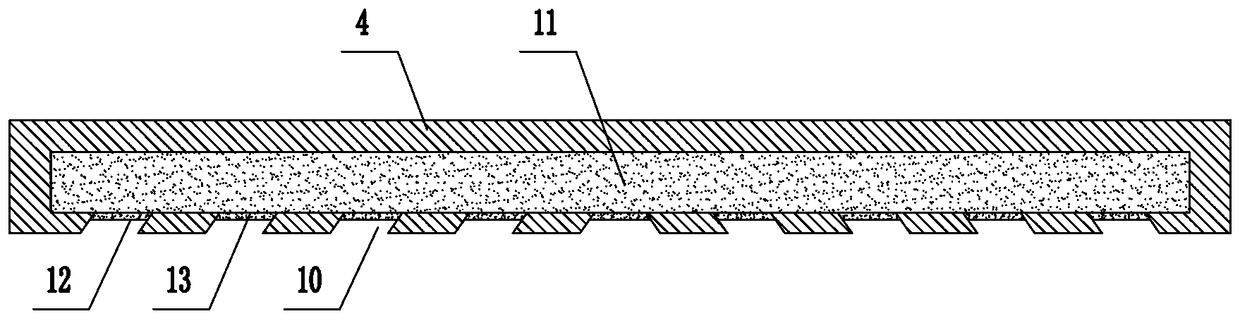

Combined floor for same-level drainage toilet and construction method

ActiveCN102852255ASolve the problem of water seepageEasy to transformFloorsDomestic plumbingRear quarterEngineering

The invention relates to a combined floor for a same-level drainage toilet. The combined floor for the same-level drainage toilet comprises a steel board box, a drainage pipe, filling concrete boards and peripheral beams around a box body, and is characterized in that the steel board box is of a box body structure with an upper opening and is formed by welding a bottom board, end side boards, side ribs and intermediate ribs, and the bottom board is provided with an anti-rust protective layer; and a plurality of through holes are arranged in web boards of the intermediate ribs at intervals, and the drainage pipe passes over the through holes in the intermediate ribs to be embedded into the filing concrete boards. The steel board box is used to thoroughly block a seepage route, so that the water seepage problem of the toilet is permanently solved.

Owner:杨众

Reinforced concrete windowsill coping adverse construction method

The invention relates to a reinforced concrete windowsill coping adverse construction method comprising the following steps: (1) making pre-cast reinforced concrete building blocks; (2) removing a form; (3) maintaining the pre-cast reinforced concrete building blocks; (4) laying a masonry; (5) burying the pre-cast reinforced concrete building blocks; (6) welding windowsill coping reinforcing steel bars with reinforcing steel bars reserved for the reinforced concrete building blocks; (7) making a template; and (8) processing the joint of the template and the wall. The reinforced concrete windowsill coping adverse construction method can ensure that the reinforced concrete windowsill coping construction is not restricted by the length of the windowsill coping, guarantee the compact construction joint and greatly improve the windowsill coping construction progress and the windowsill coping construction quality. In addition, the reinforced concrete windowsill coping adverse construction method is simple and is convenient to operate. Moreover, the reinforced concrete windowsill coping adverse construction method uses the filed concrete construction residual material to make the pre-cast reinforced concrete building blocks, thereby causing no pollution to the environment and saving the energy and the windowsill coping construction cost.

Owner:温州城建集团股份有限公司

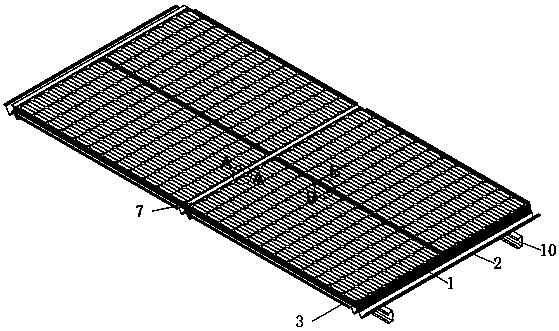

Integrated roof power generation system of building

PendingCN107809198AEasy to installAvoid punchingPhotovoltaic supportsSolar heating energyBuilding integrationWater leakage

