Integrated roof power generation system of building

A technology for power generation systems and buildings, applied in the field of building-integrated roof power generation systems, can solve problems such as high risk of water leakage and failure of drainage structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

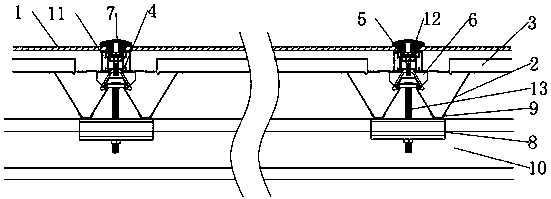

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

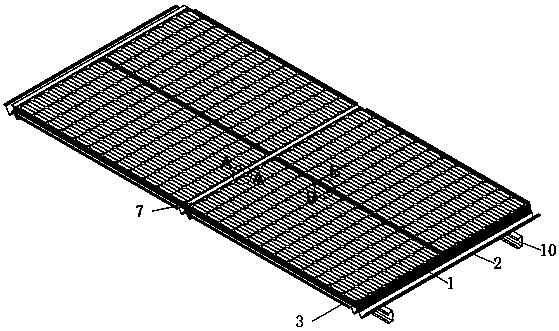

[0023] As shown in the figure, a building-integrated roof power generation system includes a main water tank 2 , a photovoltaic module 1 , a pressing block 5 and a spacer 6 , wherein the photovoltaic module 1 is composed of a photovoltaic panel and a module frame 11 .

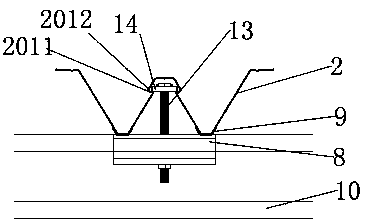

[0024] The cross section of the main water tank 2 is W-shaped, which specifically includes a main support part 201 arranged in the middle of the main water tank 2, auxiliary support parts 202 arranged on both sides of the main water tank 2 and arranged between the main support part 201 and each auxiliary support part 202 Concave drainage grooves 203 between them. The two side walls of the upper end of the main supporting part 201 protrude outward to form an undercut 2011 . As a preferred structure, undercuts 2011 are provided on both side walls of the main support part 201 along the length direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com