Fireproof power cable trench

A technology for power cables and fireproof materials, which is applied in cable installation, ground cable installation, electrical components, etc., can solve problems such as inability to achieve fire extinguishing, and achieve the effect of avoiding bottom seepage, solving water seepage, and avoiding secondary failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

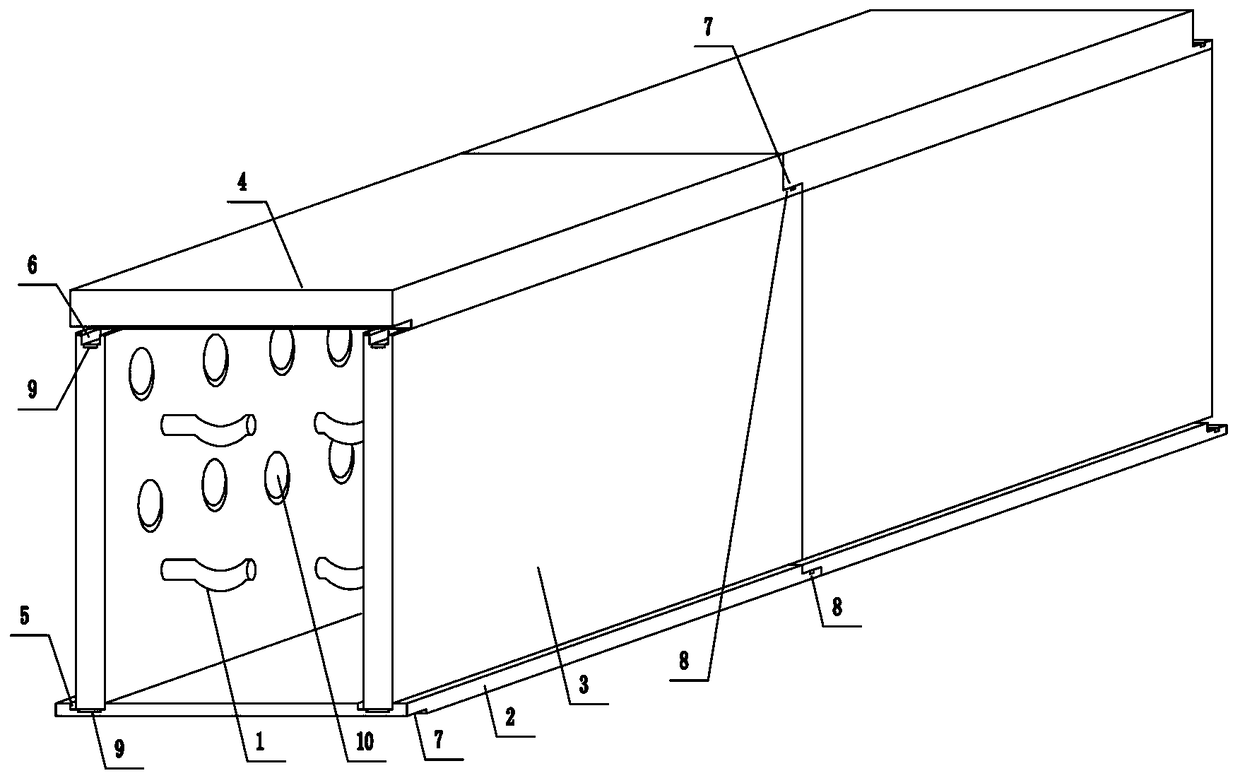

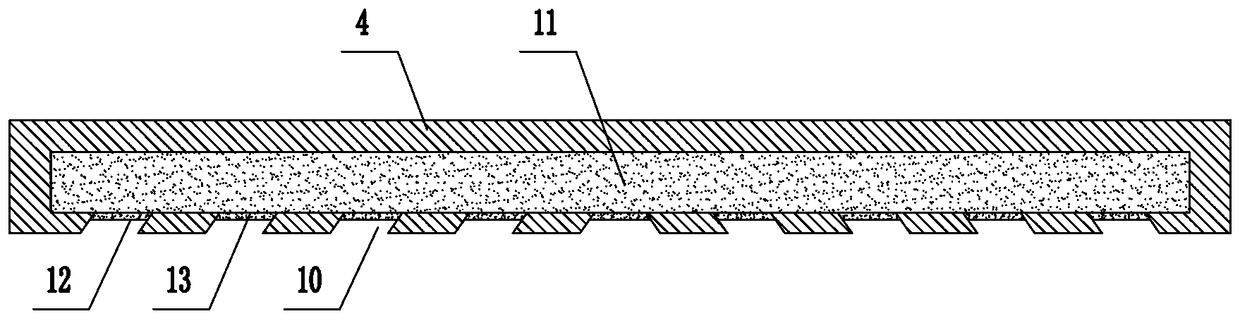

[0027] Such as figure 1 As shown, a fireproof power cable trench of the present invention includes a plurality of assembled and connected trench bodies (two are shown in the figure) and a bracket 1 arranged in the trench body for providing support for cables. The fixed part of the channel body and the support part matched with the cable, the support part is an arc-shaped structure, and a single channel body is surrounded by a bottom plate 2, two side baffles 3 and a cover plate 4. 1. A hollow cuboid structure with both ends open; the bottom plate 2 is provided with a first slot 5 for accommodating the side baffle 3; the upper end of the side baffle 3 is provided with a second slot 6; The clamping strip 14 matched with the clamping groove 6 passes through the first matching part 7 and the second matching part between two adjacent bottom plates 2, between two adjacent side baffles 3, and between two adjacent cover plates. 8 sealing connection, the first mating part 7 and the se...

Embodiment 2

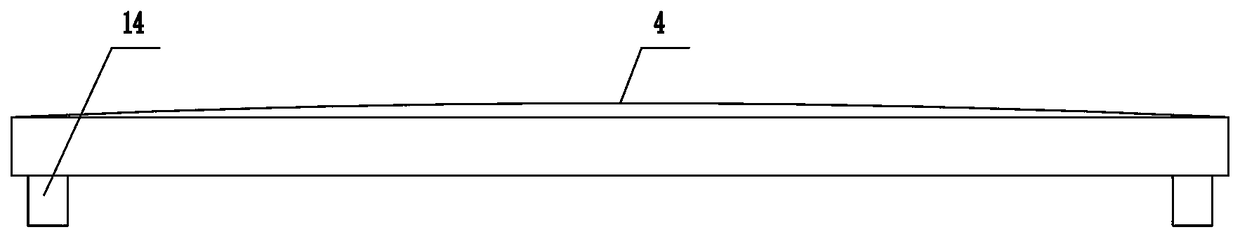

[0031] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as image 3 As shown, the upper end surface of the cover plate 4 is an upwardly protruding arc structure with an arc of 5°. In this embodiment, the structure of the cover plate 4 is improved, which can effectively improve the compressive performance of the cover plate and facilitate the passage of heavy machinery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com