The invention relates to an integrated roof power generation system of a building. The system is composed of a main water tank, photovoltaic assemblies, pressing blocks and cushion blocks. The main water tank consists of a main supporting part, auxiliary supporting parts and drainage channels; the two side walls of the main supporting part protrude outwardly to form inverted buckles; chutes are formed at parts, corresponding to the inverted buckles, in the two side walls of the main supporting part; the inverted buckles are connected with photovoltaic assembly fixed elements in a buckling manner; the cushion blocks are arranged on the photovoltaic assembly fixed elements cooperatively; and the bottoms of the cushion blocks are in contact with the main supporting part and the photovoltaic assemblies are arranged at the two sides of the cushion blocks. The pressing blocks are pressed between the photovoltaic assemblies and are fixed with the photovoltaic assembly fixed elements by boltsto compress the photovoltaic assemblies. Water-proof covers are arranged on the pressing blocks; sliding blocks are arranged in the chutes; sliding block bolts are arranged in the sliding blocks and are connected with clamping blocks to fix the main water tank and C-shaped purlines. Therefore, a water leakage problem caused by penetration and fixation of the bolt in the prior art is solved; and the photovoltaic assemblies are installed conveniently.

Owner:HANGZHOU SONNY ENERGY TECH CO LTD

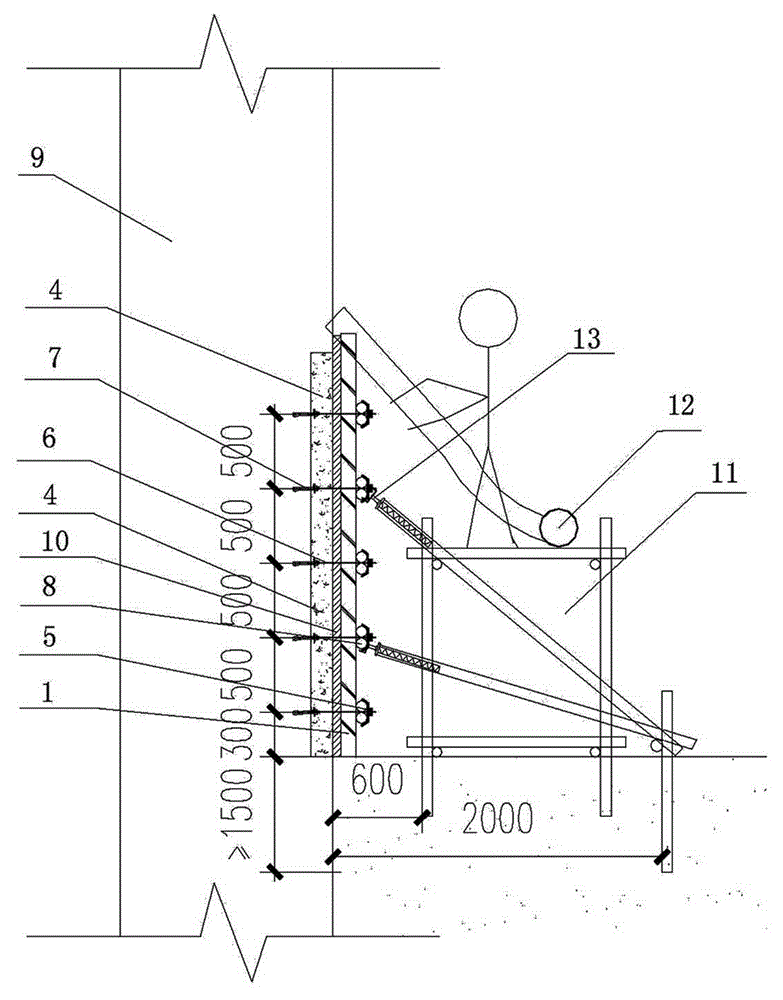

A construction method of water-stop curtain anti-seepage structure

ActiveCN104131576BSolve the problem of water seepageSolve problemsFoundation engineeringKeelConfined water

The invention relates to a waterproof curtain impervious structure and a construction method thereof. According to the waterproof curtain impervious structure, expansion bolts are arranged on two supporting piles which are located at the pervious positions of a waterproof curtain, horizontal steel bars are embedded into the positions closer to the outer sides of the supporting piles relative to the expansion bolts, the embedded horizontal steel bars need to meet the test requirements, split bolts are provided and connected with the expansion bolts in a welded mode, the split bolts are connected with the horizontal steel bars in an overlapped mode through a steel bar, vertical steel bars are bound with the horizontal steel bars to form a steel bar mesh, formworks are arranged on the periphery of the steel bar mesh in a supported mode, so that the expansion bolts are connected with the split bolts so as to tension a primary joist fixing formwork and a secondary joist fixing framework, and concrete is poured after a reinforcement measure is completed so as to form the waterproof curtain impervious structure. According to the waterproof curtain impervious structure and the construction method of the waterproof curtain impervious structure, the water seepage problem of the waterproof curtain can be solved rapidly, the problems existing in large-area water seepage treatment of the waterproof curtain when confined water is high in level and pressure are solved especially, the water-stopping and impervious effect is good, and the treatment speed is high.

