Self-joint-filling water-removing type anti-seepage building outer wall

A self-replenishing technology for building exterior walls, applied in construction, building maintenance, building components, etc., can solve the problems of easy water seepage at joints and water seepage, and achieve the effect of preventing water seepage from flowing into the interior of the exterior wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

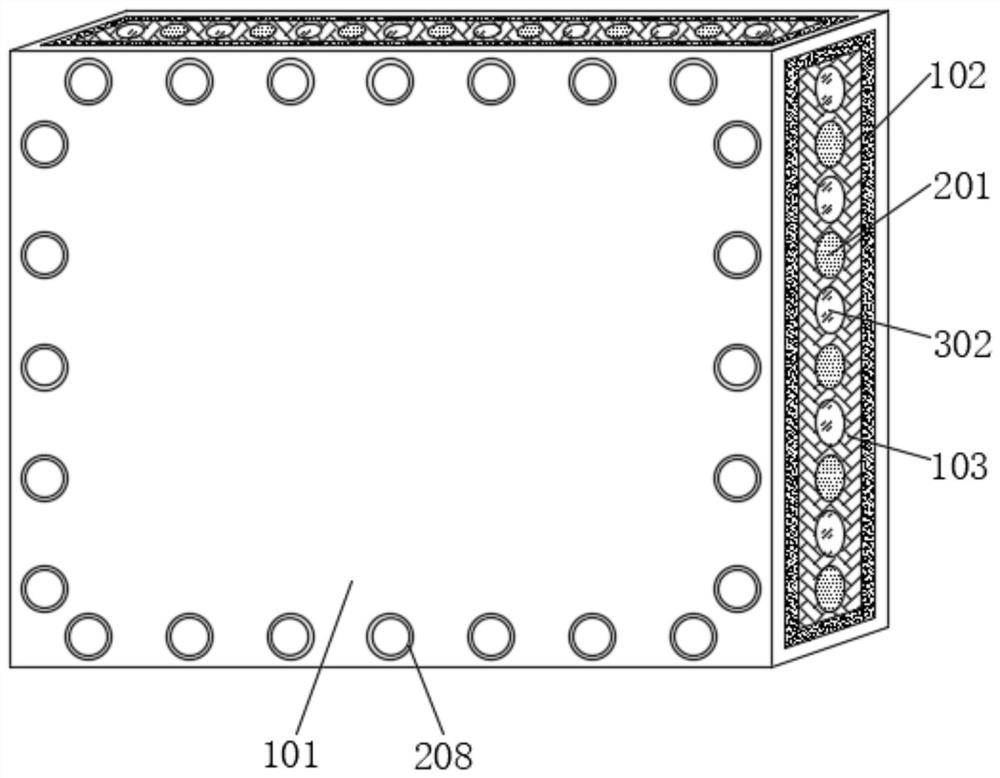

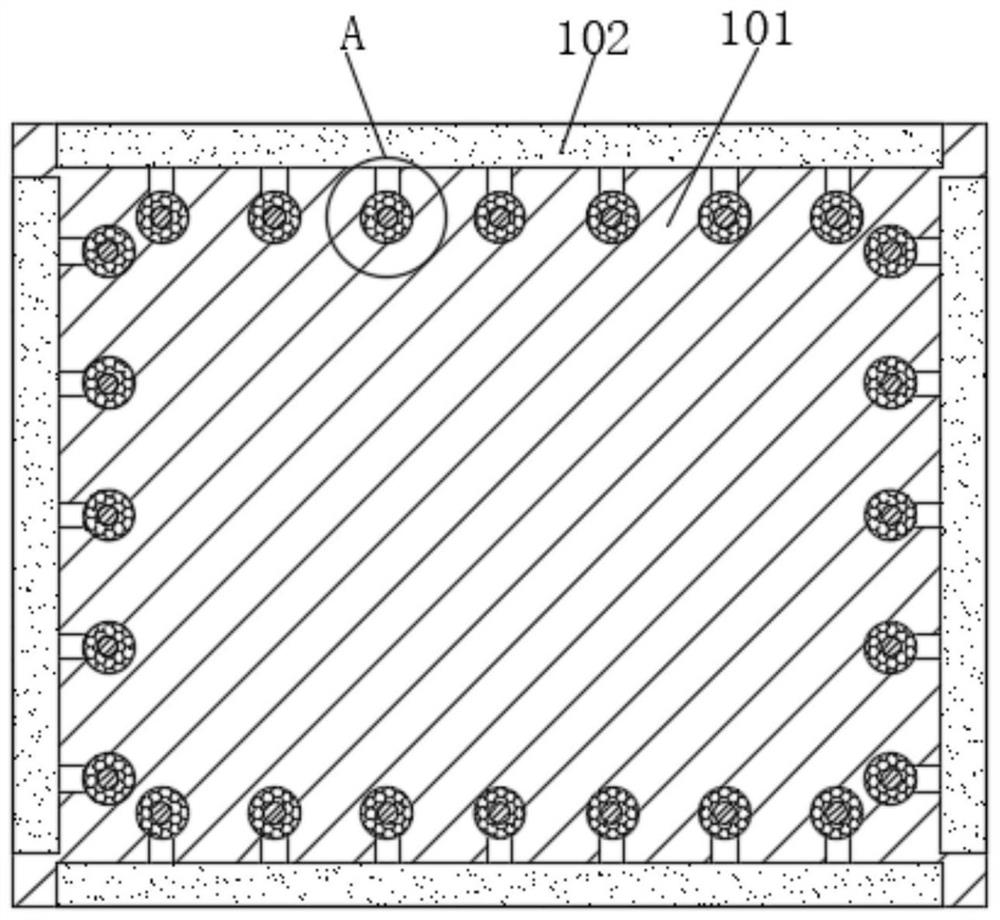

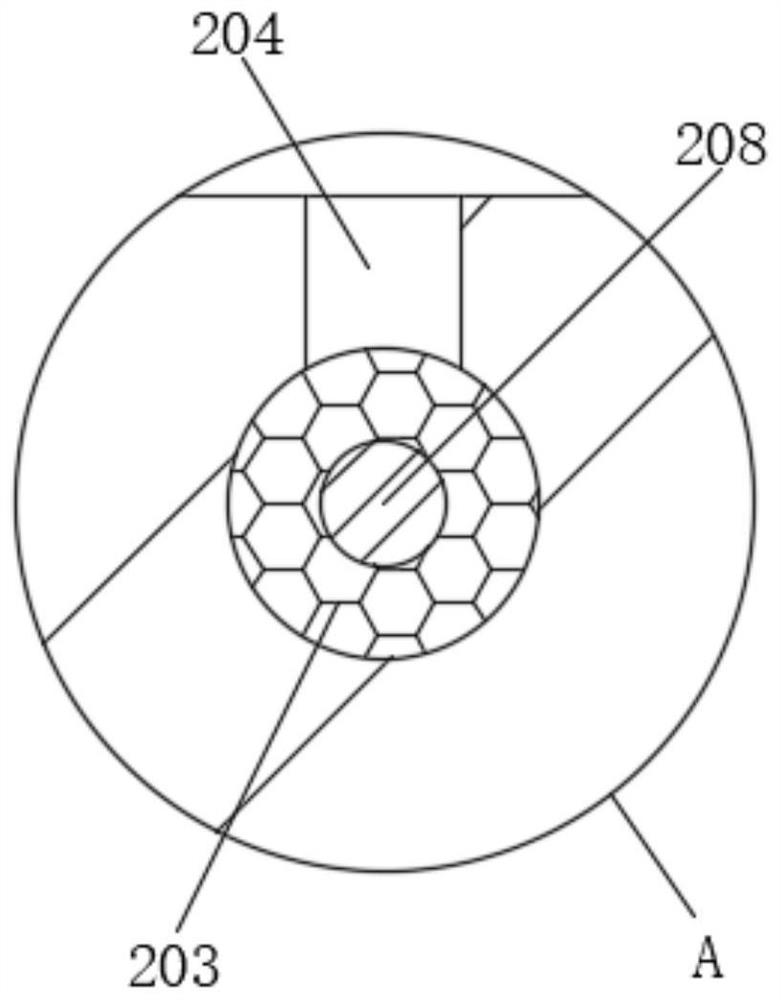

[0038] see Figure 1-5 , a self-sealing and water-removing type anti-seepage building exterior wall, including an exterior wall body 101, and waterproof groove-shaped frames 102 are inlaid on the four side walls of the exterior wall body 101, upper, lower, left, and right, Each waterproof trough-shaped frame 102 is filled with a matching reinforced filler block 103, the waterproof trough-shaped frame 102 is made of waterproof material, which can prevent water from seeping into the inside of the wall, and the reinforced filler block 103 is made of hydrophobic hard material, The hydrophobic hard material is one of fluororesin, silicone resin, and fluorosilicone resin. The reinforced filling block 103 made of hydrophobic hard material can ensure the strength of the outer wall on the one hand, and on the other hand can facilitate the direction of water seepage. At the panel 201, each reinforced filling block 103 is provided with a water removal assembly inside, and the water remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com