Combined floor for same-level drainage toilet and construction method

A technology of combining floor slabs and drainage on the same floor, which is applied to floors, indoor sanitary piping devices, water supply devices, etc., can solve the problems of large slab thickness, heavy floor slabs, affecting installation space, etc., so as to save complicated processes and reduce The self-weight of the structure and the effect of solving the impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

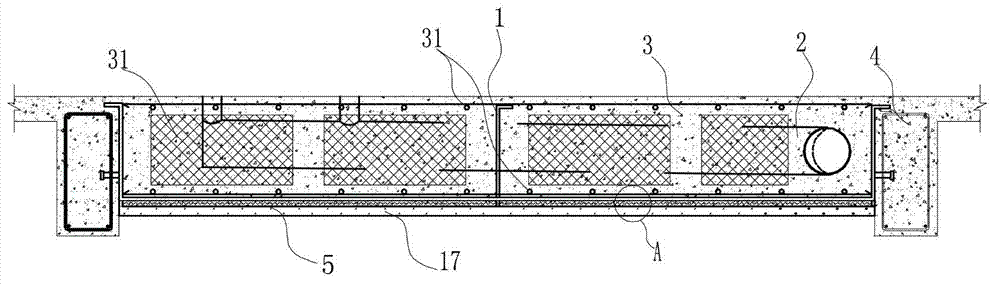

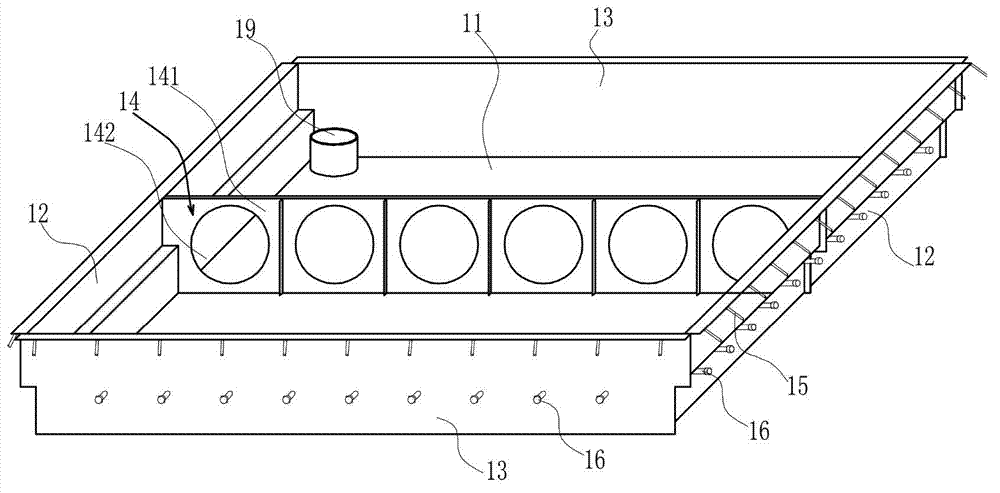

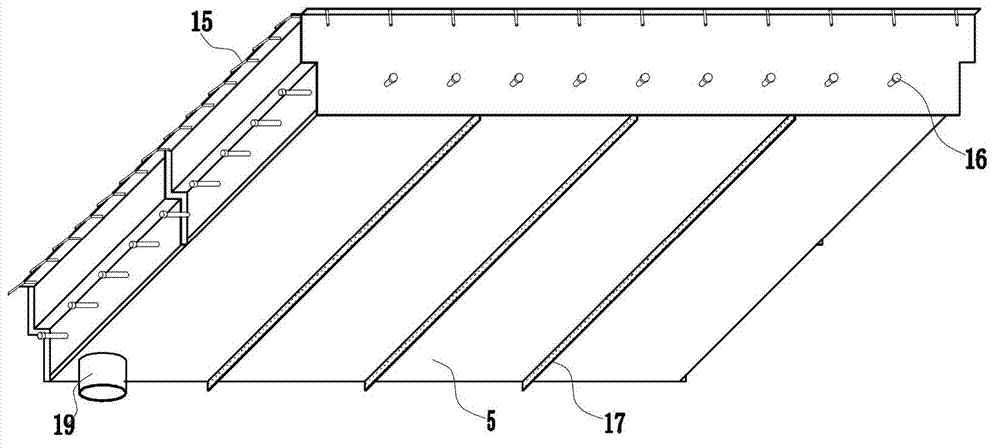

[0029] see Figure 1 to Figure 6 , a kind of embodiment that is used for the combined floor of the drainage toilet of the same floor that the present invention provides, comprises steel plate box 1, drainage pipe 2, filling concrete board 3 and box body peripheral beam 4, and described steel plate box 1 is made of The bottom plate 11, the end side plate 12, the side rib 13 and the middle rib 14 are welded into a box structure with an open top. The bottom plate 11 is provided with an anti-rust protective layer 5. A plurality of through holes 142 are arranged at intervals, and the drainage pipe 2 passes through the through holes 142 on the middle rib 14 and is buried in the filled concrete plate 3 . The combined floor slab of the toilet provided by the invention adopts a steel plate box structure, has better anti-seepage performance, and solves the problem of water seepage in the toilet. The anti-rust protective layer 5 protects the steel box 1 and prolongs the service life. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com