A construction method of water-stop curtain anti-seepage structure

A technology of water-stop curtain and construction method, which can be applied in basic structure engineering, construction, etc., can solve problems such as large-area water seepage outside the water-stop curtain, and achieve waterproof and anti-seepage quality, fast processing speed, and good water-stop and anti-seepage effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

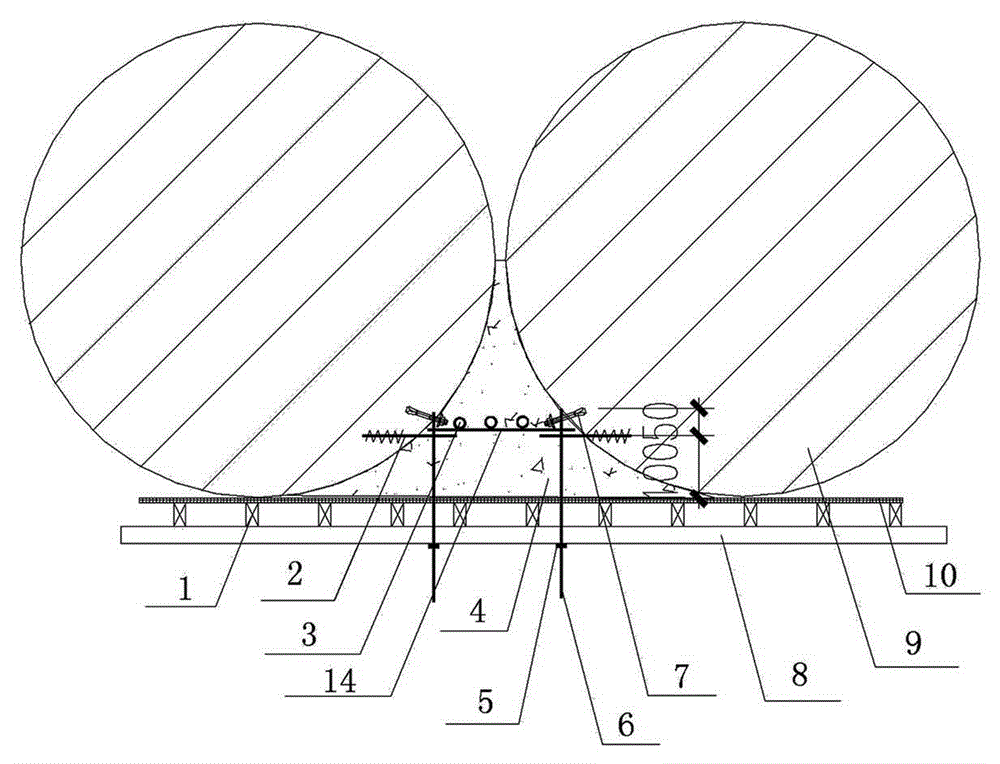

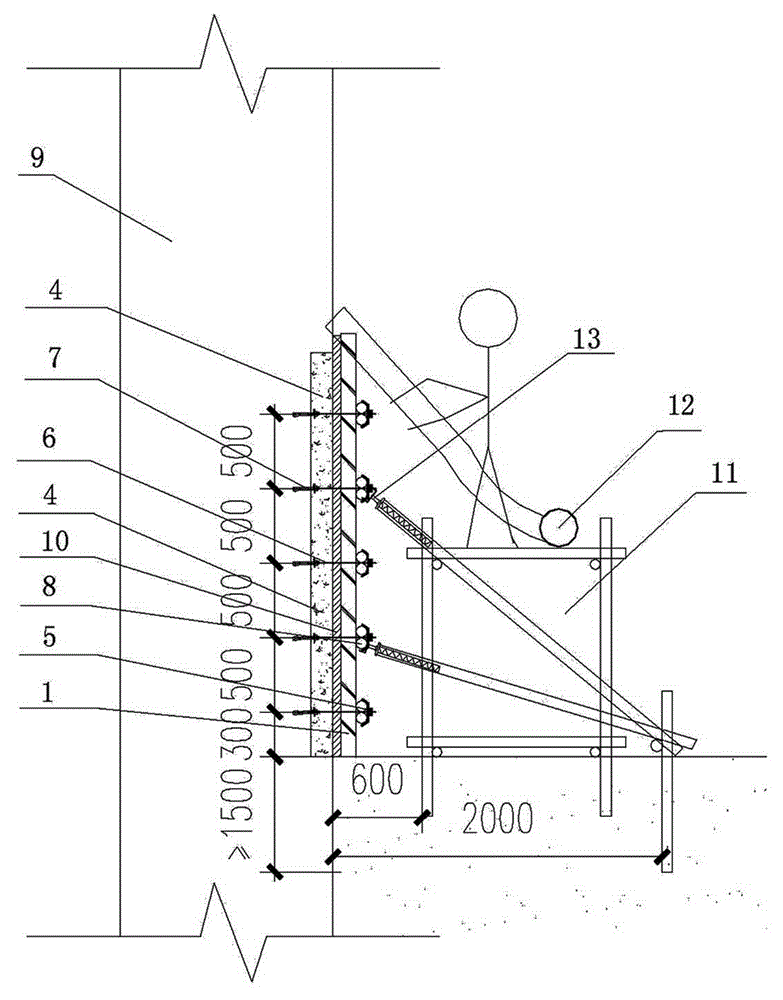

[0032] see figure 1 , figure 2 As shown, this embodiment is a rapid water-stop and anti-seepage treatment measure for large-area seepage of water-stop curtains during foundation pit construction.

[0033] Set expansion bolts 7 on the two retaining piles at the seepage of the water-stop curtain, and plant horizontal planting bars 2 at positions closer to the outside of the supporting piles relative to the expansion bolts. The implanted horizontal planting bars 2 must meet the test requirements. Pull bolts 6 and expansion bolts 7 are welded, and use horizontal steel bars 14 to connect with horizontal planting bars 2, use vertical steel bars 3, horizontal planting bars 2, and horizontal steel bars 14 to bind into steel mesh sheets, and support on the periphery of steel mesh sheets Formwork, so that the expansion bolts are connected with the tension bolts to tighten the main and secondary keels to fix the formwork. After the reinforcement measures are completed, concrete is pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com