Latch steel pipe pile cofferdam construction method

A construction method and technology of steel pipe piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of uneven hardness, inability to pass through hard rock formations, complex lithology, etc., and achieve the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

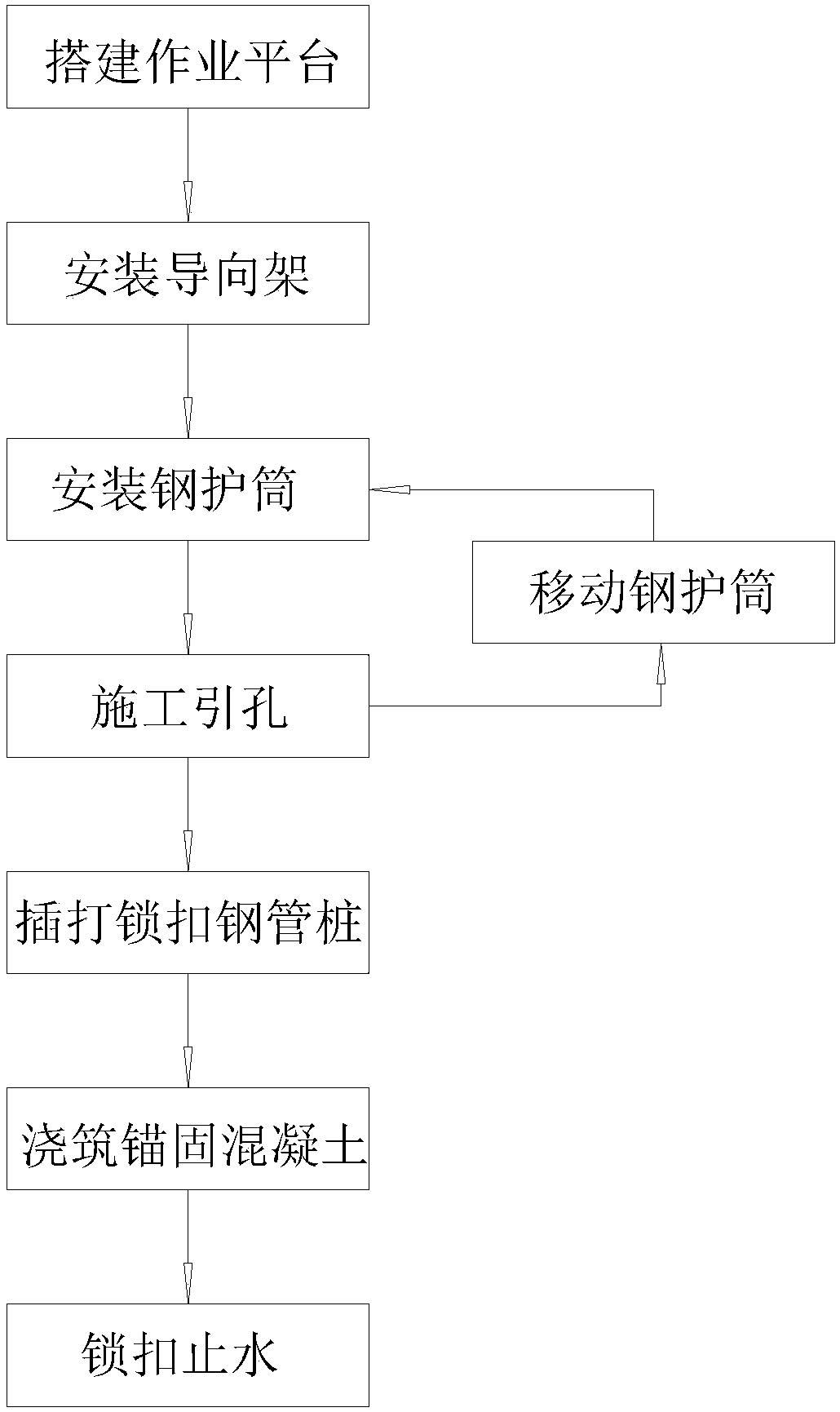

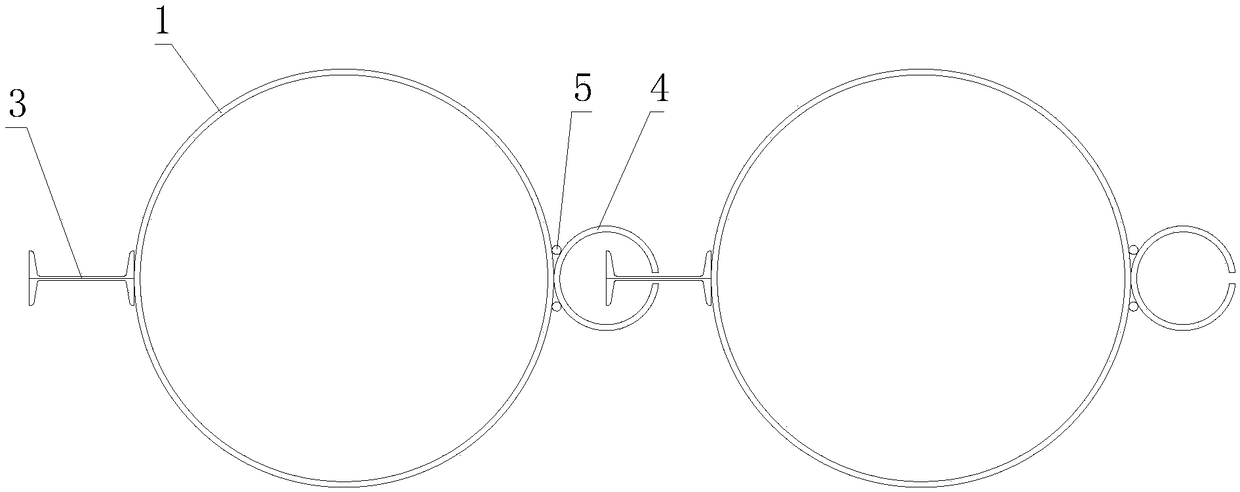

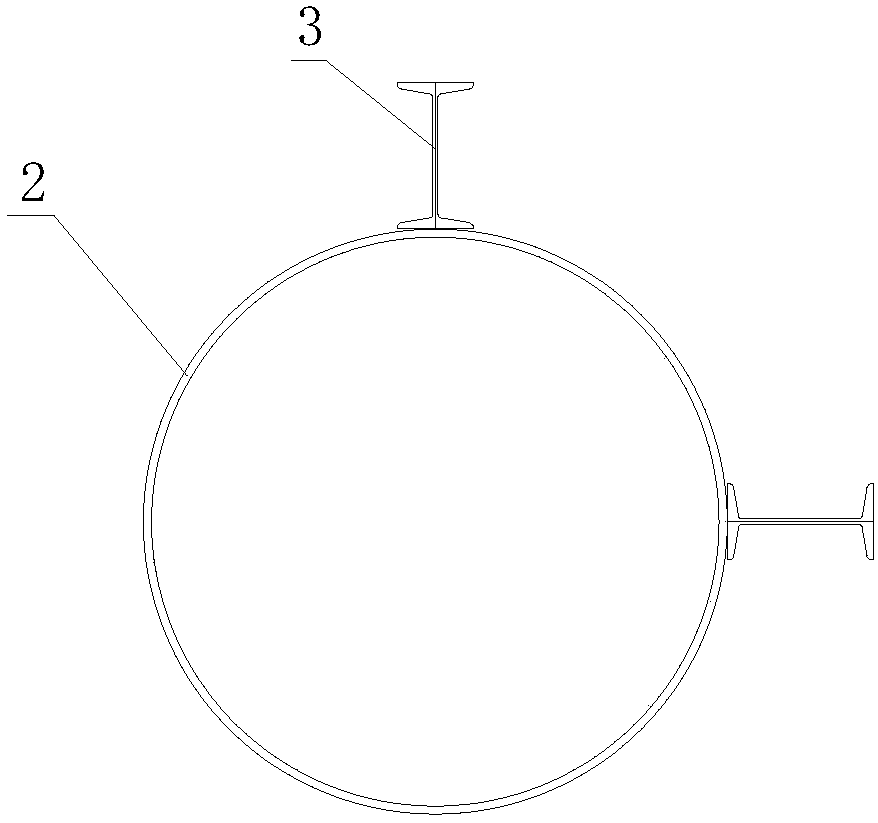

Method used

Image

Examples

Embodiment approach

[0061] 3.1.1 Calculation of rock penetration depth

[0062] The rock penetration depth is calculated according to the classical method.

[0063] According to the "Geological Explanation of Fushun Tuojiang Double-line Super Bridge" provided by the Design Institute, the rock is mudstone interbedded with sandstone W3, the stratum is in good condition, and the friction angle is 40°, γ a =22g / cm 3 .

[0064] active and passive earth pressure coefficient

[0065]

[0066] Calculate the distance y of the point where the internal force on the steel pipe pile is 0, and obtain y:

[0067] gamma p k P y=K a gamma a (H 土 +y)+γH 水 ,Available:

[0068]

[0069] ②. Calculate the equivalent beam fulcrum reaction force (that is, Ra and P0) according to the continuous beam. The content of this part of the calculation is the calculation of simply supported beams. The load is the joint action of earth pressure, and the constraints are hinged at the inner support and consolidation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com