Flexible flame-retardant filler and secondary battery

A flame retardant filling, secondary battery technology, applied in secondary batteries, batteries, battery pack components, etc., can solve problems such as reducing battery performance, reduce the occurrence of combustion accidents, reduce external impact, and quickly block oxidation reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

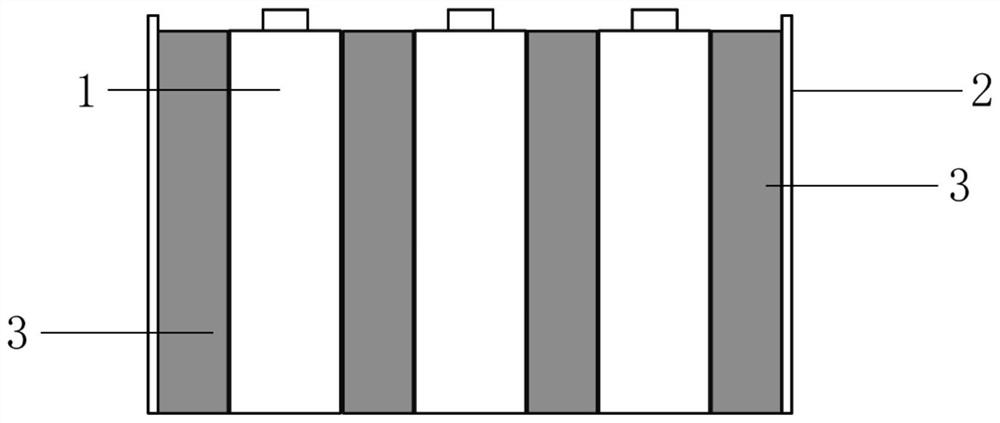

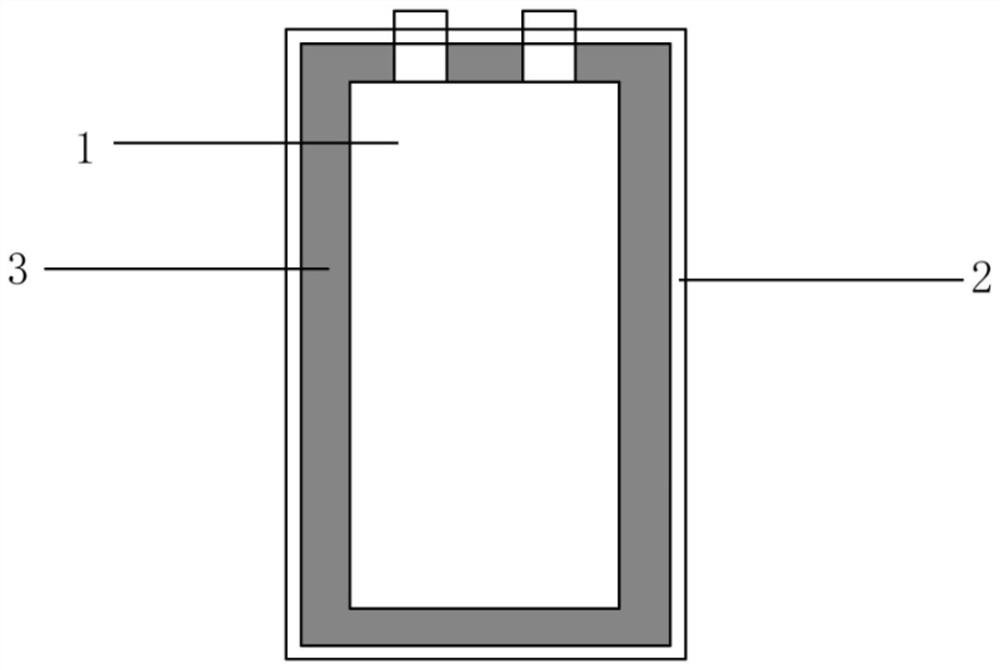

[0079] see image 3 , image 3 It is a schematic cross-sectional schematic diagram of a single battery cell of the lithium-ion battery structure provided by the present invention. Among them, 1-lithium ion battery, 2-battery shell, 3-flame retardant filler.

