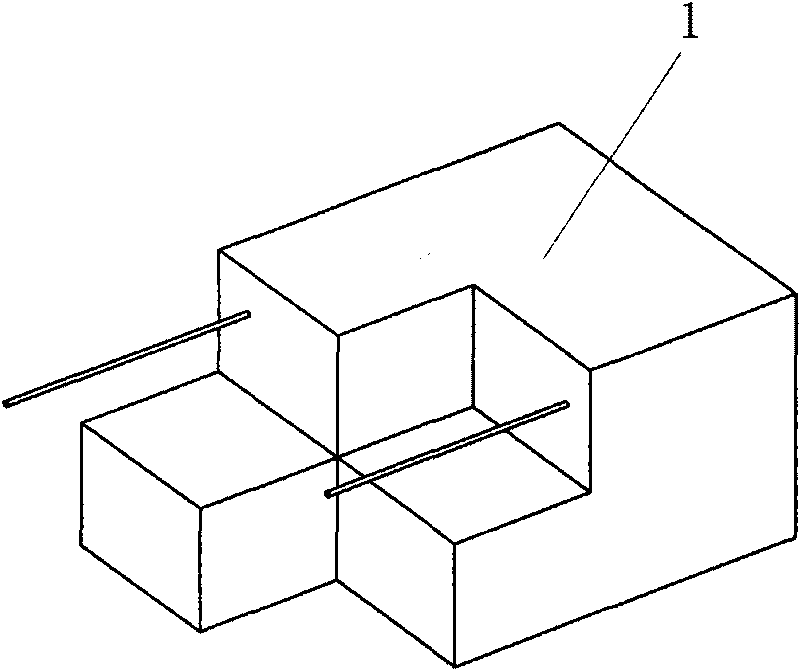

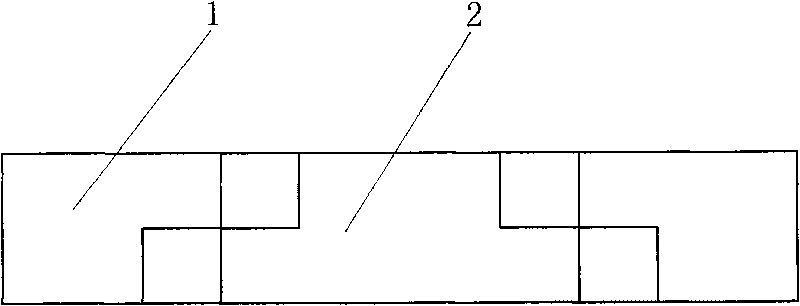

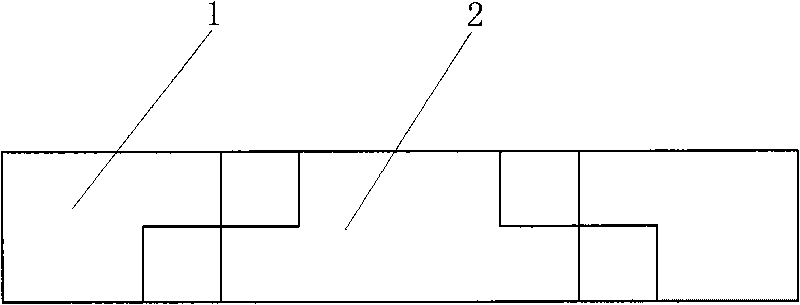

Reinforced concrete windowsill coping adverse construction method

A technology of reinforced concrete and construction methods, applied in windowsills/thresholds, etc., can solve problems such as cumbersome construction, affecting the construction period, and water seepage from the top of the window sill, and achieve the effects of saving working time, improving work efficiency, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] Huangyan Commercial Pedestrian Street project is a 10-storey small high-rise residential building with a building height of 33.6m and a total construction area of 50,000m2 2 , the main structure adopts frame structure, the filling wall adopts autoclaved aerated concrete blocks, and the outer wall adopts sintered clay porous bricks. Since it was put into use last month, there has been no phenomenon of window sill cracking or water leakage.

example 2

[0032] The Fujing Garden project is a 6-storey multi-storey residential building with a building height of 18.6m and a total construction area of 63,000m2 2 , frame structure, autoclaved aerated concrete blocks are used for filling walls, sintered clay porous bricks are used for exterior walls, the number of windows is 3156, and the window sill topping 2 adopts the construction method of cast-in-situ window sill topping. Since it was put into use in June 2008, there has been no phenomena such as window sill pressure cracking and water leakage, and the expected effect has been achieved. The responsible parties of the supervisory unit, design unit, and construction unit have good evaluations.

example 3

[0034] Aokang Commercial Pedestrian Street Project, 6-storey brick-concrete structure, building height 19.6m, total construction area 56,000m2 2 Frame structure, the filling wall is made of autoclaved aerated concrete blocks, and the outer wall is made of sintered clay porous bricks. Window sill top 2 cracking, water leakage and other phenomena, to achieve the predetermined effect, the owner and the supervision unit unanimously praised.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com