Embedded water tank and processing method thereof

A processing method and embedded technology, applied in water supply devices, indoor sanitary piping devices, cleaning equipment, etc., can solve the problems of increased manufacturing cost, inconvenient installation, failure to achieve seamless connection between the sink and the installation table, etc., to avoid Water seepage problem, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, this content of the present invention will be further described.

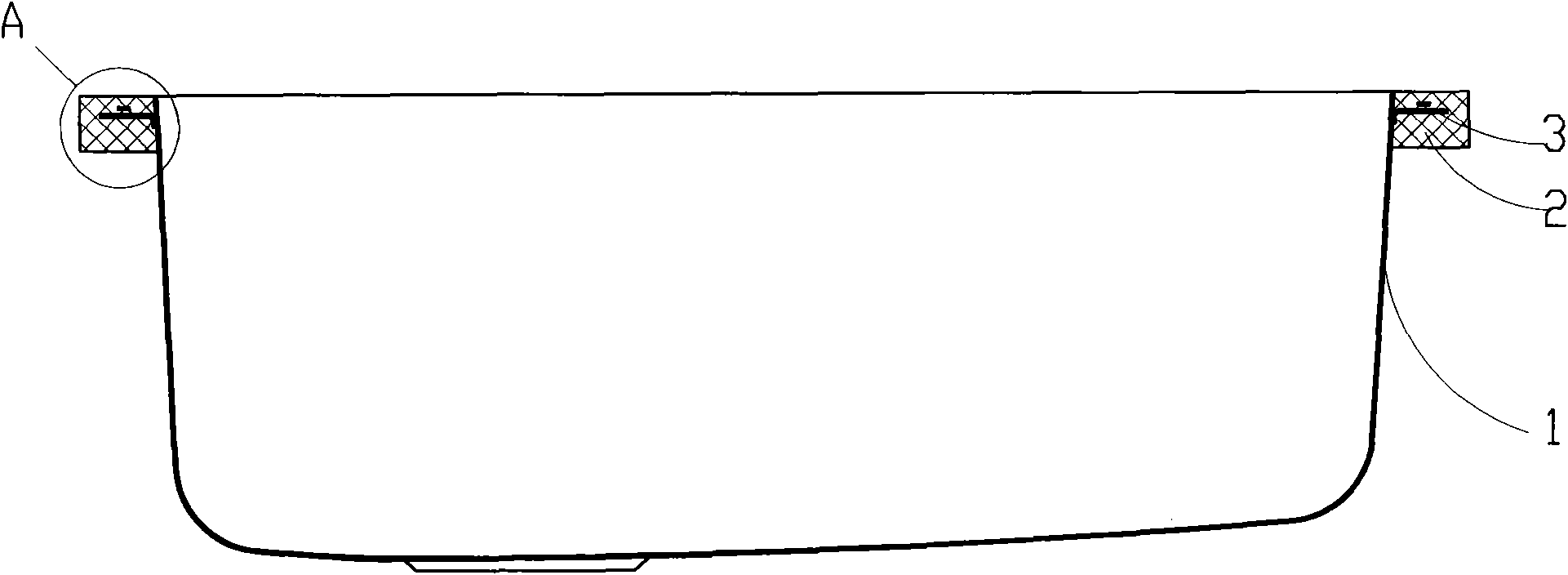

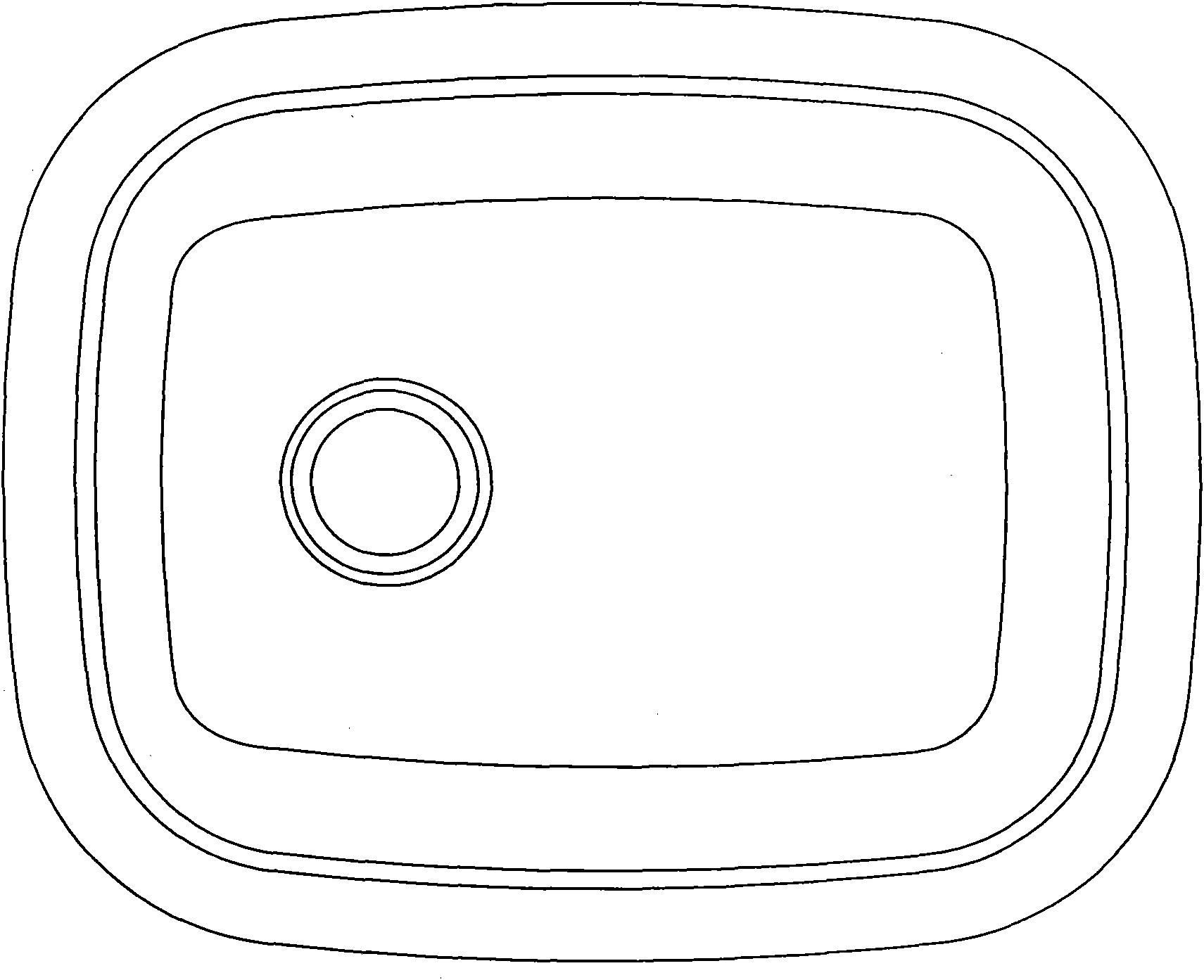

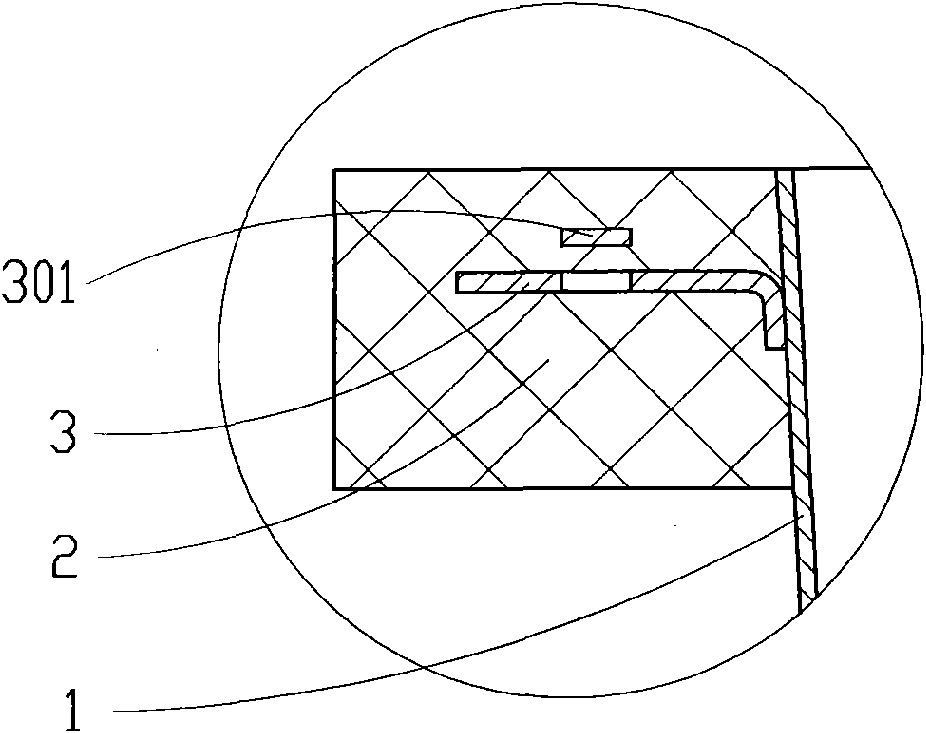

[0039] see Figure 1 to Figure 6 The embedded water tank includes a tank body 1, a surrounding bar 3 and a mounting plate 2 made of a mineral-filled polymer composite material, and the mounting plate 2 wraps the surrounding bar 3 completely. Such as image 3 The surrounding bar 3 of the shown embodiment 1 is made separately, and then fixed on the tank body 1 by welding or gluing; Figure 4 The enclosure bar 3 and the tank body 2 of the shown embodiment 2 are integrally stamped. A protruding part 301 and a penetrating area 302 are also provided on the surrounding bar 3. The protruding part 301 shown in this example is rounded, and the penetrating area 302 is an open groove. The mounting plate 2 made of mineral-filled polymer composite material fills the space of the raised part 301 and the through area 302, and the size of the mounting plate 2 in the widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com