Owner:THE THIRD CONSTR OF CHINA CONSTR FIRST GROUP +1

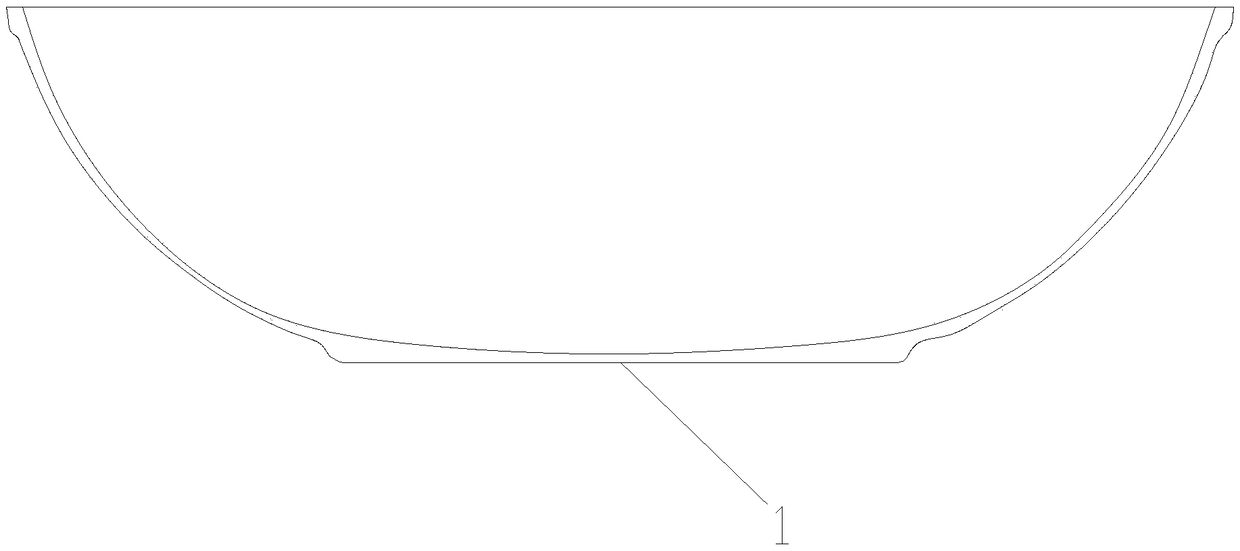

Composite steel pan and manufacturing process thereof

InactiveCN108903595AHigh strengthReduce deformation rateCooking-vessel materialsHollow articlesVolumetric Mass DensityMaterials science

The invention relates to a steel pan and a manufacturing process thereof, and discloses a composite steel pan and a manufacturing process thereof. The composite steel pan comprises a pan body (1), wherein the pan body (1) comprises an inner working layer (11) and an outer heated layer (12); the inner working layer (11) is covered by the outer heated layer (12); bosses, which are used for increasing structural intensity, are arranged at the bottom of the pan body (1) and the outer edge of a pan opening; and during manufacturing, sheet stocks are applied with oil, and multiple layers of structures undergo imitated pressing and molding, so that the multiple layers of structures are combined through imitated pressing. According to the manufacturing process provided by the invention, the various layers are closely bonded under high-tonnage pressure; under the effect of the high-tonnage pressure, a material of the pan body flows under a cold-solid state or a heated state, so that density isimproved, a molecular structure is distributed more closely and adhesive force between aluminum alloy and stainless steel or a magnetic-conductive layer material is increased; in addition, the multiple layers of composite steel materials of the pan body are integrally molded, and through a stepped-form strengthening effect between the opening and the bottom of the pan body, the pan body is prevented from getting deformed easily when sprayed and roasted at high temperature.

Owner:JH LEICAST COOKWARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com