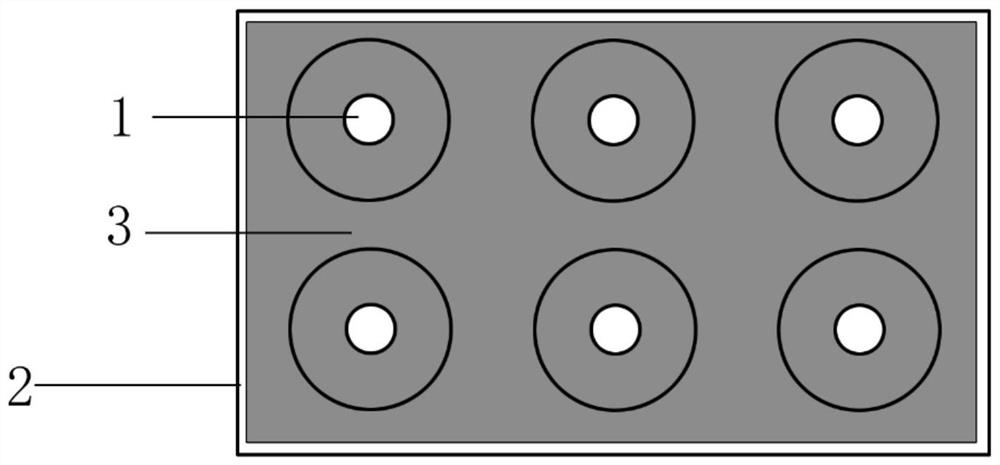

[0080] see Figure 4 , Figure 4 It is a top view schematic diagram of the structure of the lithium-ion battery containing the flexible flame retardant provided by the present invention. Among them, 1-lithium ion battery, 2-battery shell, 3-flame retardant filler.

[0081] In the 5Ah pouch battery, the flame retardant is magnesium hydroxide [Mg(OH) 2 ] as an example, the rheological additive is polyethylene oxide, the mass ratio of the flame retardant to the rheological additive is 1:2.5, and the magnesium hydroxide [Mg(OH) 2 ] mixed with polyethylene oxide and stirred for 2 hours, and its viscosity was tested with a rotational viscometer. When the viscosity value reached or approached 13500mPa·s, the flame retardan...

Embodiment 2

[0089] In a 5Ah soft pack battery, the flame retardant is aluminum hydroxide as an example, the rheological additive is fumed silica, the mass ratio of the flame retardant to the rheological additive is 1:2.4, and then polyurethane thickener is added Accounting for about 1 / 4 of the total proportion, the mixture was stirred for 2 hours, and its viscosity was tested with a rotational viscometer. When the viscosity value reached or approached 14500mPa·s, a gel state flame retardant was obtained.

[0090] The gel is then filled into a battery pack with an aluminum casing, and after being slightly solidified, the pouch battery containing the flexible flame-retardant filling prepared by the present invention is obtained. Aluminum hydroxide releases water of crystallization when it is decomposed by heat. This process is a strong endothermic reaction, which absorbs a large amount of heat and can cool the polymer. At the same time, the water vapor generated by the reaction can dilute t...

Embodiment 3

[0095] In a 5Ah soft pack battery, the flame retardant is zinc borate as an example, the rheological additive is modified polyurea, the mass ratio of the flame retardant to the rheological additive is 1:2.6, and the polyurethane thickener is added for about Accounting for 1 / 5 of the total ratio, the mixture was stirred for 2 hours, and its viscosity was tested with a rotational viscometer. When the viscosity value reached or approached 14000mPa·s, a gel state flame retardant was obtained.

[0096] The gel is then filled into a battery pack with an aluminum casing, and after being slightly solidified, the pouch battery containing the flexible flame-retardant filling prepared by the present invention is obtained. Zinc borate has a synergistic effect, which can effectively reduce the cost of materials, the amount of smoke generated during combustion, and promote the formation of charcoal layers without reducing the flame retardant grade of materials. The layer can be stabilized b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com