Expansion joint-adjustable dual-waterproof installation construction process

A construction technology and expansion joint technology, applied in the construction, building structure, processing of building materials, etc., can solve problems such as deformation of building expansion joints, water leakage, etc., to save repair costs, protect buildings, and save labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

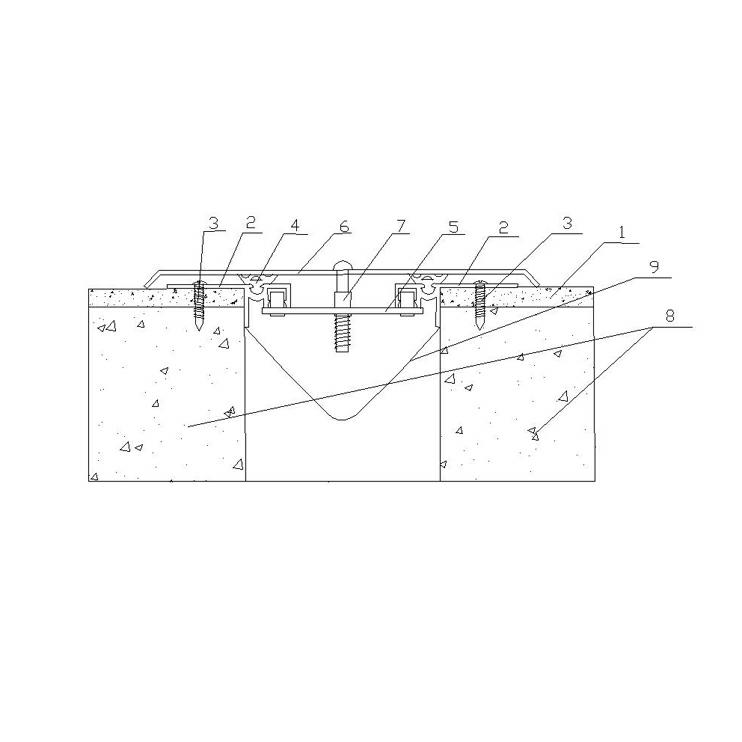

[0017] The expansion joints to be constructed in this embodiment are "inline", such as figure 1 As shown, its construction process includes the following process steps:

[0018] 1) Reservation of expansion joint accessories: Before the plastering project, the actual length of the expansion joint must be measured, and the overlapping and loss of various profiles must be calculated.

[0019] 2) Acceptance inspection of wall plastering at expansion joints: Before construction and installation, the plastering layer on the wall must be inspected to ensure the flatness and verticality of the wall 8 and ensure that the wall 8 has no hollows, crack.

[0020] 3) Construction setting out on both sides of the expansion joint: before installation, the position of the 8 expansion joints on the wall and the layout of the arrangement of the fixed points of the sliders should be prepared in advance. Carry out on-site laying-out according to the plank layout. After cleaning the part to be se...

Embodiment 2

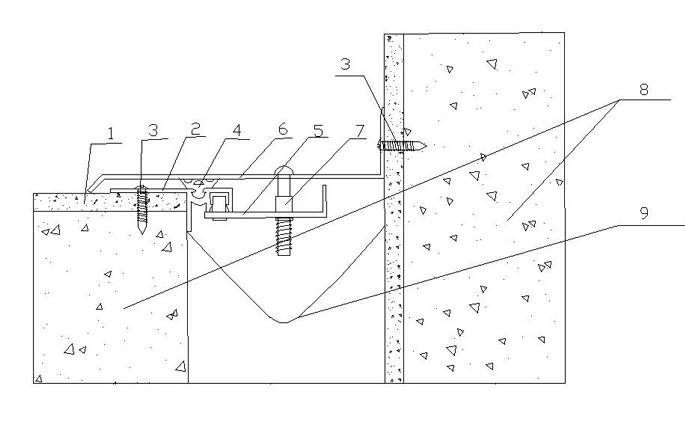

[0029] The expansion joint to be constructed in this embodiment is "L-shaped", such as figure 2 As shown, its construction process includes the following process steps:

[0030] 1) Reservation of expansion joint accessories: Before the plastering project, the actual length of the expansion joint must be measured, and the overlapping and loss of various profiles must be calculated.

[0031] 2) Acceptance inspection of wall plastering at expansion joints: Before construction and installation, the plastering layer on the wall must be inspected to ensure the flatness and verticality of the wall 8, and to ensure that the wall 8 has no hollows, crack.

[0032] 3) Construction setting out on both sides of the expansion joint: before installation, the position of the 8 expansion joints on the wall and the layout of the arrangement of the fixed points of the sliders should be prepared in advance. Carry out on-site laying-out according to the plank layout. After cleaning the part to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com